Building mortar additive and plastering mortar containing same

A technology for building sand and additives, applied in the fields of building mortar additives and plastering mortar, can solve the problems of high mortar viscosity, low construction efficiency, mortar shrinkage, deformation, hollow drum cracking, etc. Good anti-pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

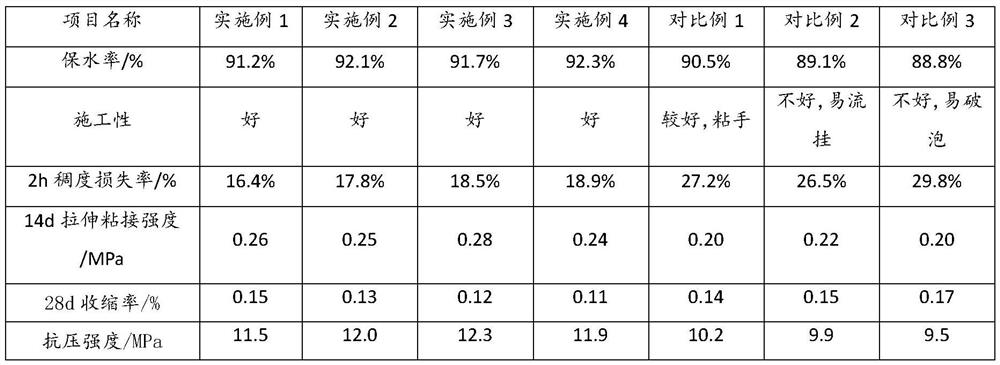

Examples

Embodiment 1

[0037] A construction mortar additive obtained by stirring the following components by weight:

[0038] 1. Pre-mixing various plant gums according to the following parts by weight, 35 parts by weight of echinacea gum, 30 parts by weight of artemisia gum, 20 parts by weight of konjac gum, and 15 parts by weight of gum arabic;

[0039] 2. Pre-mix starch ether FP6 and starch ether CMT60 according to the following weight parts, starch ether FP640 weight parts, starch ether CMT60 weight parts;

[0040]3. Various air-entraining agents are pre-mixed according to the following parts by weight, sodium lauryl sulfate: fatty alcohol polyoxyethylene sulfuric acid: sodium alpha olefin sulfonate = 1:1:1;

[0041] 4. The pre-mixed vegetable gum, starch ether and air-entraining agent are mixed and stirred with other components according to the following parts by weight to obtain the construction mortar additive of the present embodiment;

[0042] 10 parts by weight of hydroxypropyl methylcel...

Embodiment 2

[0044] A construction mortar additive suitable for summer is obtained by stirring the following components by weight:

[0045] 1. Pre-mixing various plant gums according to the following parts by weight: 40 parts by weight of safflower gum, 35 parts by weight of artemisia gum, 20 parts by weight of konjac gum, and 5 parts by weight of gum arabic;

[0046] 2. Pre-mix starch ether FP6 and starch ether CMT according to the following weight parts, starch ether FP640 weight parts, starch ether CMT 60 weight parts;

[0047] 3. Each component in the air-entraining agent is pre-mixed according to its parts by weight, sodium lauryl sulfate: fatty alcohol polyoxyethylene sulfuric acid: sodium α-olefin sulfonate=1:1:1;

[0048] 4. The pre-mixed vegetable gum, starch ether and air-entraining agent are mixed and stirred with other components according to the following parts by weight to obtain the construction mortar additive of the present embodiment;

[0049] 8 parts by weight of hydrox...

Embodiment 3

[0051] A building mortar additive suitable for winter, obtained by stirring the following components by weight:

[0052] 1. Pre-mixing various plant gums according to the following parts by weight, 40 parts by weight of echinacea gum, 35 parts by weight of artemisia gum, 20 parts by weight of konjac gum, and 5 parts by weight of gum arabic;

[0053] 2. Pre-mix starch ether FP6 and starch ether CMT according to the following weight parts, starch ether FP640 weight parts, starch ether CMT 60 weight parts;

[0054] 3. Each component in the air-entraining agent is pre-mixed according to its parts by weight, sodium lauryl sulfate: fatty alcohol polyoxyethylene sulfuric acid: sodium α-olefin sulfonate=1:1:1;

[0055] 4. The pre-mixed vegetable gum, starch ether and air-entraining agent are mixed and stirred with other components according to the following parts by weight to obtain the construction mortar additive of the present embodiment;

[0056] 16 parts by weight of hydroxyprop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com