Texture coating and preparation method thereof

A technology of textured coatings and raw materials, applied in the direction of coatings, etc., can solve the problems of not meeting market development requirements, high cost of surfactants, high VOC, etc., achieve good moisturizing effect, improve energy saving and environmental protection performance, and reduce VOC emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a mother liquor of a textured paint and a preparation method thereof, comprising the following steps:

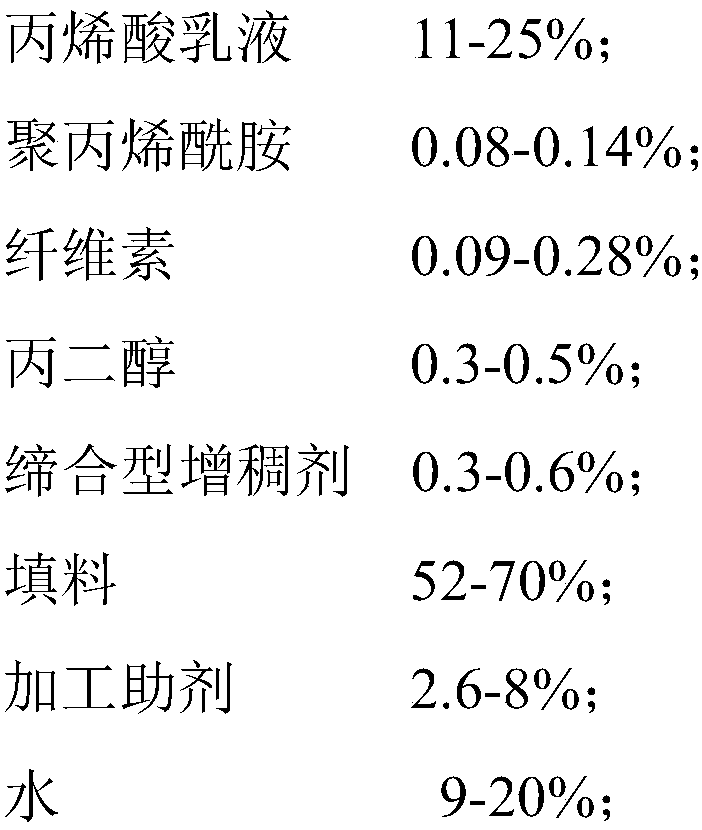

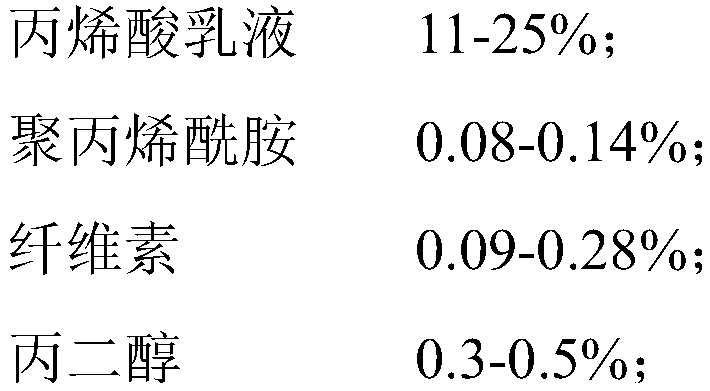

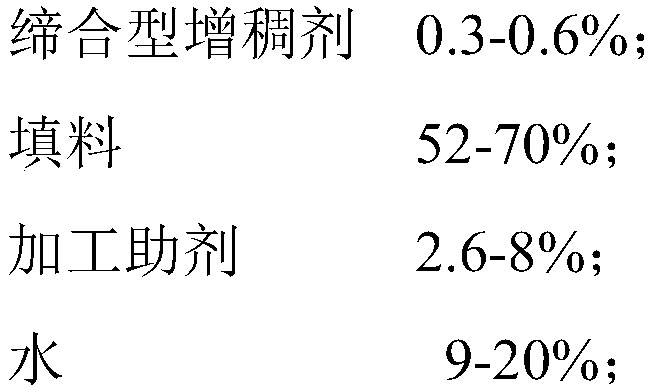

[0051] Step 1. Weigh each raw material according to the following weight percentages.

[0052] Water 32.15%, acrylic emulsion RS998A 51.83%, non-ionic polyacrylamide VA4058FC 0.3%, cellulose HK75000S 0.66%, propylene glycol 1%, polyacrylic acid sodium salt PA30 0.72%, film-forming agent (alcohol ester-12) 1.95% , defoamer CF-246 0.19%, titanium dioxide 9.72%, EPW antifungal agent 0.64%, LXE fungicide 0.64%.

[0053] Among them, the polyacrylamide is a nonionic polyacrylamide with a molecular weight of 3 million.

[0054] Step 2, mixing and dispersing.

[0055] Put polyacrylamide, alcohol ester-12, propylene glycol, cellulose HK75000S, polyacrylic acid sodium salt PA30 and 0.26% defoamer CF-246 into water and disperse for 10-15 minutes, stir until there are no particles, then add titanium dioxide and EPW anti-foaming agent Mold agent, adjust...

Embodiment 2-3 and comparative example 1-2

[0057] Referring to the preparation method of the texture paint mother liquor in Example 1, according to the raw materials and their dosages in Table 1, prepare the texture paint mother liquors of Examples 2-3 and Comparative Example 1-2.

[0058] Table 1

[0059]

[0060] performance test 1

[0061] Using JG / T24-2000 "Synthetic Resin Emulsion Sand Wall Architectural Coatings" standard, the viscosity, freeze-thaw stability and heat storage stability of the texture paint mother liquors of Examples 1-3 and Comparative Examples 1-4 were tested.

[0062] The test results are shown in Table 2.

[0063] Table 2

[0064]

[0065] It can be seen from Table 2 that in Examples 1-3 and Comparative Example 4, after adding nonionic polyacrylamide and anionic polyacrylamide, the viscosity of the mother liquor decreased significantly, which provided very convenient conditions for the transportation of the mother liquor, and the polyacrylamide The network structure can improve the ...

Embodiment 4

[0086] This embodiment provides a textured paint and a preparation method thereof, comprising the following steps:

[0087] Step 1. Weigh each raw material according to the following weight percentages.

[0088] Mother liquor 33% of embodiment 1, thickener TT-615 0.3%, water 8.2%, pH regulator AMP95 0.1%, diatomite Celabrite 7.5%, 100 mesh expanded perlite 0%, 200 mesh sand 27%, 16 - 30 mesh sand 26%, 3mm polyester fiber 0.5% and defoamer CF-246 0.1%.

[0089] Step 2. Mix and disperse the above-mentioned raw materials to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com