Production process of large-size texture cleavage brick

A production process and a technology for splitting bricks, which are applied in the field of large-scale splitting brick production technology, can solve problems such as deformation of wet blanks, drying and cracking of brick blanks, and achieve the effects of reducing deformation of wet blanks, avoiding compression deformation, and ensuring flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

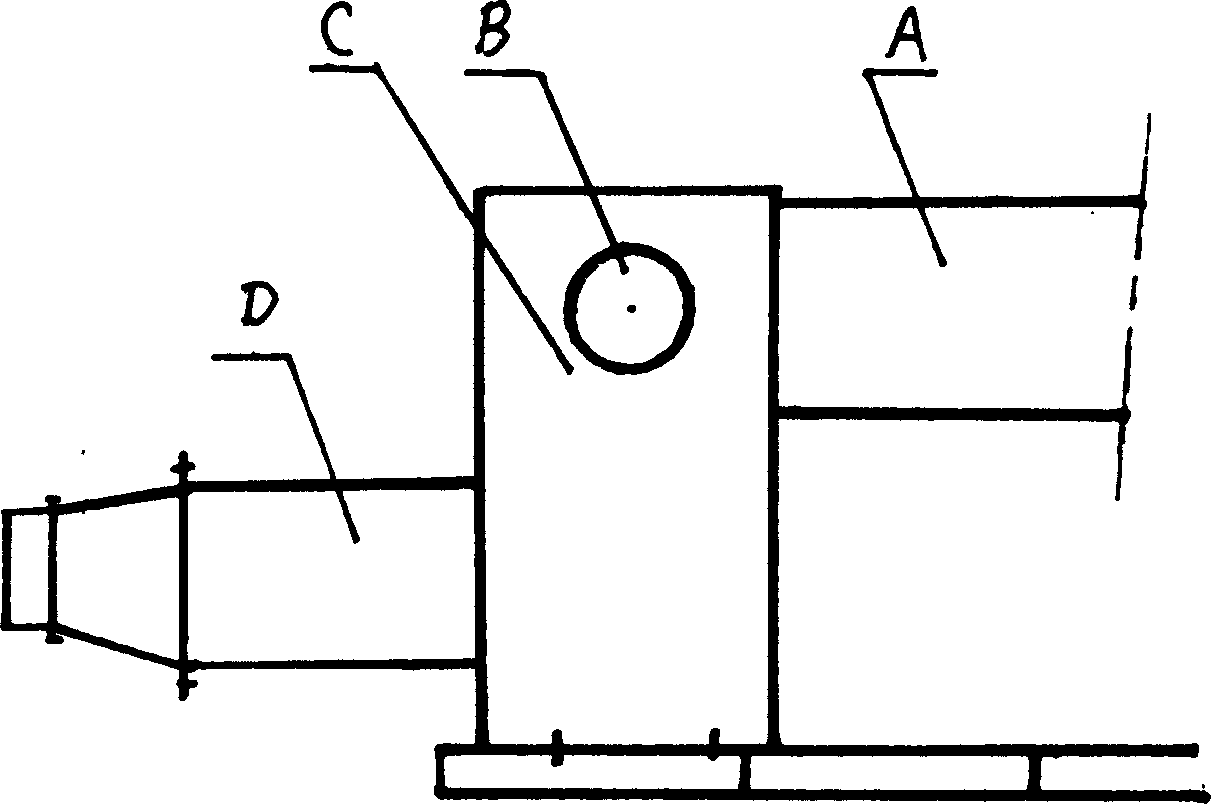

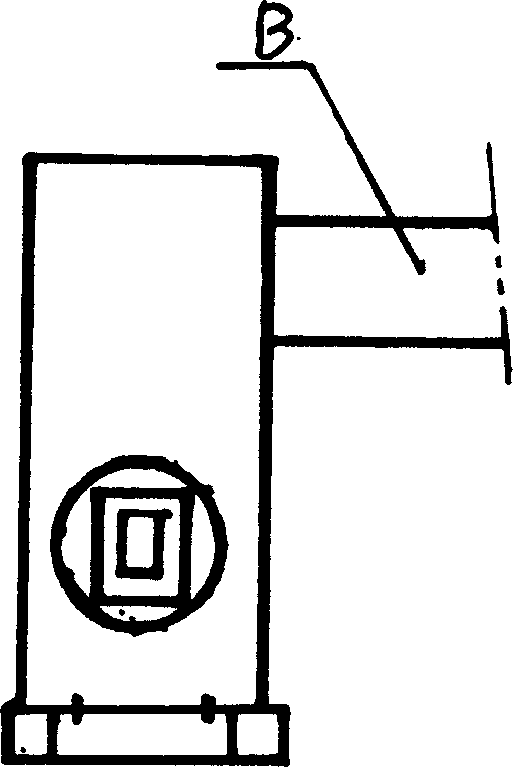

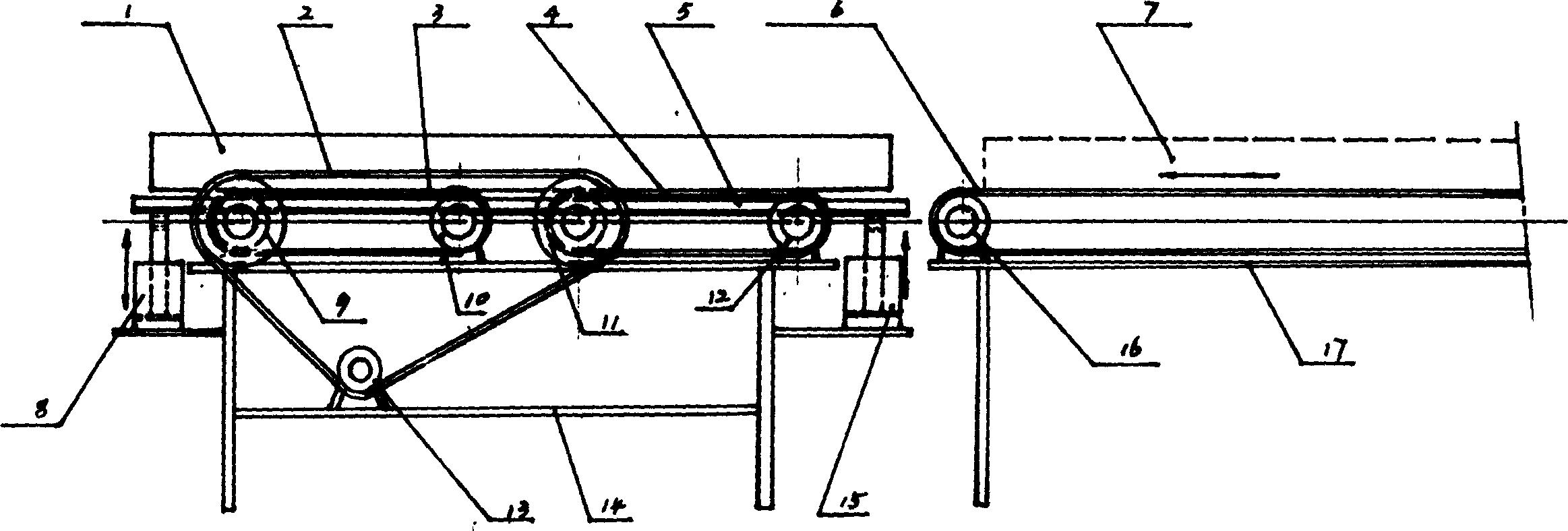

[0034] Example 1. After the raw materials are prepared, the ratio of the amount of mud output at the upper outlet A of the forming brick machine to the mud output at the outlet B of the core extruder is 50:50 according to the color contrast. The outlet B of the mud core extruder enters the vacuum chamber C continuously at the same time. After the initial mixing, it is propelled by the lower spiral blade of the forming brick machine, and is extruded through the mud cylinder head D to form a large plate. The static cutting machine cuts bricks according to the specified size, and the billets are automatically loaded by the automatic billet loading machine. Immediately, the billet frame 5 (the existing bricks) is lifted manually and placed on the drying car, and then the spare track is stored for more than 24 hours. Ensure that the moisture content of the adobe is about 5-12%, and then advance the drying kiln to dry at a drying speed of 30 minutes / car, and ensure that the moisture ...

Embodiment 2

[0035] Embodiment 2: develop the formula that is different colors after roasting, as:

[0036] 1. Use light beige as the base material and red as the texture material.

[0037] 2. Use light beige as the base material and dark coffee as the texture material.

[0038] 3. Use light beige as the base material and black as the base material.

[0039] 4. Use medium yellow as the base material and red as the texture material.

[0040] 5. Use medium yellow as the base material and dark coffee as the texture material.

[0041] 6. Use medium yellow as the base material and black as the texture material. Etc. method, adopt the method for embodiment 1, can produce the product of different color effects.

Embodiment 3

[0042] Example 3: After the raw materials are prepared, adjust the ratio of the mud output at the upper outlet A of the forming brick machine to the mud output at the mud core extrusion outlet B according to the color contrast to be 55:45. The bottom blank passes through the upper outlet A, and the texture material passes through the mud. The outlet B of the core extruder enters the vacuum chamber C at the same time. After the initial mixing, it is propelled by the lower stage of the forming brick machine, and is extruded through the mud cylinder head D to form a large plate, extruded through the forming frame, and pressed by the static cutting machine. The specified size is determined to be a brick, and the automatic billet loading machine automatically loads the billet rack, and immediately lifts the billet frame 5 (the existing brick) manually and puts it on the drying car, and then stores it on the spare track for pre-drying for more than 24 hours. When the moisture content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com