Supramolecular material film constructed by biomass extracted small molecules and preparation and application of supramolecular material film

A technology of biological small molecules and material films, which is applied in the preservation, application, and food ingredients of food ingredients as antimicrobial agents, can solve problems such as human health hazards, increase surface gloss, delay decay and deterioration, and avoid dehydration and sluggishness. Harmful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

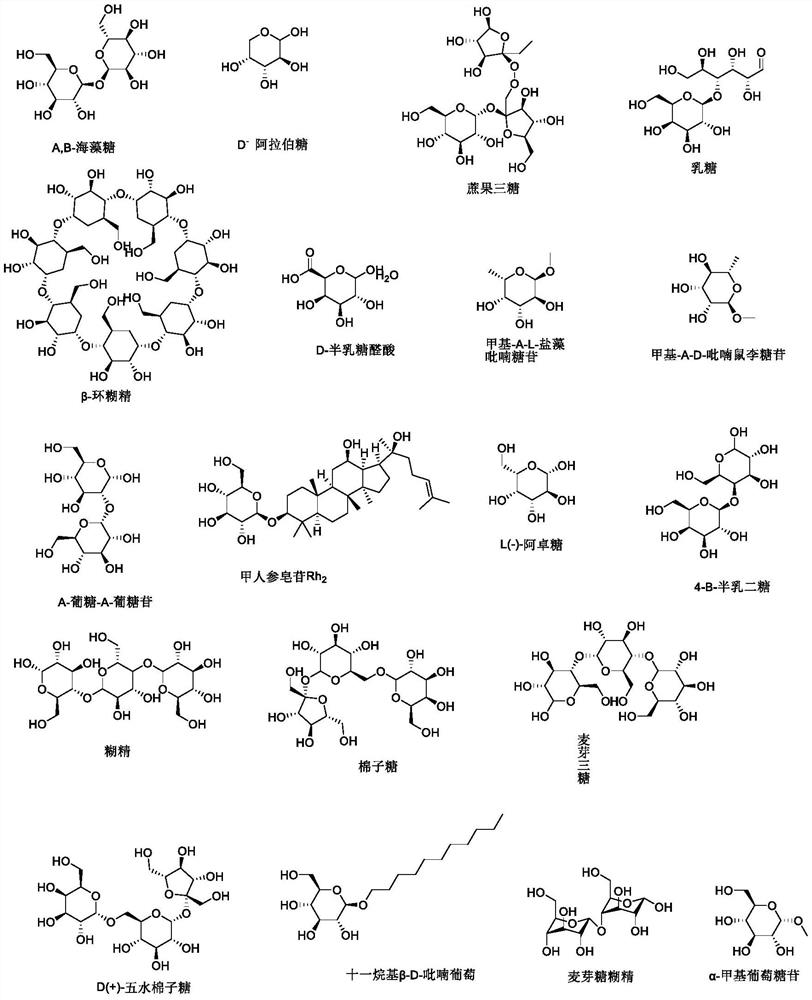

[0024] A thin film of supramolecular materials constructed from small molecules extracted from biomass, including the following raw materials: arabinose and citric acid.

[0025] A method for preparing a supramolecular material film constructed by extracting small molecules from biomass, comprising the following steps:

[0026] 1) dissolving citric acid at a concentration of 0.5wt%-5wt% by mass and arabinose at a concentration of 0.5wt%-3wt% by mass in distilled water to prepare citric acid solution and arabinose solution respectively;

[0027] 2) Combine the citric acid solution and the arabinose solution in step 1), then stir for 30 minutes at a temperature of 40°C at a stirring rate of 800rpm, then put them into an ultrasonic processor, and perform ultrasonic treatment at a temperature of 20°C for 15 minutes, The ultrasonic frequency of the ultrasonic processor is 2500Hz to cool down to room temperature;

[0028] 3) Form the coating solution prepared in step 2) into a film...

Embodiment 2

[0030] A thin film of supramolecular materials constructed by extracting small molecules from biomass, including the following raw materials: raffinose and ascorbic acid.

[0031] A method for preparing a supramolecular material film constructed by extracting small molecules from biomass, comprising the following steps:

[0032] 1) dissolving ascorbic acid in distilled water at a mass percentage concentration of 0.5wt%-5wt%, and raffinose at a mass percentage concentration of 0.5wt%-3wt%, to prepare a citric acid solution and a raffinose solution respectively;

[0033] 2) Combine the ascorbic acid solution and the raffinose solution in step 1), then stir for 30 minutes at a temperature of 40°C at a stirring rate of 800rpm, then put them into an ultrasonic processor, and perform ultrasonic treatment at a temperature of 20°C for 15 minutes, The ultrasonic frequency of the ultrasonic processor is 2500Hz to cool down to room temperature;

[0034] 3) Form the coating solution prep...

Embodiment 3

[0036] A supramolecular material film constructed by extracting small molecules from biomass, including the following raw materials: maltodextrin and gluconolactone.

[0037] A method for preparing a supramolecular material film constructed by extracting small molecules from biomass, comprising the following steps:

[0038] 1) dissolving gluconolactone in distilled water at a mass percentage concentration of 0.5wt%-5wt%, and maltodextrin at a mass percentage concentration of 0.5wt%-3wt%, to prepare a gluconolactone solution and a maltodextrin solution respectively;

[0039] 2) Combine the gluconolactone solution and the maltodextrin solution in step 1), then stir for 30 minutes at a temperature of 40°C at a stirring rate of 800rpm, then put it into an ultrasonic processor, and ultrasonicate at a temperature of 20°C After processing for 15 minutes, the ultrasonic frequency of the ultrasonic processor is 2500Hz and cooled to room temperature;

[0040] 3) Form the coating soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com