A kind of asphalt mixture with physically modified red mud instead of mineral powder and its preparation method

An asphalt mixture and physical modification technology, applied in the field of road engineering materials and preparation, can solve the problems of rising limestone ore powder prices, cost pressure of road construction investment units and construction enterprises, insufficient comprehensive utilization rate, etc., and improve water resistance. Damage ability, improve freeze-thaw splitting strength ratio, reduce comprehensive cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing physically modified red mud used to replace mineral powder, comprising:

[0052] (1) First, the red mud is subjected to conventional primary crushing, and then dried in an oven at 105°C for 1-3 hours to remove moisture, and then finely ground by a high-speed crusher to the specifications specified in the "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004). The particle size required by the filler;

[0053] (2) Pour a certain amount of modified material into water, and stir it with a booster mixer at a speed of 100-300 rpm for 10-20 minutes to fully mix it, wherein the mass ratio of the modified material to water 0.1~0.4:1;

[0054] (3) Pour a certain amount of finely ground red mud into the modified material aqueous solution, and use a booster stirrer to stir at a speed of 100-300 rpm for 10-20 minutes to fully mix, wherein the red mud and the modified material The mass ratio...

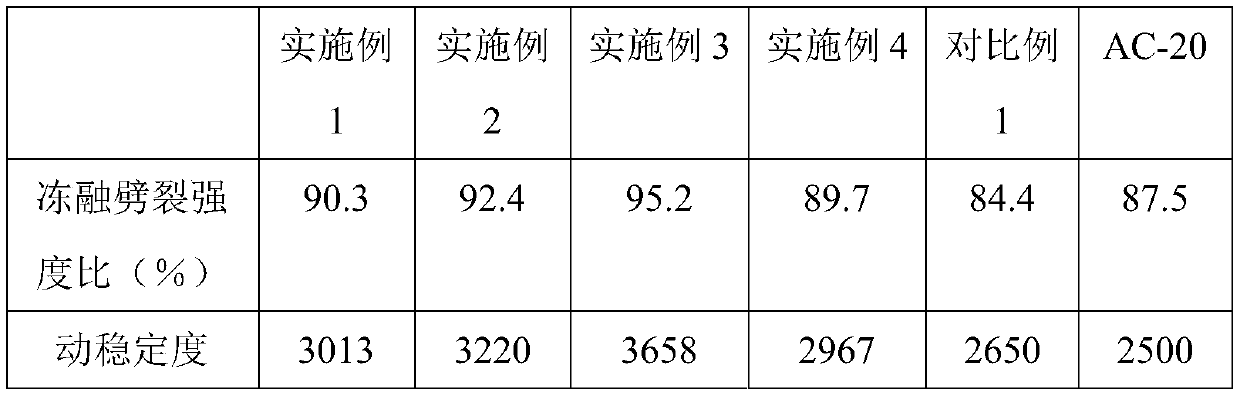

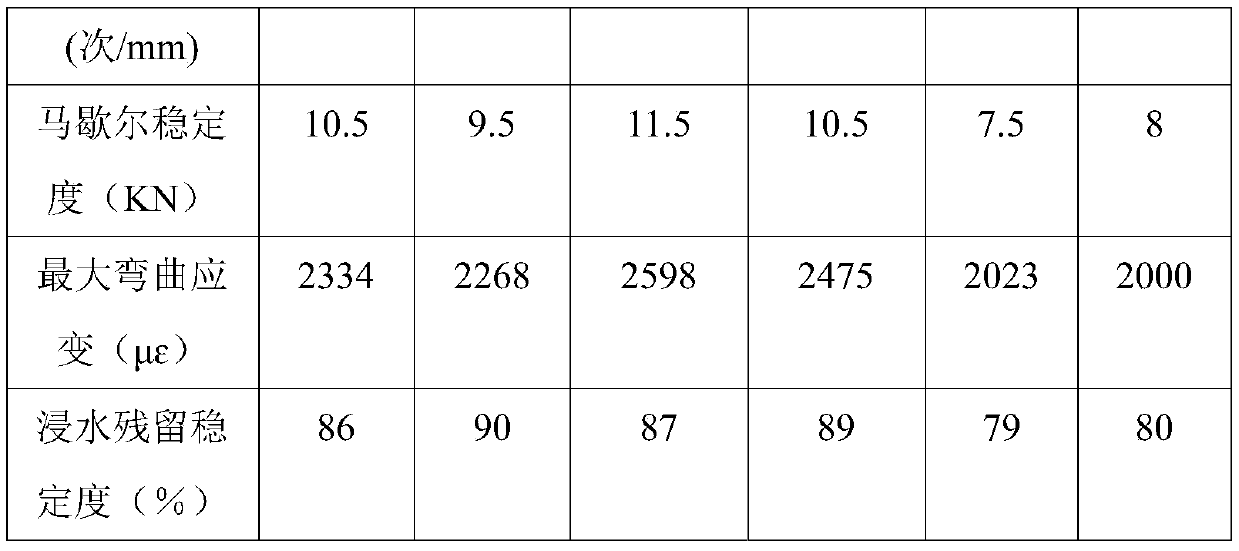

Embodiment 1

[0067] 1. An asphalt mixture that replaces slag powder with physically modified red mud, including the following components in terms of mass percentage: 40% of 0-5cm aggregate, 20% of 5-10cm aggregate, 10-15cm aggregate 30% material, No. 70 matrix road petroleum asphalt 4.5%, physically modified red mud 5.5%, the aggregate is basalt, and all technical indicators meet the relevant requirements in the "Technical Specifications for Road Asphalt Pavement Construction" (JTG F40-2004). Require. Type of asphalt mixture: AC-20.

[0068] The red mud used in the physically modified red mud is sintered red mud, and the modified materials are slaked lime, fly ash, cement, blast furnace slag, white mud and carbide slag, and the mass ratio is 1:2:1.5:3 :4.5: 3.

[0069] The physically modified red mud is a mixture of red mud and slaked lime, and the mass ratio of red mud to modified material is 1:0.5.

[0070] 2. The preparation method of the above-mentioned physically modified red mud i...

Embodiment 2

[0082] 1. An asphalt mixture that replaces slag powder with physically modified red mud, including the following components in terms of mass percentage: 40% of 0-5cm aggregate, 20% of 5-10cm aggregate, 10-15cm aggregate 30% material, No. 70 matrix road petroleum asphalt 4.5%, physically modified red mud 5.5%, the aggregate is basalt, and all technical indicators meet the relevant requirements in the "Technical Specifications for Road Asphalt Pavement Construction" (JTG F40-2004). Require. Type of asphalt mixture: AC-20.

[0083] The red mud used in the physically modified red mud is sintered red mud, and the modified materials are slaked lime, fly ash, cement, blast furnace slag, white mud and carbide slag, and the mass ratio is 1:3:2:3 :4.5: 3.

[0084] The physically modified red mud is a mixture of red mud and modified materials, and the mass ratio of red mud to modified materials is 1:0.1.

[0085] 2. The preparation method of the above-mentioned physically modified red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com