Heating forming plate for organic fertilizer granulating machine

A technology of thermoforming and organic fertilizer, applied in the direction of extrusion and granulation of raw materials, can solve the problems of inability to dry and solidify organic fertilizer particles, reduce the quality of organic fertilizer particles, and loosen organic fertilizer particles, achieve high use value and improve granulation. Efficiency, the effect of reducing the generation of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

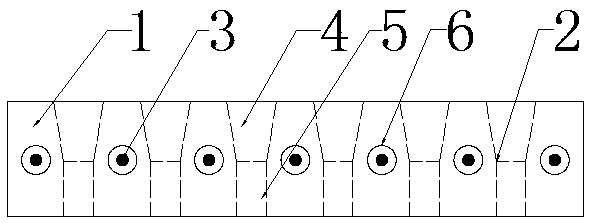

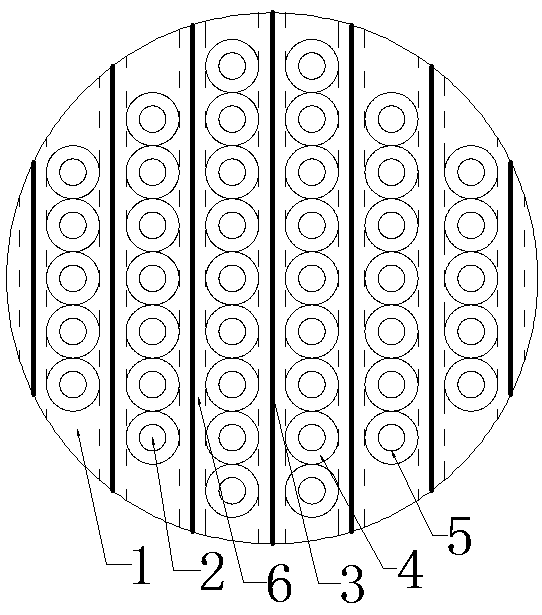

[0019] as attached figure 1 , 3 As shown, a heat-formed plate of an organic fertilizer granulator includes a plate body 1, the plate body 1 is cylindrical, the plate body 1 is provided with a forming hole 2, and the plate body 1 is provided with There are heating wires 3.

[0020] The forming hole 2 is composed of a tapered hole 4 and a circular hole 5 , and the tapered hole 4 is located on the upper side of the circular hole 5 .

[0021] The side of the board body 1 is provided with installation holes 6 arranged in a single layer, and the heating wire 3 is installed in the installation holes 6 .

[0022] When the present invention is in use: a heat forming plate of an organic fertilizer granulator, including a plate body, the plate body is cylindrical and can correspond to the shape of the pressurizing equipment, the plate body is provided with a forming hole, and the raw material is formed through the forming hole, The forming hole is composed of a conical hole and a circ...

Embodiment 2

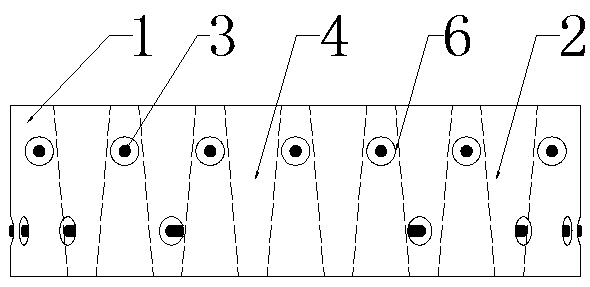

[0025] as attached figure 2 , 4 As shown, a heat-formed plate of an organic fertilizer granulator includes a plate body 1, the plate body 1 is cylindrical, the plate body 1 is provided with a forming hole 2, and the plate body 1 is provided with There are heating wires 3.

[0026] The forming hole 2 is a tapered hole 4 .

[0027] The side of the plate body 1 is provided with double-layer staggered installation holes 6 , and the heating wire 3 is installed in the installation holes 6 .

[0028] When the present invention is in use: a heat forming plate of an organic fertilizer granulator, including a plate body, the plate body is cylindrical and can correspond to the shape of the pressurizing equipment, the plate body is provided with a forming hole, and the raw material is formed through the forming hole, The forming hole is a tapered hole, and the raw material is further pressurized through the tapered hole on the upper side to increase the compression degree of the raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com