Composite modified emulsified asphalt with excellent anti-stripping performance and preparation method thereof

A technology of composite modified and emulsified asphalt, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problem of anti-stripping performance, stability of demulsification time, modifier dispersion cannot be guaranteed, sticking wheel demulsification time , emulsification difficulty increase and other problems, achieve excellent anti-peeling performance and storage stability, improve demulsification strength, and improve high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1, a composite modified emulsified asphalt with excellent anti-stripping performance

[0039] The composite modified emulsified asphalt with excellent spalling resistance is composed of the following raw materials and parts by weight thereof:

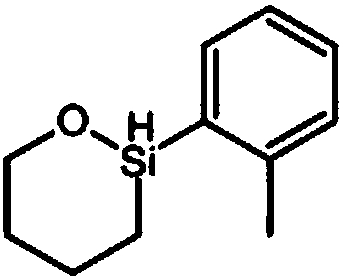

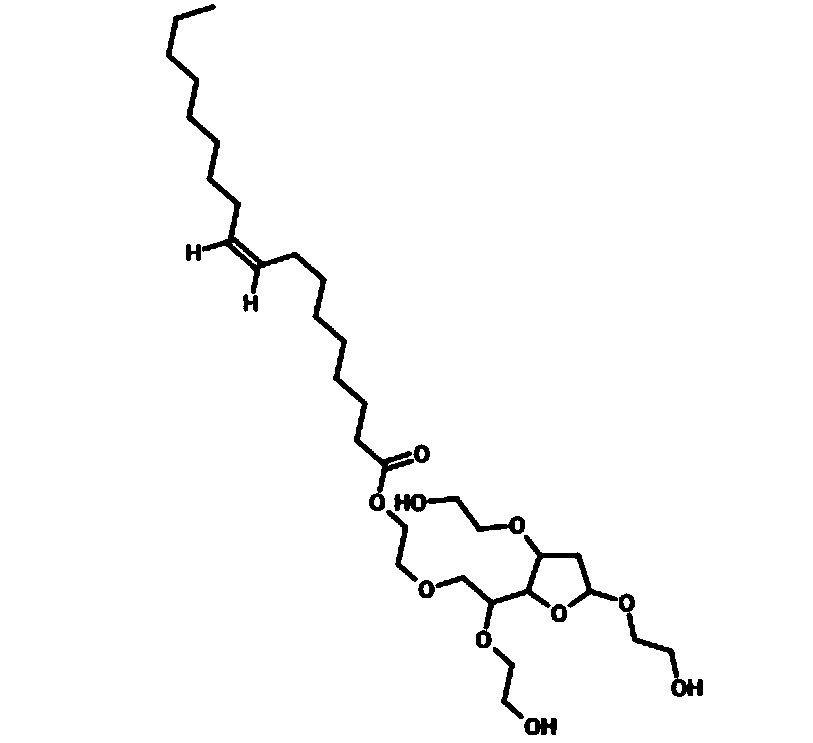

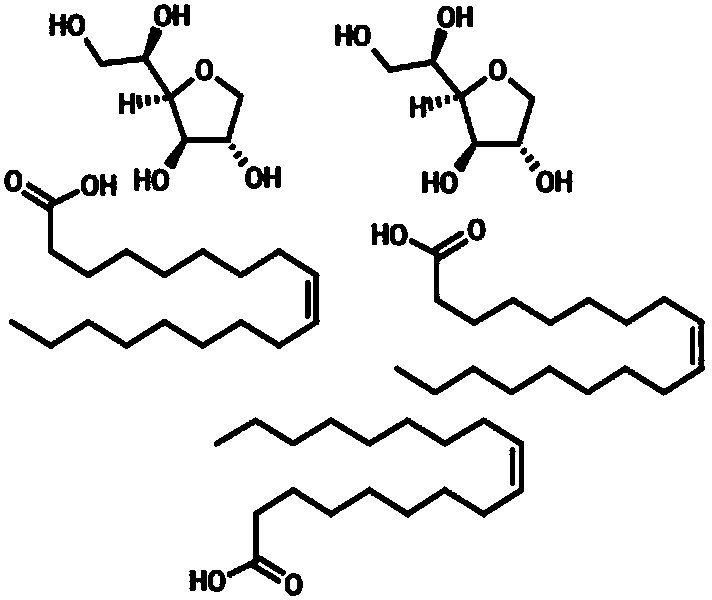

[0040] 4.0 parts of styrene-butadiene-styrene block copolymer, 70 parts of road petroleum asphalt, 1.0 part of phosphogypsum, 0.5 parts of methylphenyl silicone oil, 40 parts of water, 2.5 parts of polyoxyethylene sorbitan laurate part, 0.4 part of sorbitan sesquiisostearate, 0.5 part of sodium carboxymethylcellulose; the styrene-butadiene-styrene block copolymer is Dushanzi T161B star styrene- Butadiene-styrene block copolymer. Preparation:

[0041] S1 At a temperature of 180°C, the styrene-butadiene-styrene block copolymer and road petroleum asphalt were sheared at a speed of 3500r / min for 60min by a high-speed shearer, and stirred at a temperature of 180°C for 3h , followed by adding phosphogypsum and methyl phenyl ...

Embodiment 2

[0044] Example 2, a composite modified emulsified asphalt with excellent anti-stripping performance

[0045] The composite modified emulsified asphalt with excellent spalling resistance is composed of the following raw materials and parts by weight thereof:

[0046] 4.0 parts of styrene-butadiene-styrene block copolymer, 70 parts of road petroleum asphalt, 1.0 part of phosphogypsum, 0.5 parts of methylphenyl silicone oil, 40 parts of water, 2.5 parts of polyoxyethylene sorbitan laurate part, 0.4 part of sorbitan sesquiisostearate, 0.5 part of sodium carboxymethylcellulose; the styrene-butadiene-styrene block copolymer is Dushanzi T161B star styrene- Butadiene-styrene block copolymer. Preparation:

[0047] S1 At a temperature of 180°C, the styrene-butadiene-styrene block copolymer and road petroleum asphalt were sheared at a speed of 3500r / min for 60min by a high-speed shearer, and stirred at a temperature of 180°C for 3h , followed by adding phosphogypsum and methyl phenyl ...

Embodiment 3

[0050] Example 3, a composite modified emulsified asphalt with excellent anti-stripping performance

[0051] The composite modified emulsified asphalt with excellent spalling resistance is composed of the following raw materials and parts by weight thereof:

[0052] 3.0 parts of styrene-butadiene-styrene block copolymer, 60 parts of road petroleum asphalt, 0.5 parts of phosphogypsum, 0.5 parts of methylphenyl silicone oil, 35 parts of water, 1.5 parts of polyoxyethylene sorbitan laurate 0.2 part, 0.2 part of sorbitan sesquiisostearate, 0.5 part of sodium carboxymethylcellulose; the styrene-butadiene-styrene block copolymer is CNPC Dushanzi T161B star styrene- Butadiene-styrene block copolymer. Preparation:

[0053] S1 At a temperature of 180°C, the styrene-butadiene-styrene block copolymer and road petroleum asphalt were sheared at a speed of 3000r / min for 30min by a high-speed shearer, and stirred at a temperature of 170°C for 2h , followed by adding phosphogypsum and meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com