Weather-resistant solvent-free two-component polyurethane coating as well as preparation method and use method thereof

A two-component polyurethane, solvent-free technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of environmental pollution and high spray thickness of solvent-free coatings, achieve low overall cost, improve construction efficiency, and reduce labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

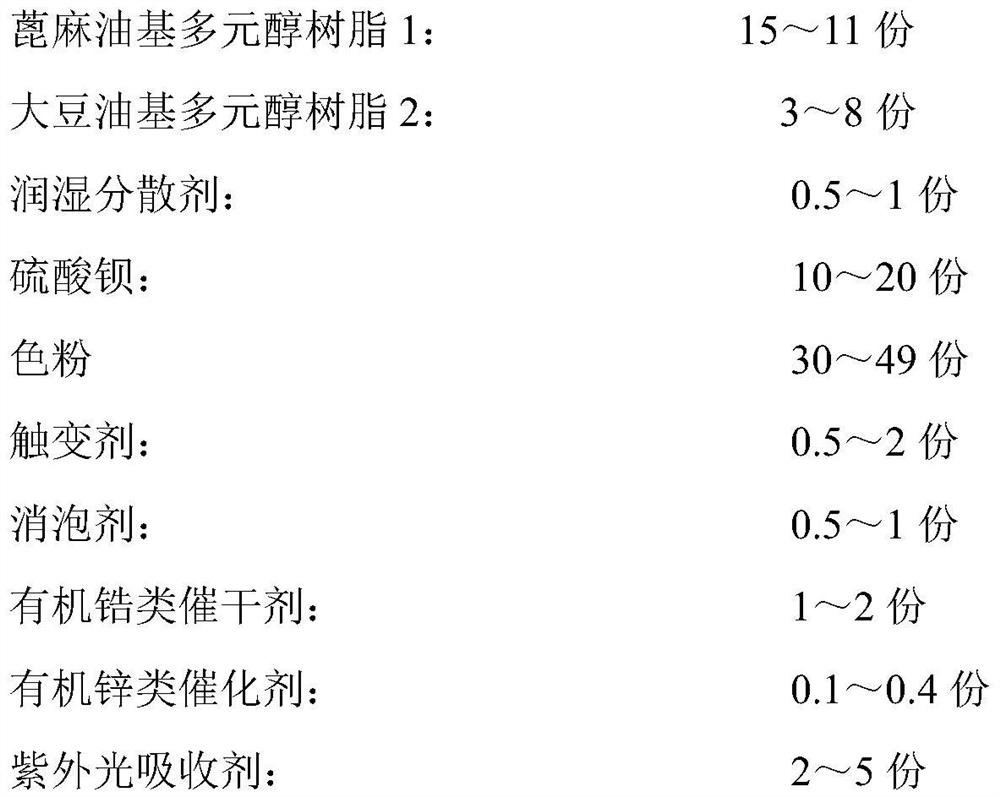

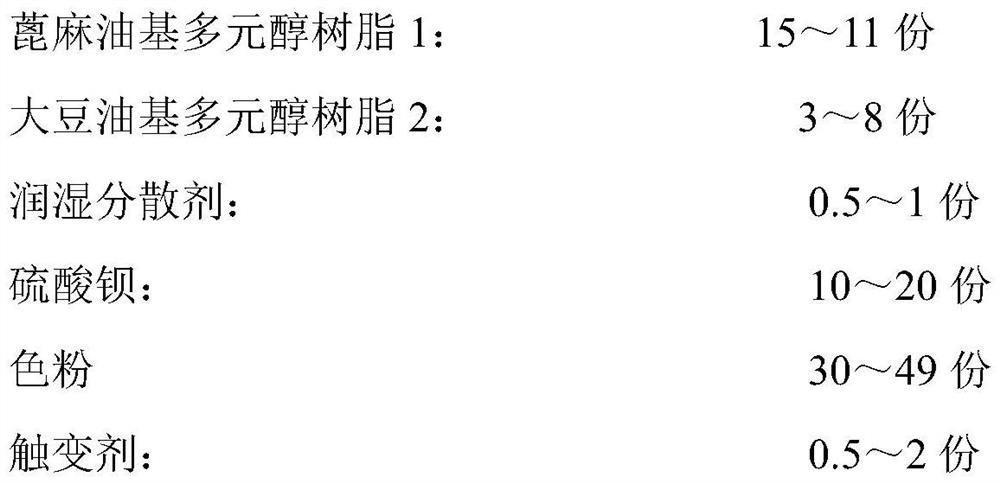

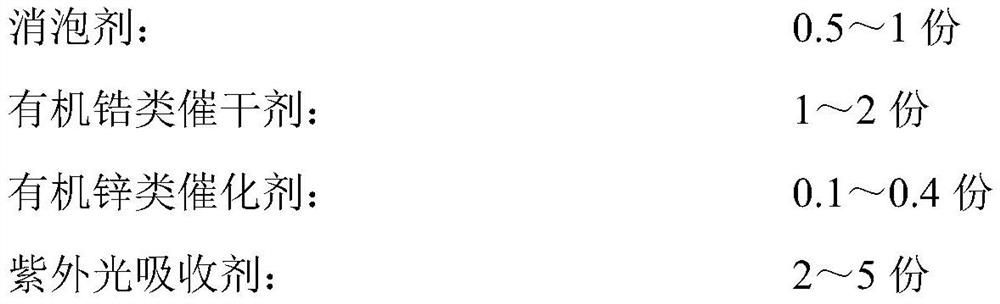

[0039] In this technology, a mixture of castor oil-based modified polyol resin and soybean oil-based polyol resin is introduced as the base material, and a wetting and dispersing agent is added, and the toner and filler are evenly dispersed in the base material by sand milling to form A The component is composed of HDI isocyanate derivative curing agent with low viscosity and good weather resistance as component B. When using, mix component A and component B evenly, and then use sprayable solvent-free two-component polyurethane coating airless spraying equipment to spray on the substrate.

[0040] Information on castor oil based polyol resins and soybean oil polyester polyols:

[0041] The castor oil-based modified polyester polyol resin is a trifunctional polyester polyol formed by the reaction of castor oil and TMP, and the hydroxyl group in its molecule is a secondary hydroxyl group.

[0042] The most commonly used preparation method of soybean oil polyol is the epoxy ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com