Online transformer oil chromatography monitoring system based on vacuum stirrer

A technology of vacuum agitator and transformer oil, applied in instruments, measuring devices, scientific instruments, etc., to achieve the effect of high degassing efficiency, ensuring safety and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

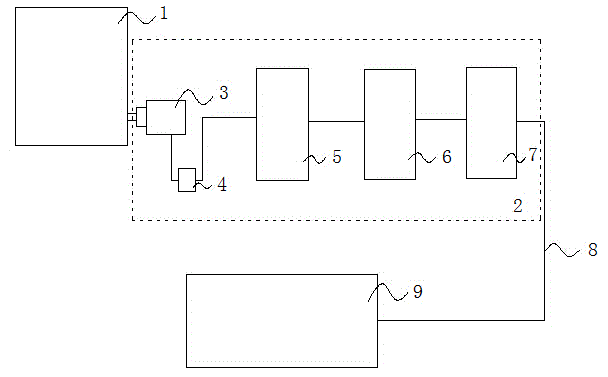

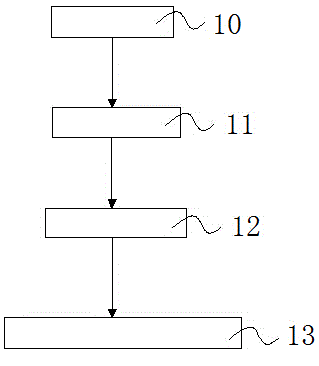

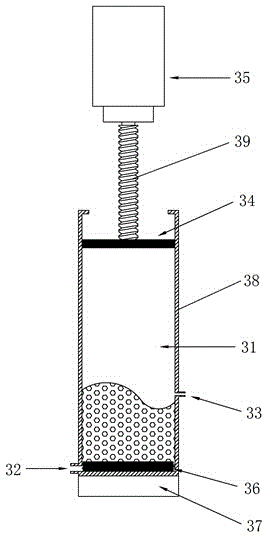

[0023] see Figure 1-3, a transformer oil chromatography on-line monitoring system based on a vacuum agitator, comprising a data collector 2 and a main control computer data processing and fault diagnosis system 9; the data collector 2 includes an oil-gas separator 3, a chromatographic column 5, a gas sensor Sensor 6 and CPU 7, the sampling end of oil-gas separator 3 is connected to transformer 1, and oil-gas separator 3 collects the transformer oil in transformer 1, and separates oil and gas from the transformer oil to obtain mixed gas. The output end of oil-gas separator 3 passes through the cold trap 4 is connected to the chromatographic column 5, and the oil vapor in the mixed gas is removed by the cold trap 4 to obtain the mixed characteristic gas. The characteristic gases are separated in turn, the output end of the chromatographic column 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com