Method for preparing insoluble sulfur through blocking molecular chain of quenching polymerization product of sulfur monomer

A molecular chain and quenching technology, applied in the preparation/purification of sulfur, etc., can solve the problems of extensive formation of polymerized sulfur, unsatisfactory thermal stability and dispersibility of products, etc., to avoid poor product stability, improve labor environment, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

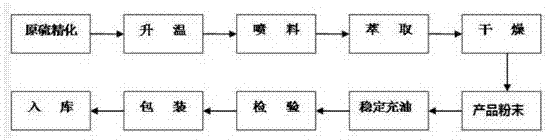

[0032] The method for preparing insoluble sulfur by capping the molecular chain of sulfur monomer quenching polymerization product, specifically includes the following steps:

[0033] In the first step, after the solid sulfur is melted, the temperature is raised to 130°C, and gradually gasified to 550°C.

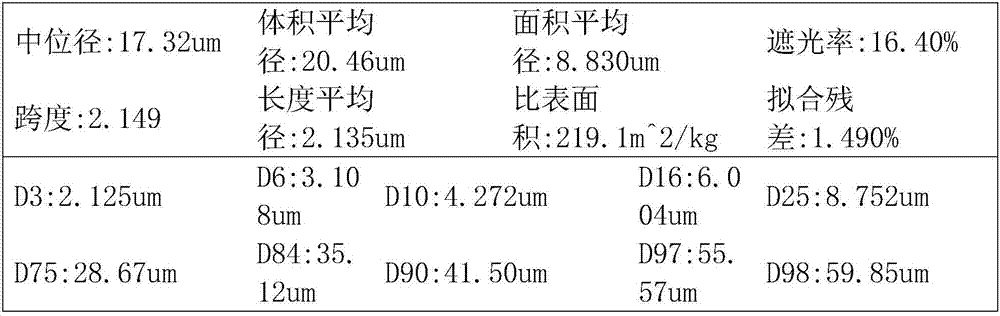

[0034] In the second step, the sulfur vapor vaporized in the first step is sprayed into the tank at a speed of 300Kg / hr through the nozzle, and the temperature is 25 ° C, the sulfur mass ratio is 45:1, and contains 0.02 parts by weight of ferric chloride, The aqueous solution of 0.03 parts by weight of nitric acid is atomized and contacted, and cooled; the formed pseudoplastic is powder, the particle size distribution is less than 100 mesh, and the content is 98%, and the intermediate contains 55% of insoluble sulfur.

[0035] In the third step, the insoluble sulfur produced in the second step is immersed in carbon disulfide for continuous extraction and stabilization, so th...

Embodiment 2

[0039] The method for preparing insoluble sulfur by capping the molecular chain of sulfur monomer quenching polymerization product, specifically includes the following steps:

[0040] In the first step, after the solid sulfur is melted, the temperature is raised to 120°C, and then gradually gasified to 580°C.

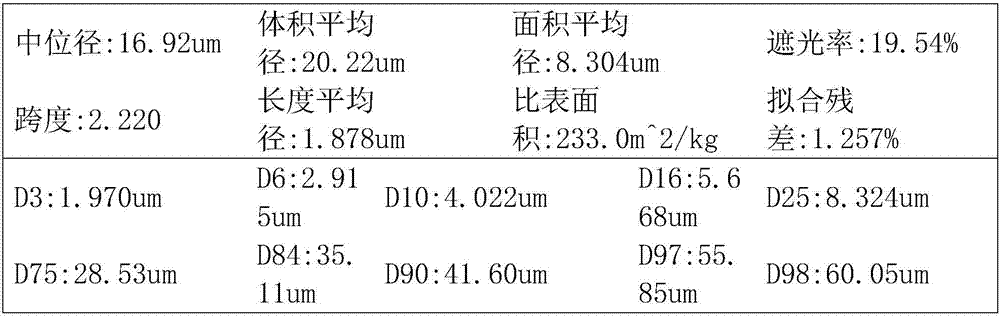

[0041] In the second step, the sulfur vapor vaporized in the first step is sprayed into the tank with a nozzle at a speed of 400Kg / hr, and the temperature is 15°C, the sulfur mass ratio is 15:1, and contains 0.02 parts by weight of elemental iodine and 0.03 parts by weight of iodine. Parts of potassium nitrate in carbon disulfide solution are atomized and contacted, and cooled; the formed pseudoplastic is powder, the particle size distribution is less than 80 mesh, and the content is 97%, and the intermediate contains 58% of insoluble sulfur.

[0042] In the third step, the insoluble sulfur produced in the second step is immersed in carbon disulfide for continuous extract...

Embodiment 3

[0046] The method for preparing insoluble sulfur by capping the molecular chain of sulfur monomer quenching polymerization product, specifically includes the following steps:

[0047] In the first step, after the solid sulfur is melted, the temperature is raised to 140°C, and gradually gasified to 635°C,

[0048] In the second step, the sulfur vapor vaporized in the first step is sprayed into the tank at a speed of 1200Kg / hr through the nozzle, and the temperature is 25°C, the sulfur mass ratio is 25:1, and contains 0.02 parts by weight of elemental iodine and 0.03 parts by weight of iodine. Parts of HClO in carbon tetrachloride solution are atomized and contacted, and cooled; the formed pseudoplastic is powder, the particle size distribution is less than 80 mesh, and the content is 93%, and the intermediate contains 58% of insoluble sulfur.

[0049] In the third step, the insoluble sulfur produced in the second step is immersed in carbon disulfide for continuous extraction an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com