Sprayable solvent-free two-component polyurethane putty and preparation method and use method thereof

A two-component polyurethane, solvent-free technology, applied in the direction of filling slurry, etc., can solve the problems of human harm, high labor cost, high labor intensity, etc., achieve the effect of reducing VOC emissions, improving social benefits, and reducing construction links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A sprayable solvent-free two-component polyurethane putty, which uses low-viscosity solvent-free bio-based resin as the basic grinding resin, and low-viscosity polyisocyanate as curing agent (low-viscosity HDI trimer, low-viscosity HDI urea Formic ester isocyanate curing agent, etc.), so that the viscosity of the entire coating mixing system is low; another hydroxyl-terminated polybutadiene-acrylonitrile resin is introduced into the formulation system to improve the wet adhesion of the system to metal substrates, flexibility properties, thereby greatly improving the anti-corrosion performance of the system.

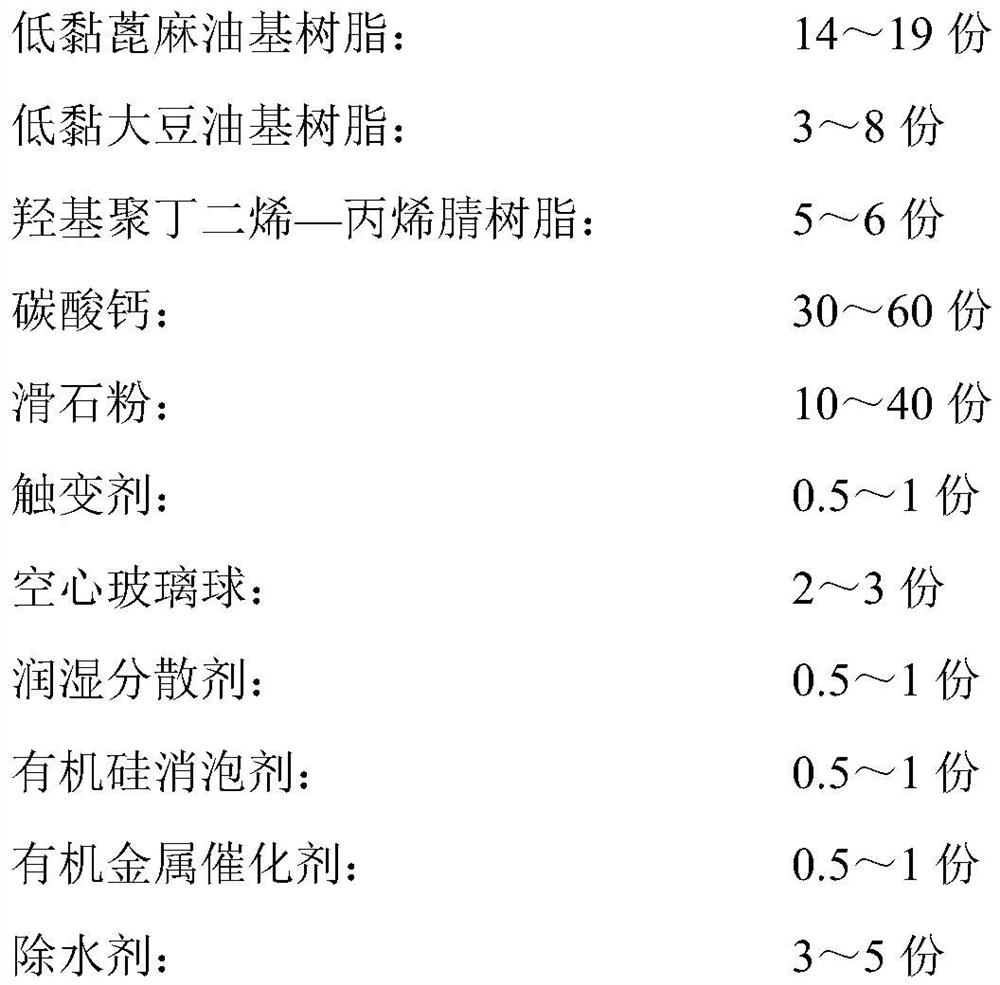

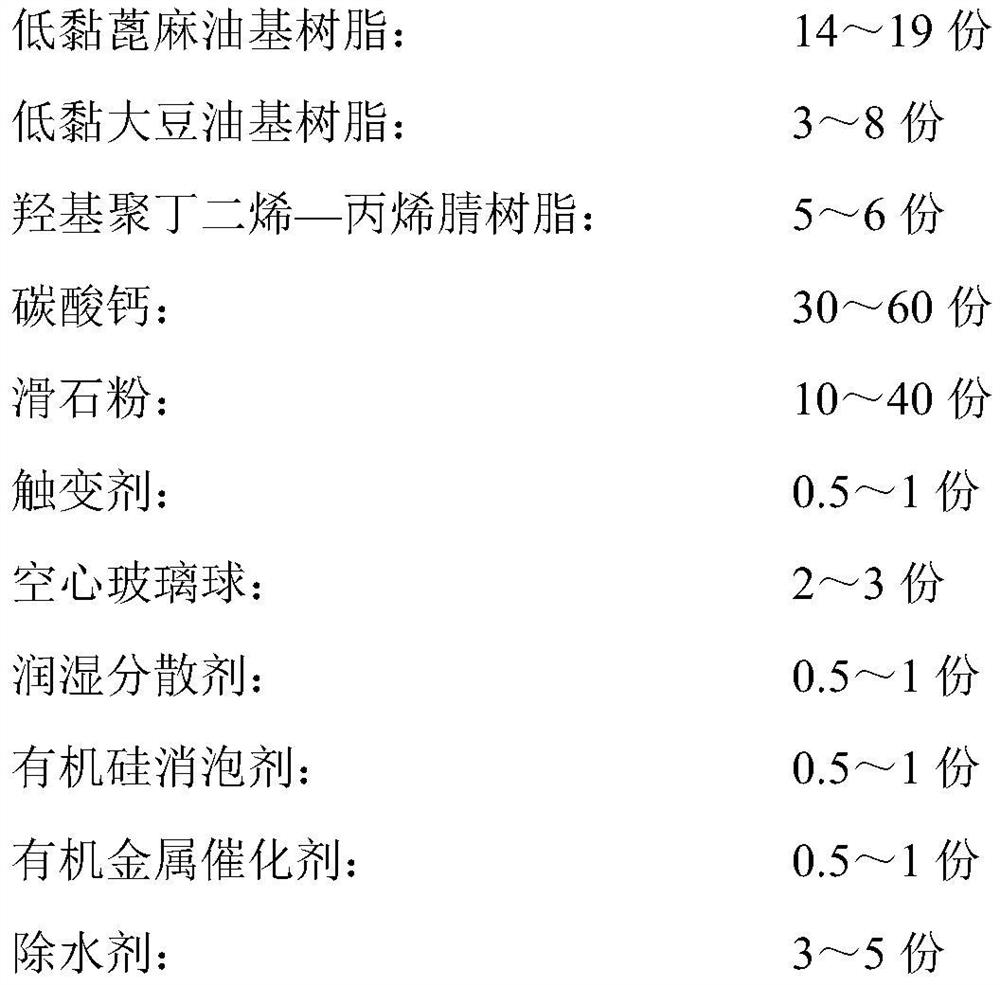

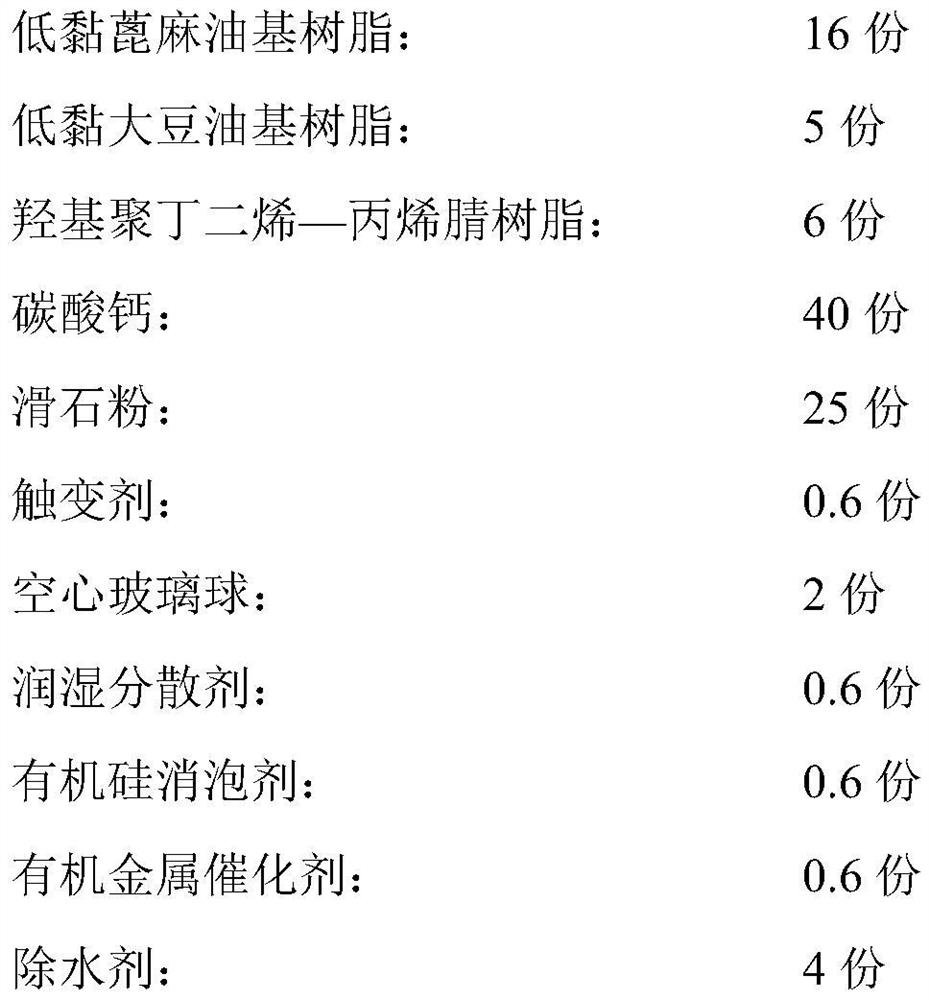

[0039] A component formula is specifically as follows (mass parts):

[0040]

[0041] B component is polyisocyanate curing agent

[0042] The mass ratio of A and B components is 6:1

[0043] Preparation:

[0044] S1: Pour the resin into the tank, add wetting and dispersing agent, defoaming agent and mix evenly with high-speed dispersing agent;

[0045] S2: A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com