A kind of anti-adhesive PU matte transparent topcoat and preparation method thereof

A technology for clear topcoat and anti-fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

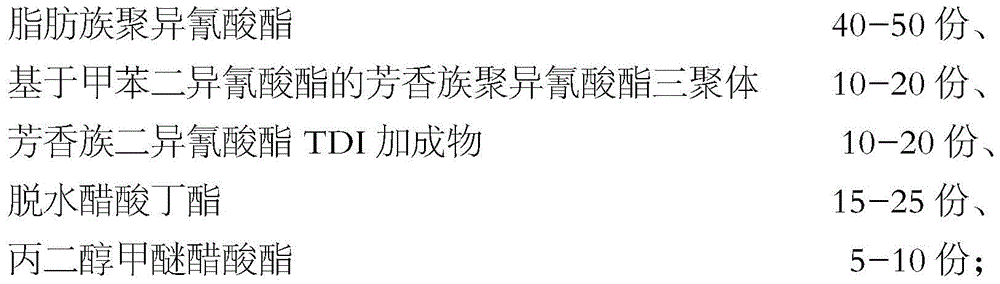

[0043] An anti-adhesive PU matte transparent topcoat, each component is prepared from the following raw materials in the following weight ratio:

[0044] (1) Pre-preparation of environmentally friendly mixed solvent: butyl acetate, propylene glycol methyl ether acetate, and divalent ester are mixed according to the mass ratio of 45:40:15 to form an environmentally friendly mixed solvent;

[0045](2) Main paint: After mixing 34 parts of tall oil modified short oil alkyd resin, 31.4 parts of soybean oil short oil alkyd resin, 0.8 part of dispersant, 1 part of defoamer and 10 parts of composite solvent, mix them at 600 - Disperse for 8-10 minutes at a speed of 800 rpm; add 2 parts of glass powder while dispersing, disperse for 5-10 minutes at a speed of 800-1000 rpm, and then add 1 part of anti-adhesion additive while dispersing, 0.8 parts of matting powder, disperse at 1200-1500 rpm for 10-15 minutes to fineness ≤ 25um; add 2 parts of anti-settling agent, 1 part of leveling agen...

Embodiment 2

[0048] Embodiment 2 (preferred embodiment)

[0049] An anti-adhesive PU matte transparent topcoat, each component is prepared from the following raw materials in the following weight ratio:

[0050] (1) Pre-preparation of environmentally friendly mixed solvent: butyl acetate, propylene glycol methyl ether acetate, and divalent ester are mixed according to the mass ratio of 45:40:15 to form an environmentally friendly mixed solvent;

[0051] (2) Main paint: After mixing 30 parts of tall oil modified short oil alkyd resin, 35 parts of soybean oil short oil alkyd resin, 1 part of dispersant, 0.5 part of defoamer, and 7 parts of composite solvent, mix it at 600 - Disperse for 8-10 minutes at a speed of 800 rpm; add 3 parts of glass powder while dispersing, disperse for 5-10 minutes at a speed of 800-1000 rpm, and then add 1.5 parts of anti-sticking additives while dispersing, 1.5 parts of matting powder, disperse at 1200-1500 rpm for 10-15 minutes until the fineness is ≤25um; add...

Embodiment 3

[0061] An anti-adhesive PU matte transparent topcoat, each component is prepared from the following raw materials in the following weight ratio:

[0062] (1) Pre-preparation of environmentally friendly mixed solvent: butyl acetate, propylene glycol methyl ether acetate, and divalent ester are mixed according to the mass ratio of 45:40:15 to form an environmentally friendly mixed solvent;

[0063] (2) Main paint: After mixing 35 parts of tall oil modified short oil alkyd resin, 28 parts of soybean oil short oil alkyd resin, 1.5 parts of dispersant, 0.2 parts of defoamer, and 3.3 parts of composite solvent, mix them at 600 - Disperse for 8-10 minutes at a speed of 800 rpm; add 4 parts of glass powder while dispersing, disperse for 5-10 minutes at a speed of 800-1000 rpm, and then add 2 parts of anti-sticking additives while dispersing, 3 parts of matting powder, disperse at 1200-1500 rpm for 10-15 minutes until the fineness is ≤25um; add 4 parts of anti-sedimentation agent, 1 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com