Water-based solvent-free epoxy anticorrosive coating and preparation method thereof

A technology of epoxy anti-corrosion coating and water-based epoxy resin, which is applied in the direction of anti-corrosion coating, epoxy resin coating, coating, etc. It can solve the problems of poor anti-corrosion performance of the coating film and affect the construction progress, and achieve excellent anti-corrosion performance and low viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

[0033] Concrete implementation process of the present invention is as follows:

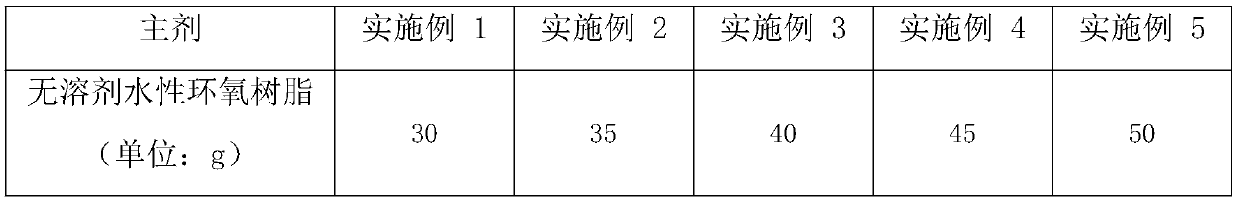

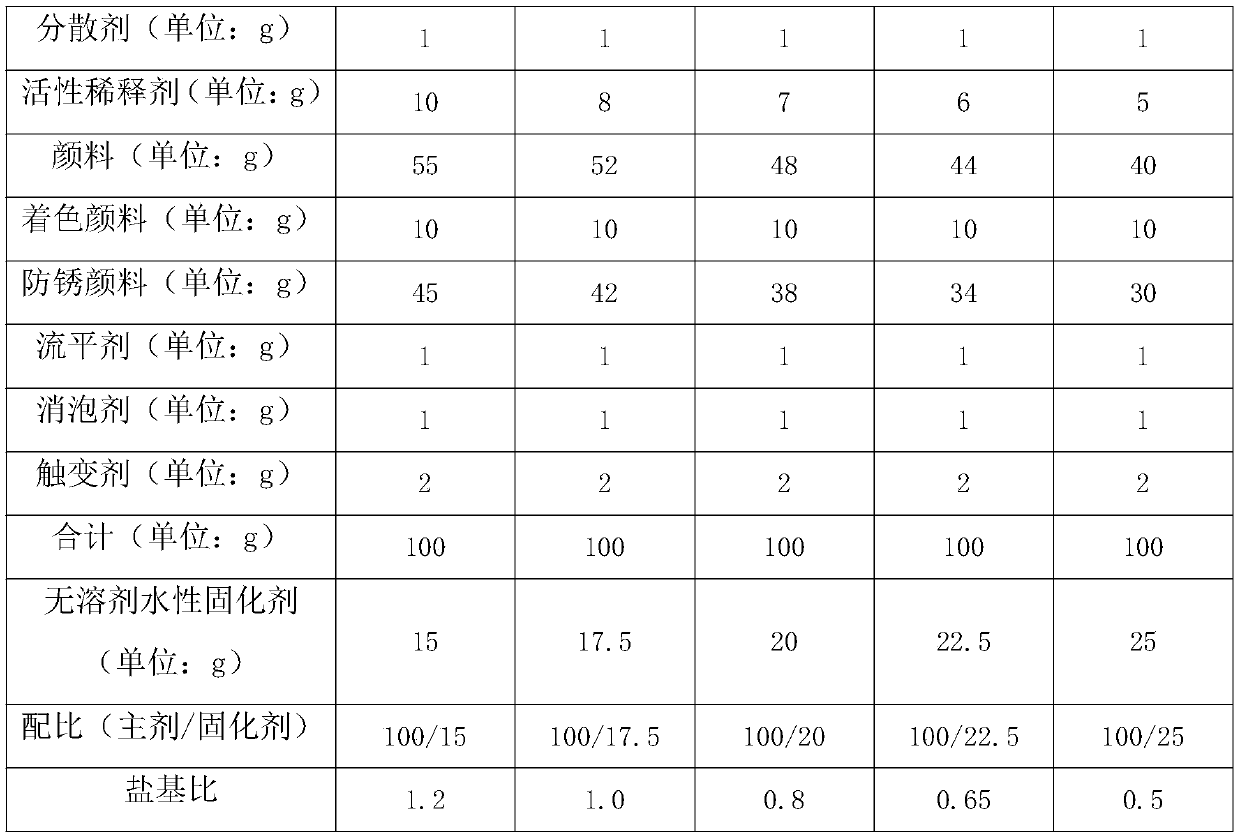

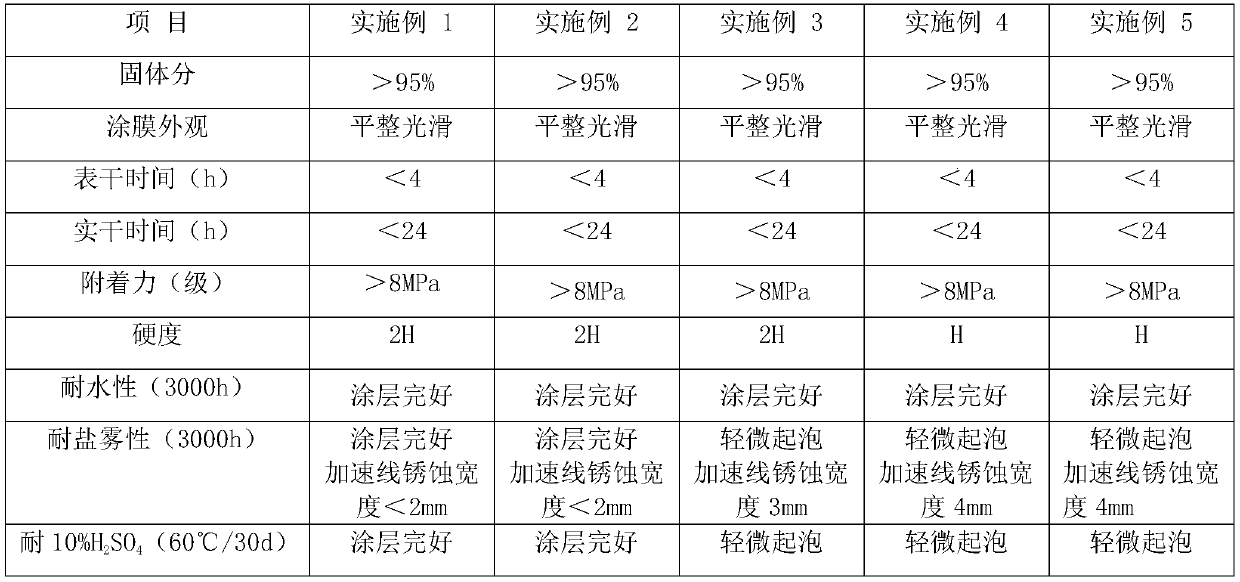

[0034] One, weigh respectively by five kinds of embodiments of table 1 (unit: g):

[0035] Table 1 embodiment formula table

[0036]

[0037]

[0038]In Example 1: the antirust pigment is composed of composite zinc phosphate, mica powder, and glass flakes, wherein the mass ratio of composite zinc phosphate, mica powder, and glass flakes is 1:2:2. The dispersant is composed of TEGO Dispers 651 and TEGO Dispers 652, wherein the mass ratio of TEGO Dispers 651 and TEGO Dispers 652 is 1:1. The coloring pigment is composed of titanium dioxide and iron oxide black, and the feeding mass ratio is 100:1. The leveling agent is composed of TEGO Glide 410 and TEGO Glide 4100, wherein the mass ratio of TEGO Glide 410 and TEGO Glide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com