Polyurethane associated thickener, and preparation method and application thereof

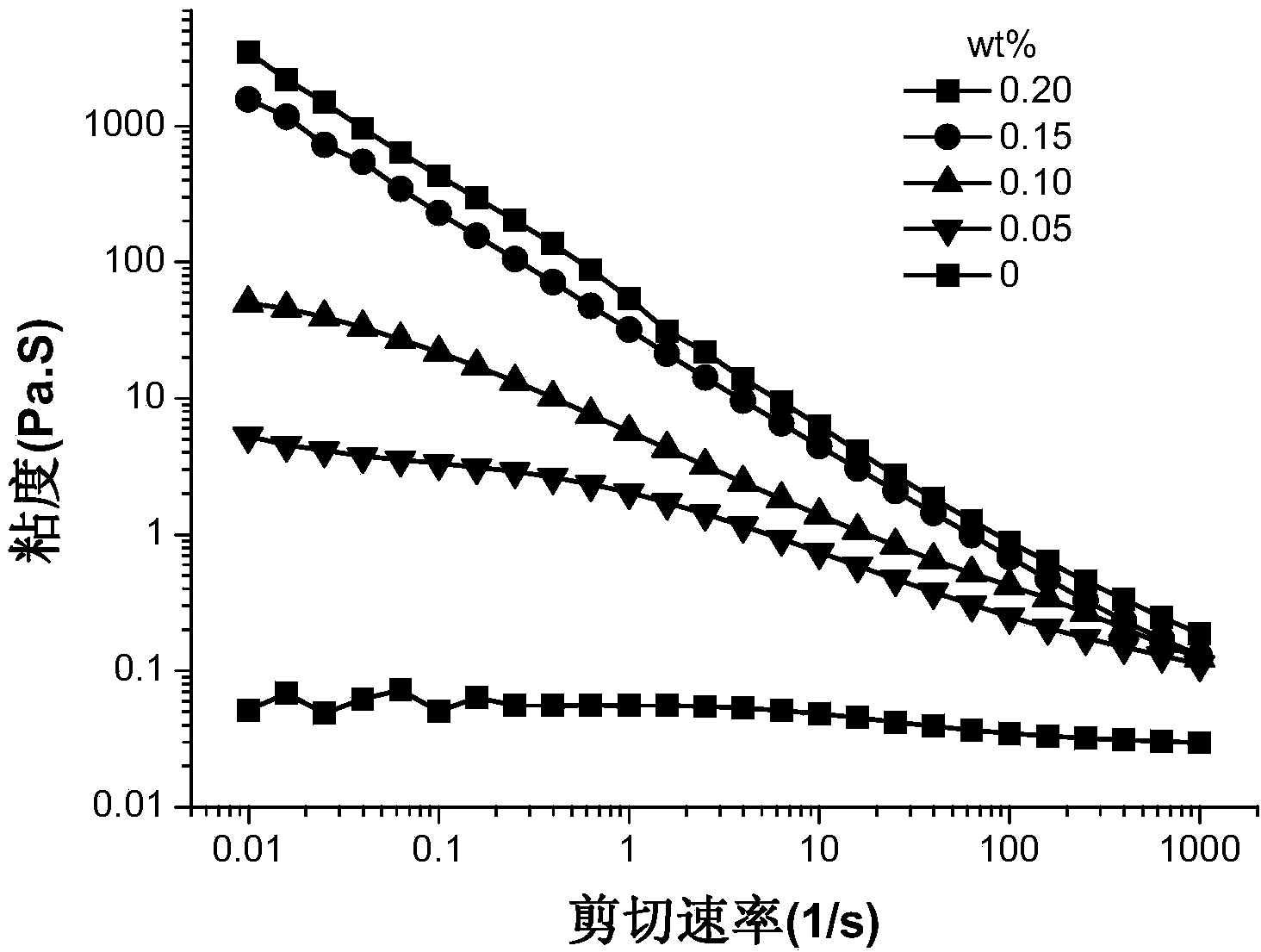

An associative thickener and polyurethane technology, which is applied in the field of polyurethane materials to achieve the effects of low construction viscosity, enhanced association ability, and enhanced hydrophobic association ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

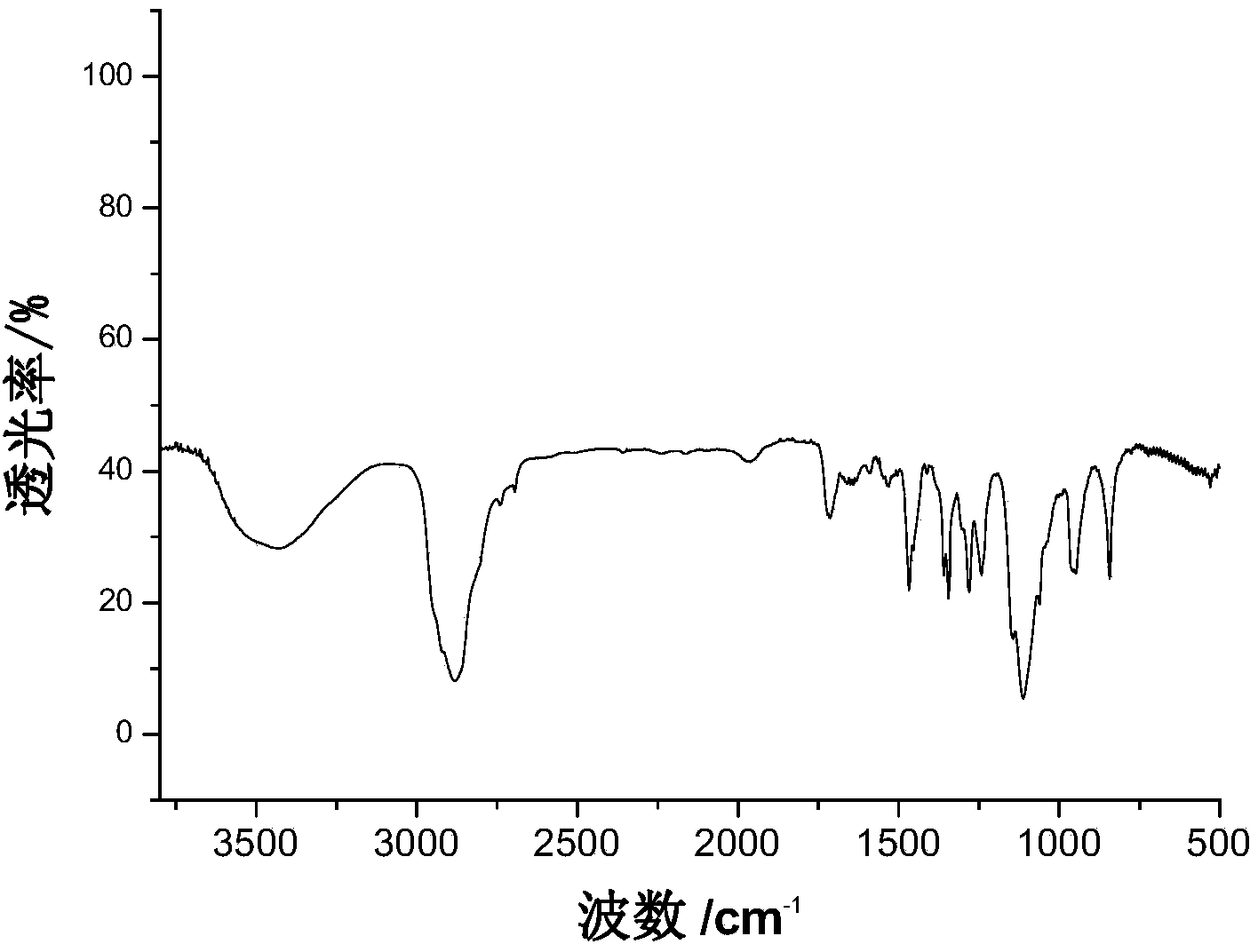

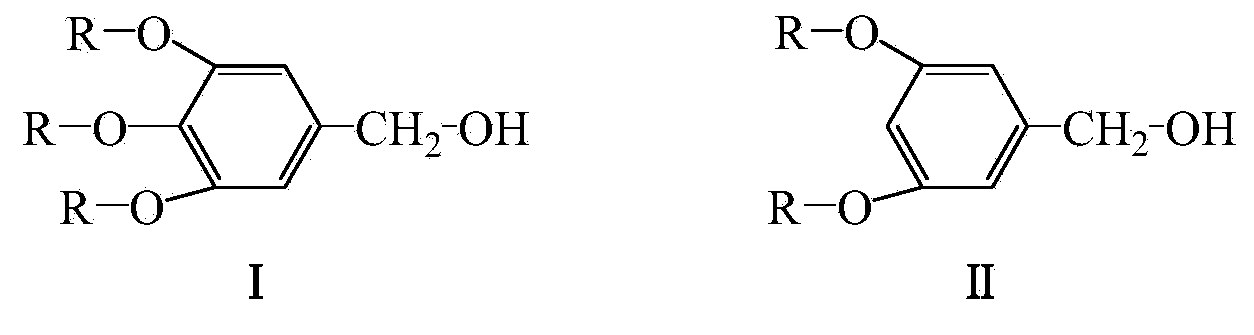

[0029] Add 23.4g (3.9mmol) of polyethylene glycol with a molecular weight of 6000g / mol and 300mL of toluene to a 500mL four-necked round-bottomed flask equipped with mechanical stirring, water separator, condenser and nitrogen inlet, when the temperature rises to 112°C (The boiling point of toluene is 110.6°C), azeotropically remove water for 3h; then cool down to 50°C, and quickly weigh 1.73g (7.76mmol) of isophorone diisocyanate (IPDI) and 0.06g of dibutyltin dilaurate (DBTDL) , were added together into the flask, then heated to 80°C, and reacted for 3 hours. When the polyurethane prepolymerization reaction is completed, the temperature is raised to 90°C, 0.83g chain extender ethylene glycol is added, and after 2 hours of reaction, 4.5g (7.67mmol) 3,4,5-tri(decadecyloxy)benzyl alcohol is added, React for 3 hours; finally take a sample and carry out the acetone-di-n-butylamine method to measure the NCO content in the product to obtain the toluene solution of the thickener whe...

Embodiment 2

[0039] Add 44g (4.4mmol) of polyethylene glycol with a molecular weight of 10000g / mol and 350mL of toluene to a 500mL four-neck round-bottomed flask equipped with mechanical stirring, water separator, condenser and nitrogen inlet, when the temperature rises to 112 °C ( The boiling point of toluene is 110.6°C), azeotropically remove water for 3h; then cool down to 60°C, quickly weigh 1.76g (7.9mmol) isophorone diisocyanate (IPDI) and 0.072g stannous octoate, and add them together to the In the flask, the temperature was then raised to 85°C, and the reaction was carried out for 3 hours. Add 0.97g of trimethylolpropane to react for 2h after the polyurethane prepolymerization reaction is completed, then raise the temperature to 95°C, add 3.4g (5.28mmol) 3,4,5-tri(dodecyloxy)benzyl alcohol, and react 3 Hour; The toluene solution of the thickener is obtained when the NCO content in the acetone-di-n-butylamine method is determined to be less than 0.3% when the final sampling is carri...

Embodiment 3

[0049] Add 5g (0.83mmol) of polyethylene glycol with a molecular weight of 6000g / mol and 80mL of toluene to a 250mL four-necked round-bottomed flask equipped with mechanical stirring, water separator, condenser and nitrogen inlet, when the temperature rises to 112°C ( The boiling point of toluene is 110.6°C), azeotropically remove water for 3h; then cool down to 44°C, quickly weigh 0.3704g (1.67mmol) isophorone diisocyanate (IPDI) and 0.012g triethylenediamine, and add them together in a flask, then the temperature was raised to 85°C, and the reaction was carried out for 3 hours. When the polyurethane prepolymerization reaction is finished, add 0.87g glycerol to react for 2h, then raise the temperature to 100°C, add 1.38g (1.67mmol) 3,4,5‐trihexadecyloxy)benzyloxypolyoxyethylene ether, reacted for 3.5 hours; the toluene solution of the thickener was obtained when the NCO content in the acetone-di-n-butylamine method was measured at last by sampling when the product was below 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com