PU sealing primer capable of high wetting and high permeability substrate and preparation method thereof

A sealing primer and high-penetration technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as shedding, swelling coatings, furniture deformation, etc., achieve small molecular weight, improve mechanical strength, increase adhesion and polish sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

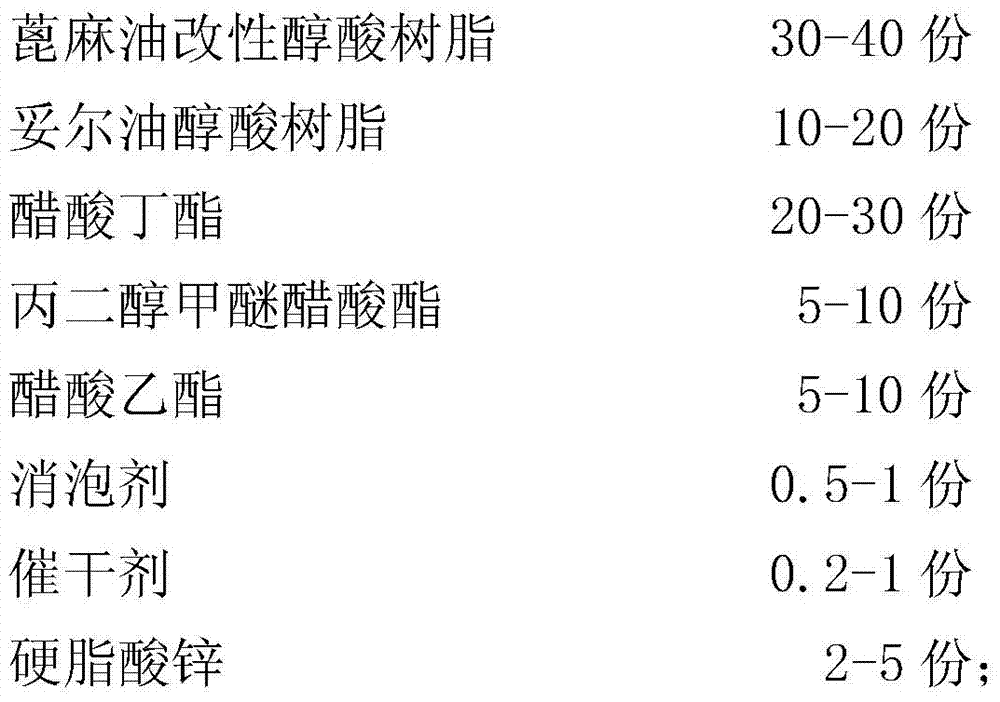

[0034] A PU sealing primer capable of high wetting and high penetration of substrates, which is formed by mixing main paint, curing agent and diluent in a mass ratio of 1:0.5-1:0.3-0.8, wherein the main paint, curing agent and diluent The agent is prepared from the following components and parts by weight ratio:

[0035] Wherein the composition and parts by weight of the main paint are as follows:

[0036]

[0037]

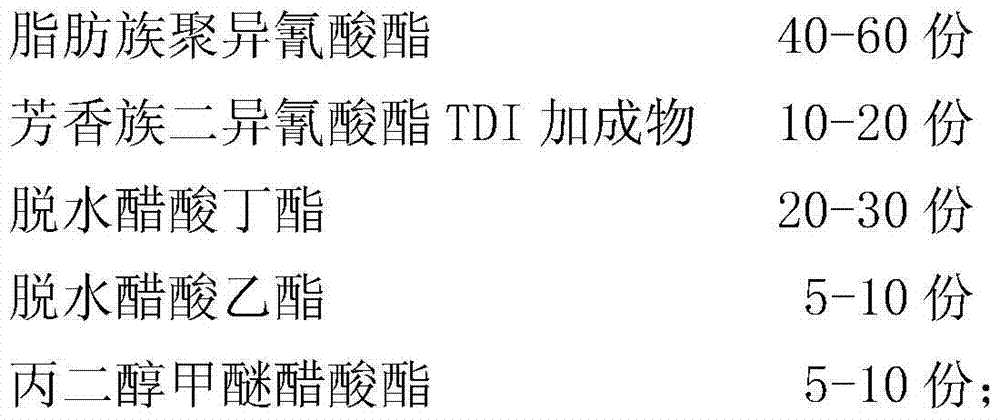

[0038] Wherein the component of curing agent and the ratio of parts by weight are as follows:

[0039]

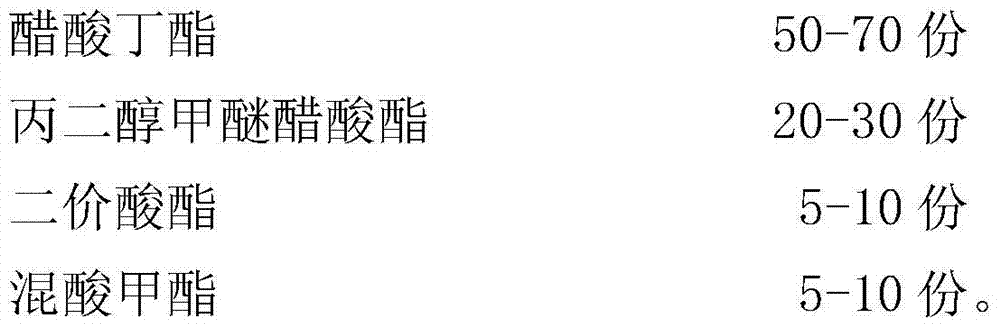

[0040] Wherein the component of diluent and the ratio of parts by weight are as follows:

[0041]

[0042] A preparation method of a PU sealing primer capable of highly wetting and highly permeable substrates, comprising the steps of:

[0043] (1), the main paint is prepared according to the following preparation method:

[0044] Mix 30-40 parts of castor oil modified alkyd resin, 10-20 parts of tall oil alkyd resin, 20-30 parts of butyl acetate,...

Embodiment 1

[0052] Embodiment 1: A kind of PU sealing primer capable of high wetting and high permeability substrate is formed by mixing main paint, curing agent and thinner in a mass ratio of 1:1:0.8, wherein main paint, curing agent and thinner The agent is prepared from the following components and parts by weight ratio:

[0053] Wherein the composition and parts by weight of the main paint are as follows:

[0054]

[0055] Wherein the component of curing agent and the ratio of parts by weight are as follows:

[0056]

[0057] Wherein the component of diluent and the ratio of parts by weight are as follows:

[0058]

[0059] A preparation method of a PU sealing primer capable of highly wetting and highly permeable substrates, comprising the steps of:

[0060] (1), the main paint is prepared according to the following preparation method:

[0061] After mixing 30 parts of castor oil modified alkyd resin, 20 parts of tall oil alkyd resin, 30 parts of butyl acetate, 10 parts of...

Embodiment 2

[0068] Embodiment 2: A kind of PU sealing primer capable of high wetting and high permeability substrate is formed by mixing main paint, curing agent and thinner in a mass ratio of 1:0.5:0.3, wherein main paint, curing agent and thinner The agent is prepared from the following components and parts by weight ratio:

[0069] Wherein the composition and parts by weight of the main paint are as follows:

[0070]

[0071] Wherein the component of curing agent and the ratio of parts by weight are as follows:

[0072]

[0073] Wherein the component of diluent and the ratio of parts by weight are as follows:

[0074]

[0075] A preparation method of a PU sealing primer capable of highly wetting and highly permeable substrates, comprising the steps of:

[0076] (1), the main paint is prepared according to the following preparation method:

[0077] After mixing 40 parts of castor oil modified alkyd resin, 10 parts of tall oil alkyd resin, 25 parts of butyl acetate, 5 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com