Variable-frequency microwave heating device

A technology of microwave heating device and microwave antenna, which is applied in microwave heating, electric heating device, electric/magnetic/electromagnetic heating, etc. It can solve the problems of difficult to meet the production process requirements, low efficiency, long drying and curing time, etc., and achieve the convenience of robot grip long-lasting operation, small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

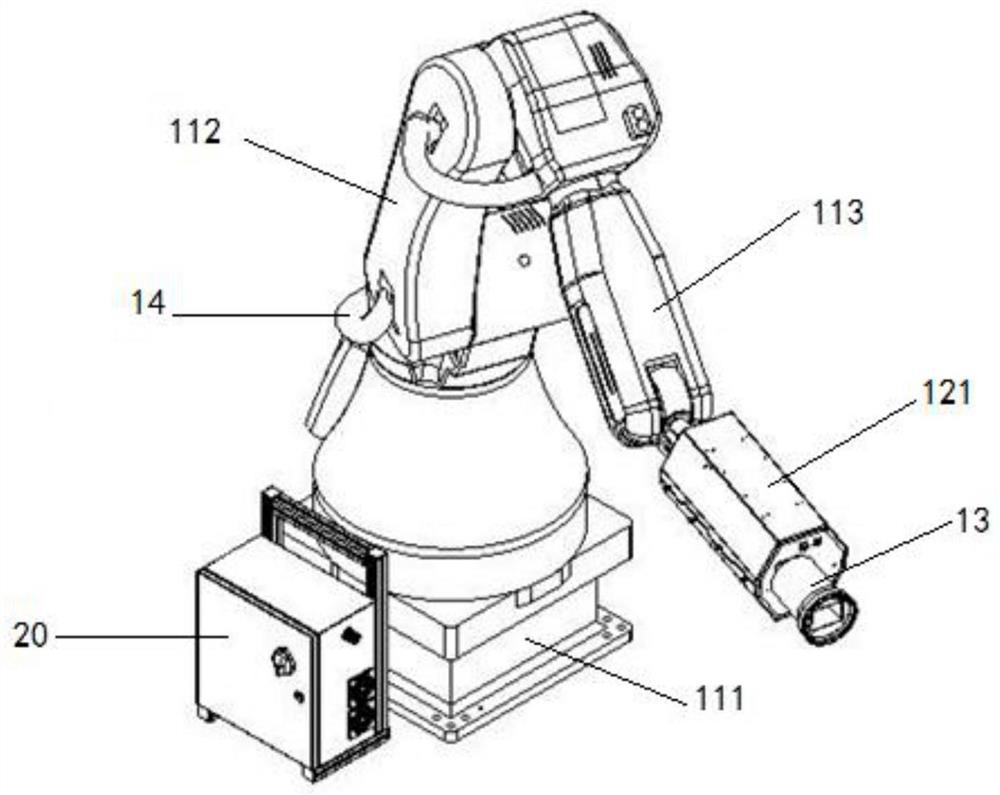

[0033] Such as Figure 1-2 As shown, the present application provides a frequency conversion microwave heating device, including a robot, a first controller, an actuator, a microwave antenna 13 , a power supply and several cables 14 .

[0034] The robot includes a base 111 , a body 112 and an operating arm 113 . During use, the power supply and the first controller are packaged in a small electrical cabinet 20 , fixedly placed next to the base 111 of the robot, and connected to the actuator through the cable 14 . The actuator is held by the robot, and the antenna is installed at the end of the actuator. When working, the area in front of the antenna will generate a high-power electromagnetic field.

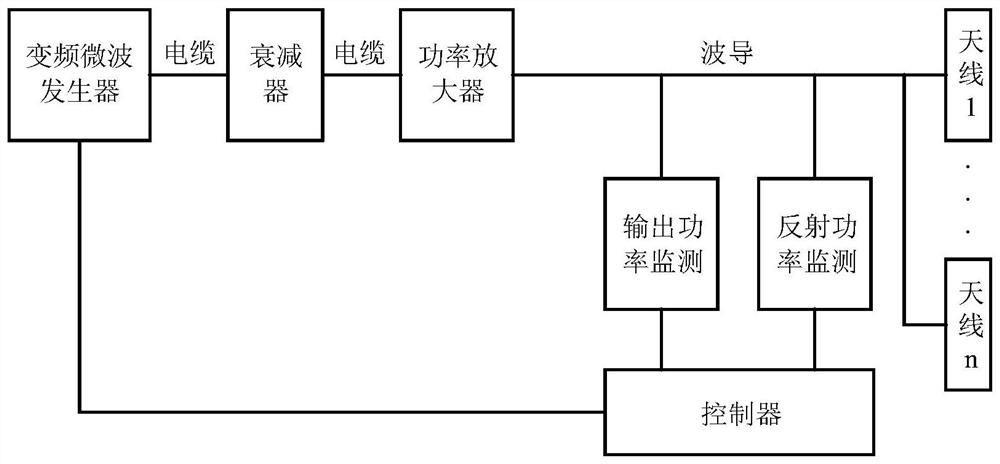

[0035]The actuator includes a coupler, a housing 121, a microwave attenuator, a variable frequency microwave generator and a power amplifier. One end of the casing 121 is connected to the operating arm 113 of the robot, and the other end of the casing 121 is connected to the one...

Embodiment 2

[0059] Distributed multi-antenna variable frequency microwave (VFM) heat gun equipment. The technical index is similar to that of Embodiment 1, except that the form of the antenna is changed to 2 antennas, which are distributed on the custom-made fixtures. The connection between the antenna and the actuator is through a flexible waveguide.

[0060] Still taking car body manufacturing as an example, in the bonding process of large-scale interior components, only a few key positions on the glued area (such as: one head and one tail) need to be quickly connected and fixed to ensure that the assembled components can be integrated in an overall form. Grabbed by the robot to start the next process, instead of requiring the entire glued area to complete the overall drying and curing in the current process. The process design of the above usage scenarios, two large interior components bonded to each other, are clamped and pressed by special fixtures after the glued surface is glued. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com