Modifier as well as preparation method and application thereof

A modifier and modification technology, used in building components, building insulation materials, building structures, etc., can solve the problems of poor construction workability and poor melt dispersion of modifiers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

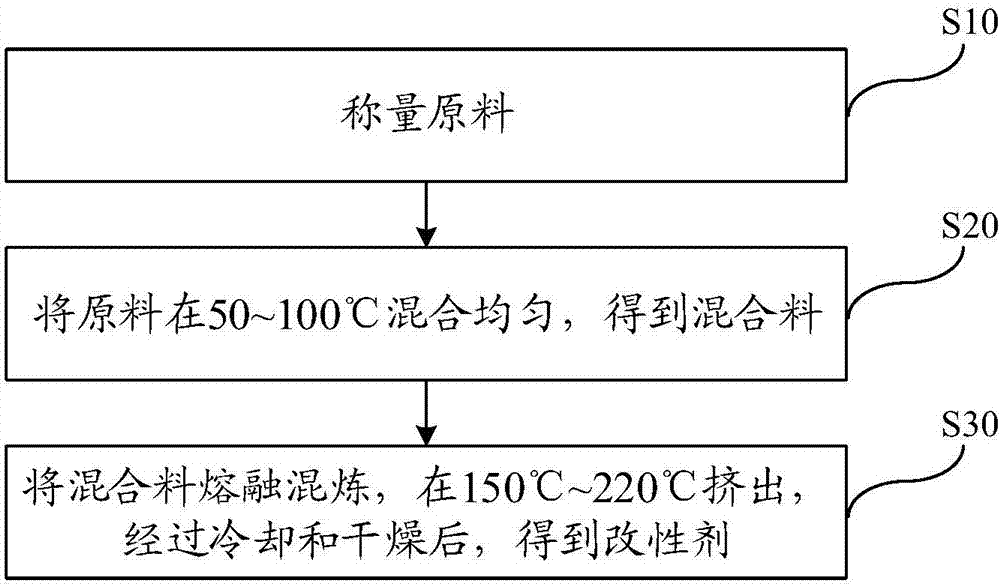

[0029] The embodiment of the invention also discloses a preparation method of the modifying agent. The preparation method prepares the above-mentioned modifying agent. Specifically, such as figure 1 Shown, the preparation method of this modifying agent comprises the steps:

[0030] Step S10: weighing raw materials.

[0031] Wherein, the raw material includes the following components in parts by weight: 40-80 parts of thermoplastic elastomer polymer, 10-30 parts of modified petroleum resin, 5-20 parts of heat-sensitive resin, 1-5 parts of stabilizer, plasticizer 5-20 parts and 1-3 parts of antioxidant. The specific composition of the raw material can be referred to the modifier mentioned above, and will not be repeated here.

[0032] Step S20: mixing the raw materials uniformly at 50-100° C. to obtain a mixture.

[0033] Specifically, this step can be carried out in a high-speed mixer, and the raw materials are uniformly mixed by high-speed stirring.

[0034] Step S30: me...

Embodiment 1

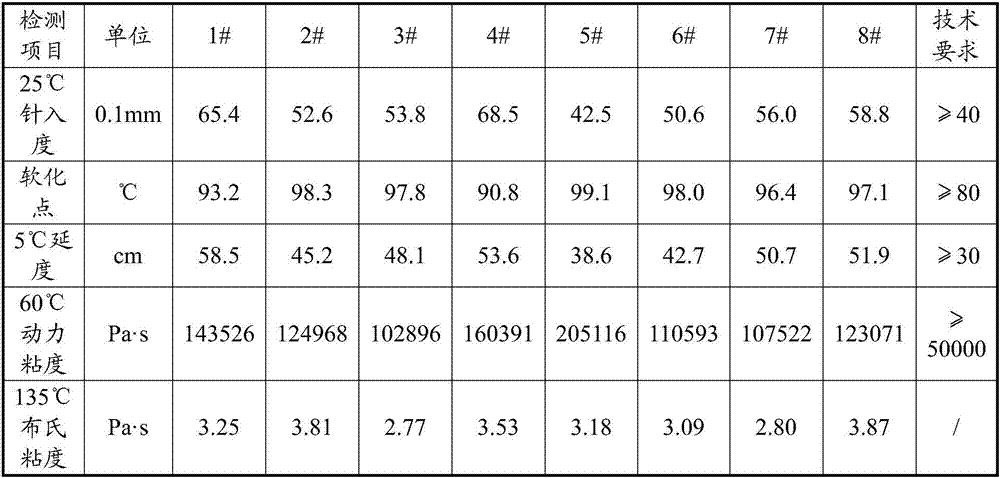

[0045] The modifying agent of embodiment 1 adopts and comprises the raw material preparation in following parts by weight: styrene-butadiene-styrene triblock copolymer (the weight percent composition of styrene is 30%, and melt index is 12g / 10min) 62 parts, 16 parts of modified C5 petroleum resin, 10 parts of polyvinyl chloride resin, 2 parts of calcium-zinc composite stabilizer, 9 parts of dioctyl phthalate, 1 part of antioxidant (1010).

[0046] The preparation method of the modifying agent in Example 1 is as follows: after weighing each raw material according to the above ratio, add it to a high-speed mixer, stir at a high speed of 50°C for 10 minutes, and then send it into a twin-screw extruder for extrusion and granulation. The barrel temperature is 180°C, the screw speed is 150r / min, and after cooling and drying, Modifier 1# is obtained.

[0047] The method of preparing high-viscosity modified asphalt from modifier 1# is as follows: heat the base asphalt to 160°C, and t...

Embodiment 2

[0050] The modifying agent of embodiment 2 adopts and comprises the raw material preparation in following parts by weight: styrene-ethylene butylene copolymer-styrene triblock copolymer (the weight percent composition of styrene is 33%, and melt index is 14g / 10min) 48 parts, modified terpene resin 22 parts, polyvinyl chloride resin 7 parts, calcium zinc composite stabilizer 2 parts, dioctyl phthalate 20 parts, antioxidant (1010) 1 part.

[0051] The preparation method of the modifying agent in Example 2 is as follows: weigh each raw material according to the above ratio and add it to a high-speed mixer, stir at a high speed of 80°C for 10 minutes, and then send it into a twin-screw extruder for extrusion and granulation. The barrel temperature is 200°C, the screw speed is 180r / min, after cooling and drying, modifier 2# is obtained.

[0052] The method of preparing high-viscosity modified asphalt from modifier 2# is as follows: heat the base asphalt to 160°C, and then add an ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com