Anticorrosive paint based on amination linoleic acid copolymerized acrylic resin and preparation method of anticorrosive paint

A technology of oleic acid copolymerized acrylic acid and anti-corrosion coatings, which is applied in the direction of anti-corrosion coatings and coatings, which can solve the problems of low coating efficiency, high viscosity, and large molecular weight of the resin, and achieve the effect of inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

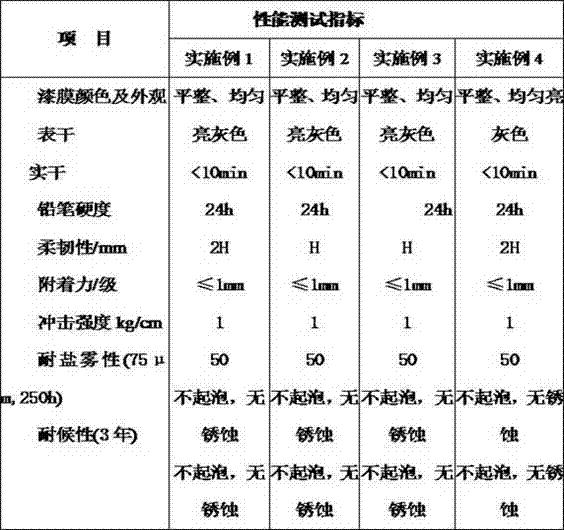

Examples

Embodiment 1

[0040] one. Synthesis of Aminated Linoleic Acid Copolymerized Acrylic Resin

[0041] 1. Raw material and dosage mass percentage

[0042] Component content

[0043] Methyl methacrylate 10%

[0044] Styrene 25%

[0045] Isooctyl Acrylate 5%

[0046] Hydroxyethyl Acrylate 4%

[0047] Linoleic Acid 5%

[0048] Ethylenediamine 0.26%

[0049] Azobisisobutyronitrile 2%

[0050] Butyl acetate 48.74%

[0051] 2. Preparation method

[0052]First, pour the linoleic acid into the reaction container, heat it to 50°C, add quantitative ratio of ethylenediamine dropwise to the linoleic acid, the dropping time is controlled within 1 hour, after the dropwise addition, the temperature is controlled at about 70°C , reacted for 1.5 hours. Aminated linoleic acid is obtained. Then all methyl methacrylate, styrene, isooctyl acrylate, hydroxyethyl acrylate and 80% of the total mass of azobisisobutyronitrile were stirred according to the formula ratio to obtain mixed monomers, and t...

Embodiment 2

[0067] one. Synthesis of Aminated Linoleic Acid Copolymerized Acrylic Resin

[0068] 1. Raw material and dosage mass percentage

[0069] Component content

[0070] Methyl methacrylate 20%

[0071] Styrene 15%

[0072] Isooctyl Acrylate 2%

[0073] Hydroxyethyl Acrylate 1%

[0074] Linoleic Acid 10%

[0075] Ethylenediamine 0.52%

[0076] Azobisisobutyronitrile 1.48%

[0077] Butyl acetate 50%

[0078] 2. Preparation method

[0079] First, pour linoleic acid into the reaction container, heat it to 70°C, add quantitative ratio of ethylenediamine dropwise to linoleic acid, control the dropping time between 0.1 hour, after the dropwise addition, control the temperature at about 85°C , reacted for 1 hour. Aminated linoleic acid is obtained. Then all methyl methacrylate, styrene, isooctyl acrylate, hydroxyethyl acrylate and 80% of the total mass of azobisisobutyronitrile were stirred according to the formula ratio to obtain mixed monomers, and the reaction ves...

Embodiment 3

[0094] 1. Raw material and dosage mass percentage

[0095] Component content

[0096] Methyl methacrylate 15.45%

[0097] Styrene 24%

[0098] Isooctyl Acrylate 6%

[0099] Hydroxyethyl Acrylate 3%

[0100] Linoleic Acid 20%

[0101] Ethylenediamine 1.05%

[0102] Azobisisobutyronitrile 0.5%

[0103] Butyl acetate 30%

[0104] 2. Preparation method

[0105] First, pour linoleic acid into the reaction container, heat it to 60°C, add quantitative ethylenediamine dropwise into linoleic acid, and control the dropping time between 0.5 hours. After the dropwise addition, the temperature is controlled at about 65°C , reacted for 2 hours. Aminated linoleic acid is obtained. Then all methyl methacrylate, styrene, isooctyl acrylate, hydroxyethyl acrylate and 80% of the total mass of azobisisobutyronitrile were stirred according to the formula ratio to obtain mixed monomers, and the reaction vessel was heated for 70 ℃, drop the mixture of the monomer and the initiator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com