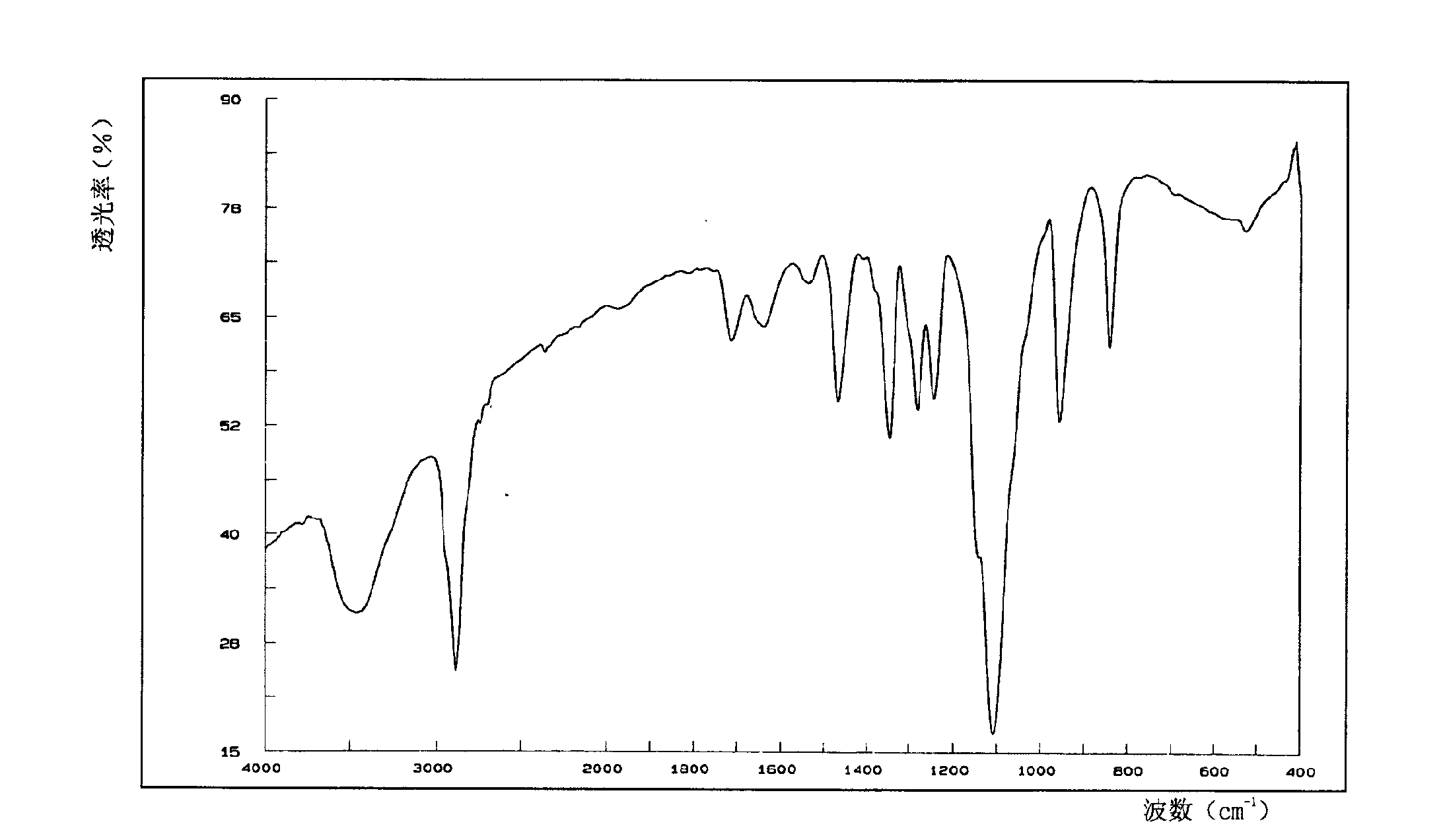

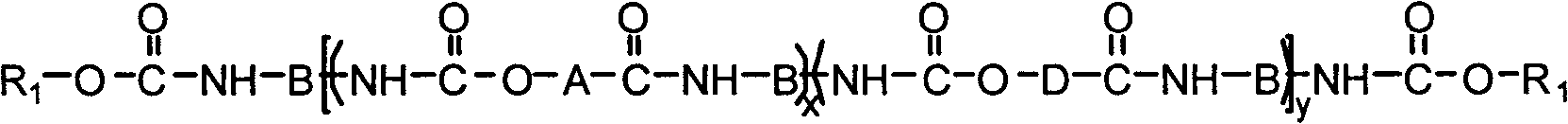

Comb polyurethane associated thickener and preparation method and application thereof

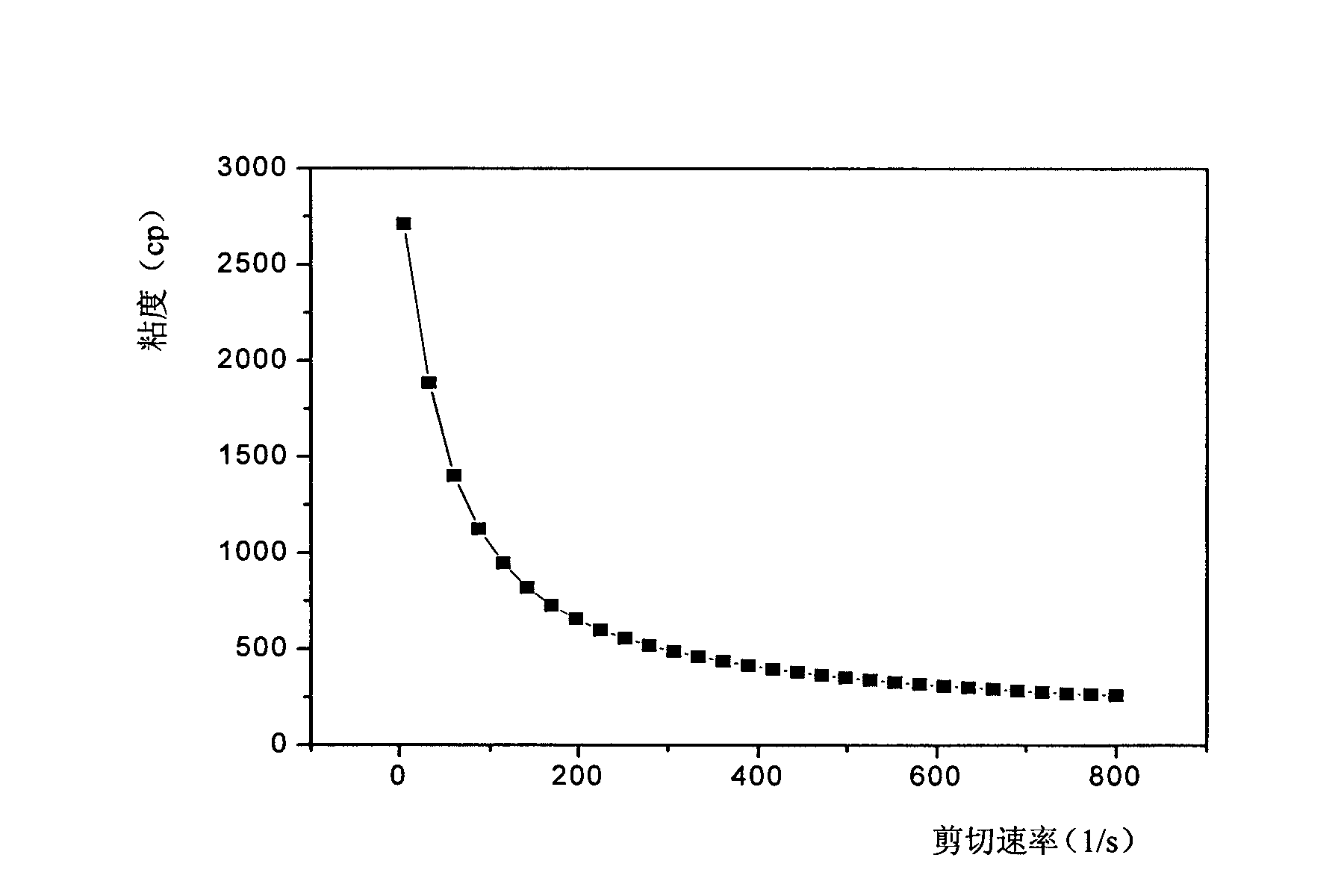

A technology of associative thickener and polyurethane, which is applied in application, adhesive additives, preparations for toiletry, etc. It can solve the problems of system viscosity increase and other problems, and achieve the effect of increasing viscosity, low construction viscosity and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Synthesis of hydrophobic diols

[0052] Put 0.1 mol of dodecylamine into a 250ml three-neck flask with a condenser, magnetic stirring, and nitrogen inlet, fill it with nitrogen, and add 0.25 mol of n-butyl glycidyl ether dropwise at 50°C for 30 minutes, then raise the temperature to React at 80°C for 10 hours, and finally distill under reduced pressure to remove unreacted reaction products, and titrate their hydroxyl value Qv=269.7mgKOH / g.

[0053] (2) Synthesis of comb-like polyurethane associative thickener

[0054] Add 3.3mmol (20.0g) of polyethylene glycol 6000 and 50g of toluene into a 250ml three-neck flask equipped with mechanical stirring, water separator and nitrogen inlet, first azeotropic dehydration for 2-3 hours, then cool down to 70°C, and add 0.03g Dibutyltin dilaurate and 4.7mmol (1.04g) of isophorone diisocyanate were reacted for 2h. After the prepolymerization reaction was completed, the temperature was raised to 80°C and 1.1mmol (0.35g) of the hy...

Embodiment 2

[0064] (1) Synthesis of hydrophobic diols

[0065] Put 0.1 mol of hexadecylamine into a 250ml three-neck flask equipped with a condenser, magnetic stirring, and nitrogen inlet, fill it with nitrogen, and add 0.25 mol of n-butyl glycidyl ether dropwise at 60°C for 30 minutes, then raise the temperature to React at 90°C for 8h, and finally distill under reduced pressure to remove the unreacted reaction product, and titrate its hydroxyl value Qv=240.0mgKOH / g.

[0066] (2) Synthesis of comb-like polyurethane associative thickener

[0067] Add 10.0mmol (20.0g) of polypropylene glycol 2000 and 50g of toluene into a 250ml three-neck flask equipped with mechanical stirring, a water separator, and a nitrogen inlet, first azeotropically dehydrate for 2-3 hours, then cool down to 50°C, and add 0.03g of octanoic acid sulfide Tin and 12.0 mmol (2.02 g) of 1,6-hexamethylene diisocyanate were reacted for 6 hours. After the prepolymerization reaction was completed, the temperature was raised...

Embodiment 3

[0074] (1) Synthesis of hydrophobic diols

[0075] Put 0.1mol of n-octylamine into a 250ml three-neck flask equipped with a condenser, magnetic stirring, and nitrogen inlet, fill it with nitrogen, and add 0.2mol of n-butyl glycidyl ether dropwise at 40°C for 20 minutes, then raise the temperature to React at 50°C for 15 hours, and finally distill under reduced pressure to remove unreacted reaction products, and titrate its hydroxyl value Qv=225.3mgKOH / g.

[0076] (2) Synthesis of comb-like polyurethane associative thickener

[0077] Add 2.0mmol (20.0g) of polyethylene glycol 10000 and 50g of toluene into a 250ml three-neck flask equipped with mechanical stirring, water separator and nitrogen inlet, first azeotropic dehydration for 2-3 hours, then cool down to 70°C, and add 0.03g Dibutyltin dilaurate and 4.0mmol (1.05g) of dicyclohexylmethane diisocyanate were reacted for 4h. After the prepolymerization reaction was completed, the temperature was raised to 90°C and 1.5mmol (0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com