Solvent type low-VOC bus intermediate coat and preparation method thereof

A solvent-based, bus technology, applied in the direction of coating, can solve the problems of high viscosity, poor compatibility and bonding strength, can not reduce VOC content, etc., to achieve high solid content, low construction viscosity, good leveling and surface effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment one: be made up of A component and B component of equal weight;

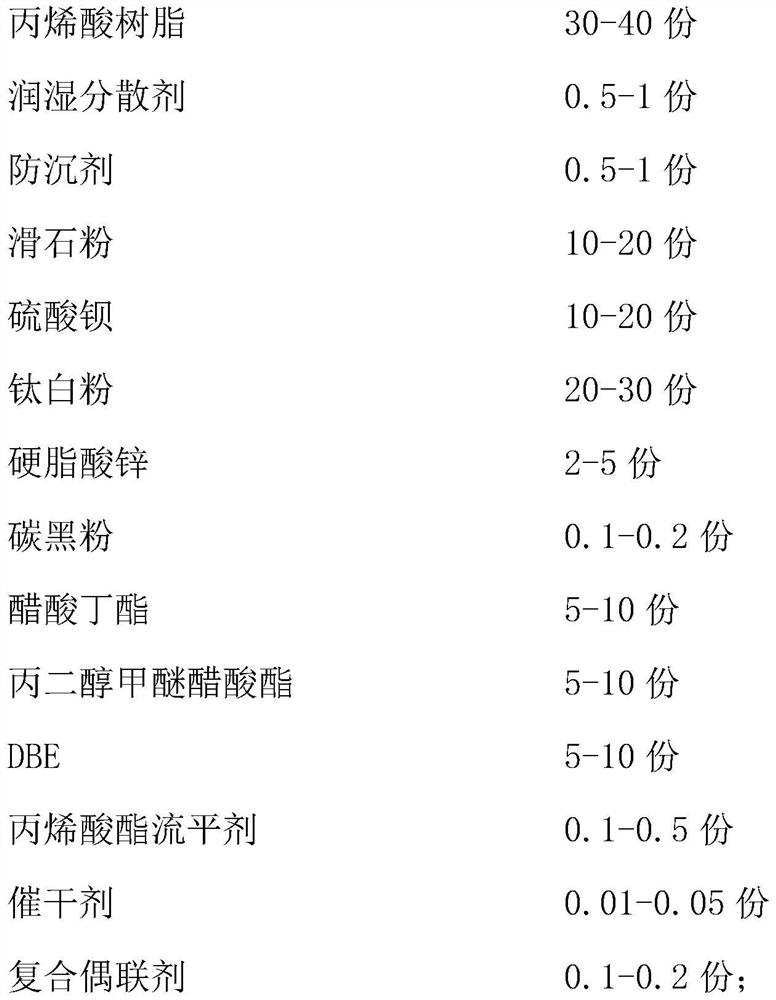

[0041] Component A is made up of the following components in parts by weight:

[0042]

[0043] Component B is made up of the following components in parts by weight:

[0044] Isocyanate 500 parts

[0045] Butyl acetate 10 parts

[0046] DBE 10 copies.

[0047] The method for measuring the total amount of VOC painted in the solvent-based low-VOC bus is to inject the sample into the chromatographic column, record the chromatogram, and measure the peak surface area of each compound whose retention time is lower than the marker. The standard method is used to measure the mass fraction of each compound contained in the paint, and then calculate the total amount of VOC and the total amount of toluene, xylene, and ethylbenzene at different stages of the paint in the solvent-based low-VOC bus according to the formula;

[0048] In the formula, is the total amount of volatile organic compounds,...

Embodiment 2

[0066] Embodiment two: be made up of component A and component B of equal weight;

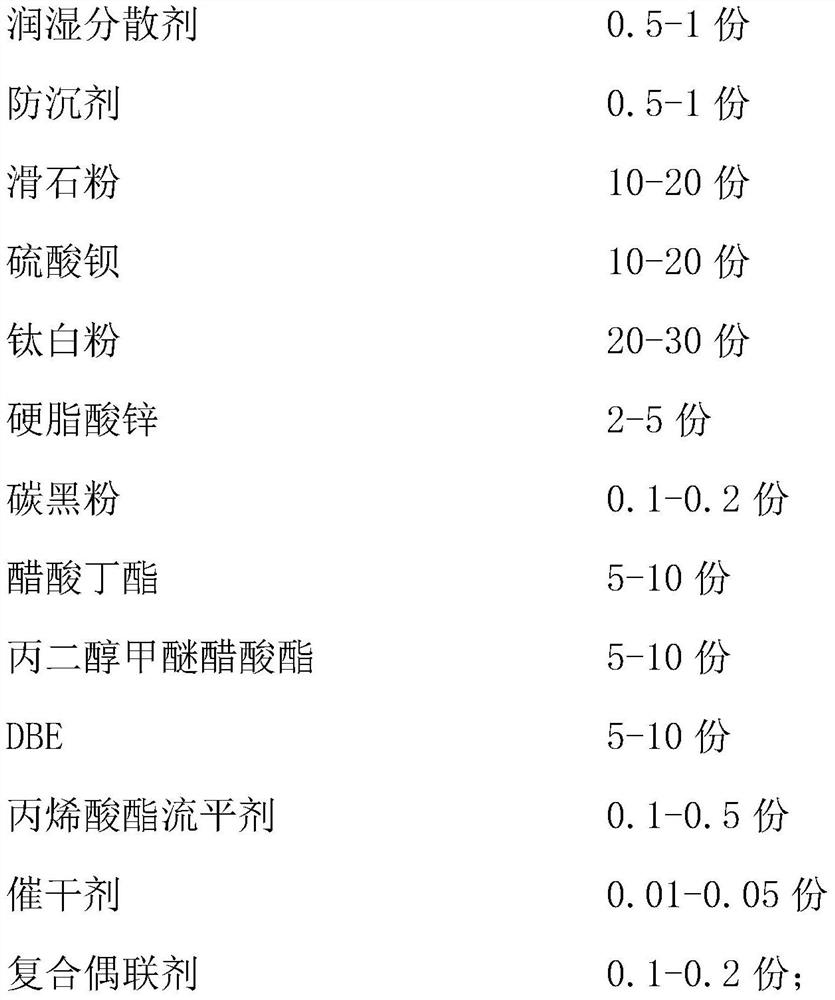

[0067] Component A is made up of the following components in parts by weight:

[0068]

[0069]

[0070] Component B is made up of the following components in parts by weight:

[0071] 60 parts of isocyanate

[0072] Butyl acetate 20 parts

[0073] 15 copies of DBE.

[0074] The method for measuring the total amount of VOC painted in the solvent-based low-VOC bus is to inject the sample into the chromatographic column, record the chromatogram, and measure the peak surface area of each compound whose retention time is lower than the marker. The standard method is used to measure the mass fraction of each compound contained in the paint, and then calculate the total amount of VOC and the total amount of toluene, xylene, and ethylbenzene at different stages of the paint in the solvent-based low-VOC bus according to the formula

[0075] where VOC 总量 is the total amount of volatile or...

Embodiment 3

[0091] Embodiment three: be made up of component A and component B of equal weight;

[0092] Component A is made up of the following components in parts by weight:

[0093]

[0094] Component B is made up of the following components in parts by weight:

[0095] 70 parts of isocyanate

[0096] Butyl acetate 30 parts

[0097] 20 copies of DBE.

[0098] The method for measuring the total amount of VOC painted in the solvent-based low-VOC bus is to inject the sample into the chromatographic column, record the chromatogram, and measure the peak surface area of each compound whose retention time is lower than the marker. The standard method is used to measure the mass fraction of each compound contained in the paint, and then calculate the total amount of VOC and the total amount of toluene, xylene, and ethylbenzene at different stages of the paint in the solvent-based low-VOC bus according to the formula

[0099] where VOC 总量 is the total amount of volatile organic comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com