Method for preparing modified maize starch glue

A technology of modified corn starch and corn starch, which is applied in the direction of starch-derived adhesives, adhesive types, non-polymer adhesive additives, etc., and can solve the problems of decreased bonding strength, poor water resistance and moisture resistance, and complex processes, etc. problem, to achieve the effect of good adhesion, fast drying and curing, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A preparation method of denatured cornstarch glue, it comprises the steps:

[0015] 1. Take 85 Kg of cornstarch and add 9kg of oxidizing agent, after stirring evenly, seal it, and oxidize it for 10 hours. Add 6kg of quick-drying agent, stir evenly again, and cool down for 10 hours to obtain denatured cornstarch;

[0016] 2. After mixing 30kg of the prepared denatured cornstarch with 70kg of water, add 3kg of sodium hydroxide for gelatinization, then add 0.25kg of borax, stir again, and finally add 15 mg of defoamer. Stir evenly and put into barrels for use.

Embodiment 2

[0018] A preparation method of denatured cornstarch glue, it comprises the steps:

[0019] 1. Take 90 Kg of cornstarch and 11 kg of oxidizing agent first, stir evenly, seal it, and oxidize for 10 hours. Add 7kg of quick-drying agent, stir evenly again, and make denatured cornstarch after cooling for 10 hours;

[0020] 2. After mixing 35kg of the prepared denatured cornstarch with 73kg of water, add 4kg of sodium hydroxide for gelatinization, then add 0.30kg of borax, stir again, and finally add 17 mg of defoamer. Stir evenly and put into barrels for use.

Embodiment 3

[0022] A preparation method of denatured cornstarch glue, it comprises the steps:

[0023] 1. First take 95Kg cornstarch and 13kg oxidant, after stirring evenly, seal it, and oxidize it for 10 hours. Add 9kg of quick-drying agent, after stirring again, cool down for 10 hours to obtain denatured cornstarch;

[0024] 2. After mixing 40kg of the prepared denatured cornstarch with 80kg of water, add 5kg of sodium hydroxide for gelatinization, then add 0.35kg of borax, stir again, and finally add 20 mg of defoamer. Stir evenly and put into barrels for use.

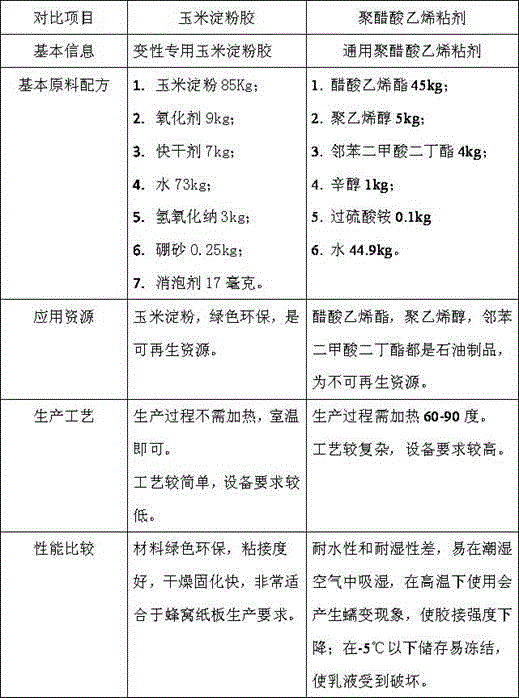

[0025] Comparative Analysis Table of Modified Corn Starch Glue and Polyvinyl Acetate Adhesive.

[0026]

[0027] .

[0028] The applicant has continuously researched and improved the production process and materials in the production practice. Among them, the applicant has developed the modified cornstarch glue specially used for the honeycomb paperboard production line, which has made breakthrough progress, reduced produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com