A kind of preparation method of refractory lightweight particle and wood-plastic composite board

A lightweight particle, wood-plastic composite technology, used in household appliances, other household appliances, household components, etc., can solve the problems of serious pollution on the cutting and filling site, increased power consumption, labor costs, and increased production cycles. To achieve the effect of reducing energy consumption, reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention more clear, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

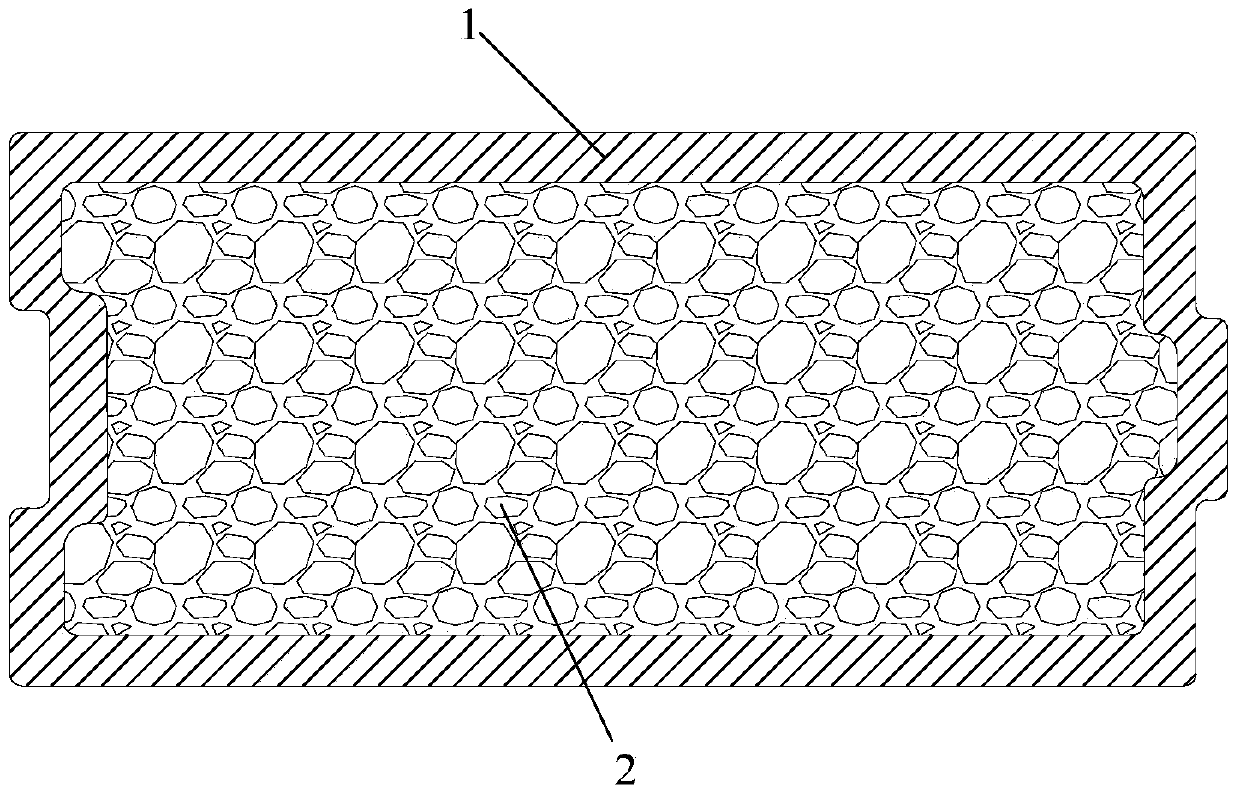

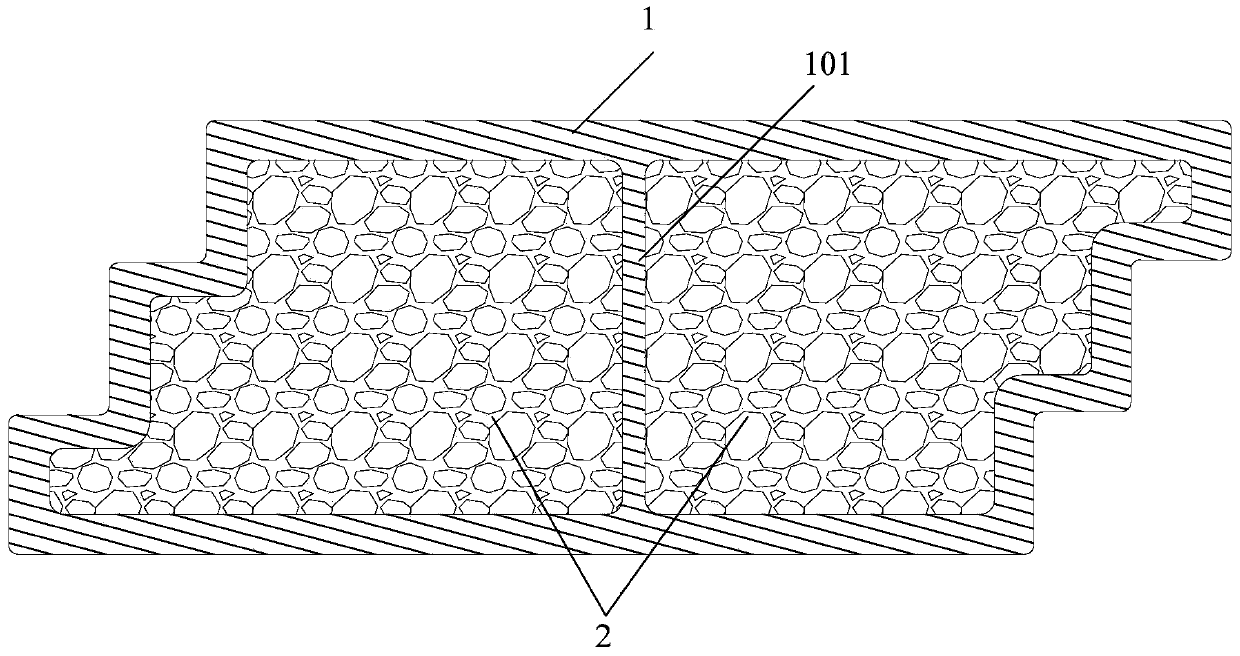

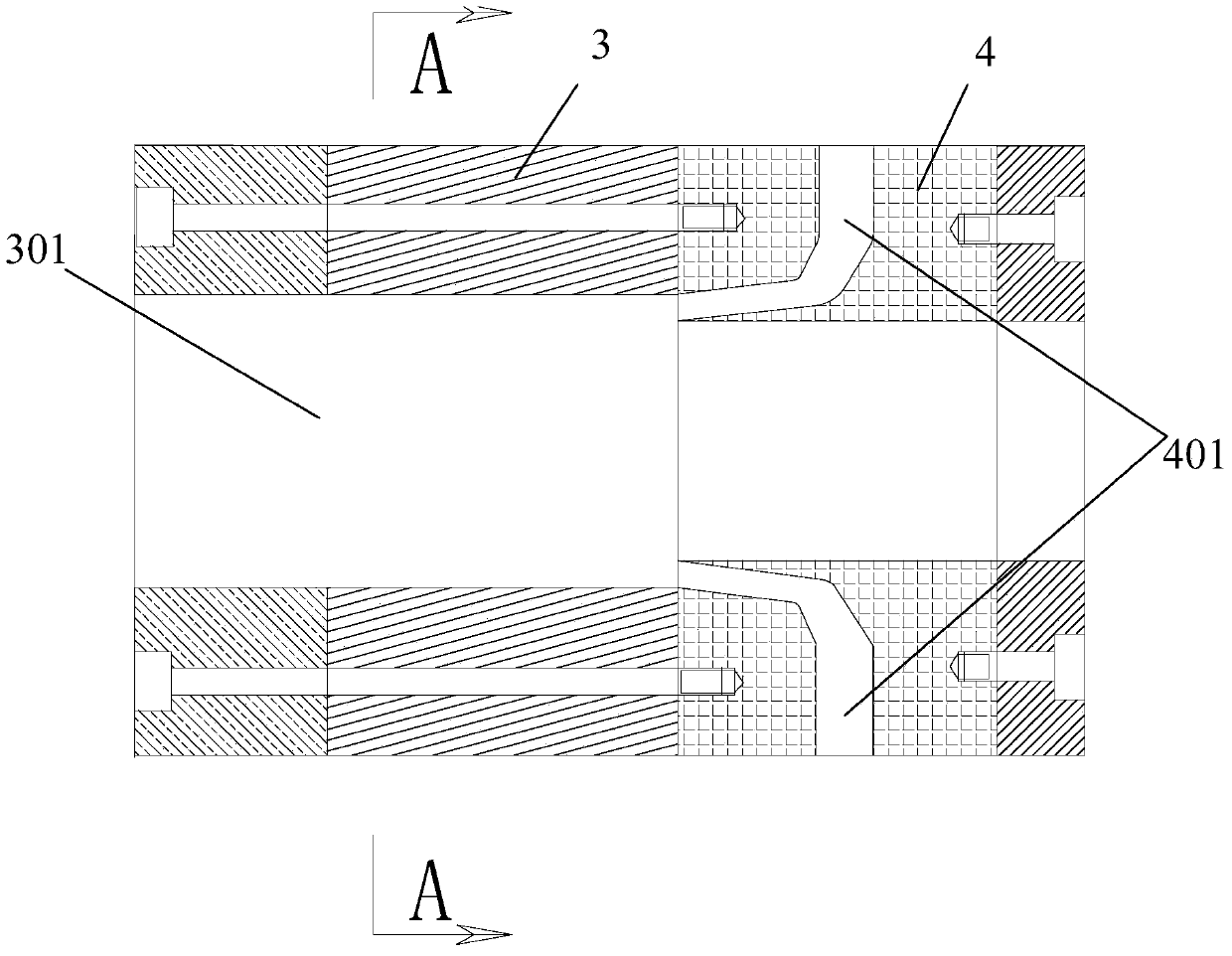

[0029] figure 1 and figure 2 It is a refractory lightweight particle and wood-plastic composite board. The composite board includes a wood-plastic frame and a filling layer based on refractory light particles inside. The outer profile of the wood-plastic frame can be changed according to requirements, and the wood-plastic frame is a hollow structure. figure 1 It is a schematic diagram of a composite plate without stiffeners, such as figure 1 As shown, the filling layer 2 is filled in the wood-plastic frame 1. figure 2 It is a schematic diagram of a composite plate with stiffeners, such as figure 2 As shown, the wood-plastic frame 1 is provided with reinforcing ribs 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com