Multipurpose micro-mass sensor of porous cantilever structure

A cantilever beam, multi-purpose technology, applied in the direction of material absorption weighing, instrumentation, weighing, etc., can solve the problems of sensitivity impact, sensitivity reduction, increase measurement cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

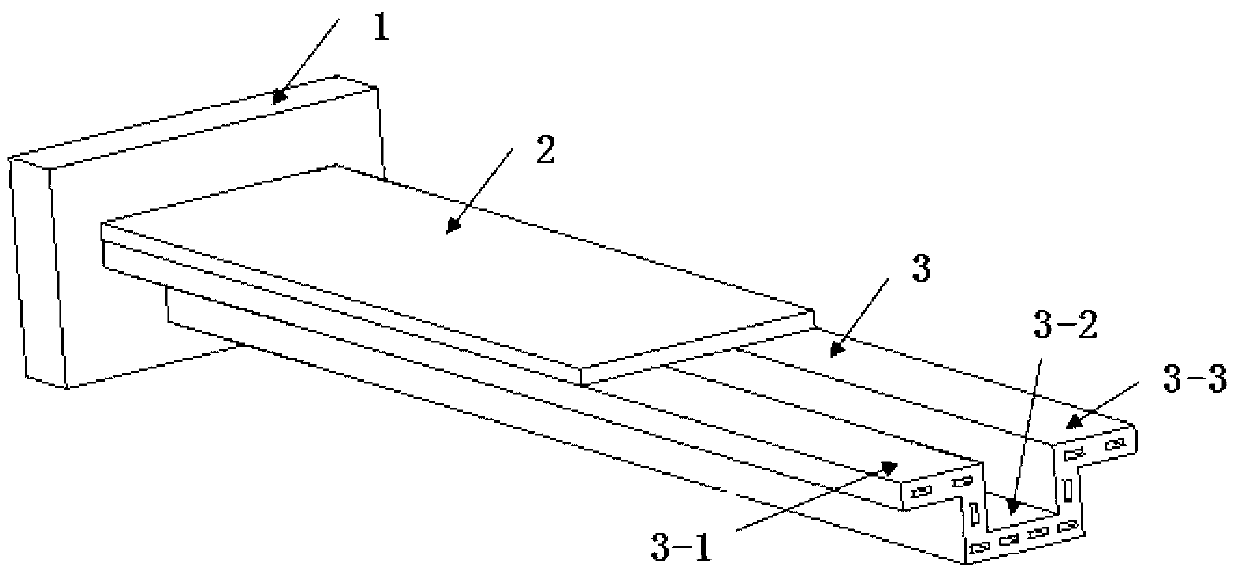

[0040] figure 1 A structural schematic diagram of a multipurpose micromass sensor with a porous cantilever beam structure is given. Wherein, the lower surface of the piezoelectric film 2 is connected to the upper surface of the porous cantilever beam 3, one section of the piezoelectric film 2 and the porous cantilever beam is connected to the fixed block 1, and the other end is suspended to form a composite cantilever beam structure. There is no gap connection between the piezoelectric film 2 and the porous cantilever beam, and the length of the piezoelectric film 2 is smaller than the porous cantilever beam structure. Bounded by the free end of the piezoelectric film 2, the composite cantilever beam structure is divided into two parts: the composite layer and the extension layer. Both the flange surface of the extension layer and the inner surface of the square groove can be used as the detection area to detect the quality of the measured object. The porous cantilever beam ...

Embodiment 2

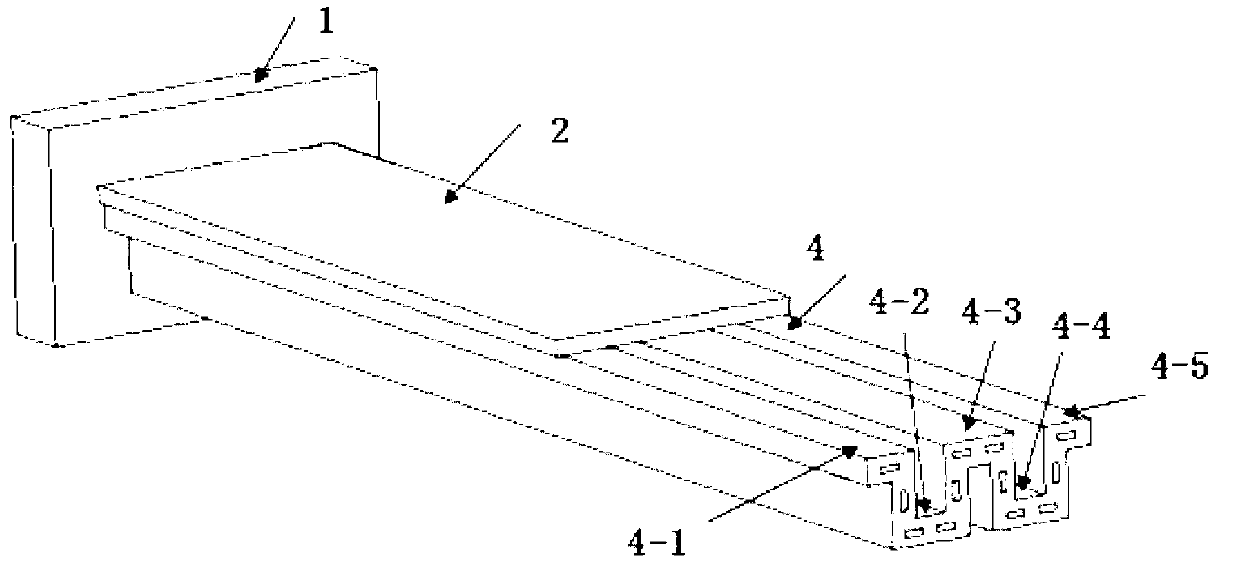

[0050] image 3 It is a structural schematic diagram of Embodiment 2 of a multipurpose micromass sensor with a porous cantilever beam structure in the present invention. On the basis of Embodiment 1, the porous cantilever beam 3 is replaced by the double-groove porous cantilever beam 4, and the number of its measurable areas is further expanded to 5, which are respectively areas 4-1, 4-2, and 4-3 , 4-4, 4-5.

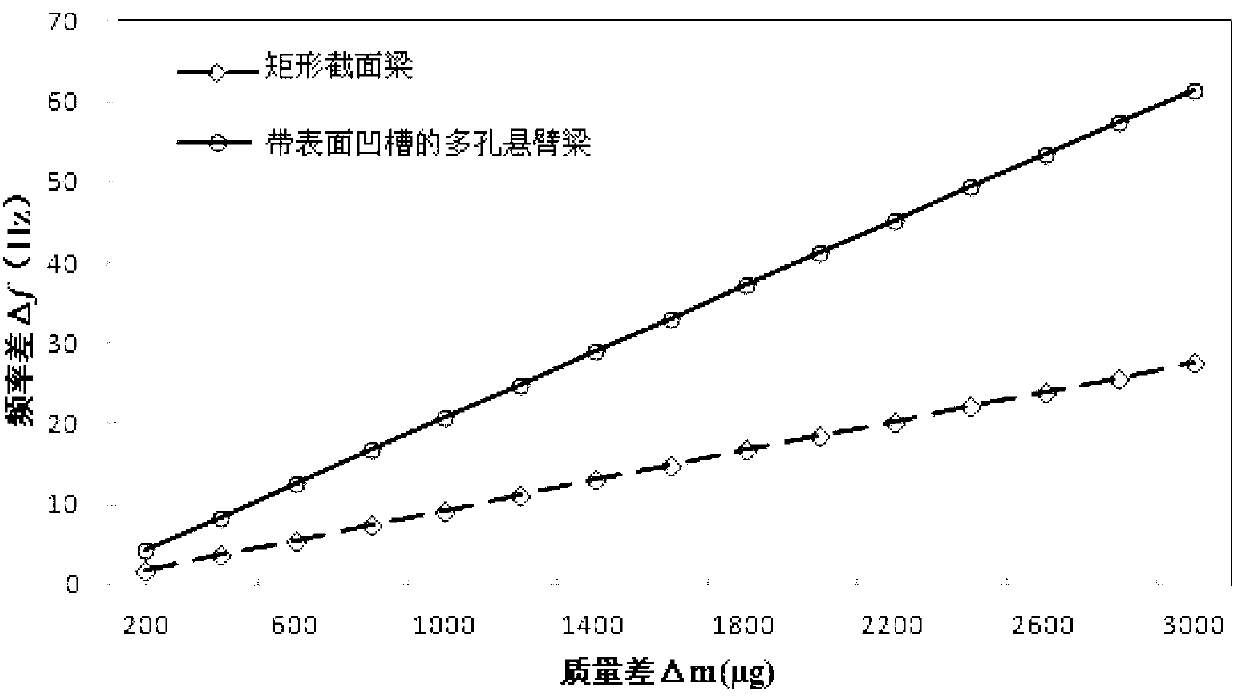

[0051] Figure 4 It is a calculation example of Embodiment 2 of the present invention, and the sensitivity under the same geometric parameters (as shown in Table 1) is compared with the sensitivity of the rectangular cross-section beam structure. According to the definition of sensor sensitivity, the slope of the straight line in the figure is the sensitivity of the corresponding sensor. When the length of the porous cantilever beam is 20.0mm, the sensitivity of the second embodiment is 1.87 times higher than that of the rectangular planar sensor, which effectively im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com