Solvent-free two-component reactive type polyurethane adhesive applied to woodworking industry and using method of adhesive

A polyurethane adhesive and solvent-free technology, which is applied in the field of solvent-free two-component reactive polyurethane adhesives, can solve the problems of non-continuous production, many processing restrictions, and inconvenient use, so as to improve adhesion, increase production efficiency, and expand The effect of market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

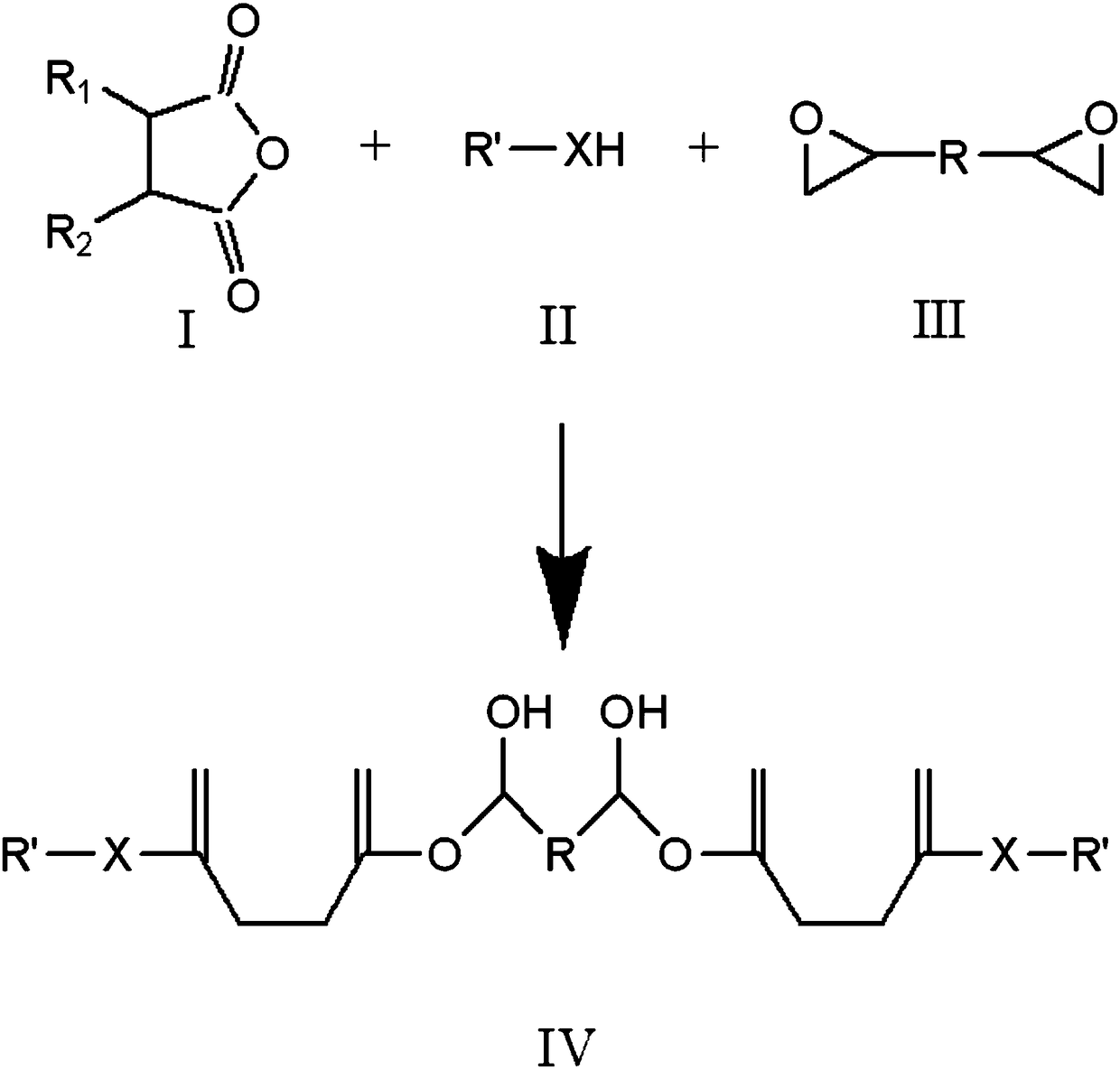

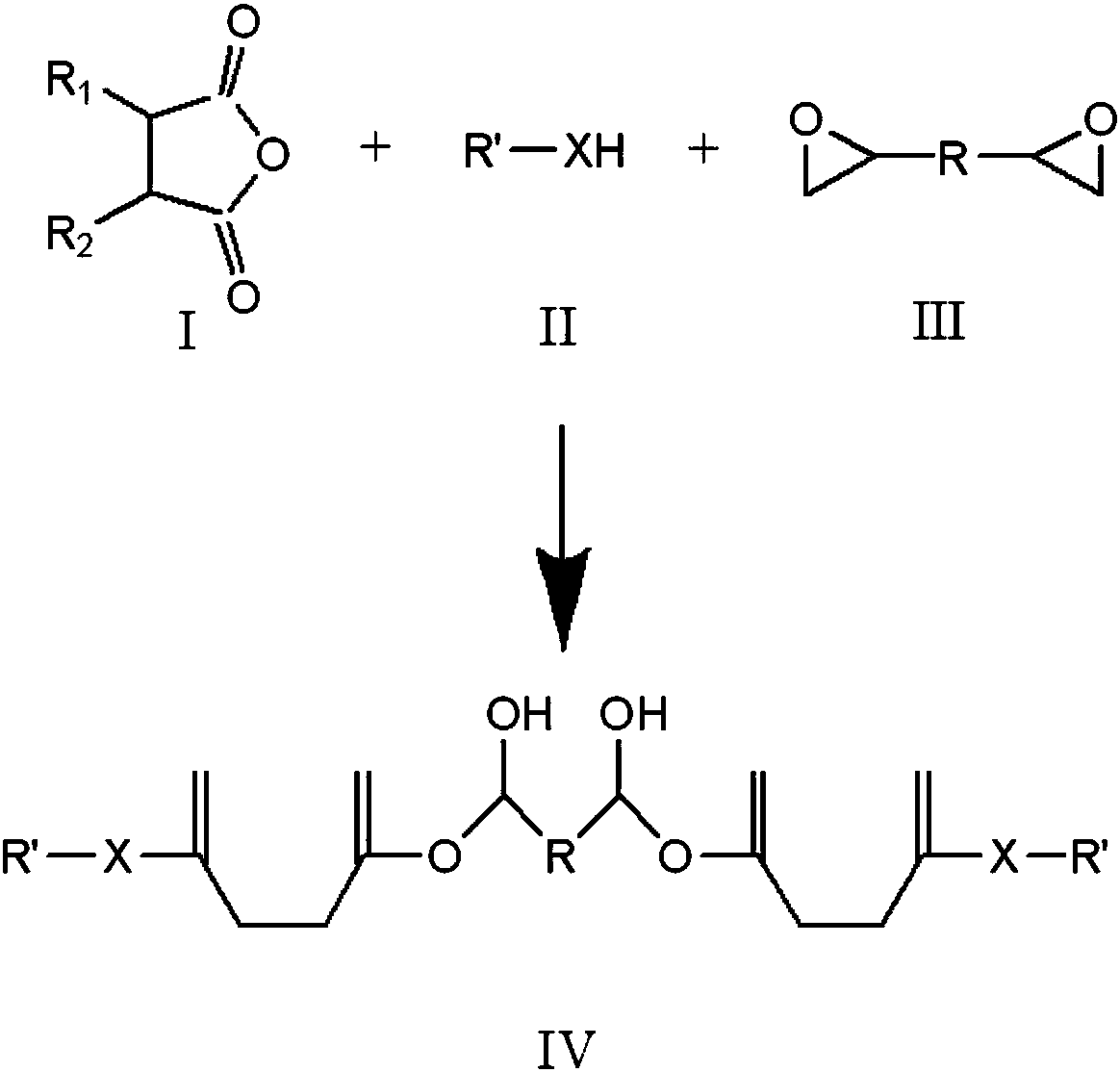

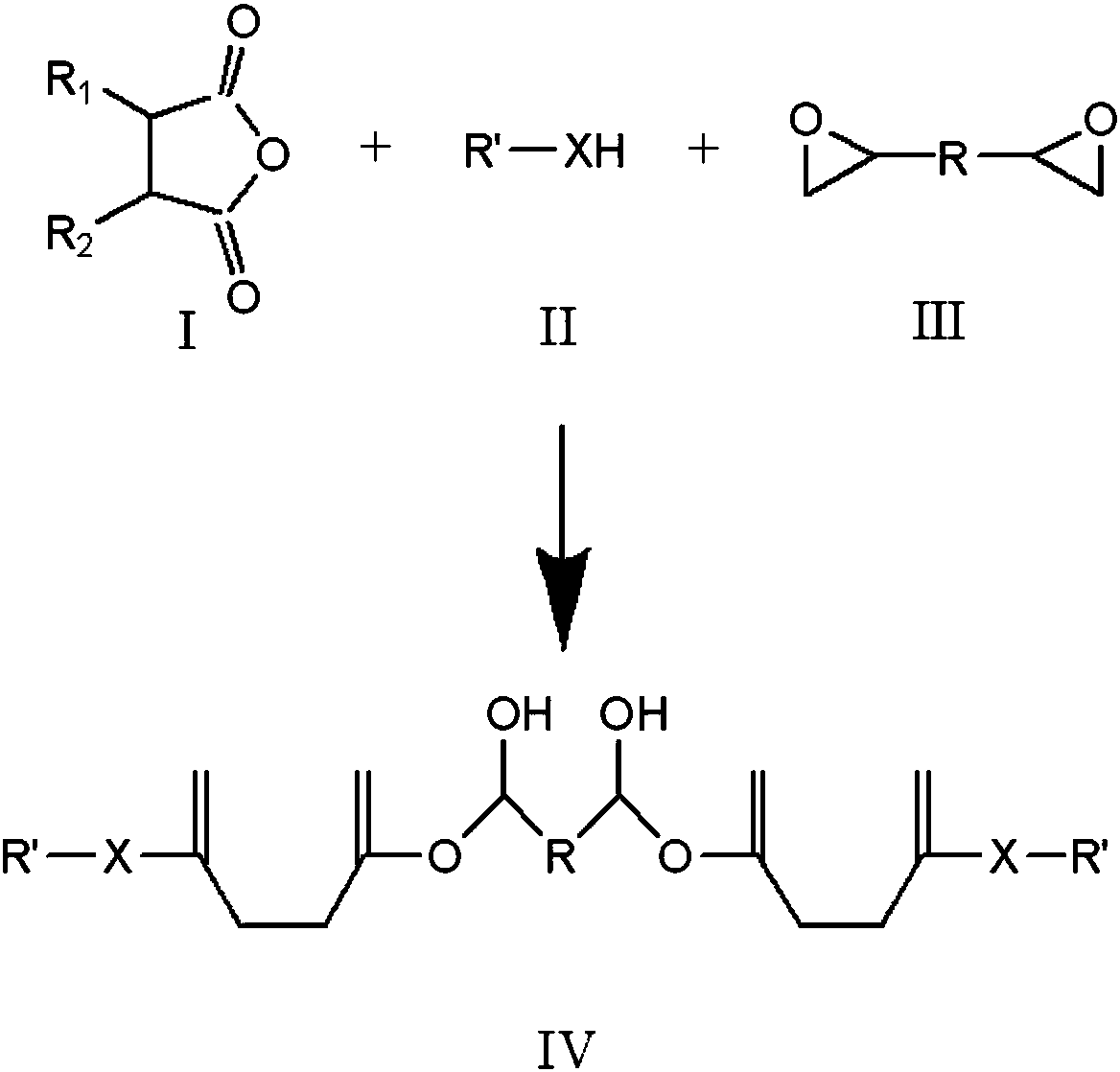

Method used

Image

Examples

Embodiment 1

[0029] A kind of solvent-free two-component reactive polyurethane adhesive applied to the woodworking industry described in Example 1 of the present invention includes component A and component B:

[0030] ——The component A includes a prepolymer with a partially blocked or completely blocked isocyanate group in the side chain or main chain, an end-capping agent, an auxiliary agent, and a first catalyst; wherein the functionality of the prepolymer is equal to 1 , whose isocyanate content is 15%;

[0031] The prepolymer in the component A is polymerized by polyisocyanate and polyhydroxy compound b, and then reacted with blocking agent to generate, wherein the polyisocyanate is polyisocyanate is isophorone diisocyanate (IPDI) and diphenyl Methyl methane diisocyanate (MDI) according to the composition of IPDI:MDI=1.5, accounts for 55% of the total mass of component A; The polyhydroxy compound b is polyester polyol, selects Risheng Chemical Co., Ltd. P-2707 polymer The hydroxyl va...

Embodiment 2

[0044] The present invention described in Embodiment 2 of the present invention also relates to a method for using a two-component solvent-free reactive polyurethane adhesive for wood bonding, including the following steps:

[0045] (1) Before use, component A and component B are packaged with independent airtight containers respectively, and the airtight containers are tinplate barrels, PET / Al / Nylon / PP films, etc.;

[0046] (2) In the process of use, put the A component and the B group into the glue melting machine at room temperature and output them in proportion (100:100) through the metering pump to the static mixing tube for mixing or mechanical mixing so that the two components are evenly mixed to obtain Two-component solvent-free reactive polyurethane adhesive that meets the specified conditions;

[0047] (3) Preheating the glue-coated wood substrate until the surface of the substrate reaches 50°C;

[0048] (4) After heating the uniformly mixed polyurethane glue to 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com