Low-viscosity steel structure anticorrosive paint and construction process thereof

A construction technology and steel structure technology, applied in anti-corrosion coatings, coatings, special surfaces, etc., can solve the problems of complex process processing, long processing time, low VOC content, etc., and achieve long-term high-efficiency rust and corrosion resistance. , The effect of low VOC content and low construction viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

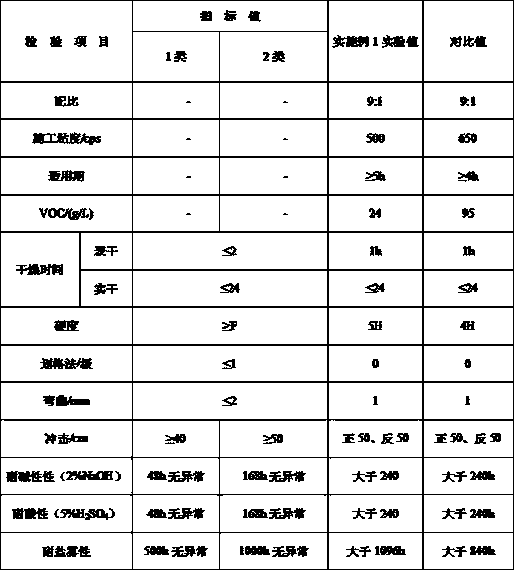

Examples

Embodiment 1

[0027] A low-viscosity steel structure anticorrosion paint and its construction process, prepared from the following components A and B in parts by mass:

[0028] Component A: 80 parts of water-based hydroxyacrylic acid,

[0029] 1.5 parts of dispersant,

[0030] 0.6 part of defoamer,

[0031] 0.8 parts of antiseptic and bactericide,

[0032] Cellulose 5 parts,

[0033] 38 parts of titanium dioxide,

[0034] 0.4 parts of film-forming aids,

[0035] 18 parts of deionized water;

[0036] Component B: 20 parts of isocyanate,

[0037] 15 parts of propylene glycol methyl ether acetate,

[0038] 0.2 parts of tartaric acid;

[0039] The construction process of the low-viscosity steel structure anticorrosion paint includes: step 1, cleaning treatment on the surface of the steel structure: cleaning the steel structure before painting the polyurethane paint, and sandblasting the structure to be painted to remove oil stains and rust trace; step 2, stirring, diluting, aging: fi...

Embodiment 2

[0046] A low-viscosity steel structure anticorrosion paint and its construction process, prepared from the following components A and B in parts by mass:

[0047] Component A: 90 parts of water-based hydroxyacrylic acid,

[0048] 2 parts of dispersant,

[0049] 1.1 parts of defoamer,

[0050] 1.4 parts of antiseptic and bactericide,

[0051] 6 parts of cellulose,

[0052] 40 parts of titanium dioxide,

[0053] 0.6 parts of film-forming aids,

[0054] 21 parts of deionized water;

[0055] Component B: 22 parts of isocyanate,

[0056] 18 parts of propylene glycol methyl ether acetate,

[0057] 0.3 parts of tartaric acid;

[0058]The construction process of the low-viscosity steel structure anticorrosion paint includes: step 1, cleaning treatment on the surface of the steel structure: cleaning the steel structure before painting the polyurethane paint, and sandblasting the structure to be painted to remove oil stains and rust trace; step 2, stirring, diluting, aging: fir...

Embodiment 3

[0065] A low-viscosity steel structure anticorrosion paint and its construction process, prepared from the following components A and B in parts by mass:

[0066] Component A: 100 parts of water-based hydroxyacrylic acid,

[0067] 2.5 parts of dispersant,

[0068] 1.5 parts of defoamer,

[0069] Antiseptic bactericide 2 parts,

[0070] Cellulose 7 parts,

[0071] 42 parts of titanium dioxide,

[0072] 0.9 parts of film-forming aids,

[0073] 24 parts of deionized water;

[0074] Component B: 24 parts of isocyanate,

[0075] 20 parts of propylene glycol methyl ether acetate,

[0076] 0.5 parts of tartaric acid;

[0077] The construction process of the low-viscosity steel structure anticorrosion paint includes: step 1, cleaning treatment on the surface of the steel structure: cleaning the steel structure before painting the polyurethane paint, and sandblasting the structure to be painted to remove oil stains and rust Step 2, stirring, diluting, aging: firstly, add compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com