Photocuring double-component polyurea waterproof coating and preparation method thereof

A waterproof coating, two-component technology, used in polyurea/polyurethane coatings, coatings, etc., can solve problems such as low construction efficiency, dependence on ambient temperature, and strength requiring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The light-cured two-component polyurea waterproof coating provided in this embodiment, its raw material formula is shown in Table 1, wherein,

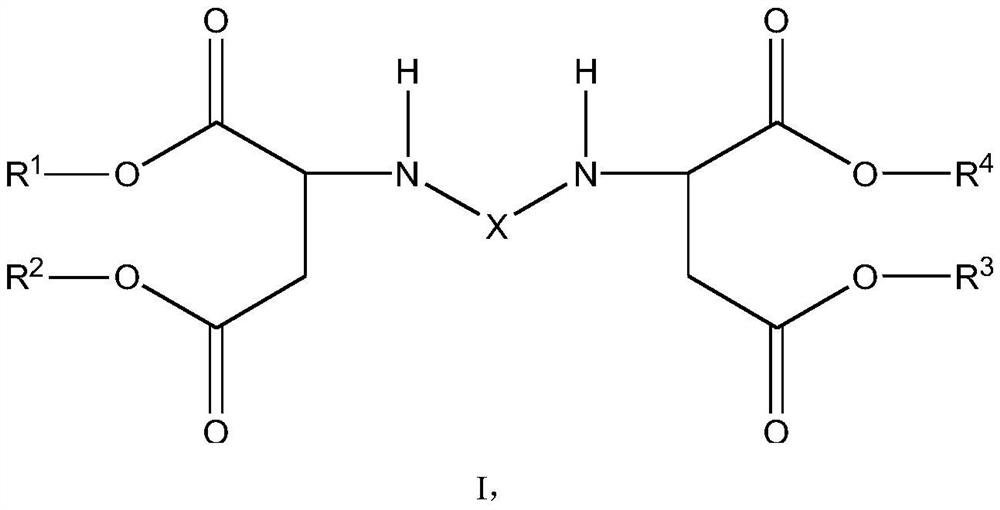

[0046] The sterically hindered secondary amine has the following structural formula, and JH334 from Junhe Chemical (Shanghai) Co., Ltd., referred to as amine chain extender No. 1 for short:

[0047]

[0048] In formula I, X is CH 2 , R 1 , R 2 , R 3 , R 4 Respectively CH 2 CH 3 .

[0049] The isocyanate is MDI-MIPS.

[0050] The amino-terminated polyether is Huntsman SD2001.

[0051] The amine chain extender has the following structural formula, specifically JH334 from Junhe Chemical (Shanghai) Co., Ltd., referred to as amine chain extender No. 1:

[0052]

[0053] In formula I, X is CH 2 , R 1 , R 2 , R 3 , R 4 Respectively CH 2 CH 3 .

[0054] The photoinitiator is JRCURE-1110.

[0055] The defoamer is polysiloxane defoamer 8110.

[0056] The antioxidant is 2,6-tertiary butyl-4-methylphenol.

[0057] ...

Embodiment 2

[0070] The light-curing two-component polyurea waterproof coating provided in this example differs from Example 1 in that in component A, the mass ratio of polyurea prepolymer and acrylic modified polyurea prepolymer is different.

[0071] In this example, the raw material formulations of components A and B are shown in Table 1. Among them, the hindered secondary amine has the following structural formula, and JH334 from Junhe Chemical (Shanghai) Co., Ltd., referred to as amine chain extender No. 1, is selected specifically:

[0072]

[0073] In formula I, X is CH 2 , R 1 , R 2 , R 3 , R 4 Respectively CH 2 CH 3 .

[0074] The isocyanate is MDI-MIPS.

[0075] The amino-terminated polyether is Huntsman SD2001.

[0076] The amine chain extender has the following structural formula, specifically JH334 from Junhe Chemical (Shanghai) Co., Ltd., referred to as amine chain extender No. 1:

[0077]

[0078] In formula I, X is CH 2 , R 1 , R 2 , R 3 , R 4 Respective...

Embodiment 3

[0095] The light-curing two-component polyurea waterproof coating provided in this example is different from Example 1 in that in component A, the mass ratio of polyurea prepolymer and acrylic modified polyurea prepolymer is different.

[0096] In this example, the raw material formulations of A and B components are shown in Table 1, wherein,

[0097] The sterically hindered secondary amine has the following structural formula, and JH334 from Junhe Chemical (Shanghai) Co., Ltd., referred to as amine chain extender No. 1 for short:

[0098]

[0099] In formula I, X is CH 2 , R 1 , R 2 , R 3 , R 4 Respectively CH 2 CH 3 .

[0100] The isocyanate is MDI-MIPS.

[0101] The amino-terminated polyether is Huntsman SD2001.

[0102] The amine chain extender has the following structure, specifically JH334 from Junhe Chemical (Shanghai) Co., Ltd., referred to as amine chain extender No. 1:

[0103]

[0104] In formula I, X is CH 2 , R 1 , R 2 , R 3 , R 4 Respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com