UV (ultraviolet) paint capable of being quickly dried from inside to outside

A quick-drying paint and quick-drying technology, applied in the coating and other directions, can solve the problems of short curing time of UV paint, long drying time of paint, slow drying speed, etc., to promote rapid curing, fast drying speed, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

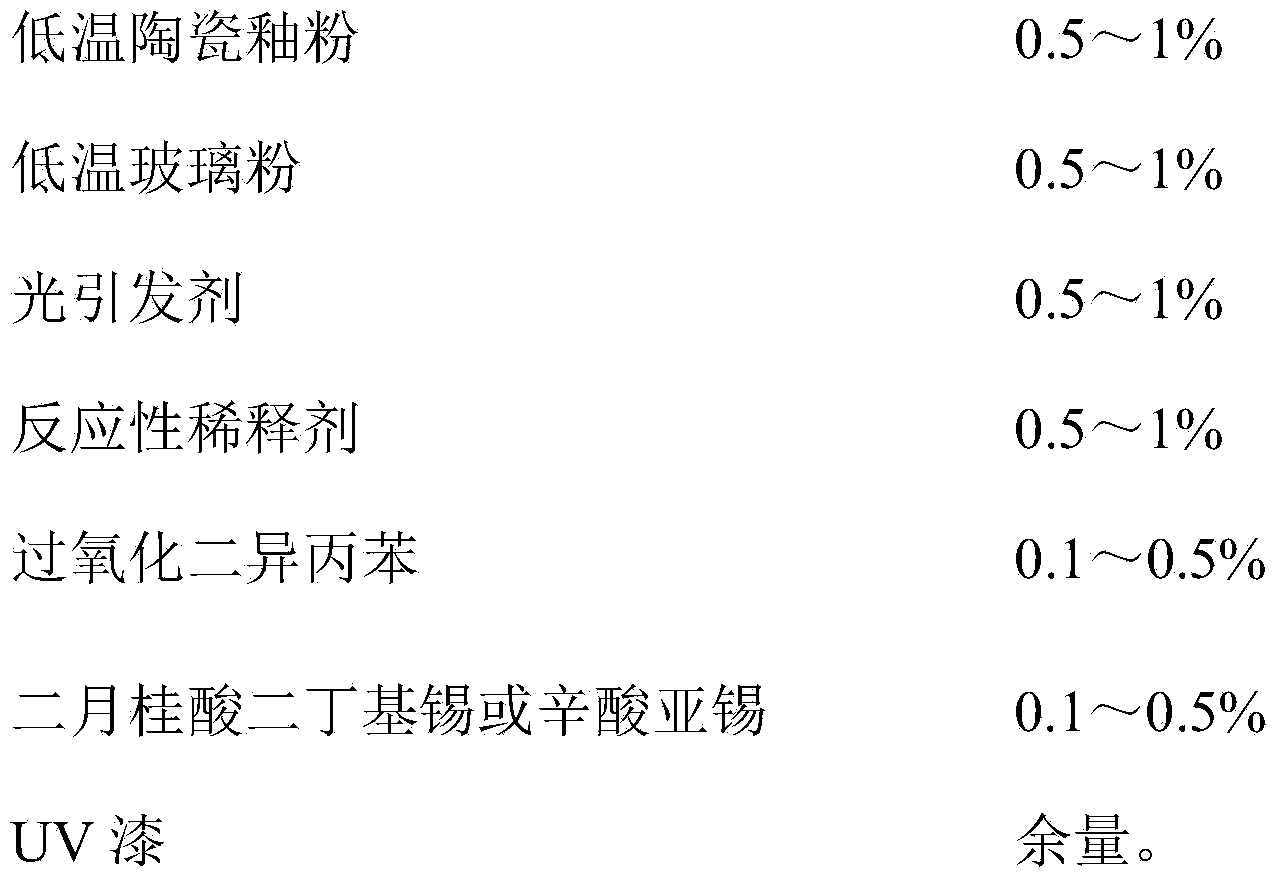

[0022] A quick-drying UV paint from the inside out, the quick-drying paint includes the following components by weight:

[0023]

[0024]

[0025] Wherein, the mesh number of the above-mentioned low-temperature ceramic glaze powder is 800-1500 mesh, and the mesh number of the low-temperature glass powder is 800-1500 mesh.

[0026] The above reactive diluents are selected from tripropylene glycol diacrylate, dipropylene glycol diacrylate, neopentyl glycol diacrylate, trimethylpropane triacrylate, dipentaerythritol pentaacrylate or dipentaerythritol hexaacrylate one or a mixture of more than one.

Embodiment 2

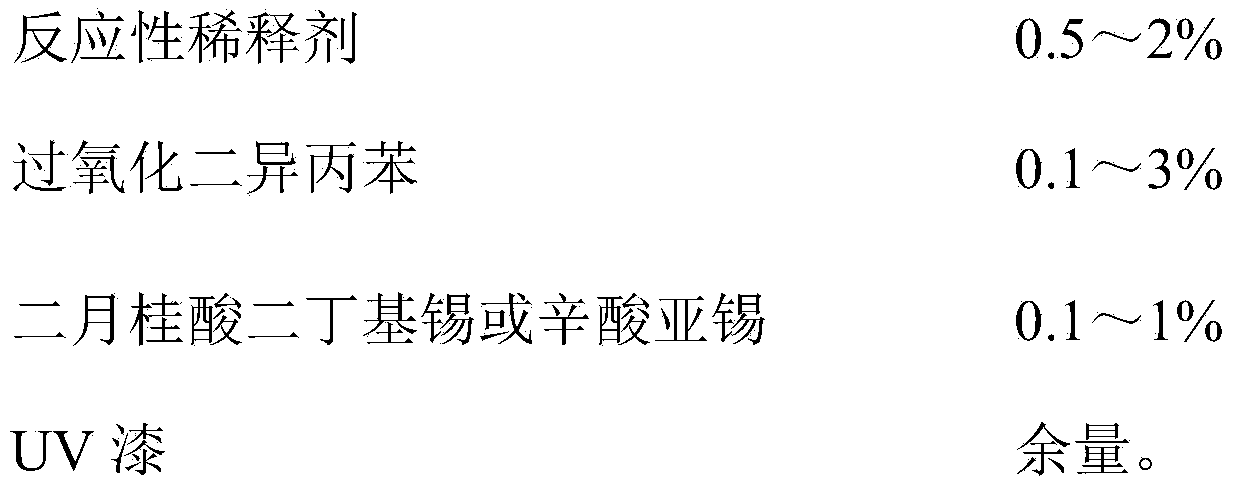

[0028] A quick-drying UV paint from the inside out, the quick-drying paint includes the following components by weight:

[0029]

[0030] Wherein, the mesh number of the above-mentioned low-temperature ceramic glaze powder is 800-1500 mesh, and the mesh number of the low-temperature glass powder is 800-1500 mesh.

[0031] The above reactive diluents are selected from tripropylene glycol diacrylate, dipropylene glycol diacrylate, neopentyl glycol diacrylate, trimethylpropane triacrylate, dipentaerythritol pentaacrylate or dipentaerythritol hexaacrylate one or a mixture of more than one.

Embodiment 3

[0033] A quick-drying UV paint from the inside out, the quick-drying paint includes the following components by weight:

[0034]

[0035] Wherein, the mesh number of the above-mentioned low-temperature ceramic glaze powder is 800-1500 mesh, and the mesh number of the low-temperature glass powder is 800-1500 mesh.

[0036] The above reactive diluents are selected from tripropylene glycol diacrylate, dipropylene glycol diacrylate, neopentyl glycol diacrylate, trimethylpropane triacrylate, dipentaerythritol pentaacrylate or dipentaerythritol hexaacrylate one or a mixture of more than one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com