Ti microalloyed ultra-fine grain hot rolled steel at 700MPa class and production method thereof

A technology of microalloying and production methods, applied in the direction of temperature control, etc., can solve the problems of difficult implementation and high requirements for rolling equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The production process of this embodiment specifically includes: electric furnace or converter smelting, refining, thin slab continuous casting (slab thickness 50-60mm), soaking, hot continuous rolling, laminar cooling, coiling and other processes.

[0036]The chemical composition weight ratio of molten steel after alloying treatment in the refining process is: C: 0.03wt.%, Si: 0.29wt.%, Mn: 2.10wt.%, P: 0.020wt.%, S: 0.008wt. %, Ti: 0.10wt.%, the rest is Fe and other unavoidable impurity elements.

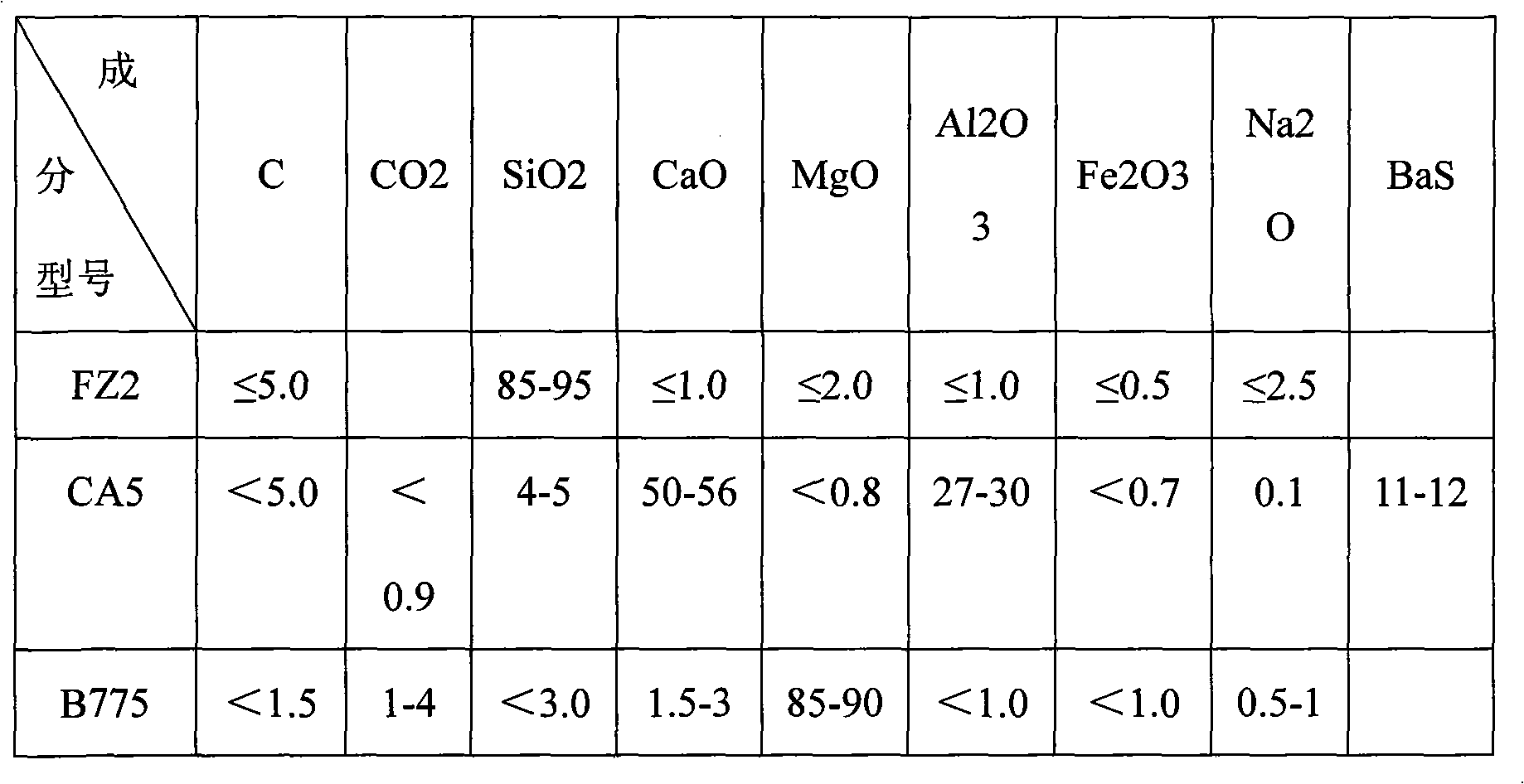

[0037] Tundish molten steel adopts tundish covering agent to protect the molten steel surface. The addition scheme of the tundish covering agent is B775 for the long nozzle side, CA5 for the bottom layer on the stopper rod side, and FZ2 for the surface layer. The main components of various types of covering agents are shown in Table A.

[0038] Table A The main components of the covering agent in various models (%)

[0039]

[0040] The process is as follows:

[0041...

Embodiment 2

[0047] The production method of the present embodiment is basically the same as that of Example 1, and the different processes are as follows:

[0048] The chemical composition weight ratio of molten steel after alloying treatment in the refining process is: C: 0.07wt.%, Si: 0.10wt.%, Mn: 1.0wt.%, P: 0.008wt.%, S: 0.003wt. %, Ti: 0.14wt.%, and the rest are Fe and other unavoidable impurity elements.

[0049] The casting speed is maintained at 4.1m / min, the casting superheat is 30°C, the slab soaking temperature is 1150°C, the starting rolling temperature is 1080°C, the finishing rolling temperature is 930°C, the post-rolling cooling rate is 15°C / s, and the coiling temperature is 580°C. ℃.

[0050] See Table 2 for the mechanical properties of the 700MPa grade Ti microalloyed ultra-fine-grained hot-rolled steel sheet produced in Example 2.

[0051] The mechanical property of table 2 embodiment 2 steel plate

[0052] Steel plate thickness

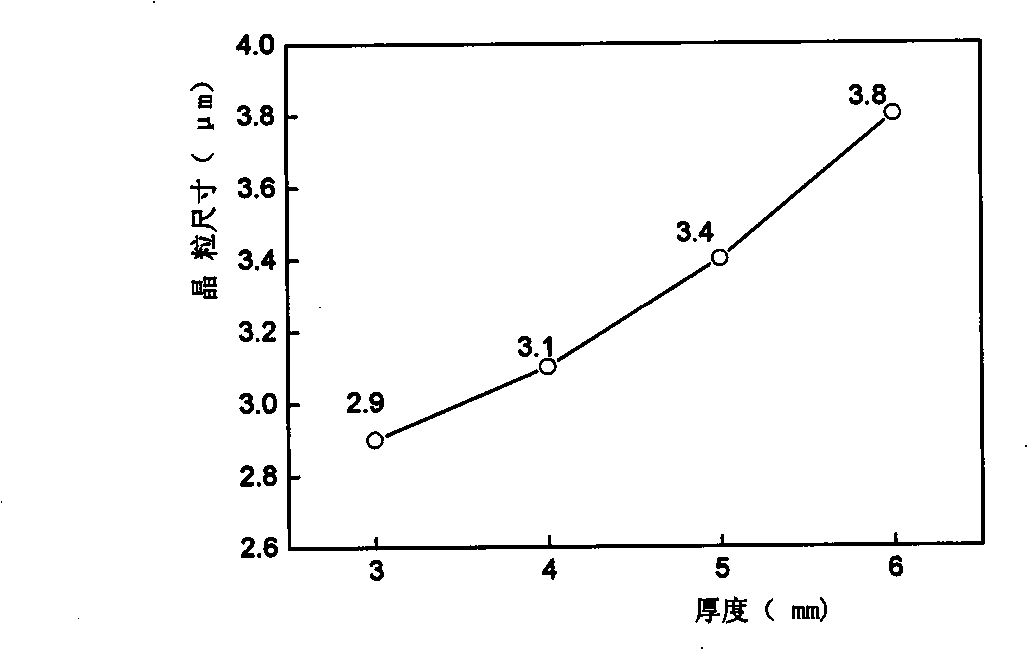

[0053] The ferrite grain s...

Embodiment 3

[0055] The production method of the present embodiment is basically the same as that of Example 1, and the different processes are as follows:

[0056] The chemical composition weight ratio of molten steel after alloying treatment in the refining process is: C: 0.05wt.%, Si: 0.20wt.%, Mn: 1.5wt.%, P: 0.013wt.%, S: 0.005wt. %, Ti: 0.12wt.%, and the rest are Fe and other unavoidable impurity elements.

[0057] The casting speed is maintained at 4.5m / min, the casting superheat is 25°C, the slab soaking temperature is 1130°C, the starting rolling temperature is 1070°C, the finishing rolling temperature is 910°C, the post-rolling cooling rate is 25°C / s, and the coiling temperature is 620°C. ℃.

[0058] See Table 3 for the mechanical properties of the 700MPa grade Ti microalloyed ultrafine-grained hot-rolled steel sheet produced in Example 3.

[0059] The mechanical property of table 3 embodiment 3 steel plate

[0060] Steel plate thickness

[0061] The ferrite grain si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com