Composite modified desulfurized rubber asphalt and preparation method thereof

A desulfurized rubber, compound modification technology, applied in building components, building insulation materials, construction, etc., can solve problems such as difficult to use, high temperature performance and elastic decline, poor elastic performance, etc., to improve social and economic benefits, high and low temperature Good performance, the effect of solving rubber pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

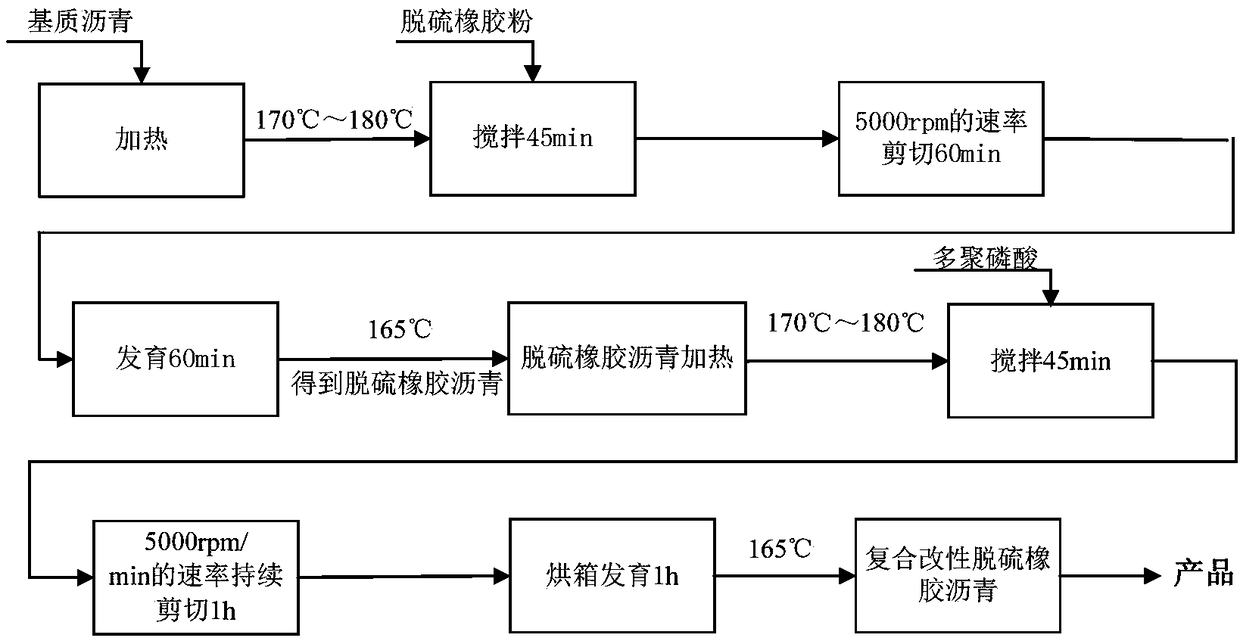

[0034] Such as figure 1 Shown, a kind of preparation method of composite modified devulcanized rubber asphalt comprises the following steps:

[0035] Step 1), raw materials are calculated by weight percentage: 18%-26% of devulcanized rubber, 1%-26% of composite modifier, and the rest is matrix asphalt;

[0036] Step 2), heating the base asphalt to a molten state, then adding the devulcanized rubber into the molten base asphalt, stirring evenly to obtain a mixture A;

[0037] Step 3), cutting mixture A at 160°C to 200°C for 30min to 90min; then taking it out and growing it at a constant temperature at 155-165°C to obtain mixture B;

[0038] Step 4), adding the composite modifier into the mixture B, continuously stirring and developing, and then shearing to obtain the mixture C, and developing the mixture C at a constant temperature to obtain the composite modified desulfurized rubber asphalt.

[0039] In step 2), the base asphalt is heated to 135°C-180°C to a molten state; th...

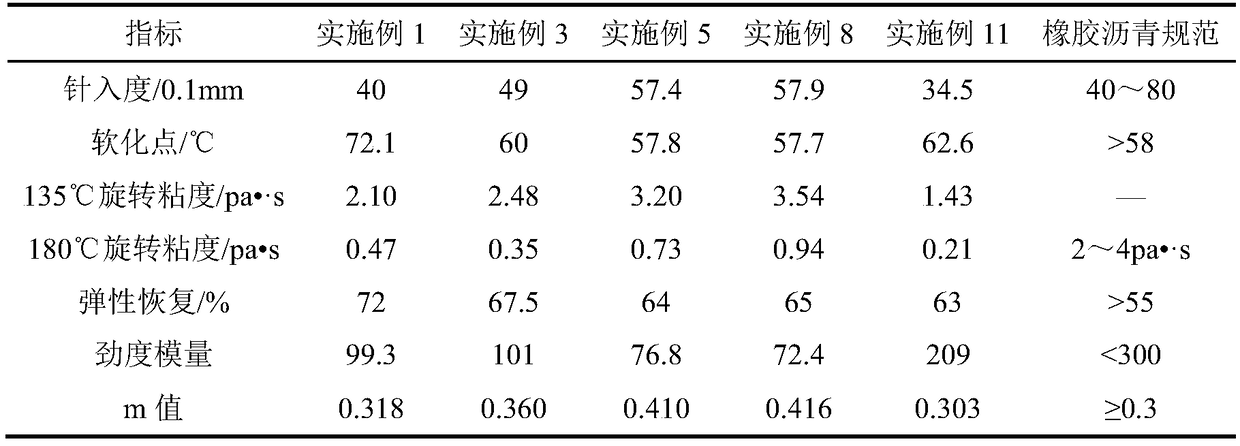

Embodiment 1

[0046] Raw materials calculated by weight percentage: general desulfurized rubber powder 22%, polyphosphoric acid compound modifier 1.25%, Dongming 70# matrix asphalt 76.75%;

[0047] Heat Dongming 70# base asphalt to 170°C to a molten state, add desulfurized rubber powder in the molten state of Dongming 70# base asphalt at 170°C, and stir at 170°C for 45 minutes to mix the devulcanized rubber in the base asphalt evenly to obtain mixture A;

[0048] Cut mixture A at 170°C with a shearing machine at a shear rate of 5000rpm / min for 45min; then take it out and develop at a constant temperature of 165°C for 60min to obtain mixture B;

[0049] Add polyphosphoric acid composite modifier to mixture B, shear at 170°C at a rate of 5000rpm / min for 45min to obtain mixture C, and develop mixture C at 165°C for 45min to obtain polyphosphoric acid composite modified desulfurization Rubberized asphalt.

Embodiment 2

[0051] Raw materials are calculated by weight percentage: 18% of general desulfurized rubber powder, 2% of polyphosphoric acid compound modifier, 80% of Shell 70# matrix asphalt;

[0052] Heat Shell 70# base asphalt to 135°C to a molten state, add desulfurized rubber powder in the molten state of Shell 70# base asphalt at 135°C, and stir at 135°C for 55 minutes to mix the devulcanized rubber in the base asphalt evenly to obtain mixture A;

[0053] Mixture A was cut at 135°C with a shearing machine at a shear rate of 6000rpm / min for 60min; then it was taken out and grown at a constant temperature of 155°C for 50min to obtain mixture B;

[0054] Add the polyphosphoric acid composite modifier to the mixture B, cut at 175°C for 55 minutes at a rate of 6000rpm / min to obtain the mixture C, and develop the mixture C at 180°C for 40 minutes to obtain the polyphosphoric acid composite modified desulfurization Rubberized asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com