Grafting modification method of waste rubber powder used for asphalt modification

A technology of graft modification and asphalt modification, which is applied in the field of preparation of a graft modified waste rubber powder, which can solve the problems of weak bonding between waste rubber powder and asphalt interface, and achieve stacking treatment, environmental protection application, and aging resistance The effect of construction performance, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

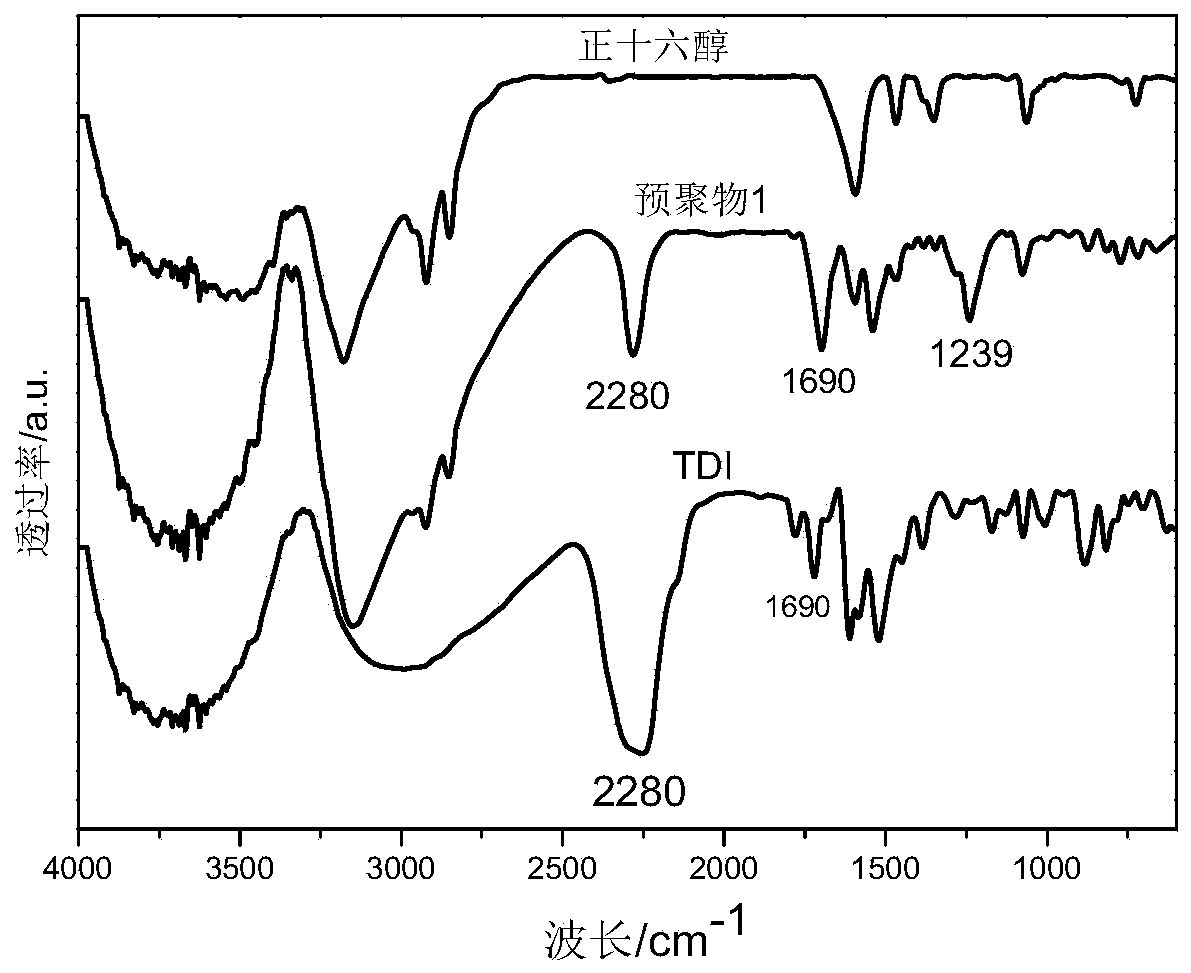

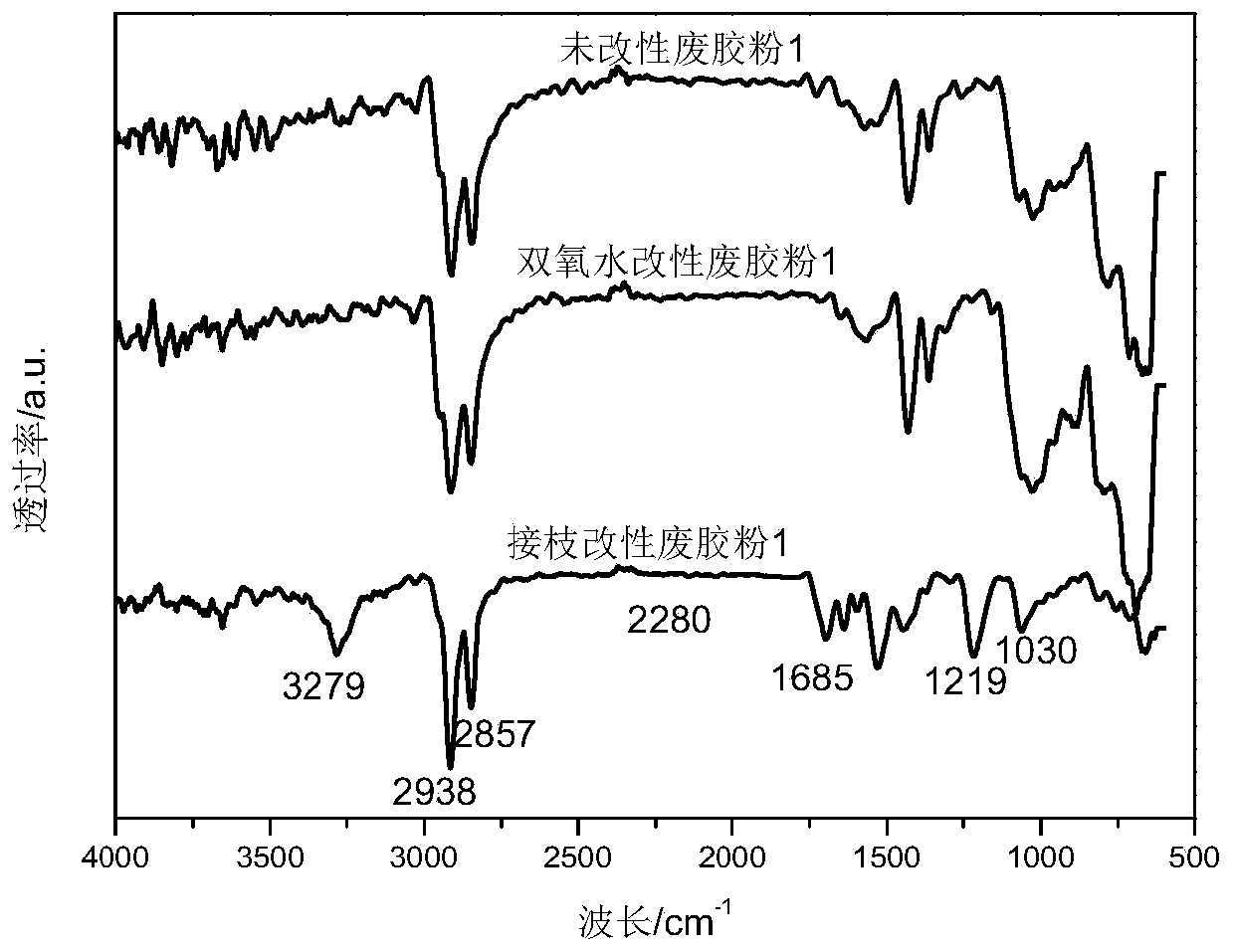

[0030] Put water and 20 mesh unmodified normal temperature waste rubber powder 1 into the container according to the mass ratio of 1:1, and prepare the waste rubber powder suspension by ultrasonic dispersion for 10 minutes; add hydrogen peroxide dropwise to the waste rubber powder according to the mass ratio of 0.05:1 suspension, then mechanically stirred at 30°C for 4 hours, and the reaction product was washed with distilled water and dried to obtain hydrogen peroxide modified waste rubber powder 1; at 50°C under nitrogen protection, the equivalent ratio of isocyanate groups and hydroxyl groups was weighed as 0.1:1 toluene diisocyanate and n-hexadecanol, add isocyanate to the alcohol dropwise within 60 minutes, react for 4 hours, and prepare prepolymer 1; add hydrogen peroxide modified waste rubber powder into prepolymer 1 in a mass ratio of 1:1, °C for 1 h to obtain graft modified waste rubber powder 1.

[0031] In order to prove the synthesis of prepolymer 1, p-toluene diis...

Embodiment 2

[0034]Put water and 100-mesh unmodified wet-process waste rubber powder 2 into a container at a mass ratio of 4:1, and disperse ultrasonically for 60 minutes to prepare a waste rubber powder suspension; add hydrogen peroxide dropwise to the waste rubber powder at a mass ratio of 0.4:1 suspension, then mechanically stirred at 80°C for 1 h, the reaction product was washed with distilled water and dried to obtain hydrogen peroxide modified waste rubber powder 2; at 120°C under nitrogen protection, the equivalent ratio of isocyanate groups and hydroxyl groups was weighed as 2:1 octacosanol and leaf alcohol are mixed alcohols, the equivalent ratio of diphenylmethane diisocyanate and mixed alcohol is 1:1, and isocyanate is added dropwise to the mixed alcohol within 10 minutes, and the reaction is 1 hour to prepare a prepolymer; Hydrogen peroxide modified waste rubber powder was added to prepolymer 2 at a mass ratio of 3:1, and reacted at 80°C for 4 hours to obtain graft modified wast...

Embodiment 3

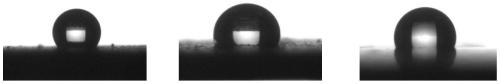

[0037] In order to compare the influence of modified waste rubber powder on asphalt properties, the unmodified waste rubber powder 1 obtained in the preparation process of Example 1, the hydrogen peroxide modified waste rubber powder 1, the graft modified waste rubber powder 1, and the waste rubber powder 15wt% of powder was added to asphalt to prepare rubber-modified asphalt, and its comprehensive performance was tested. The results are shown in Table 1. Compared with the properties of unmodified waste rubber powder 1 / asphalt, the softening effect of hydrogen peroxide modified waste rubber powder 1 / asphalt Point, ductility at 5°C and penetration ratio at 25°C increased after aging, viscosity at 175°C and penetration at 25°C decreased, and the above properties of asphalt after graft modification were further optimized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com