Wear-resistant and deformation-resistant invisible car cover

An invisible and car-coating technology, applied in the direction of film/sheet adhesive, application, coating, etc., can solve problems such as fogging, scratches, and affecting appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

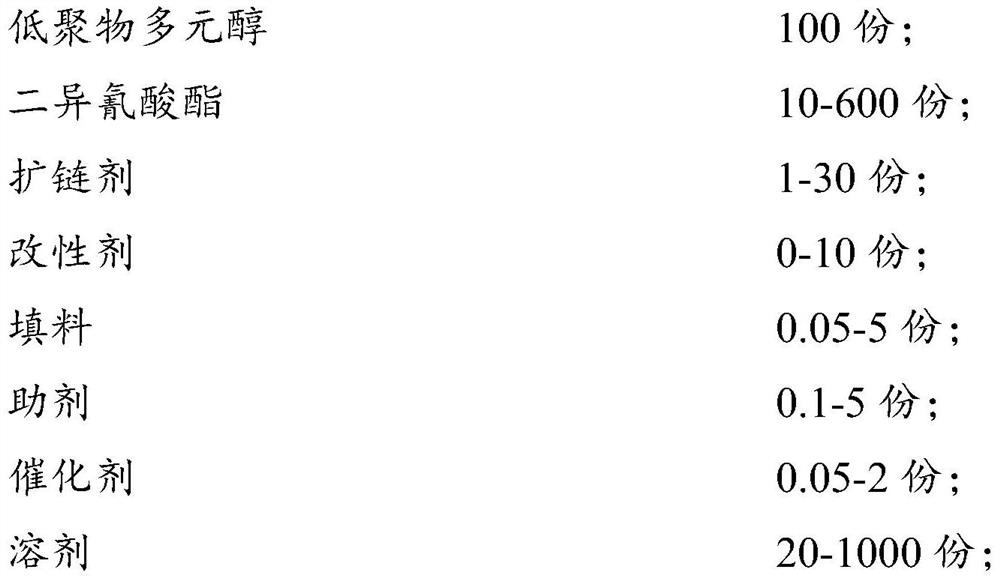

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 provides a wear-resistant and deformation-resistant invisible car cover. The wear-resistant and deformation-resistant invisible car cover of this embodiment includes a transparent base, one side of the transparent base is covered with a top coat, and the side of the top coat away from the transparent base is covered with a transparent release film, and the other surface of the transparent base is covered with Assemble the adhesive layer, the side of the assembled adhesive layer facing away from the transparent base is covered with a translucent release film (that is, the invisible car cover includes a transparent release film, a top coat, a transparent base, an assembled adhesive layer, and a translucent release film from top to bottom. ), wherein the transparent base is a polyurethane film with a thickness of 150 microns; the polyacrylate pressure-sensitive adhesive obtained by known techniques for assembling the adhesive, has a thickness of 20 microns; the...

Embodiment 2

[0038] Embodiment 2 provides a wear-resistant and deformation-resistant invisible car cover. The wear-resistant and deformation-resistant invisible car cover of this embodiment includes a transparent base, one side of the transparent base is covered with a top coat, and the side of the top coat away from the transparent base is covered with a transparent release film, and the other surface of the transparent base is covered with Assemble the adhesive layer, the side of the assembled adhesive layer facing away from the transparent base is covered with a translucent release film (that is, the invisible car cover includes a transparent release film, a top coat, a transparent base, an assembled adhesive layer, and a translucent release film from top to bottom. ), wherein the transparent substrate is a polyvinyl chloride film with a thickness of 120 microns; the polyacrylate pressure-sensitive adhesive obtained by known techniques for assembling glue, and a thickness of 25 microns; ...

Embodiment 3

[0044] Embodiment 3 provides a wear-resistant and deformation-resistant invisible car cover. The wear-resistant and deformation-resistant invisible car cover of this embodiment includes a transparent base, one side of the transparent base is covered with a top coat, and the side of the top coat away from the transparent base is covered with a transparent release film, and the other surface of the transparent base is covered with Assemble the adhesive layer, the side of the assembled adhesive layer facing away from the transparent base is covered with a translucent release film (that is, the invisible car cover includes a transparent release film, a top coat, a transparent base, an assembled adhesive layer, and a translucent release film from top to bottom. ), wherein the transparent substrate is a polyvinyl chloride film with a thickness of 100 microns; the polyacrylate pressure-sensitive adhesive obtained by known techniques for assembling the adhesive, has a thickness of 10 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com