Patents

Literature

237results about How to "Affect the tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

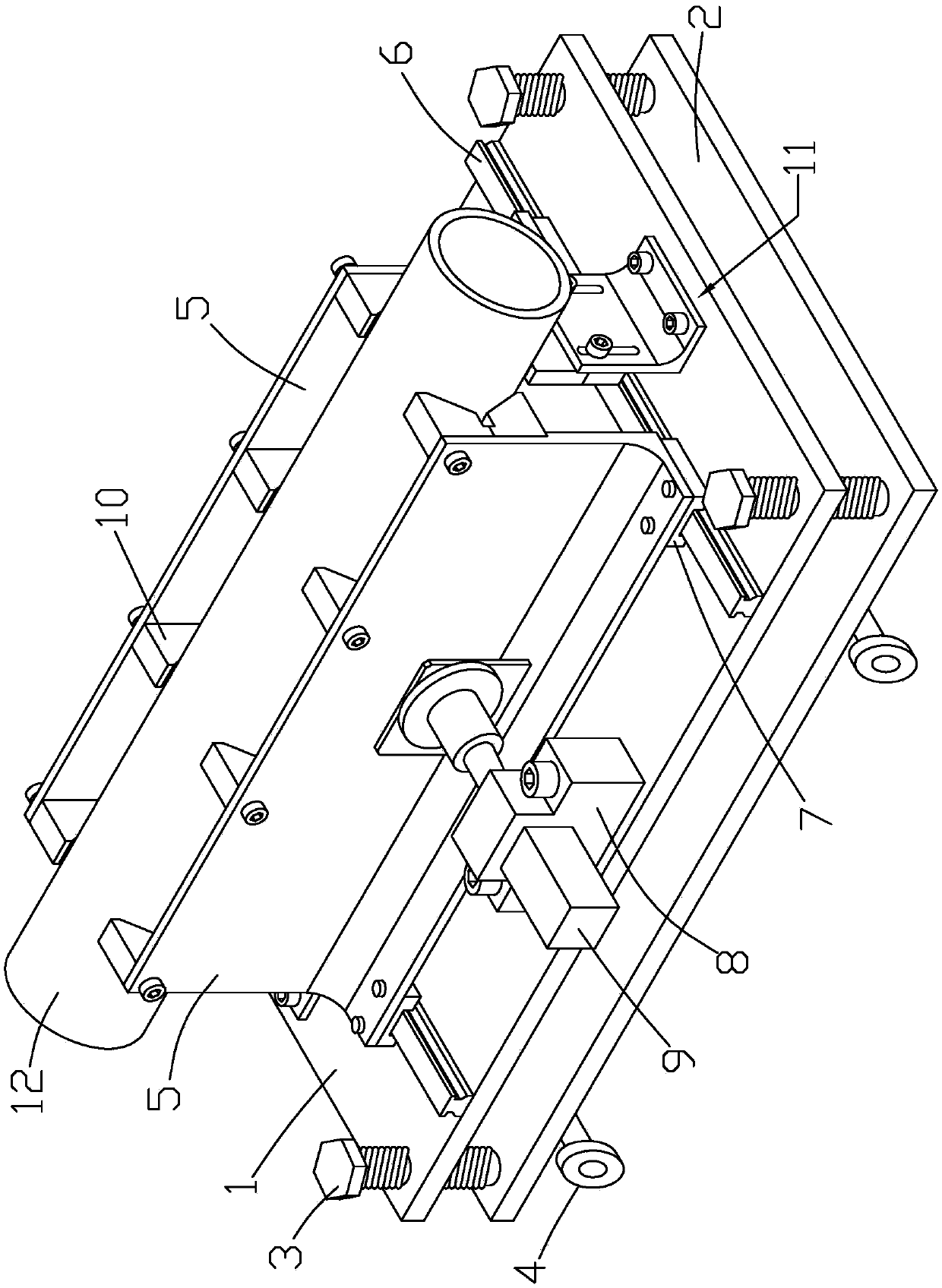

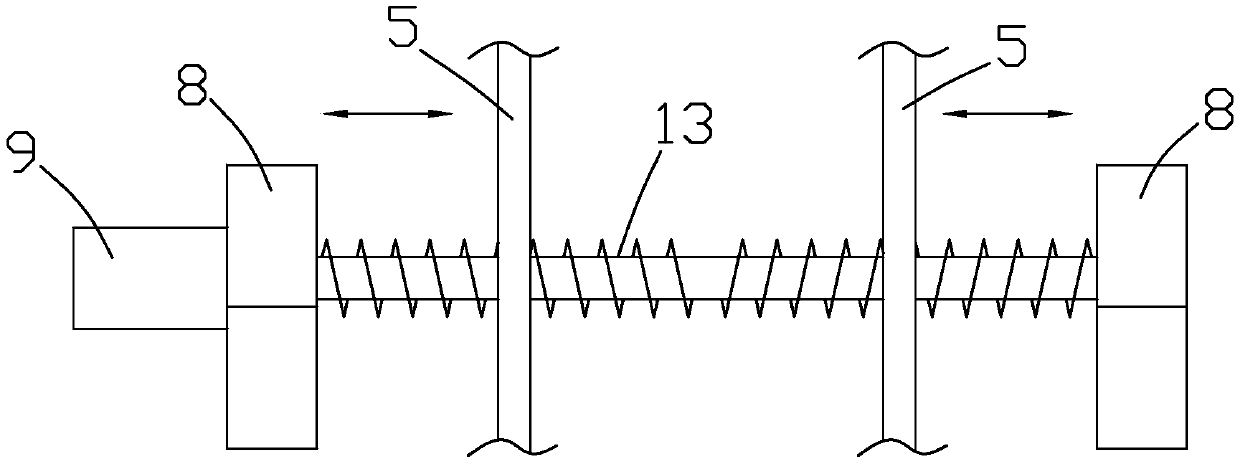

Locating device for long pipeline construction mounting

ActiveCN109555904AImprove stabilityImprove reliabilityPipe laying and repairArchitectural engineeringDrive motor

Owner:江苏省中瑞设备安装有限公司

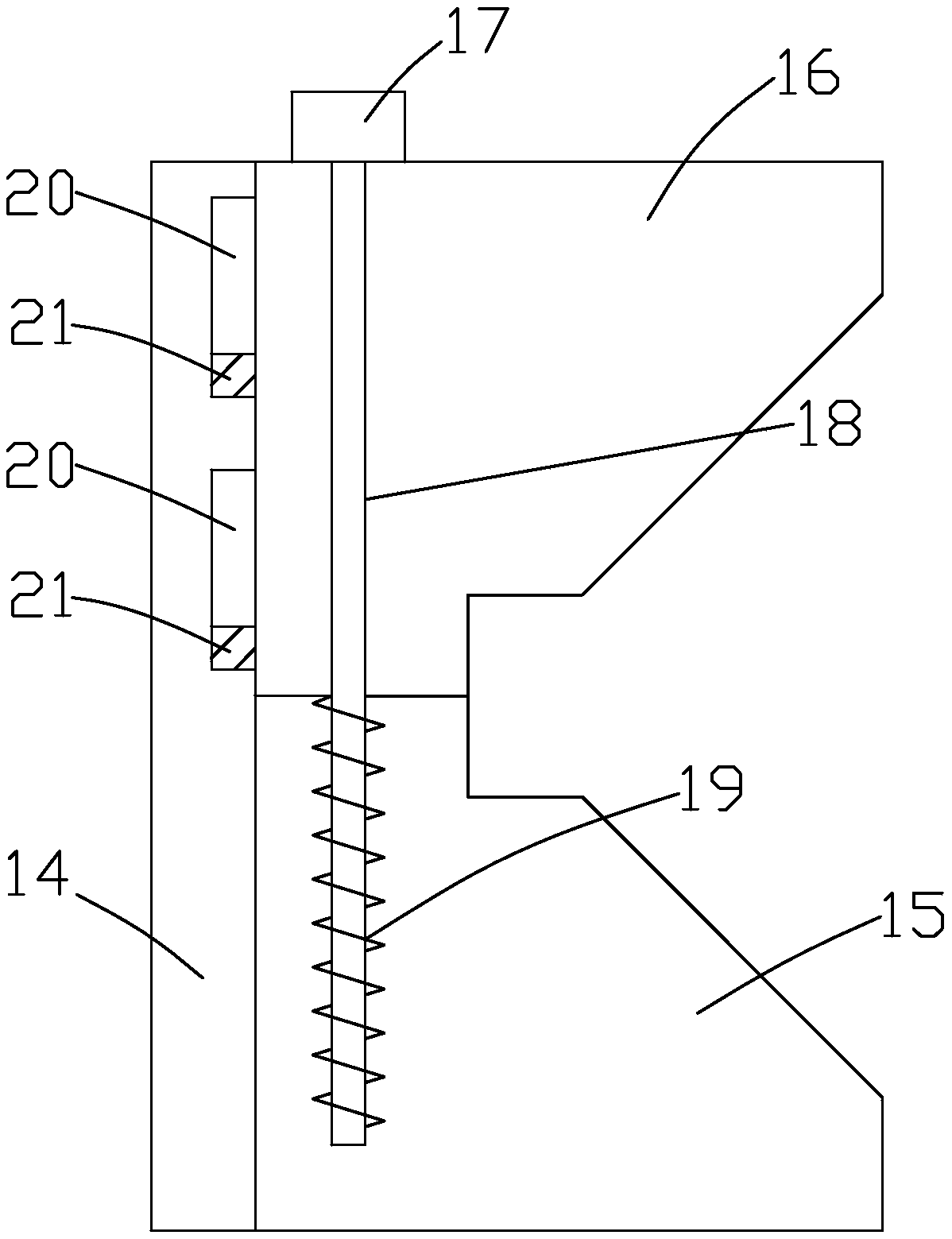

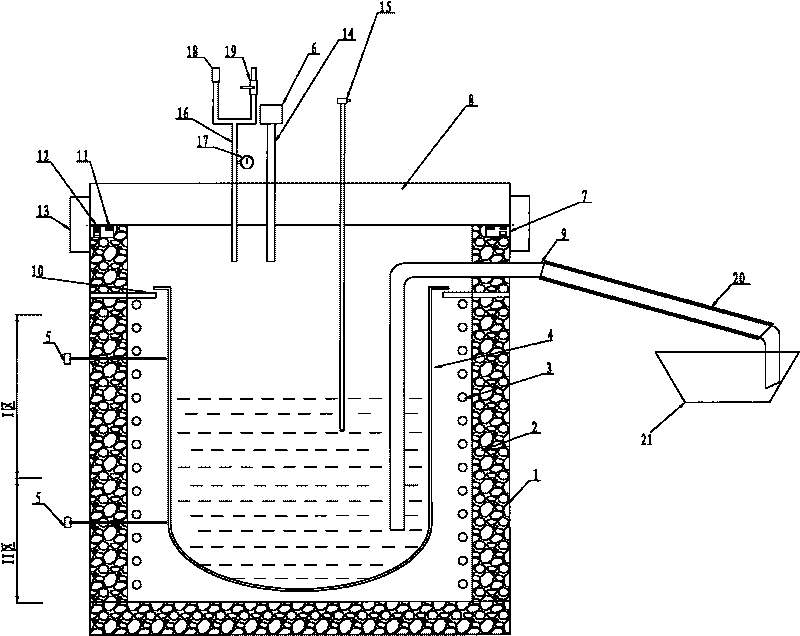

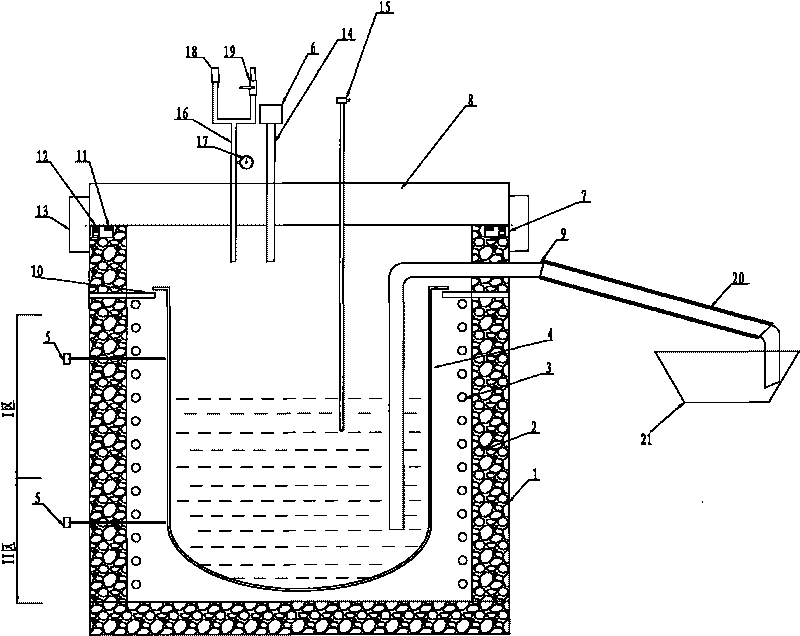

Pressure-flow-type magnesium alloy smelting heat insulating furnace

InactiveCN101706205AHighlight substantive featuresSignificant progressCrucible furnacesExhaust valveHearth

The invention relates to a pressure-flow-type magnesium alloy smelting heat insulating furnace which comprises a furnace body provided with a heat insulating layer, a crucible arranged inside a hearth, a heating element, a temperature measuring device and a furnace cover, wherein the furnace body comprises a furnace shell and a furnace liner; a water-cooling flange is arranged at a position where the upper part of the furnace body is matched with the furnace cover, and internally provided with high temperature resistant and fire-resistant filler material and a silicon rubber sealing ring; the water-cooling flange is internally filled with circulating cooling water; the furnace cover is locked with the furnace body by a compressing mechanism; a temperature thermocouple and a protection gas input pipeline extend into the furnace through inserting holes of the furnace cover, a pressure release pipe is arranged on the furnace cover, and the top of the pressure release pipe is provided with a safety valve and an exhaust valve; and a transfer pipette is introduced into the hearth through the furnace body. The furnace integrates the functions of smelting, heat insulating and melt transmission, accurately controls the flow rate of magnesium alloy melt, extracts the purer magnesium alloy melt at the middle part of the crucible, realizes continuous transmission with fixed flow rate, and prevents oxidation and combustion of the magnesium alloy. Furthermore, by combining corresponding foundry equipment, the magnesium alloy product with high quality can be prepared, and the equipment can be safe in use as well as simple and convenient for operation.

Owner:苏州有色金属研究院有限公司

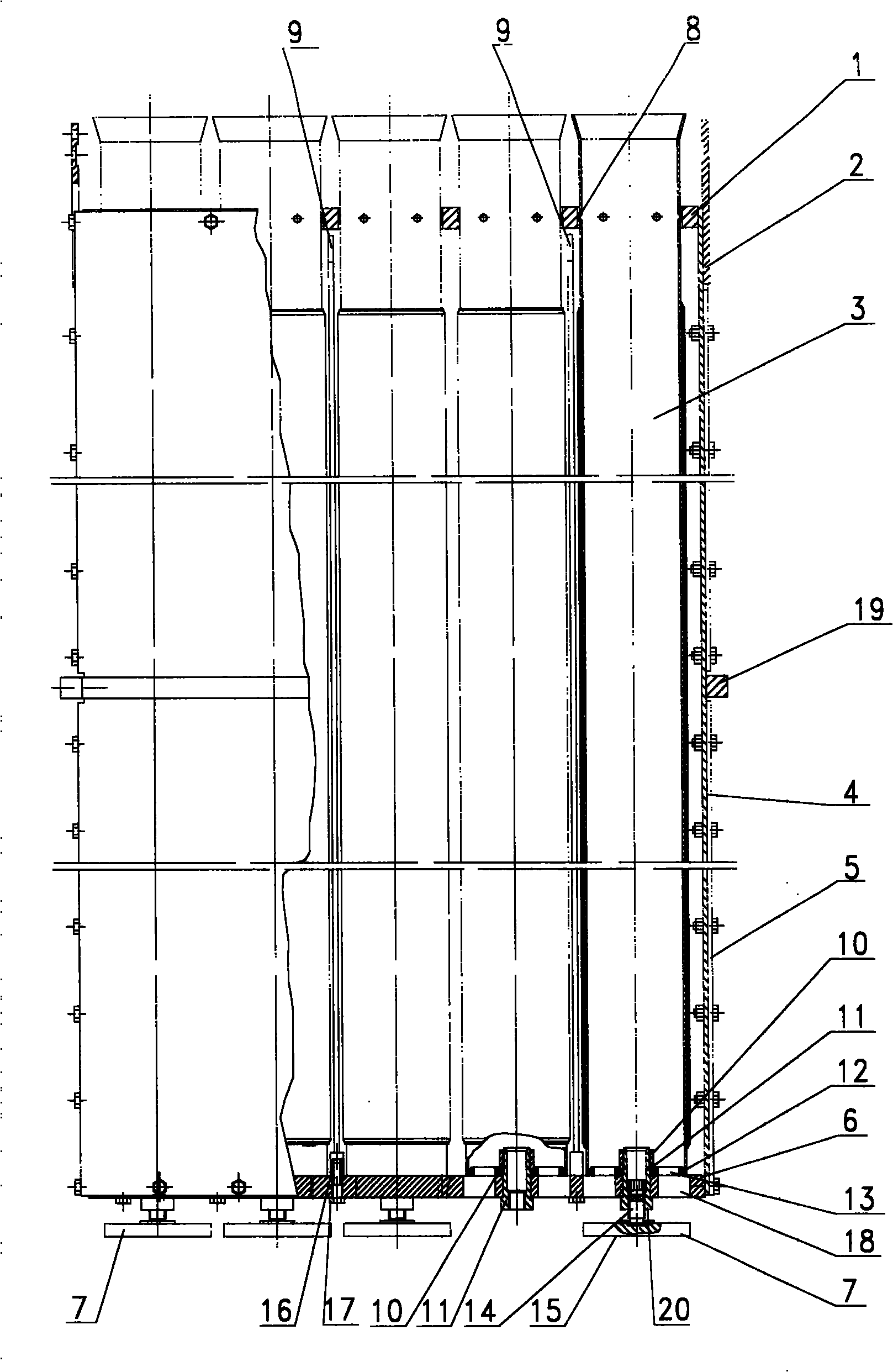

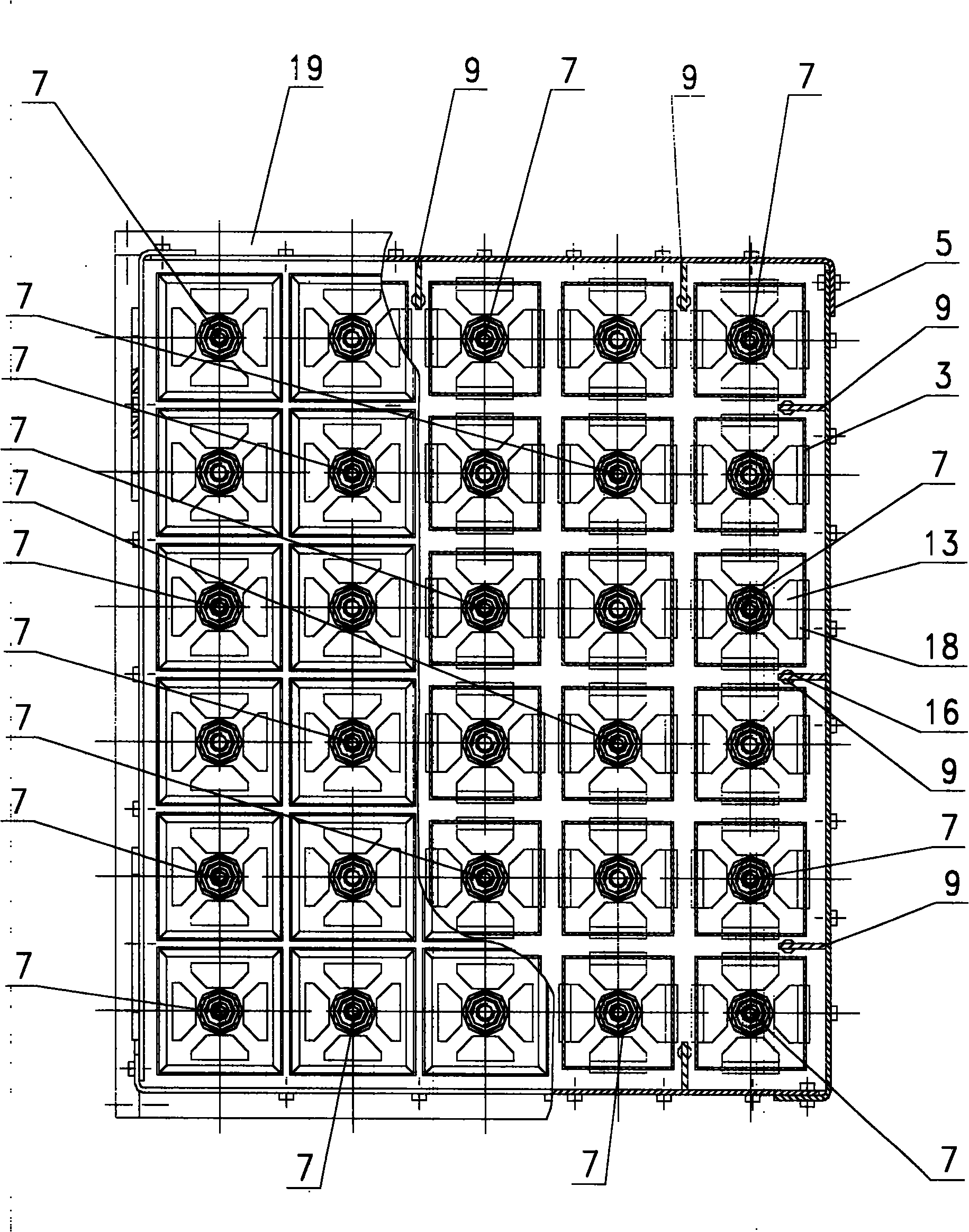

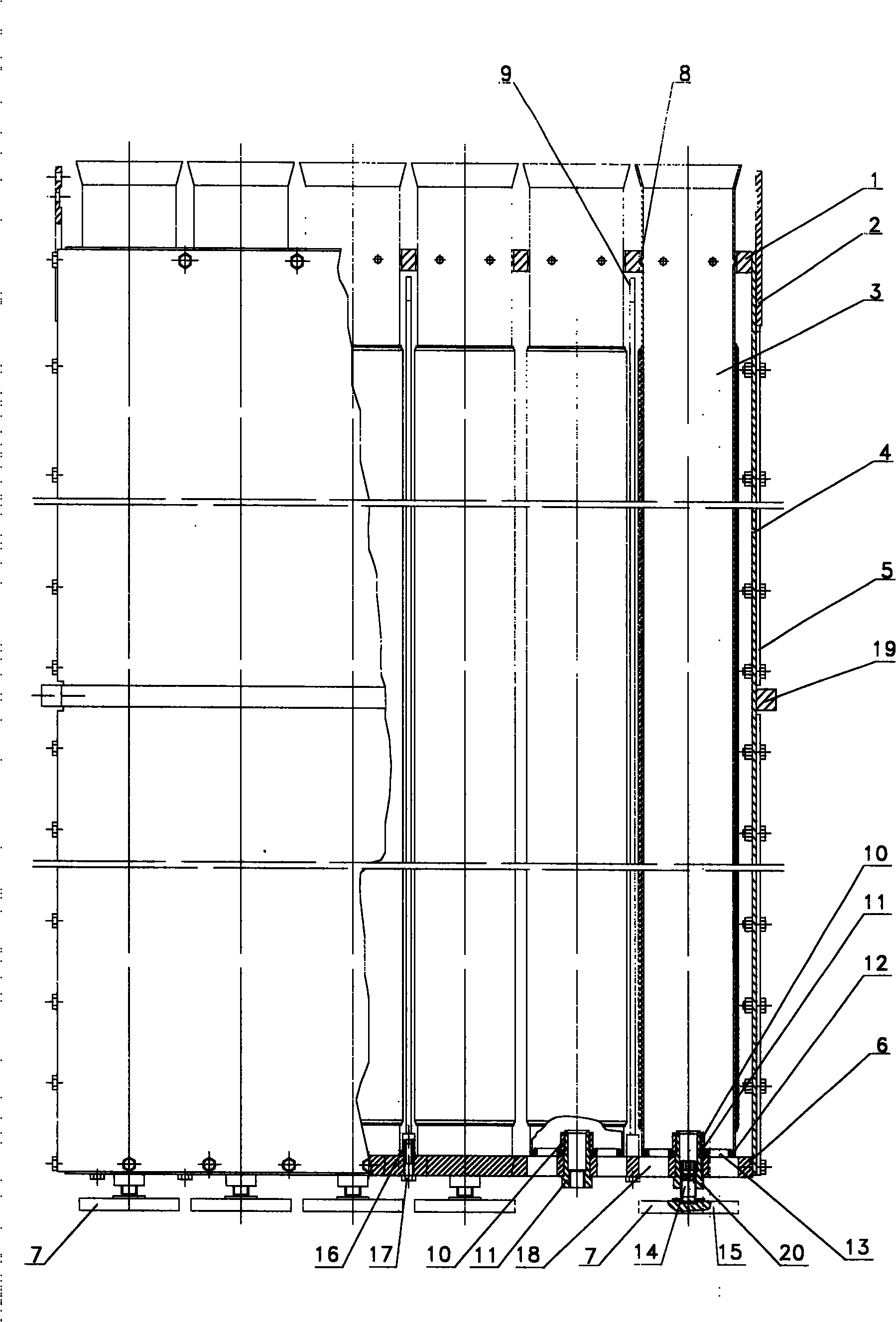

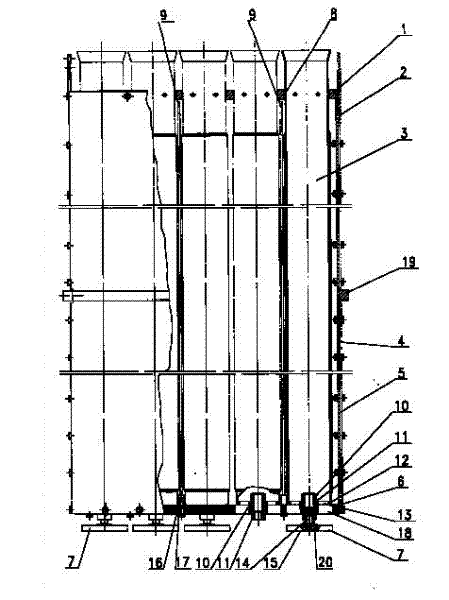

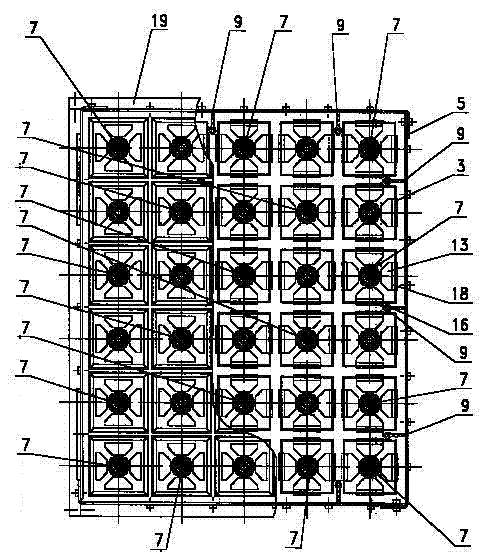

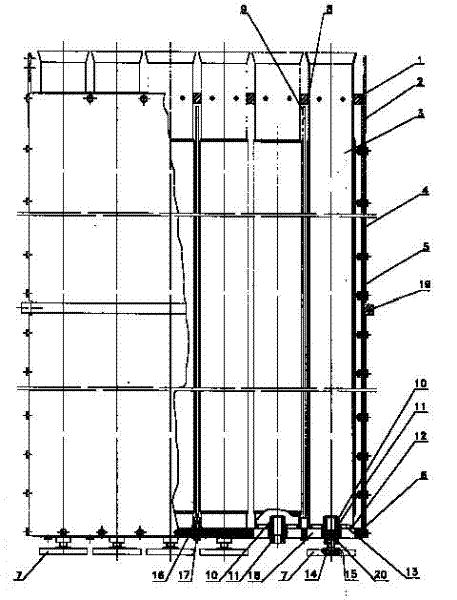

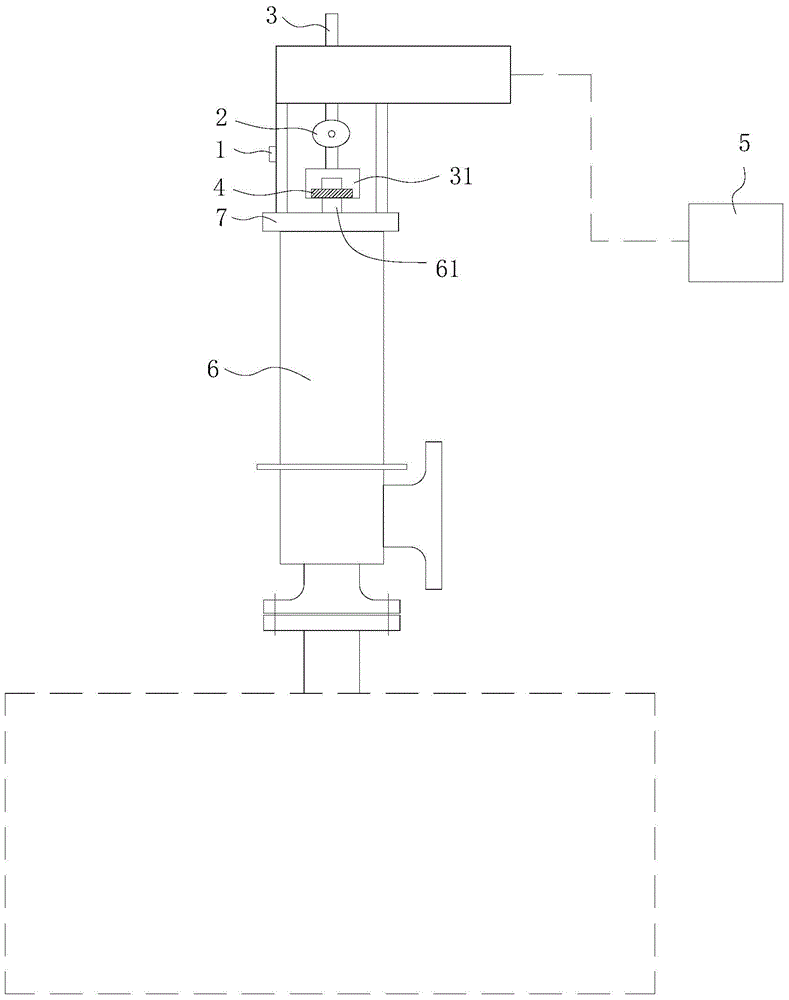

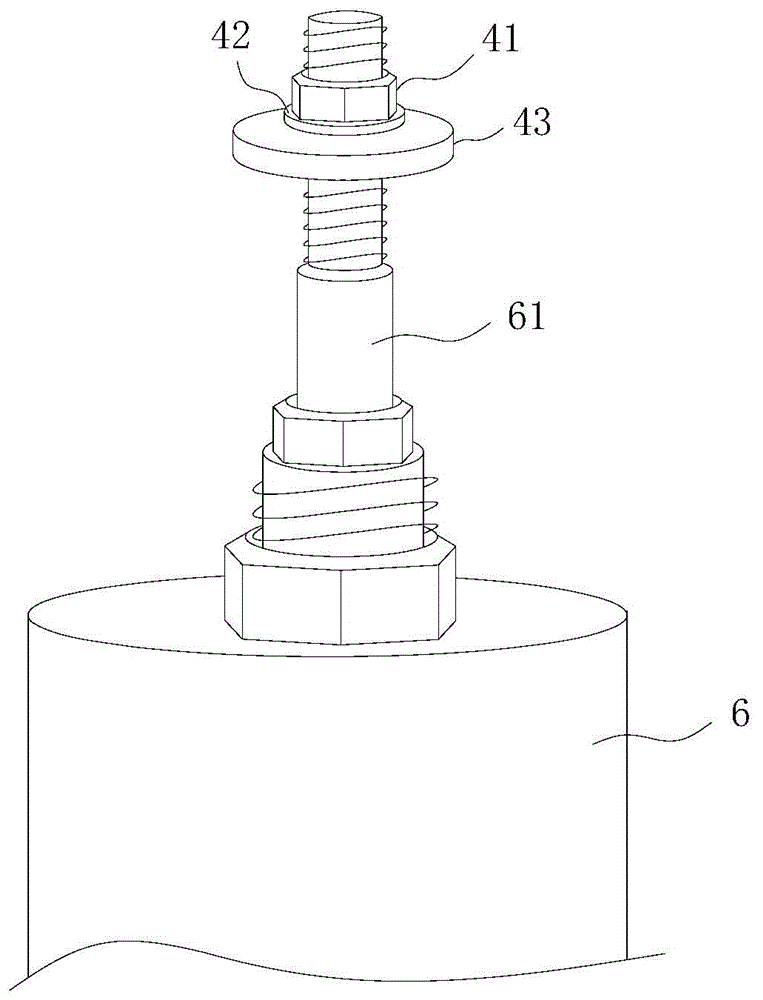

Spent fuel storage rack in pressurized water reactor nuclear power station

InactiveCN101783189AGuaranteed levelnessGuaranteed stabilityNuclear energy generationReactor fuel elementsPressurized water reactorNuclear power

The invention relates to a spent fuel storage rack and in particular discloses a spent fuel storage rack in a pressurized water reactor nuclear power station. The storage rack comprises four enclosing plates, an upper bearing plate positioned at the tops of the enclosing plates, and a lower bearing plate and a storage sleeve which are positioned at the bottoms of the enclosing plates, wherein the enclosing plates, the upper bearing plate and the lower bearing plate form a cubic cavity; the storage sleeve is positioned in the square holes on the upper bearing plate and the lower bearing plate; base plates of the storage sleeve are positioned on the lower bearing plate; legs are fixedly connected with the lower bearing plate; thread sleeves on the legs are welded with the lower bearing plate; cylindrical convex plates are arranged at the bottoms of the thread sleeves; the upper ends of the thread sleeves are fastened with the lower bearing plate and the base plates by nuts; adjusting screws are arranged in and in threaded connection with the thread sleeves; the bottoms of the adjusting screws are freely positioned in the spherical recesses of bottom backing plates; and the base plates are provided with through holes communicated with the inside of the storage sleeve and the through holes are communicated with the through holes on the bearing plates. The storage rack has high storage capacity and good shock resistance.

Owner:CHINA NUCLEAR POWER ENG CO LTD

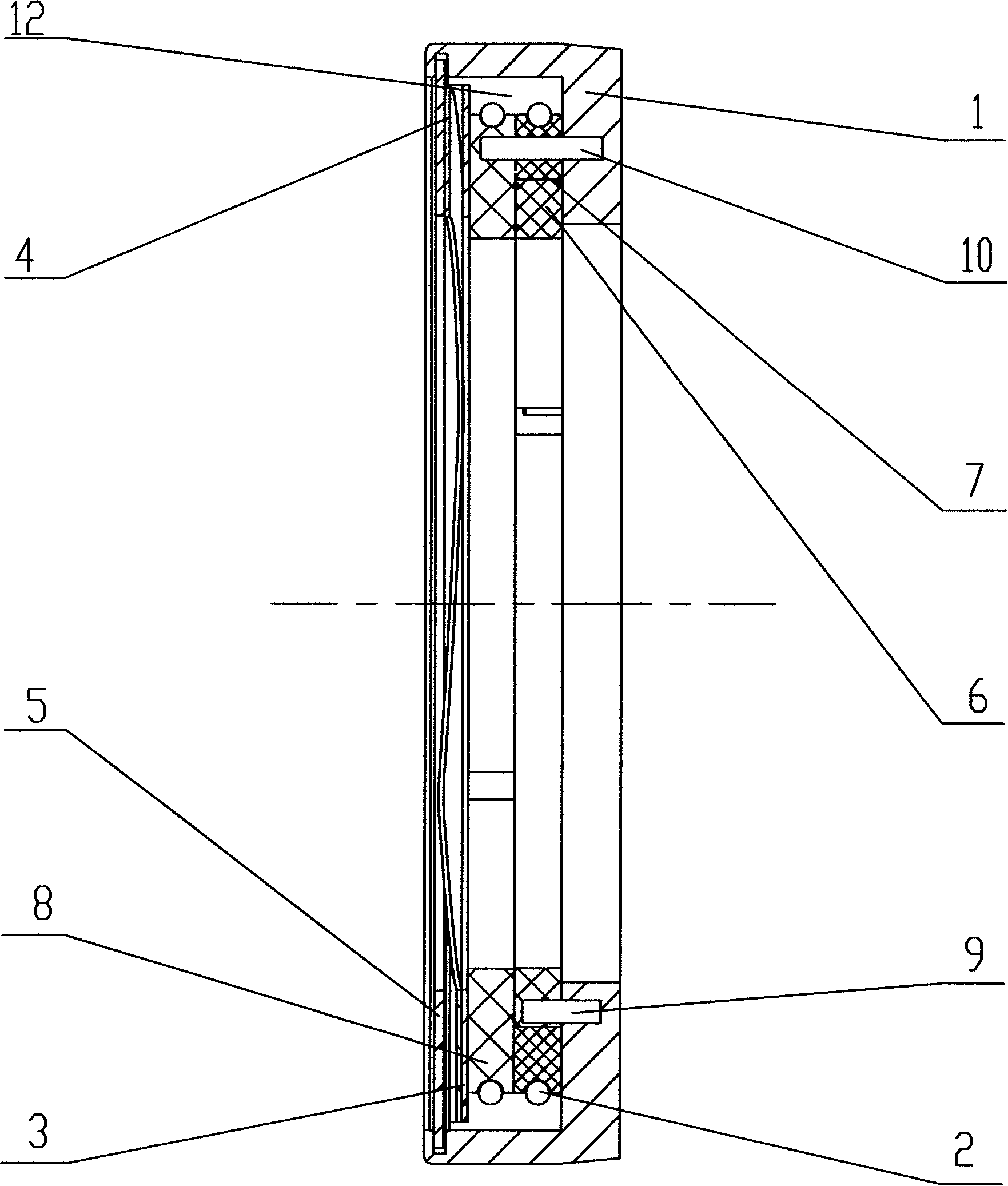

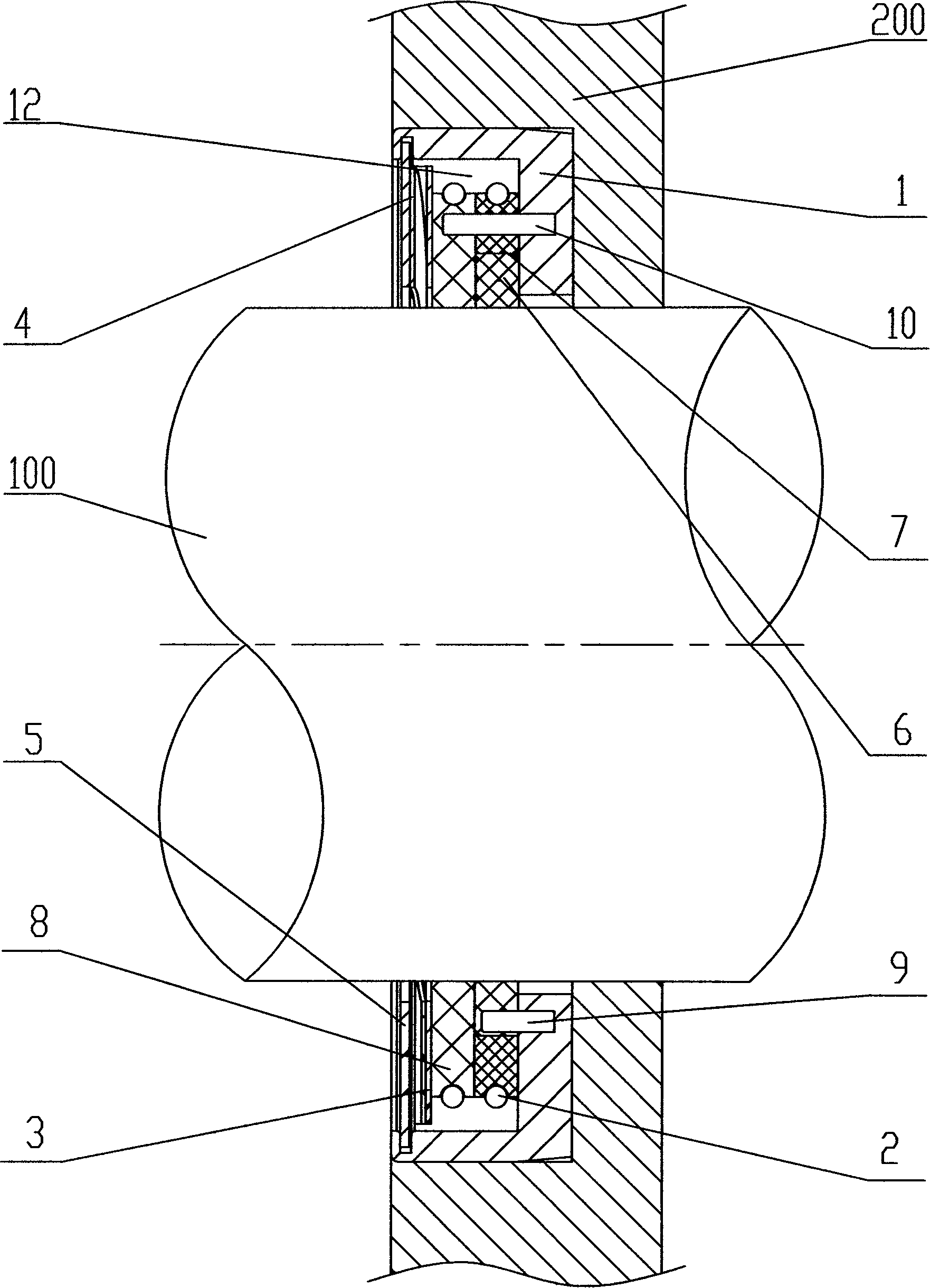

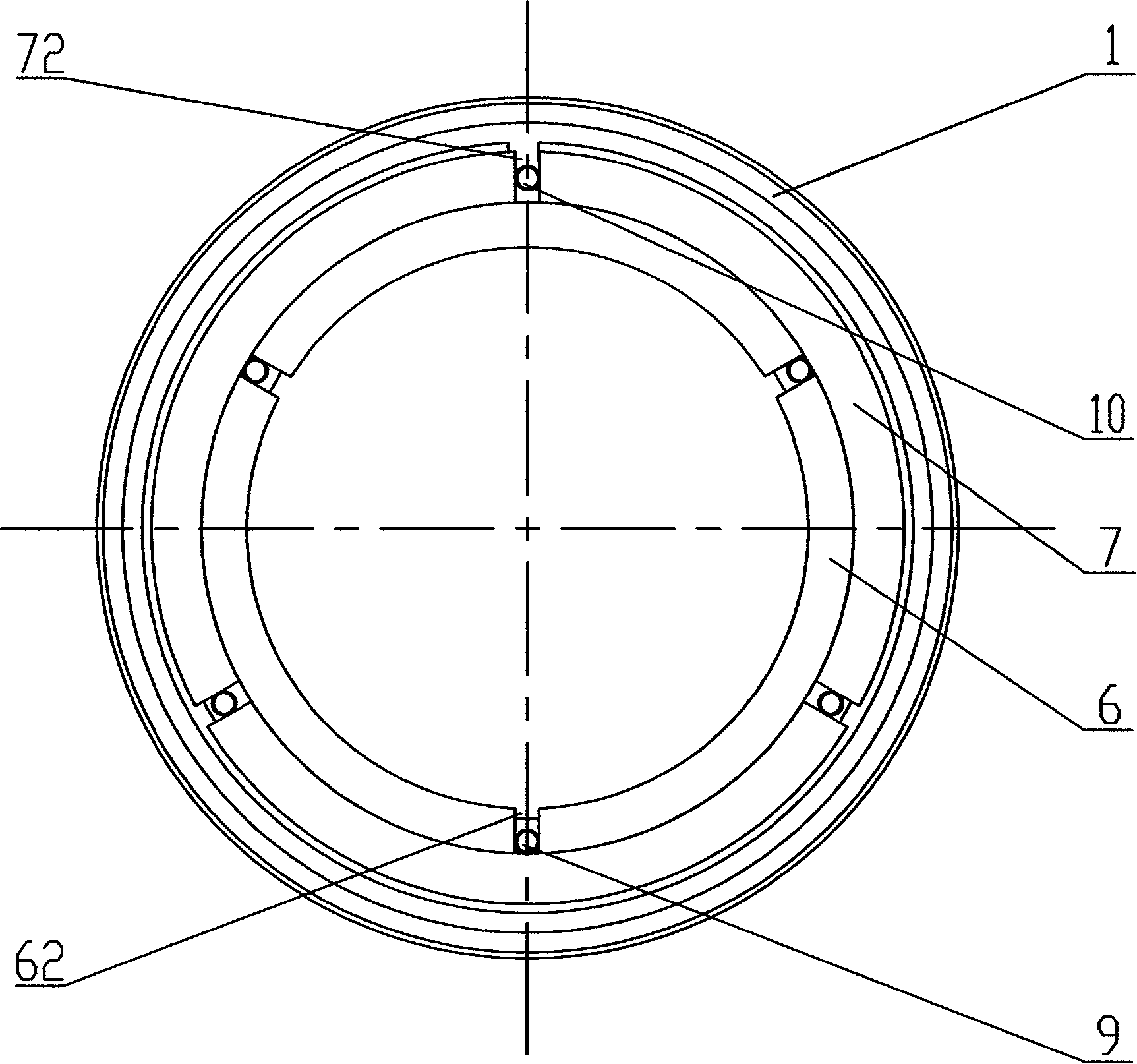

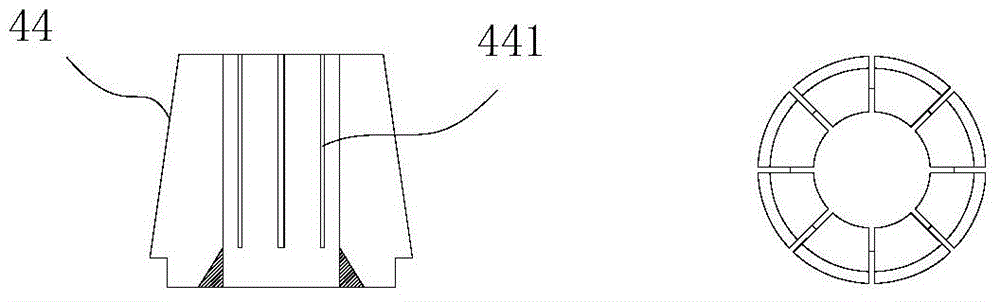

Dynamic seal device

ActiveCN101187425AExtended service lifeGood sealing performanceEngine sealsGearboxesEngineeringHigh pressure

The invention relates to a dynamic seal device, which is installed between a rotating shaft and a box body, and is sleeved on the rotating shaft. The dynamic seal device comprises a ring-shaped base body, and a seal ring group which is located in the base body, wherein the seal ring group comprises an inner seal ring and an outer ring which are radially arranged along the rotating shaft. At least one slit is respectively opened on the inner seal ring and the outer seal ring, and the positions of the slits on the inner seal ring and the outer seal ring are mutually staggered. When the dynamic seal device with the structure is in working state, the axial motion and the radial motion can be kept, and the invention can freely float together with the rotating shaft. Therefore, the dynamic seal device of the invention has higher service life, and excellent seal property, which can meet the sealing needs of high temperature and high pressure.

Owner:靖江市华信科技创业园有限公司

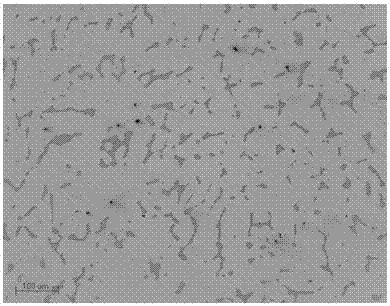

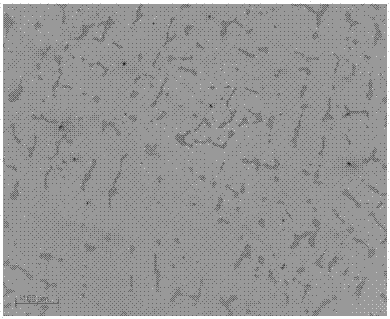

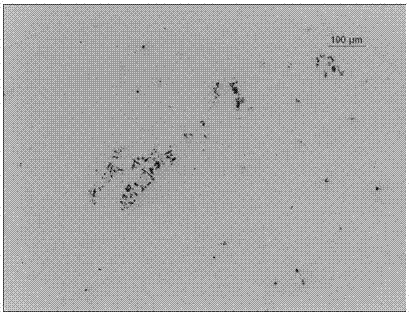

Austenitic stainless steel for low temperature, casting of austenitic stainless steel and manufacturing method of casting

ActiveCN106893945AGood low temperature impact toughnessGood welding performanceFoundry mouldsFoundry coresAustenitic stainless steelNickel

The invention provides austenitic stainless steel for low temperature, a casting of austenitic stainless steel and a manufacturing method of the casting. The austenitic stainless steel comprises lower than 0.08% of C, 1.0%-1.6% of Mn, 0.6%-1.2% of Si, 17.0%-20.0% of Cr, 10.0%-13.0% of Ni, 2.0%-3.0% of Mo, 0.04%-0.12% of N and the balance Fe and impurities; in the impurities, P is smaller than or equal to 0.04%, S is smaller than or equal to 0.02%, Sn is smaller than or equal to 0.015%, As is smaller than or equal to 0.01%, Pb is smaller than or equal to 0.01%, Sb is smaller than or equal to 0.01%, and the sum of the Sn, the As, the Pb and the Sb is smaller than or equal to 0.035%. Chemical components are adjusted, the temperature points of Ms and Md (30 / 50) are controlled, the casting process is reasonably controlled, high-nickel welding rod selection, heat treatment temperature control and the like are achieved, the stability of a cast structure is guaranteed, and the good mechanical performance and size stability are achieved.

Owner:FUJIAN PROVINCE DATONG RECIPROCITY VALVE CO LTD

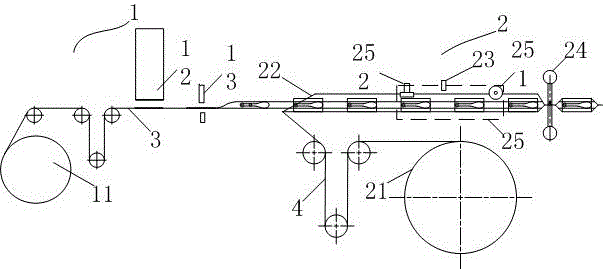

Pillow type packaging machine

ActiveCN105800002ARapid heat softeningRapid heating to soften and bondWrapper twisting/gatheringBiochemical engineeringAssembly line

The embodiment of the invention discloses a pillow type packaging machine which comprises a limiting belt containing unit. The limiting belt containing unit is arranged at one end, for membrane feeding, of a packaging unit and comprises a first membrane containing roller. Limiting belts are overlaid on packaging membranes. By means of the packaging machine, processing and production of a pillow type packaging assembly line provided with the limiting belts can be achieved, the structure is simple, cost is low, stability is high, and the packaging quality is effectively improved.

Owner:汕头市甜甜乐糖果食品有限公司

Welding method of copper tube

ActiveCN103801847AAffect the tightnessGuaranteed welding strengthWelding/soldering/cutting articlesWelding apparatusSilver electrodeChromium nickel

The invention relates to the technical field of welding, in particular to a welding method of a copper tube. The welding method comprises the following steps: a surface of the copper tube to be welded is cleaned; a groove and two ends of the copper tube to be welded are preheated; a clamping device is arranged at the groove of the copper tube to be welded, the inlet / the outlet for a welding torch is formed in the clamping device, when the welding torch is placed in the inlet / the outlet, the clamping device and the outer wall of the copper tube to be welded form a closed space, the groove of the copper tube to be welded is heated after vacuumizing, a flux is coated at welding parts, a chromium nickel stainless steel electrodes and silver electrodes are respectively placed at different welding parts to carry out a primary welding and a secondary welding, the silver electrodes are fixed between the outer wall of the copper tube to be welded and the clamping device by the clamping device; after the silver electrodes are molten completely, the power is shut off, and heat preservation is carried out, and the clamping device is removed. The welding method of the copper tube disclosed by the invention enhances the welding strength and sealing of the copper tube, and further reduces the generation of air holes in welding parts and improves the quality for the welded copper tube.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

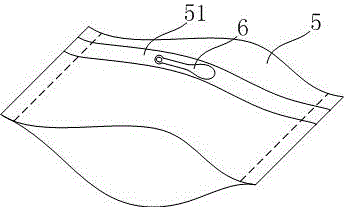

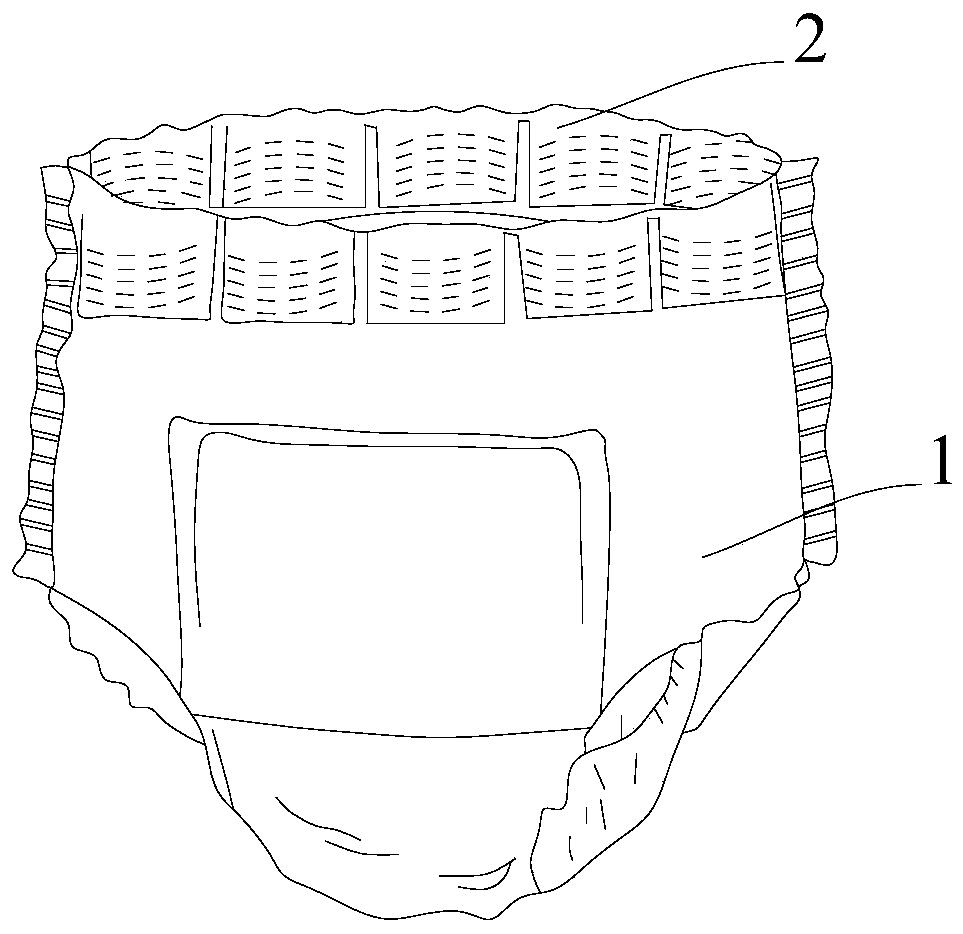

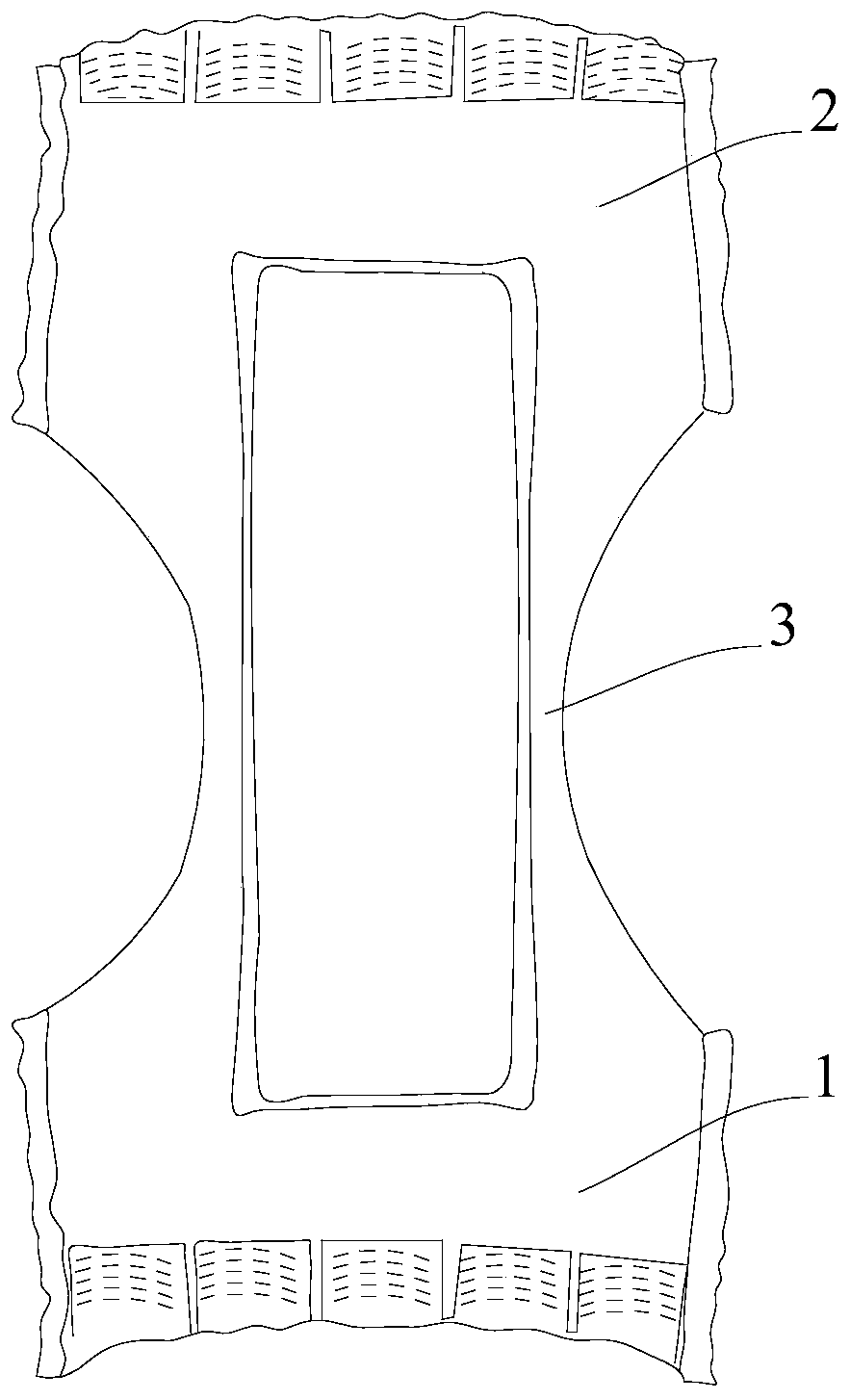

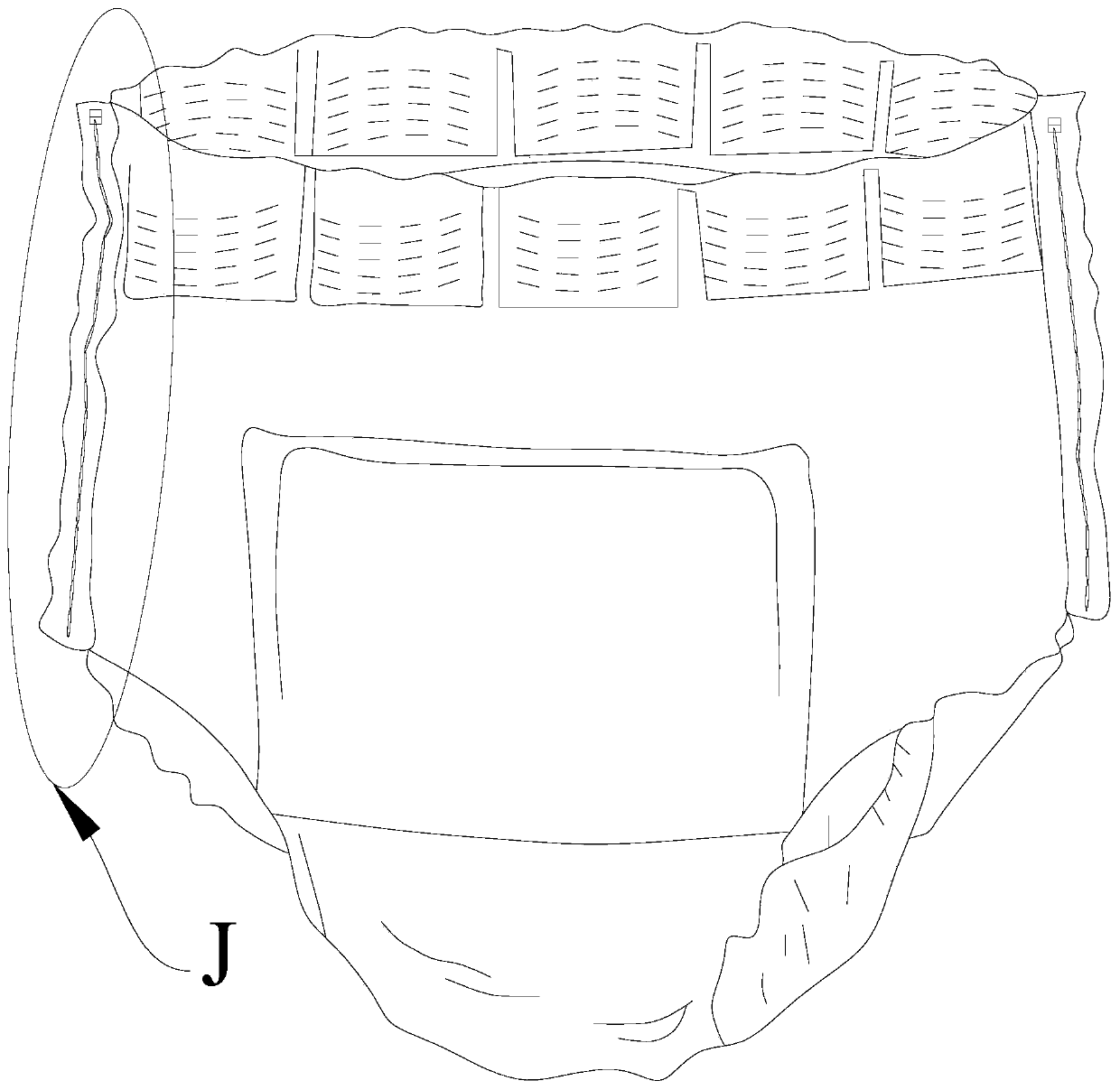

Pull-up diaper

ActiveCN111134967AFirmly connectedFixed connection is convenient and labor-savingAbsorbent padsBandagesEngineeringMechanical engineering

The present invention discloses a pull-up diaper. The pull-up diaper uses a chain structure to realize fixed connection of waist edges, the chain structure comprises a plurality of chain rings which are serially locked from head to tail, the head of each chain ring is limited by the first waist edge, each chain ring sequentially passes through the second waist edge and the previous chain ring, sothat the tail of the previous chain ring is limited at one side, deviated from the first waist edge, of the second waist edge; and the last chain ring is provided with a locking structure, under action of the locking structure, the last chain ring limits the tail of the previous chain ring to one side, deviated from the first waist edge, of the second waist edge, when the locking structure of thelast chain ring is released, any waist edge is pulled away from an end where the last chain ring is located, and all the chain rings are sequentially unlocked from back to front to release the fixed connection of the waist edges. Therefore, the pull-up diaper with the waist edge fixed connection structure can be released by one hand, so that the pull-up diaper is more convenient to take off and has characteristics of ingenious conception, simple structure, easy modification, etc.

Owner:刘品伽

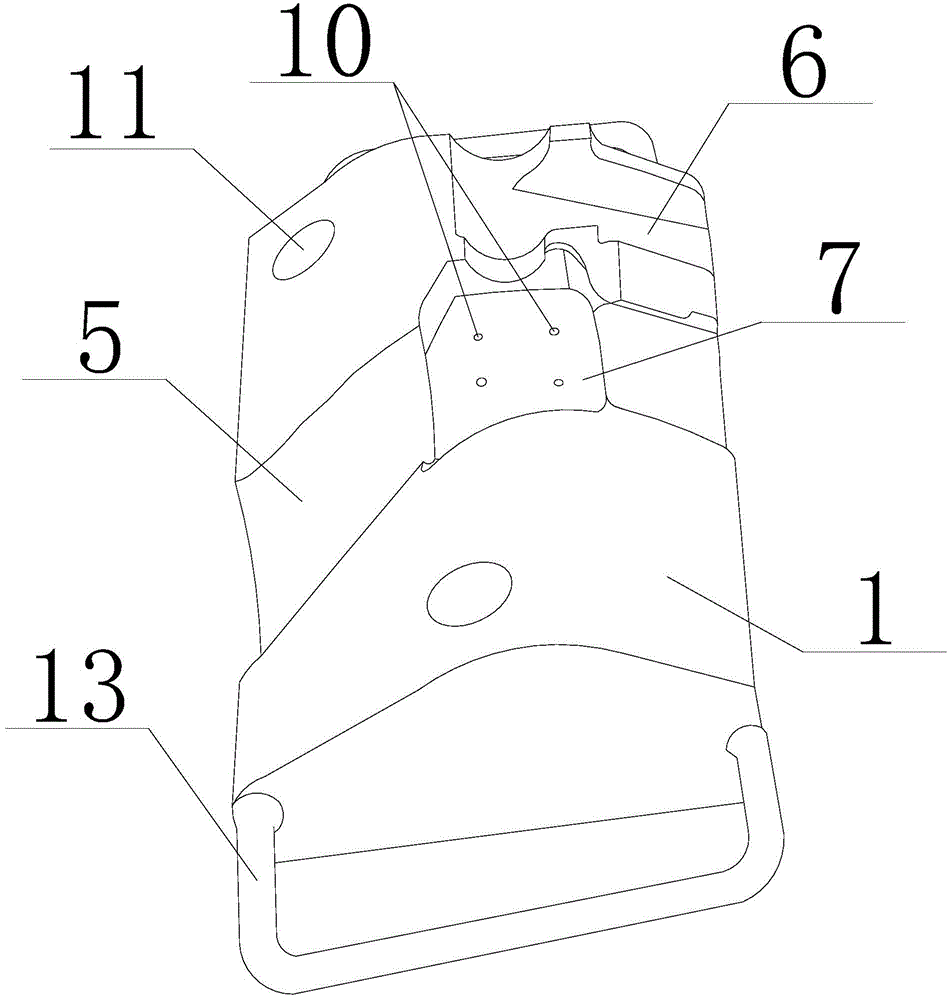

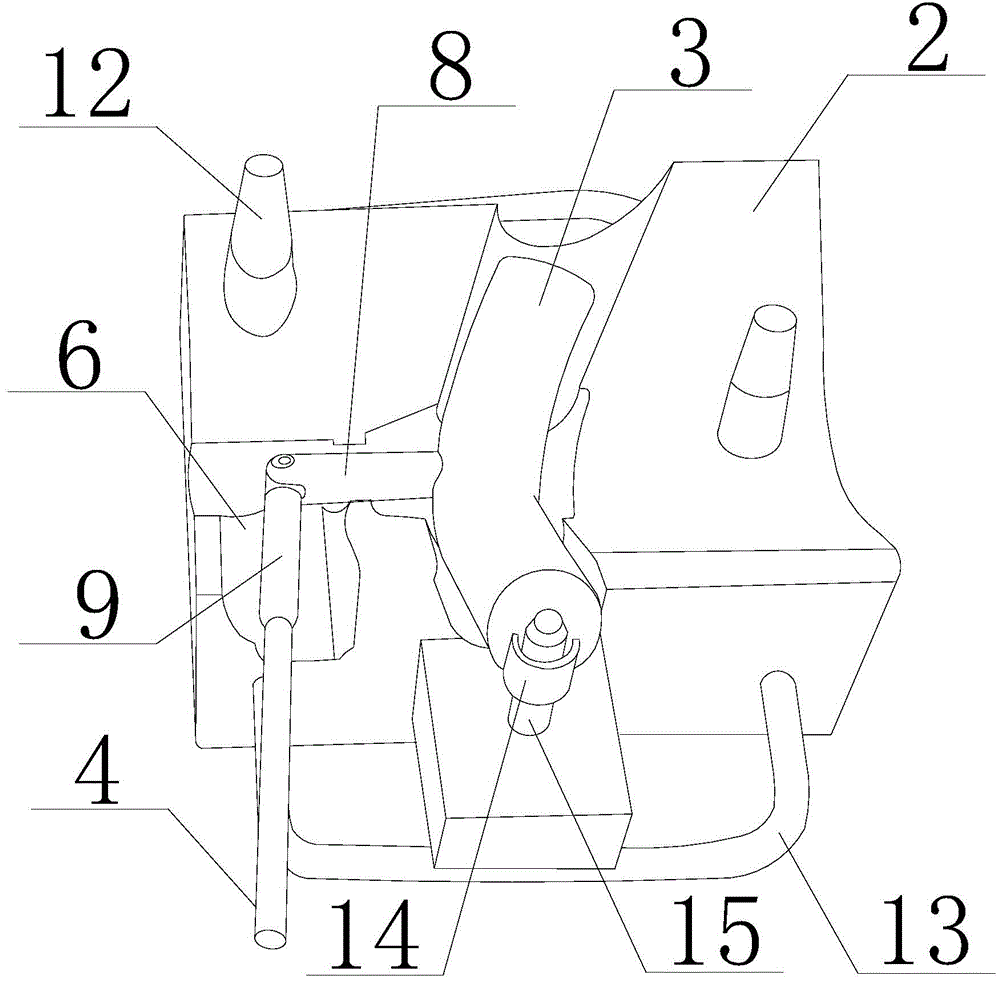

Anti-explosion main junction box for high-voltage compact motor

ActiveCN101958602APlay the role of insulation and sealingAffect the tightnessSupports/enclosures/casingsEngineeringHigh pressure

The invention discloses an anti-explosion main junction box for a high-voltage compact motor, comprising a box base and a box cover. The box base is detachably and hermetically connected with a motor body; the box cover is detachably and hermetically connected with the box base; a junction post is arranged in the box base; a pressure release hole is arranged on the lower part of the box base; the box base is provided with a hollow pressing plate inside the pressure release hole; two layers of hollow sealing cushions are arranged between the pressing plate and the box base; a layer of pressure release film is arranged between the two layers of sealing cushions; and the box base is provided with a protection cover having an opening outside the pressure release hole. With simple structure, easy installation manufacture and novel valving design, compared with the traditional junction box, the invention greatly improves the security and has the characteristics of reasonable electric gap, creepage distance and shell intensity, more convenient installation and use, high reliability, convenient use, compact structure and attractive appearance.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

Molding technology of bending connection pipe

The invention discloses a molding technology of a bending connection pipe; the bending connection pipe is manufactured by molding a bendable branch pipe mandril; after being molded in a way of vulcanization, the branch pipe mandril can be easily and conveniently pulled out from the bending connection pipe, so that the bending connection pipe can be manufactured into any needed size. According to the molding technology of the bending connection pipe, a connecting rubber die cavity is arranged at the connecting part of a main pipe and a branch pipe, and a vulcanized rubber material in the connecting rubber die cavity is used for closely wrapping the connecting part of the main pipe and the branch pipe, so that the integral bending connection pipe can be manufactured, the sealing property of the bending connection pipe is effectively improved, and the service life of the bending connection pipe is effectively prolonged.

Owner:SICHUAN FUXIANG TECH

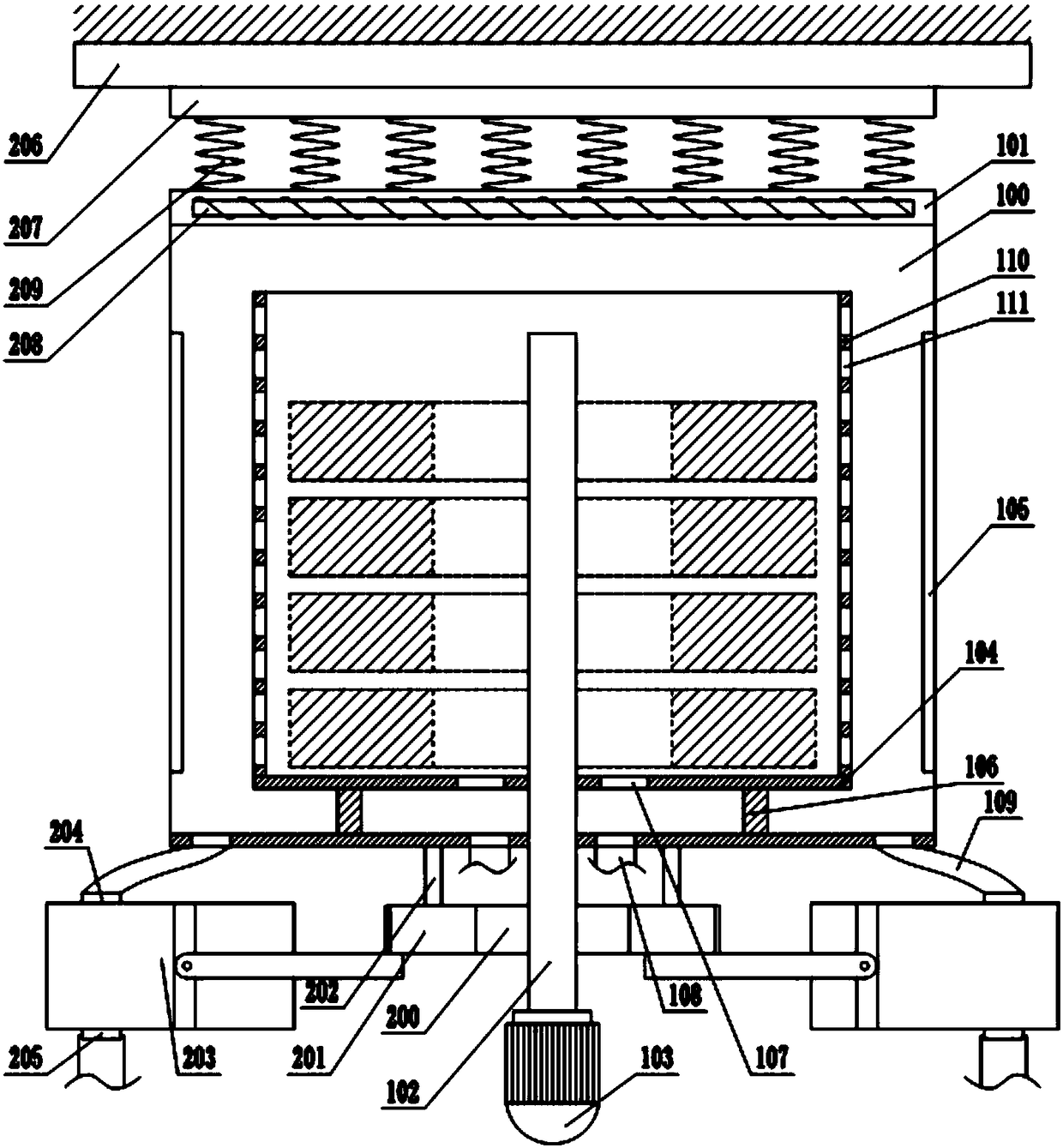

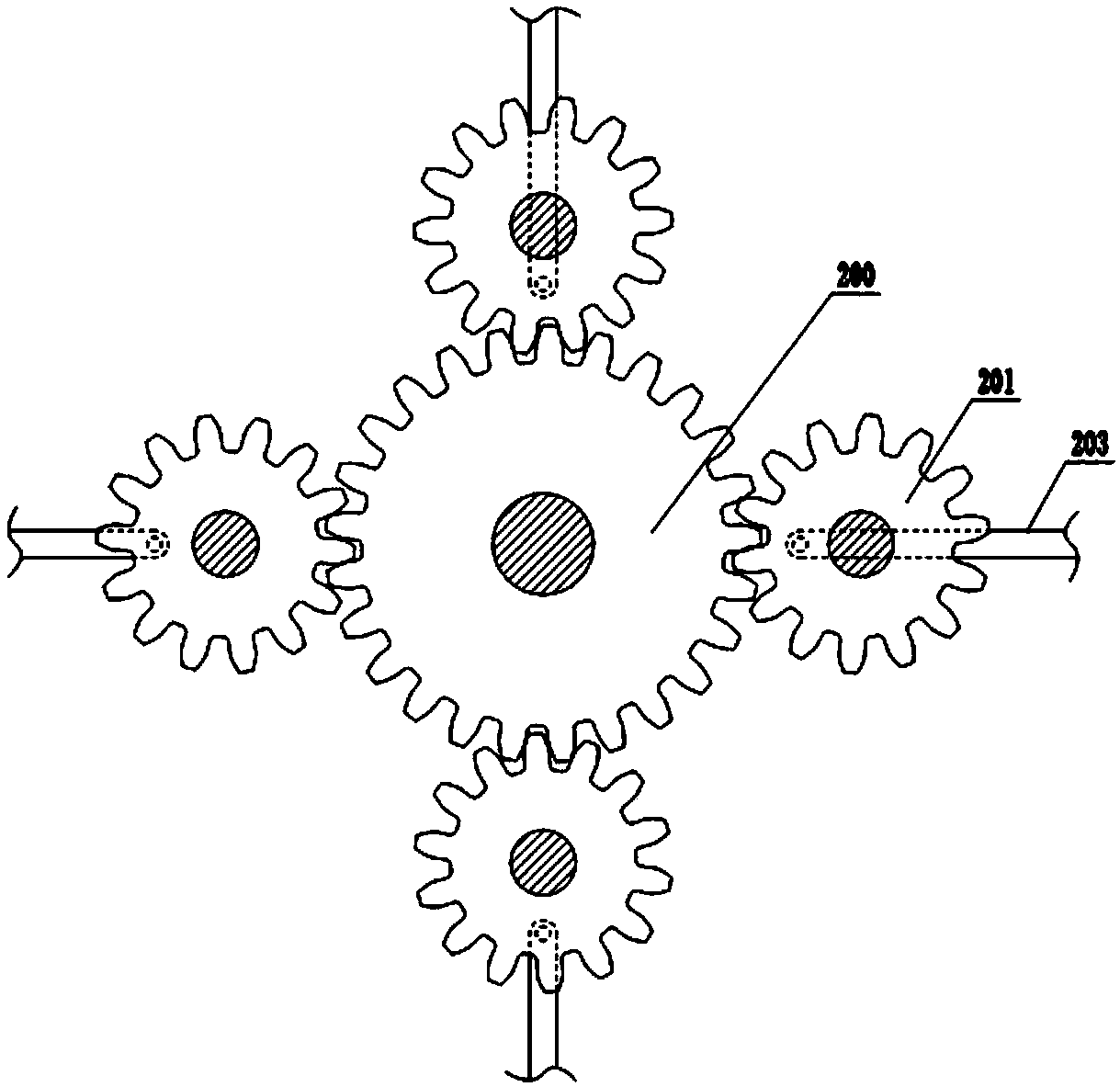

Copper wire circulating heating annealing furnace

ActiveCN108285969AIncrease air pressurePrevent oxidationFurnace typesHeat treatment furnacesCopper wirePiston

The invention discloses a copper wire circulating heating annealing furnace. The copper wire circulating heating annealing furnace comprises an annealing box, wherein a rotating shaft driven by a motor is rotationally connected to the bottom of the annealing box, a rotating disc is fixedly connected to a rotating shaft in the annealing box, electric heating wires capable of being electrified are arranged on the inner wall of the annealing box, a hollow supporting cylinder is arranged between the rotating disc and the bottom of the annealing box, a plurality of hot air holes communicating withthe supporting cylinder are formed in the bottom of the rotating disc in the circumferential direction of the rotating shaft, air inlet pipes communicating with the supporting cylinder are arranged atthe bottom of the annealing box, and air outlet pipes are arranged between the supporting cylinder and the annealing box; the rotating shaft outside the annealing box is fixedly connected with driving gears, the driving gears are meshed with driven gears, the driven gears are connected with air cylinders, air inlet one-way valves and air outlet one-way valves are arranged on the side walls of theair cylinders between the bottom of the air cylinders and pistons, the air inlet one-way valves are connected with the air outlet pipes, and the air outlet one-way valves are connected with the air inlet pipes. According to the technical scheme, heating in the copper wire annealing furnace is uniform, and oxidation and excessively high gas pressure cannot appear.

Owner:重庆博创知识产权运营有限公司

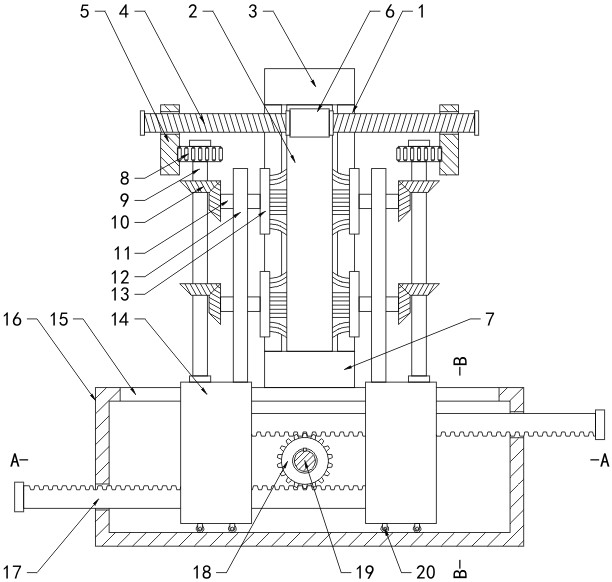

Anti-jamming open-type gate valve

ActiveCN111692356AAffect the tightnessAffect the service lifeOperating means/releasing devices for valvesCleaning using toolsGear wheelEngineering

The invention discloses an anti-jamming open-type gate valve. The gate valve comprises a valve body; a valve seat is arranged at the bottom of the valve body; a movable valve plate is arranged insidethe valve body and realizes opening and closing of the valve body; and a fixed block is fixedly connected with one side, near the top, of the valve plate. According to the gate valve, in the process that a driving member drives the valve plate to move back and forth in the valve body to realize opening / closing of the valve body, synchronous movement of a first rack and a valve door is realized viaconnection of the fixed block and a threaded rod, and under the action of a transmission system which is composed of a first gear, a first rotary shaft, a bevel gear and a second rotary shaft, rotation of a brush is realized; the rotating brush is in contact with the surface of the valve plate which moves relatively, and debris on the valve plate is cleaned, so the influence of overly stacked debris on the sealing effect and service life of the open-type gate valve is avoided; and at the same time, motion of the transmission system is realized by virtue of the driving member of the open-typegate valve, so use of other electrical driving devices is reduced, resources are saved and use cost is lowered.

Owner:ZHEJIANG ZHONGHOU VALVE GRP CO LTD

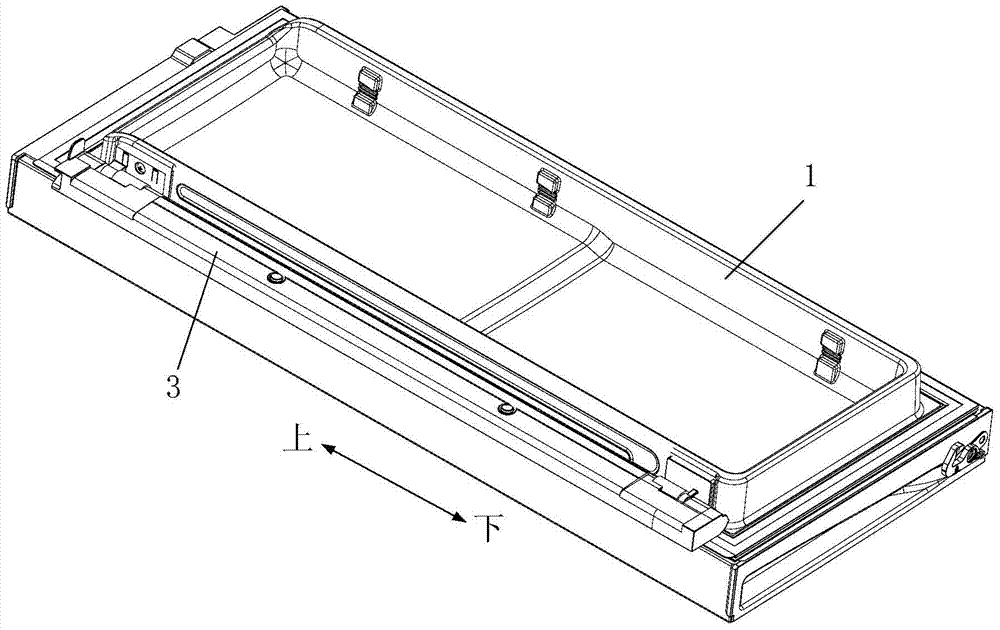

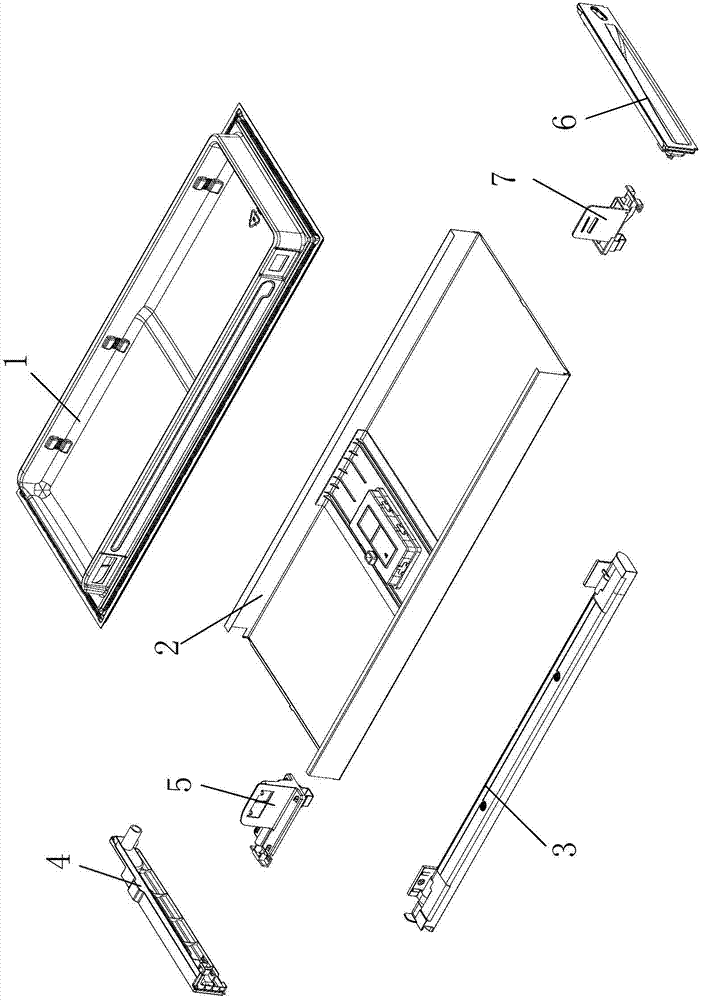

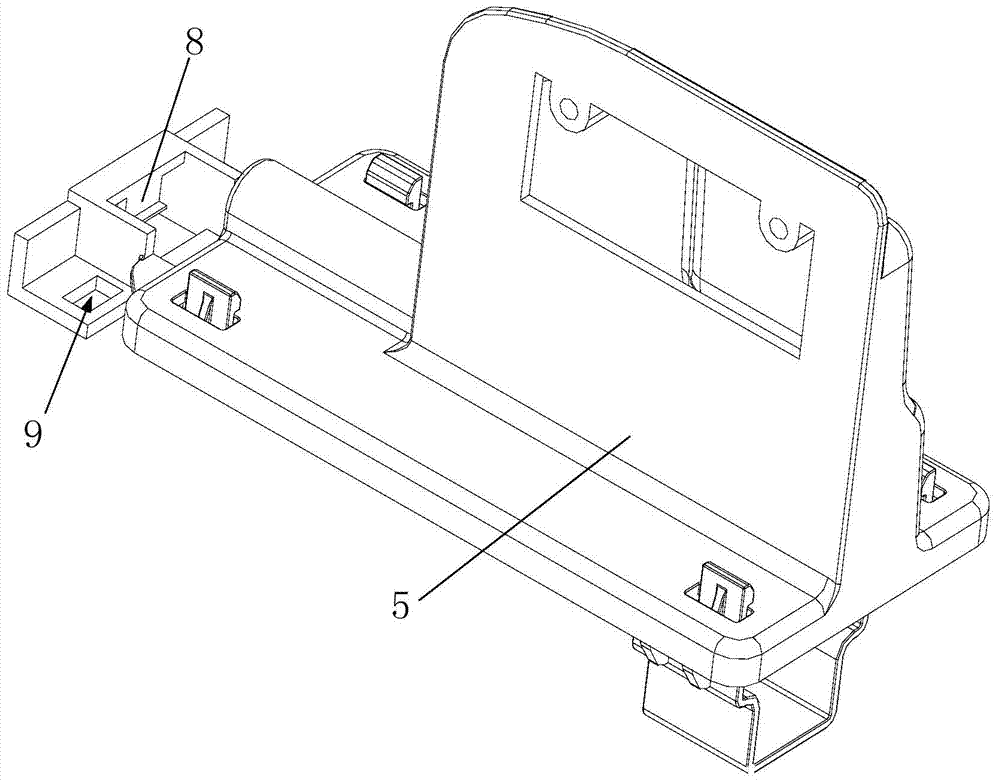

Refrigerator door body

ActiveCN104236226AImprove insulation effectSmall sizeDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

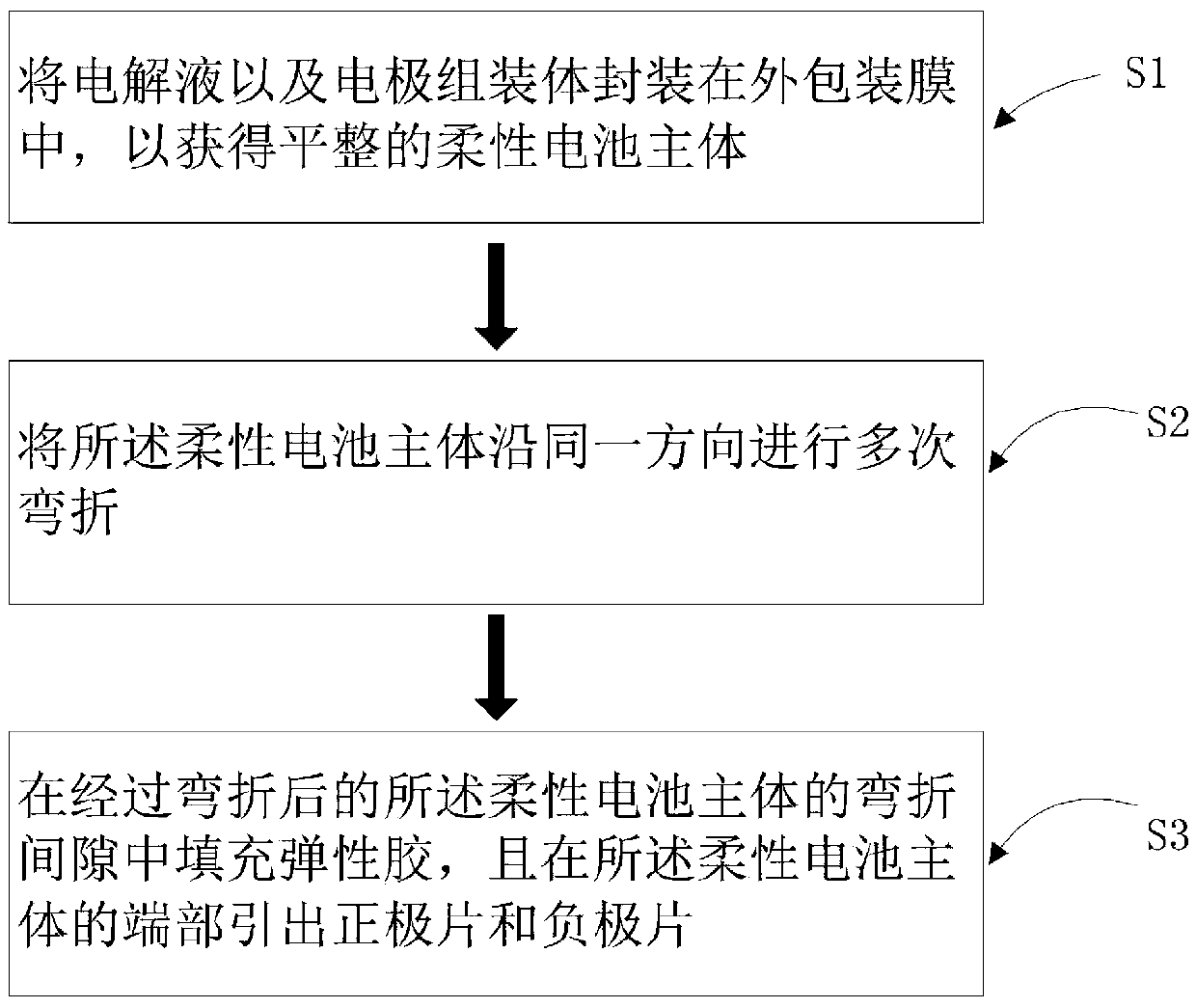

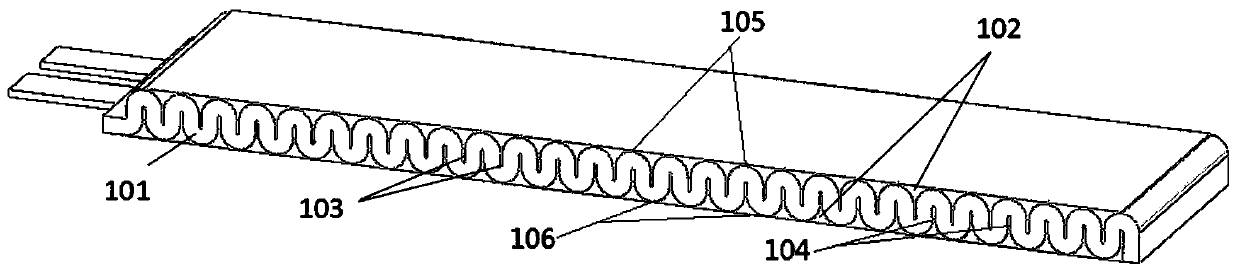

Flexible battery and preparation method thereof

PendingCN109713376AExtend your lifeAffect electrical propertiesFinal product manufactureSecondary cells manufactureElectrical performanceEngineering

Owner:柔电(武汉)科技有限公司 +1

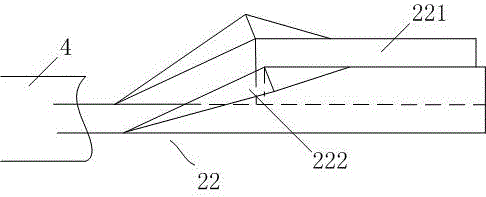

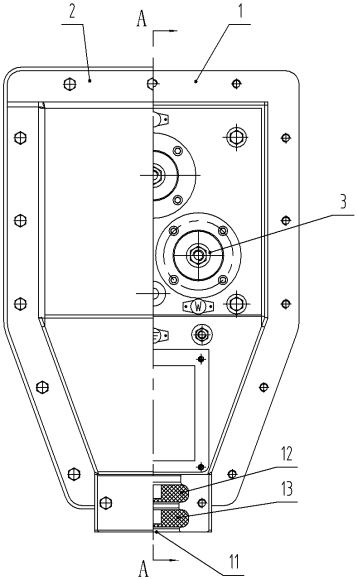

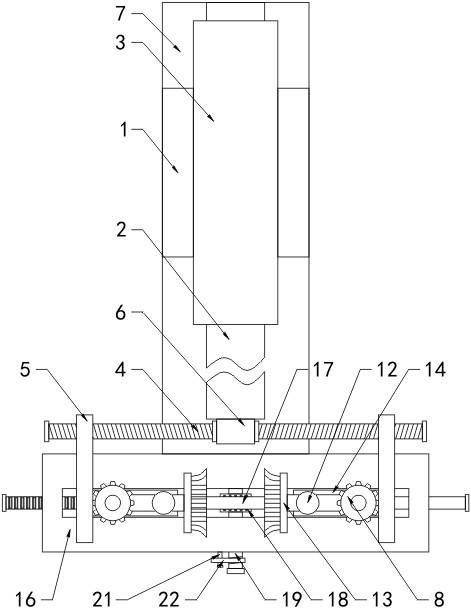

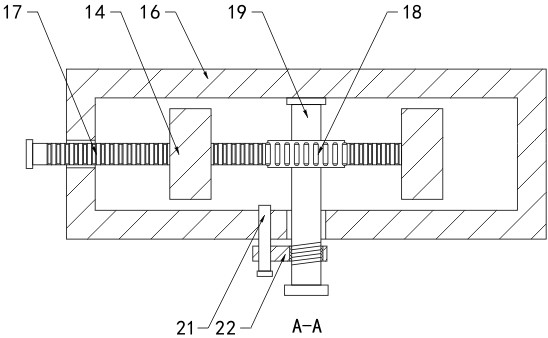

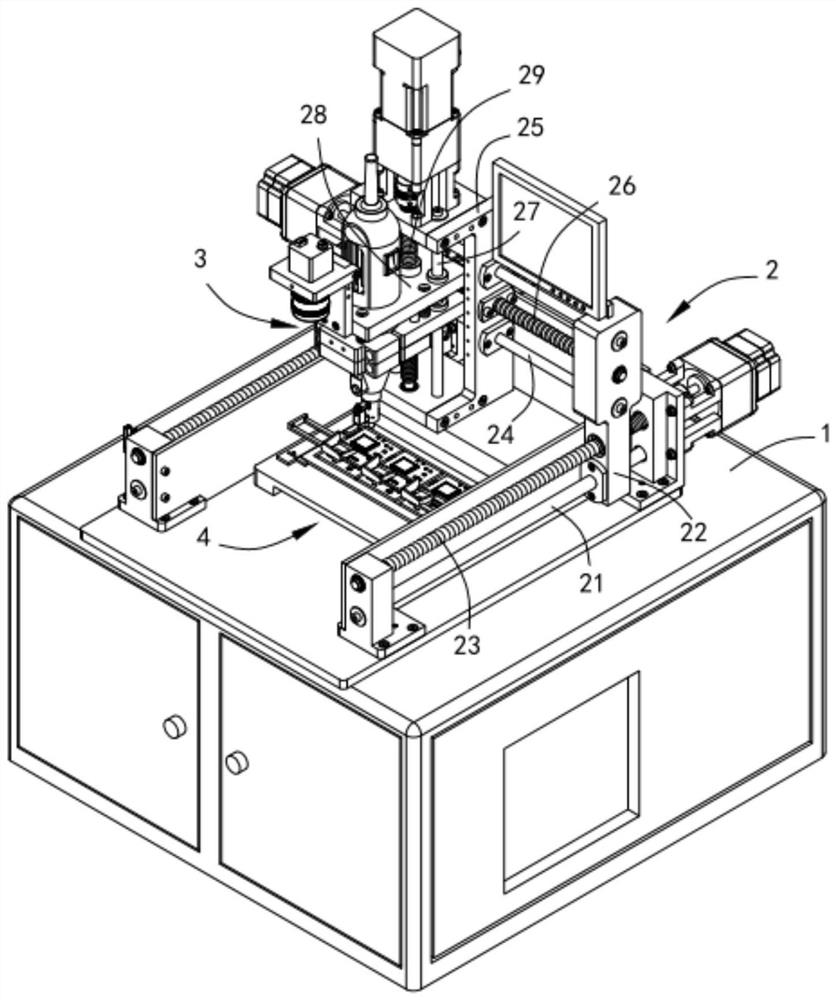

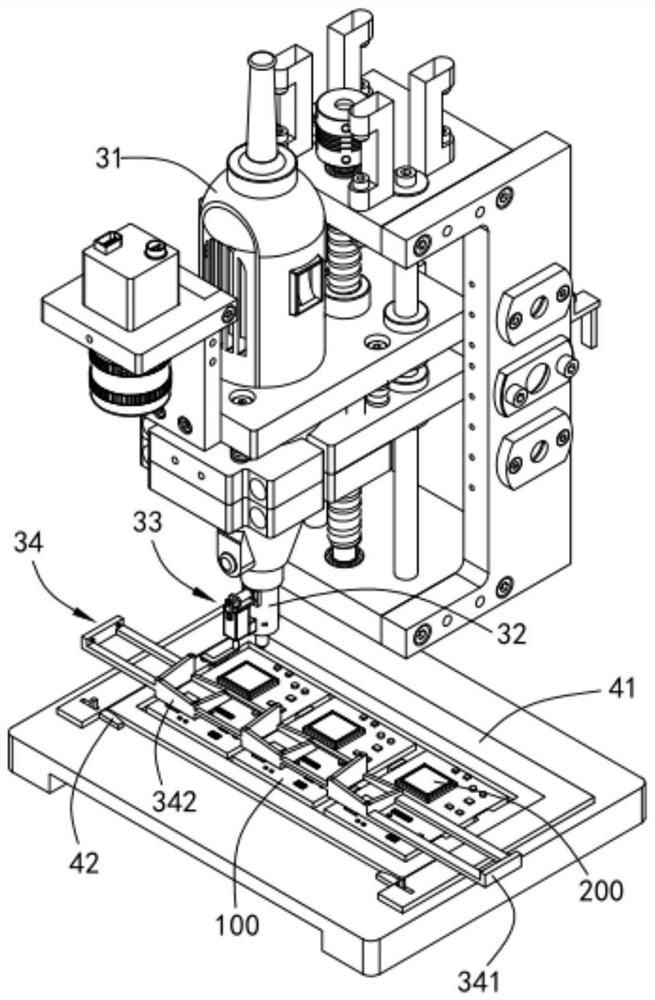

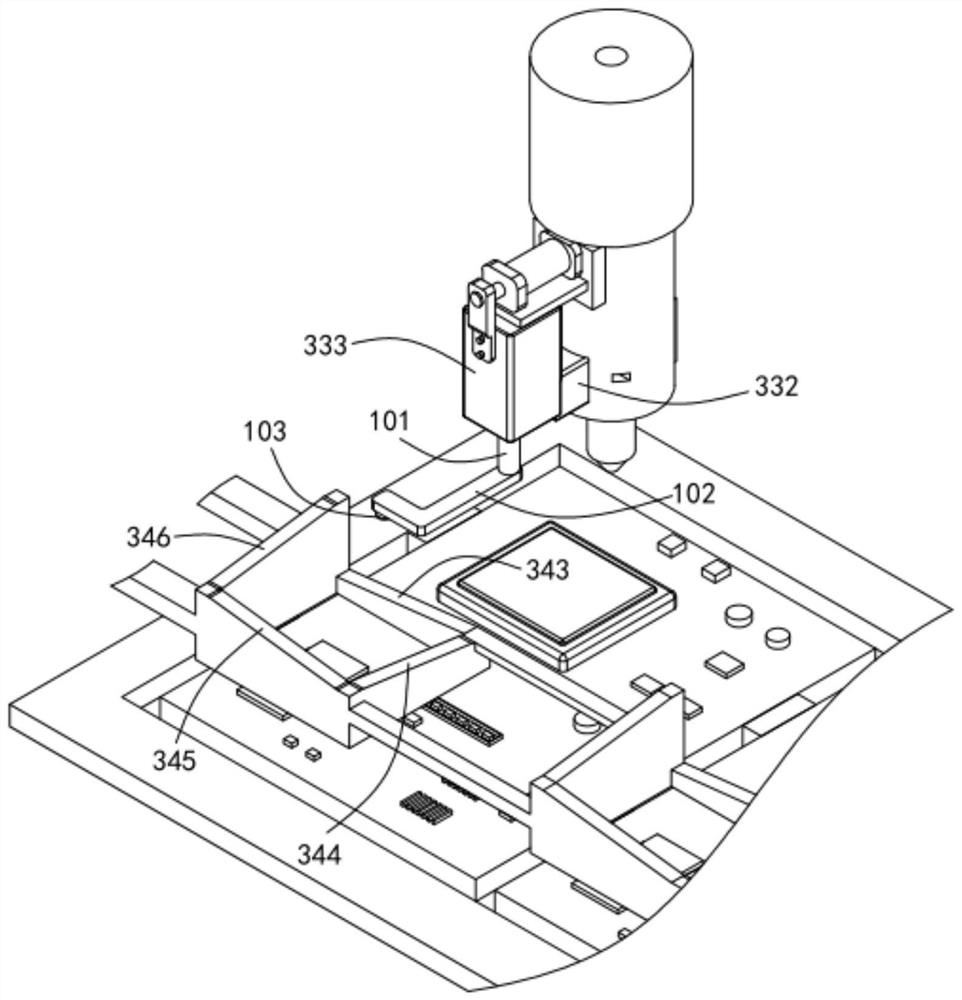

Jet dispensing equipment for chip packaging

PendingCN113477468AThe dosage is easy to controlAvoid the situation where there is a large deviation in the amountLiquid surface applicatorsSpraying apparatusAdhesive glueMachine

The invention relates to jet dispensing equipment for chip packaging. The equipment comprises a machine base, a driving mechanism, a dispensing mechanism driven by the driving mechanism and a positioning clamp arranged below the dispensing mechanism, wherein the dispensing mechanism comprises a glue barrel and a glue outlet pipe arranged at the bottom of the glue barrel, the glue outlet pipe comprises a glue supply section and a glue outlet section, a glue pushing assembly is arranged between the glue supply section and the glue outlet section, a guiding assembly cooperating with the glue pushing assembly is arranged above the positioning clamp accordingly, the glue pushing assembly is used for cutting off communication between the glue supply section and the glue outlet section before glue dispensing operation, and a glue pushing piston arranged in the glue pushing assembly is pushed downwards to extrude glue along an inner wall of the glue outlet section by means of pneumatic pressure under the action of the guiding assembly during the glue dispensing operation. The equipment solves the problems that when glue spraying equipment extrudes the glue, the amount of the glue extruded each time has large deviation, extrusion is uneven, when a translation driving force fault occurs, glue spraying cannot be stopped in time, so that a whole circuit board is easily scrapped. And when a translation driving force fault occurs, glue spraying cannot be stopped in time, so that the whole circuit board is easily scrapped.

Owner:浙江巨创半导体科技有限公司

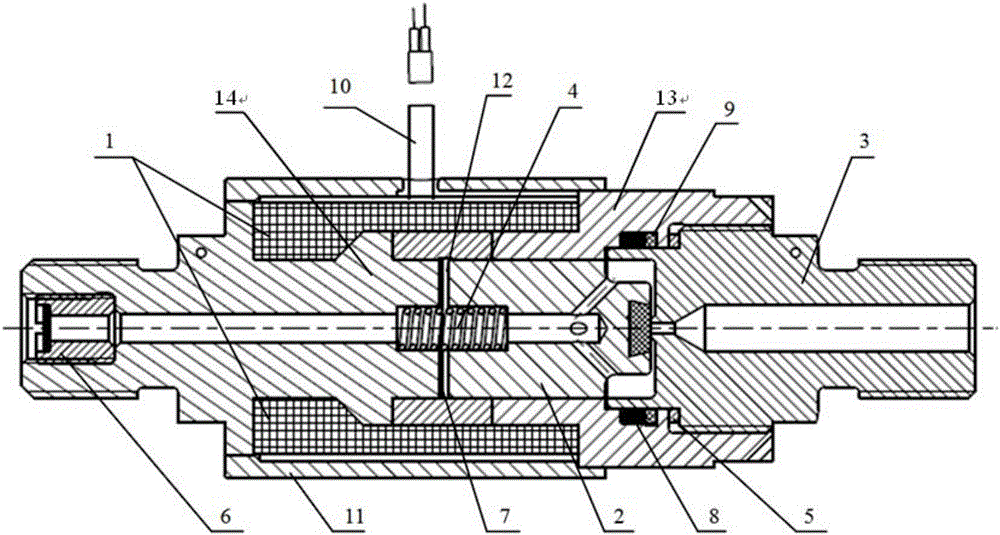

Micro high-pressure two-position two-way solenoid valve

InactiveCN106286855ASafe and reliable workWork reliablyOperating means/releasing devices for valvesLift valveSolenoid valveButt joint

The invention provides a micro two-position two-way solenoid valve which is used in a high-pressure environment and is reliable in sealing and light. The two-position two-way solenoid valve comprises a valve body, a coil assembly, a valve element arranged in the valve body, a valve base, a spring applying force to the valve element and an air inlet connector. A polygon and rectangle combined irregular coil window structure is adopted for the coil assembly of the solenoid valve, redundant space in an electromagnet magnetic path is designed into an irregular coil window, the space in the electromagnet magnetic path is fully utilized to achieve the compact structure, the size is reduced, and the mass is reduced. A mushroom-shaped sealing mode with the flat end face and a trapezoidal boss in butt joint is adopted in the valve element and valve base sealing structure; an O-shaped sealing ring, a plastic check ring and a metal gasket are sequentially arranged at the connecting end of the valve base and the valve element to achieve multiple redundant sealing. It is guaranteed that miniaturization design is achieved during safe, reliable and lasting work in the high-pressure environment, and the production cost is greatly reduced.

Owner:XIAN AEROSPACE PROPULSION INST

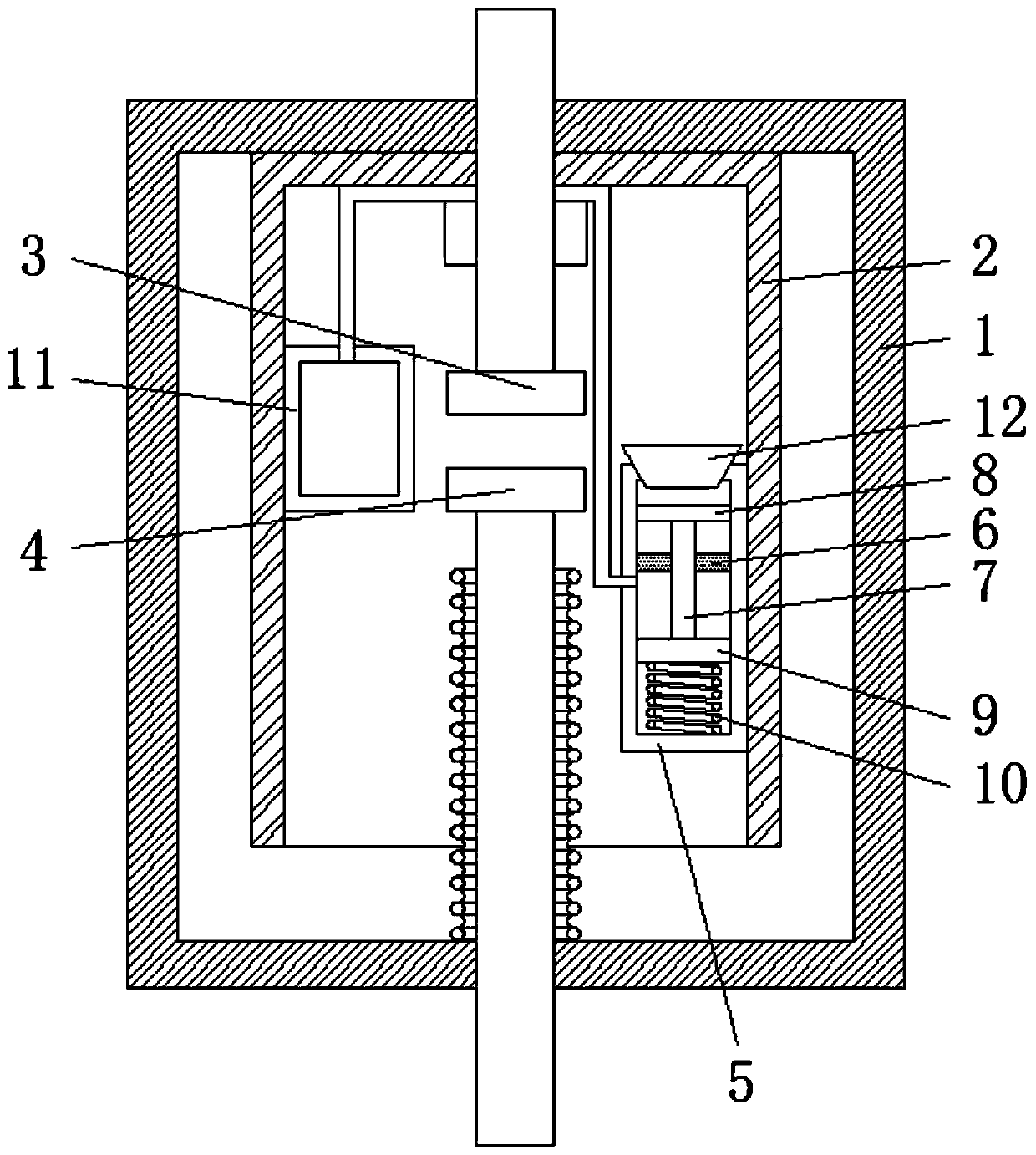

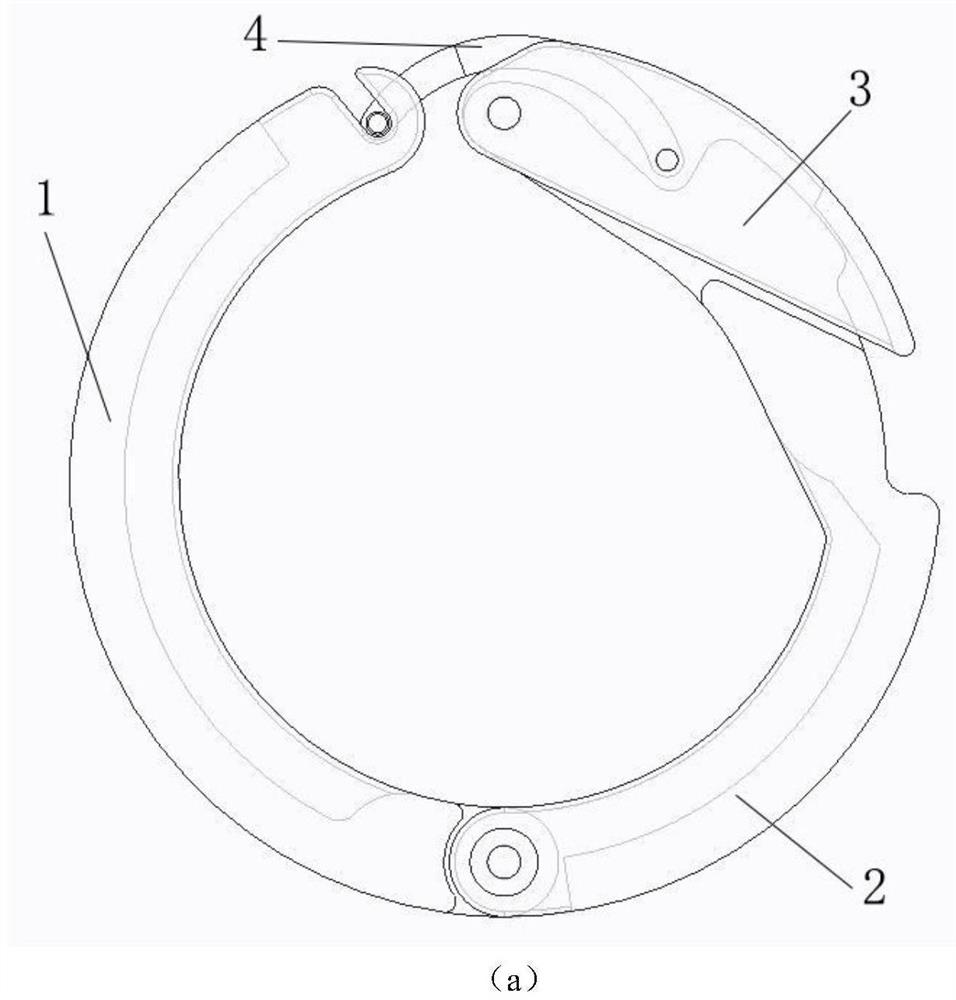

Vacuum arc-extinguishing chamber contact protection device

ActiveCN110828228AEasy to useReduce metal vapor contentHigh-tension/heavy-dress switchesContacts enclosures/screensElectric power equipmentEngineering

The invention relates to the technical field of power equipment, and further discloses a vacuum arc-extinguishing chamber contact protection device that comprises an insulating cover, a main shieldingcover, a static contact and a moving contact; a suction pipe is fixedly connected to the inner wall of one side of the main shielding cover, a sealing piston is fixedly installed on the inner wall ofthe suction pipe, a plunger rod is arranged in the suction pipe and movably connected with the sealing piston in a sleeved mode, and an upper plunger and a lower plunger are fixedly connected to theupper end and the lower end of the plunger rod respectively. A heat collection box and the suction pipe are arranged on the two sides of the contact respectively; on one hand, part of metal steam is received in time through the side edge of the heat collection box; on the other hand, after the heat collection box absorbs heat, internal gas expands, and the lower plunger is pushed to move downwards, so that a similar injector composed of the upper plunger and the suction pipe can suck the metal steam near the contact in time; the content of the metal steam at the contact can be quickly reducedby matching with the heat collection box, the amount of the metal steam falling back to the surface of the contact is greatly reduced, and the use safety of the contact is protected.

Owner:ZHEJIANG TAIKONG ELECTRIC CO LTD

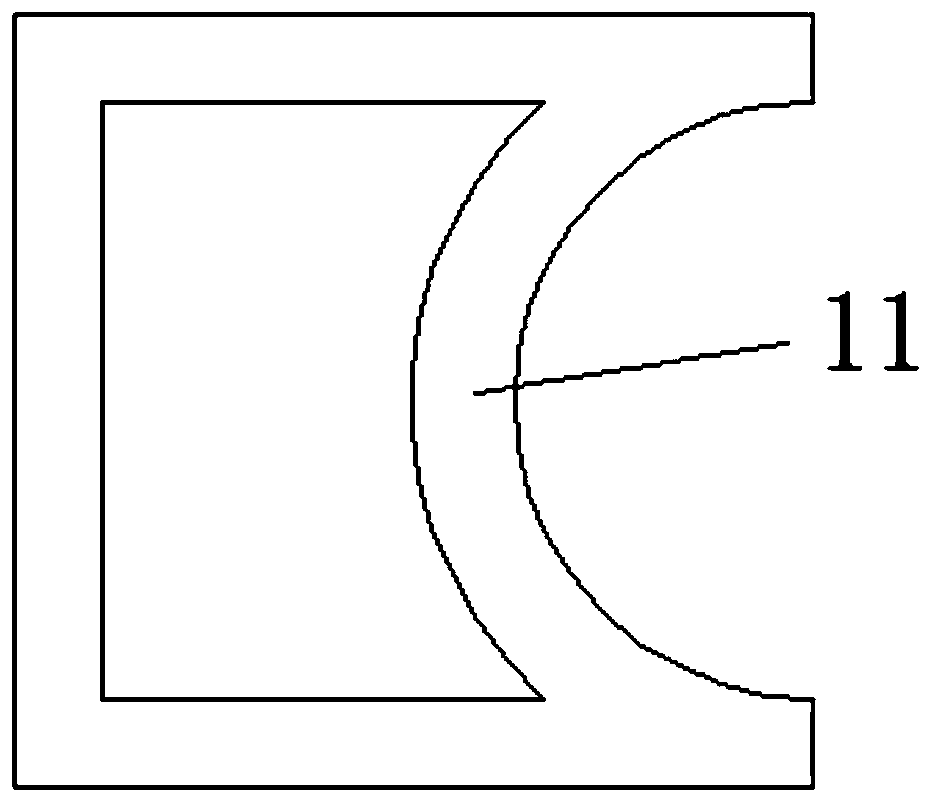

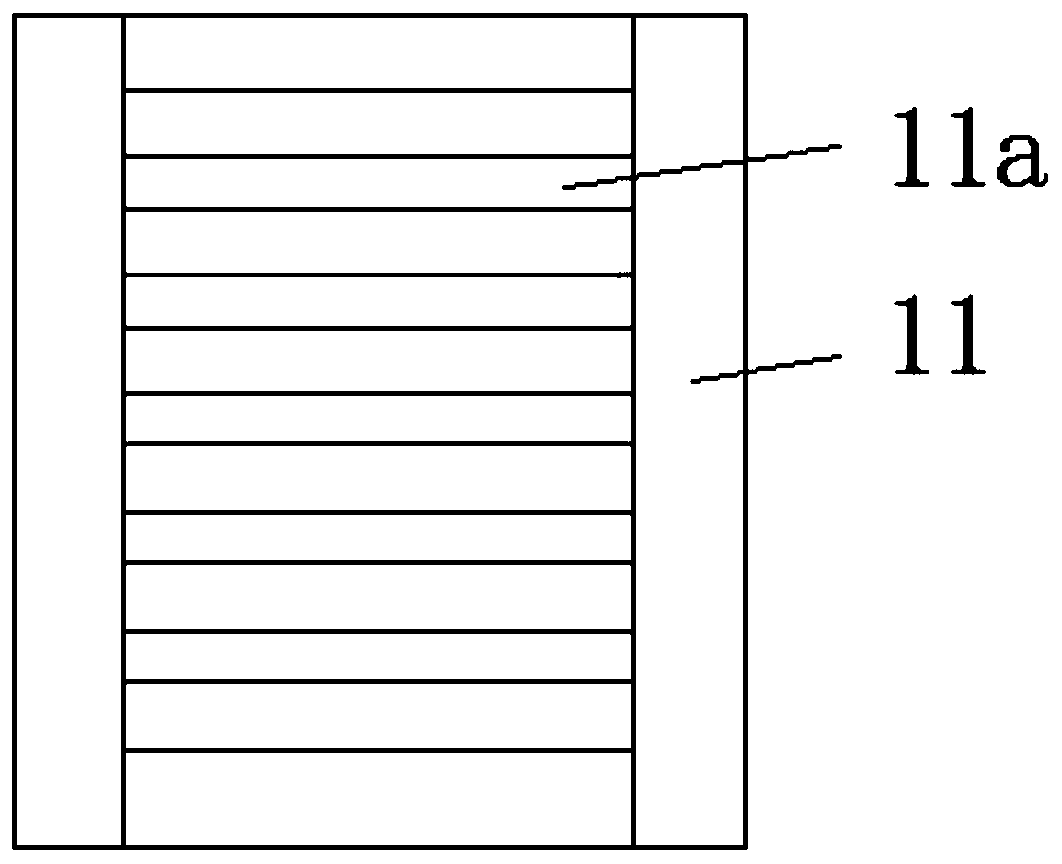

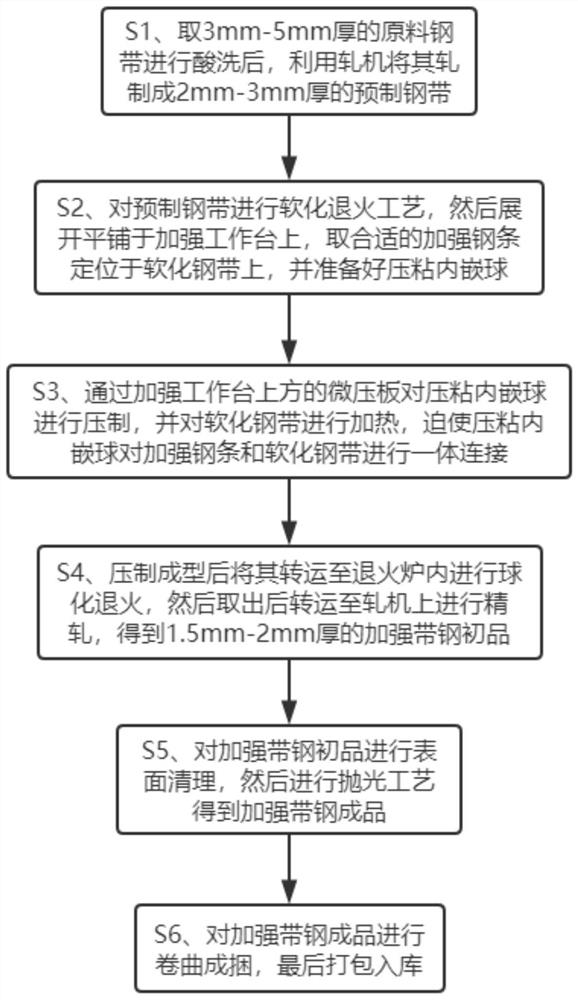

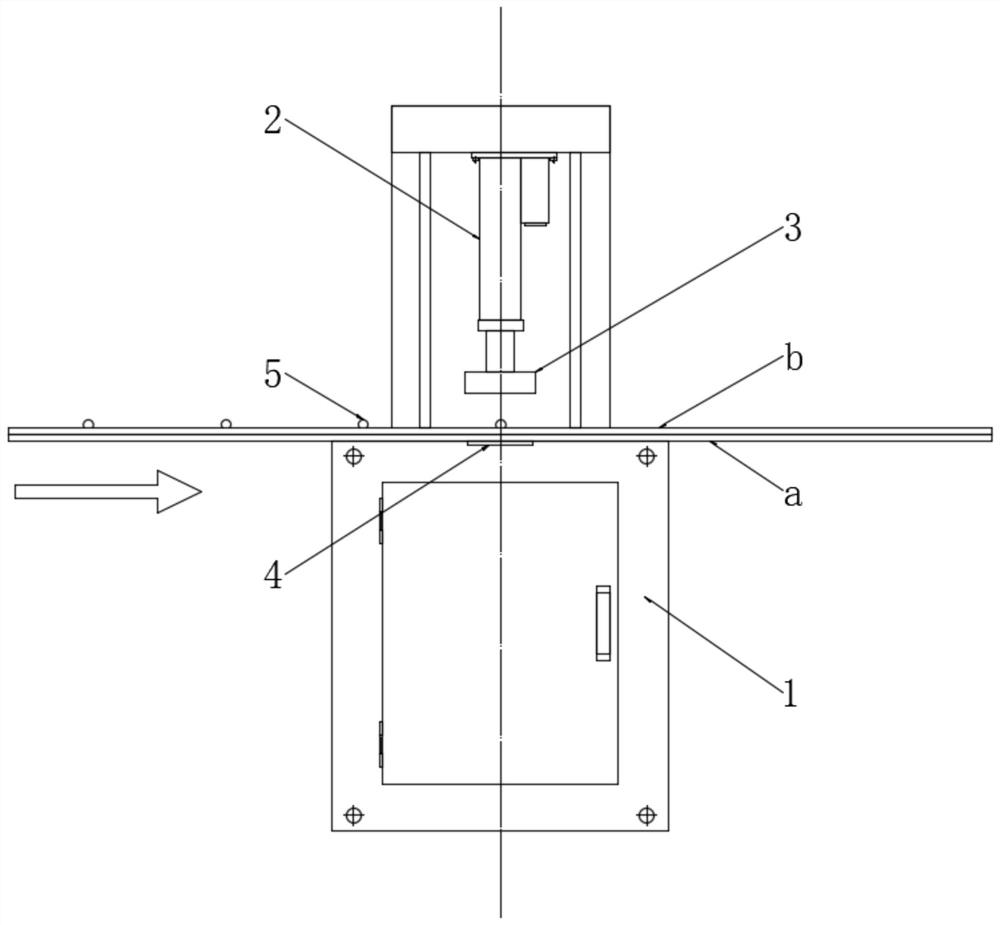

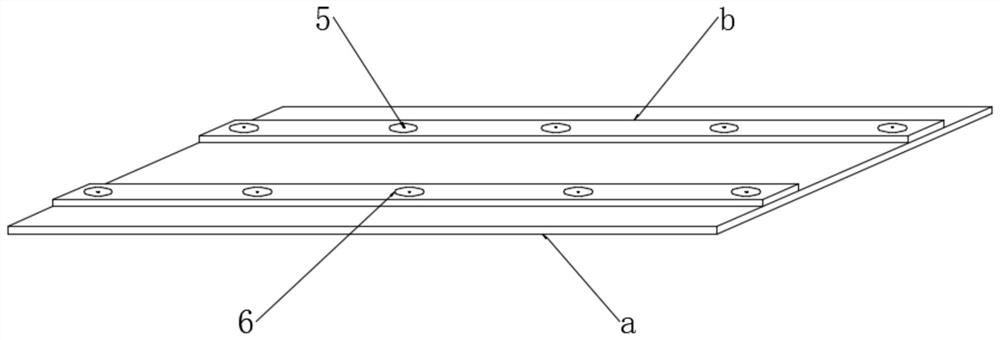

Machining technology of reinforced strip steel

PendingCN112503382AAchieving an all-in-one connectionSimple processing technologyShaping toolsElongated constructional elementsStrip steelMachining process

The invention discloses a machining process of reinforced strip steel, and belongs to the technical field of strip steel machining. The machining process of strip steel can be optimized, a reinforcingsteel bar is introduced to reinforce the strip steel, an extrusion connection mode using pressing-bonding embedded balls is innovatively adopted, then punched sunken holes in the reinforcing steel bar are forced to deform and be embedded into the strip steel in annular protrusions, then the deformed punched sunken holes are filled with bonding resin particles released in the pressing-bonding embedded balls for high-strength bonding, so that integrated connection between the reinforcing steel bar and the strip steel is realized, the connection strength is high, the stripping and falling phenomena seldom occur, meanwhile, the pressing-bonding embedded balls are directly and permanently embedded in the punched sunken holes, so that the effect of a connecting medium between the reinforcing steel bar and the strip steel is achieved, in addition, the stable ball structure of the pressing-bonding embedded balls can reinforce the area near the punched sunken holes, therefore, the strip steelis effectively and stably reinforced, and the mechanical strength of the strip steel is greatly improved.

Owner:刘伟良

Portable disinfection liquid generator

The invention provides a portable disinfection liquid generator. The disinfection liquid generator comprises a battery, an anode piece electrically connected with the cathode of the battery and a cathode piece which is electrically connected with the anode of the battery, wherein the anode piece is a silver piece or a silver alloy piece, and a water-proof seal cavity used for wrapping the batteryis formed outside the battery. By putting the disinfection liquid generator into water, silver ions can be released in water by using an electrolytic reaction to form a silver ion disinfection liquid,the disinfection liquid can be prepared according to the needs, and the problems of wasting, contamination and storage safety of the disinfection liquid can be effectively solved. Besides, it is notrequired that an electrolytic cell body and other large-sized parts are arranged, the disinfection liquid generator is convenient to take when a user goes out, and the application range is relativelywide.

Owner:朱君秋

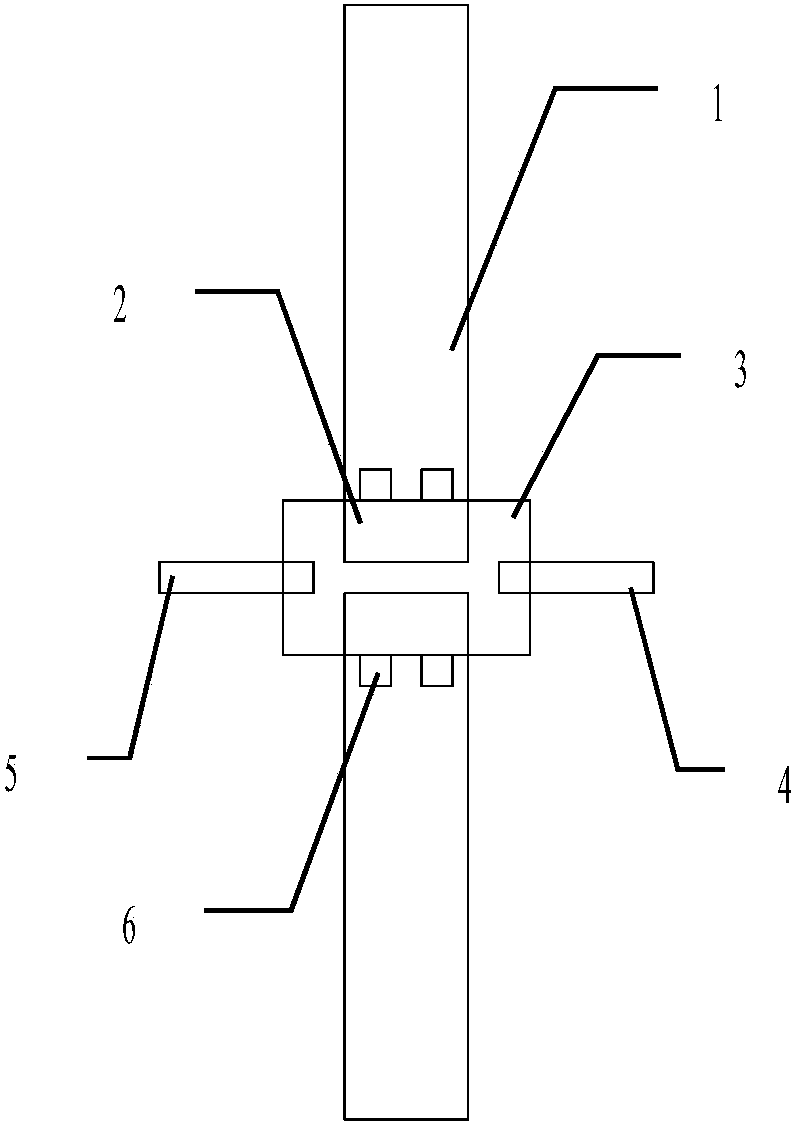

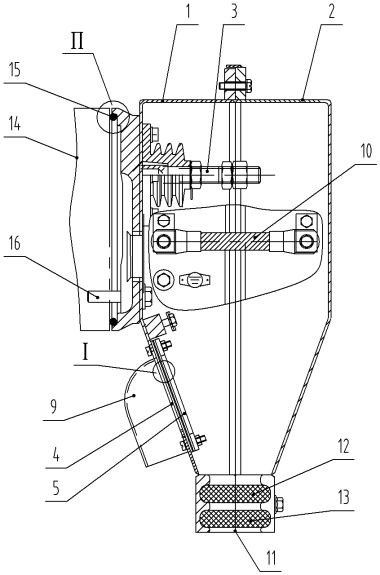

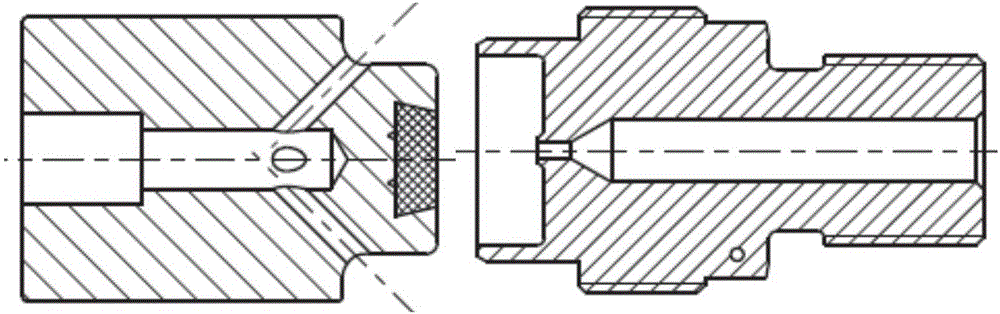

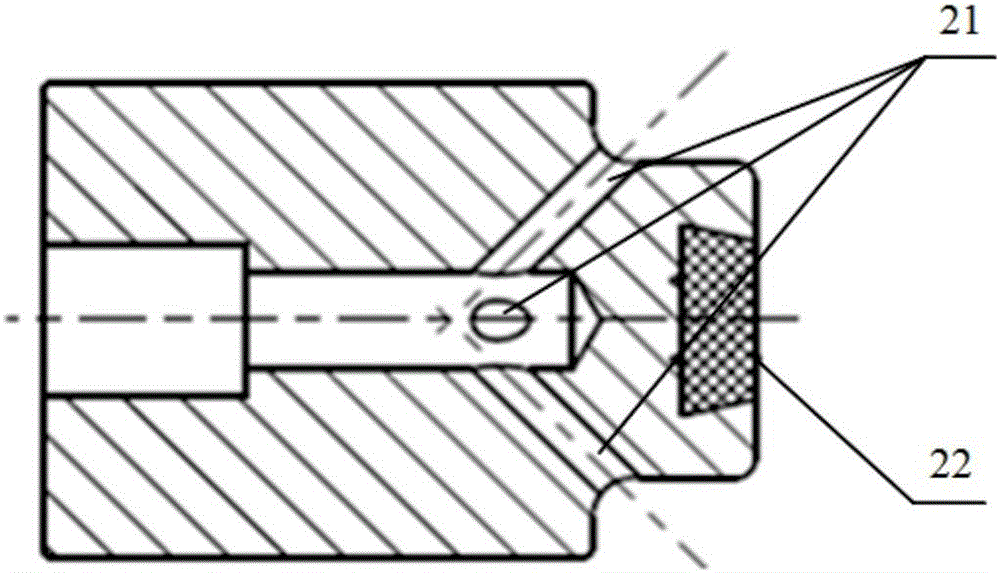

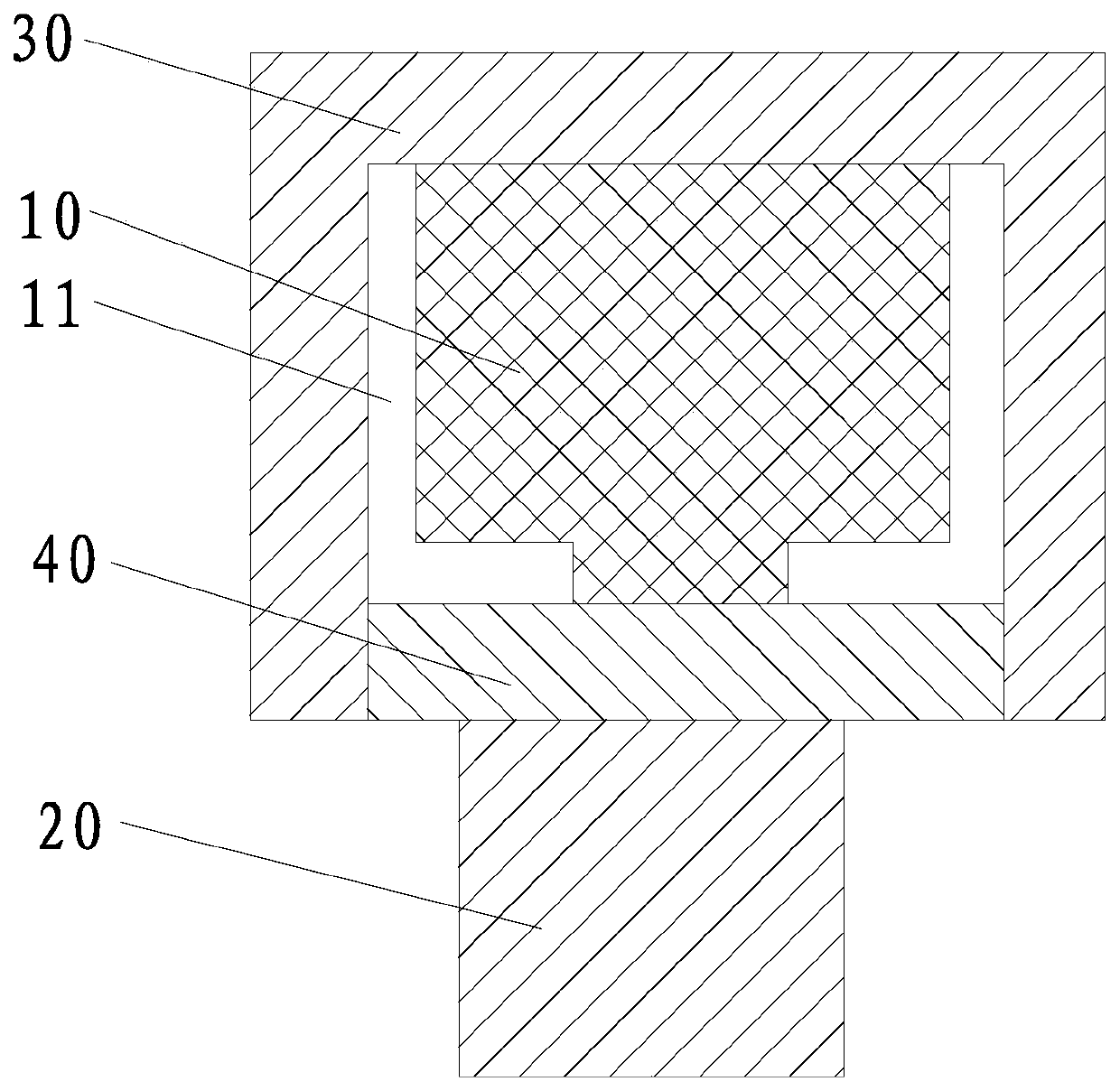

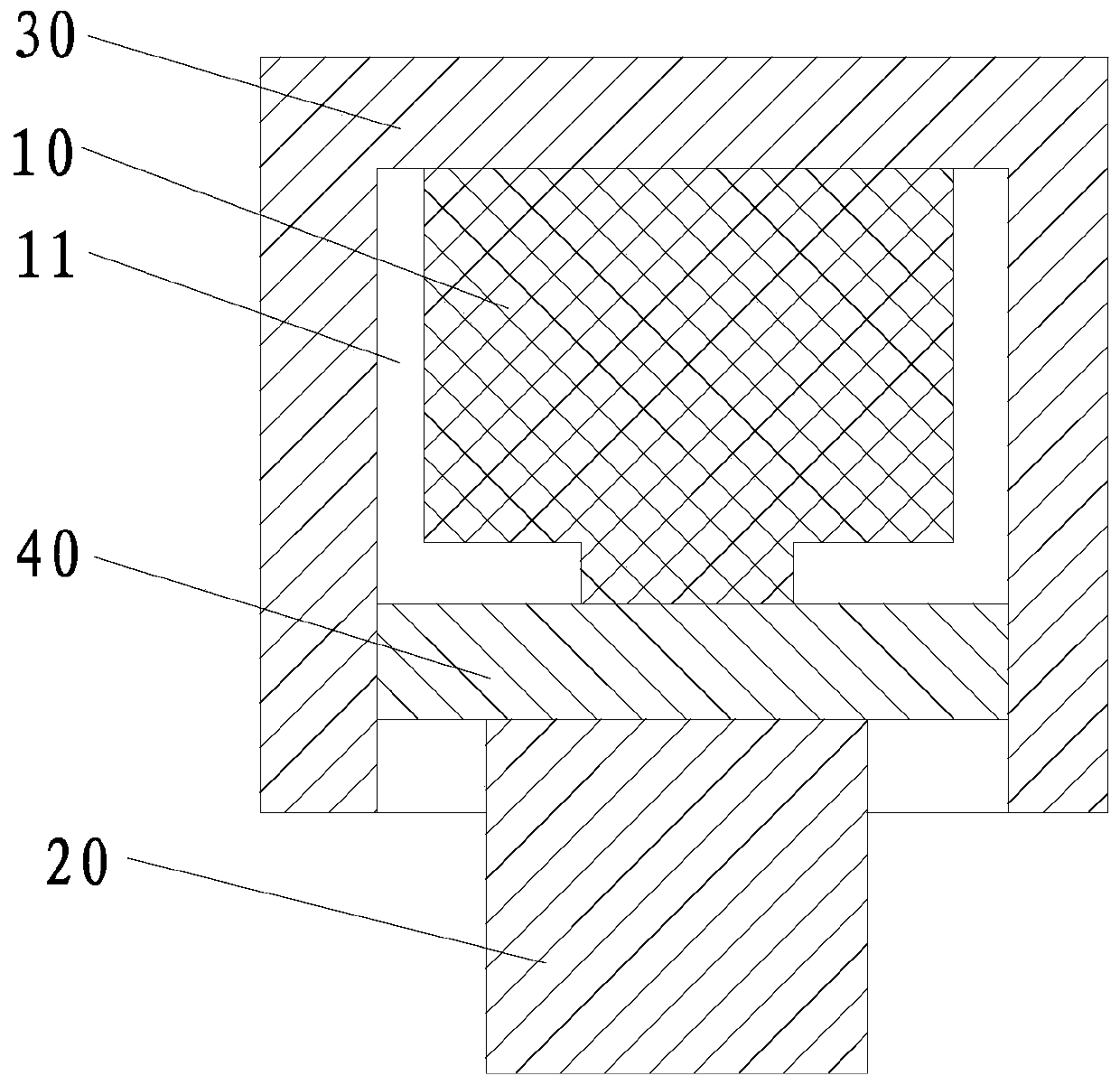

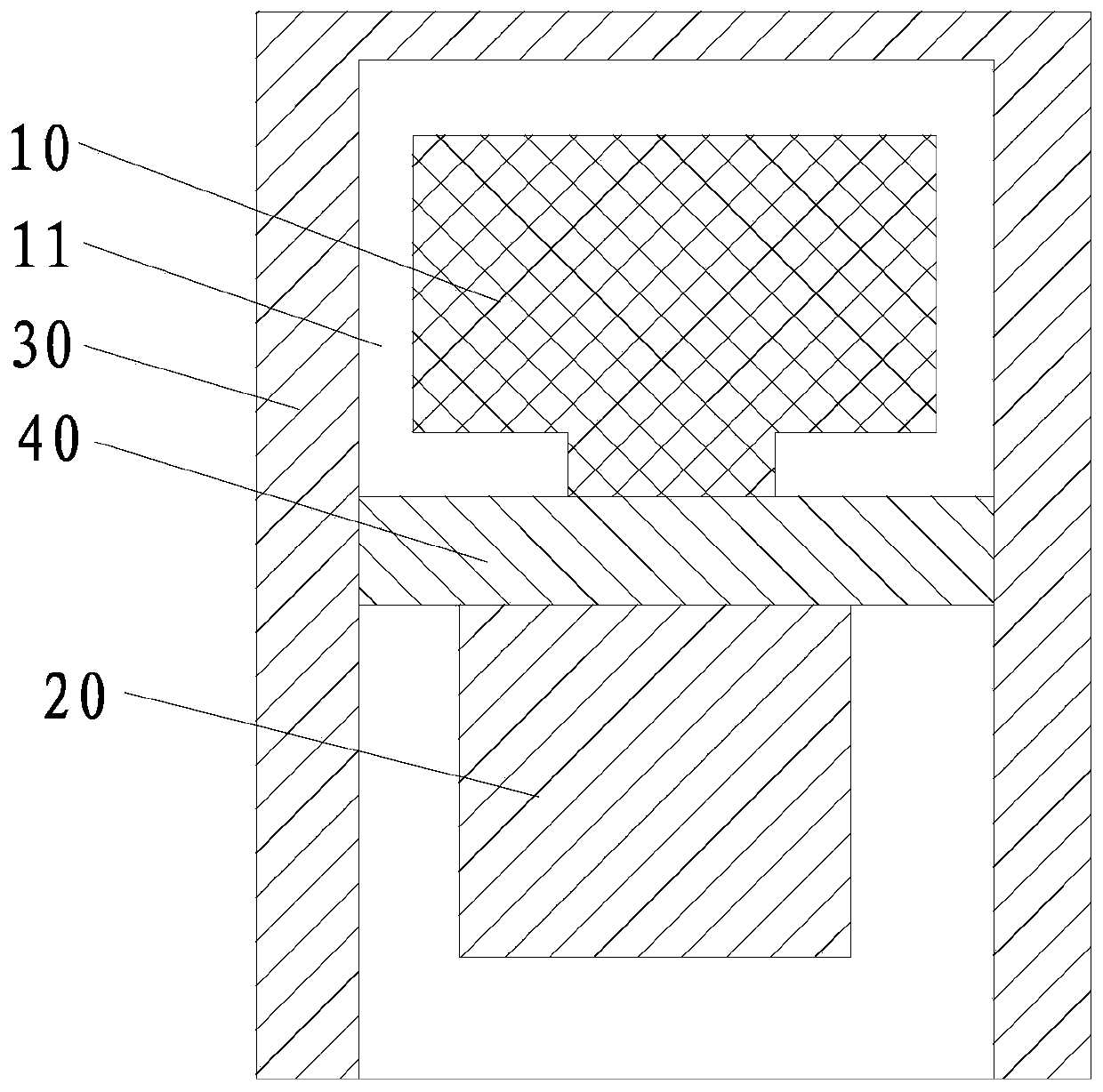

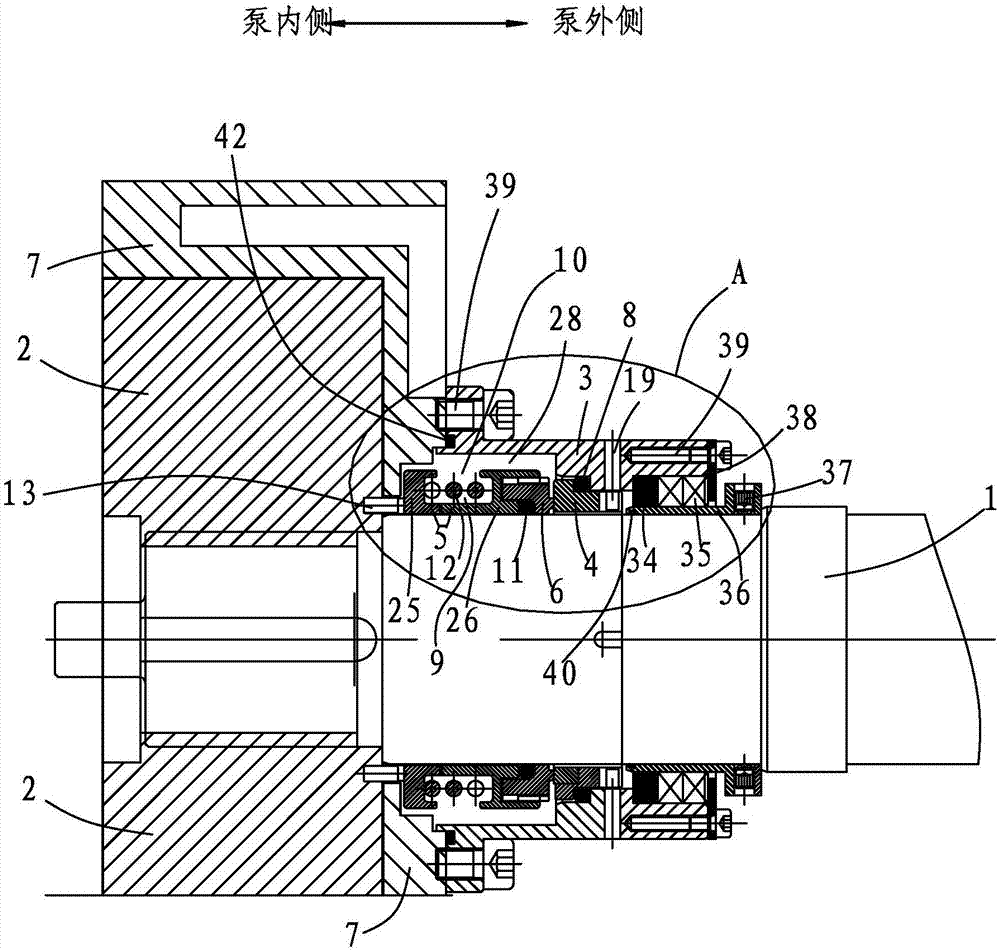

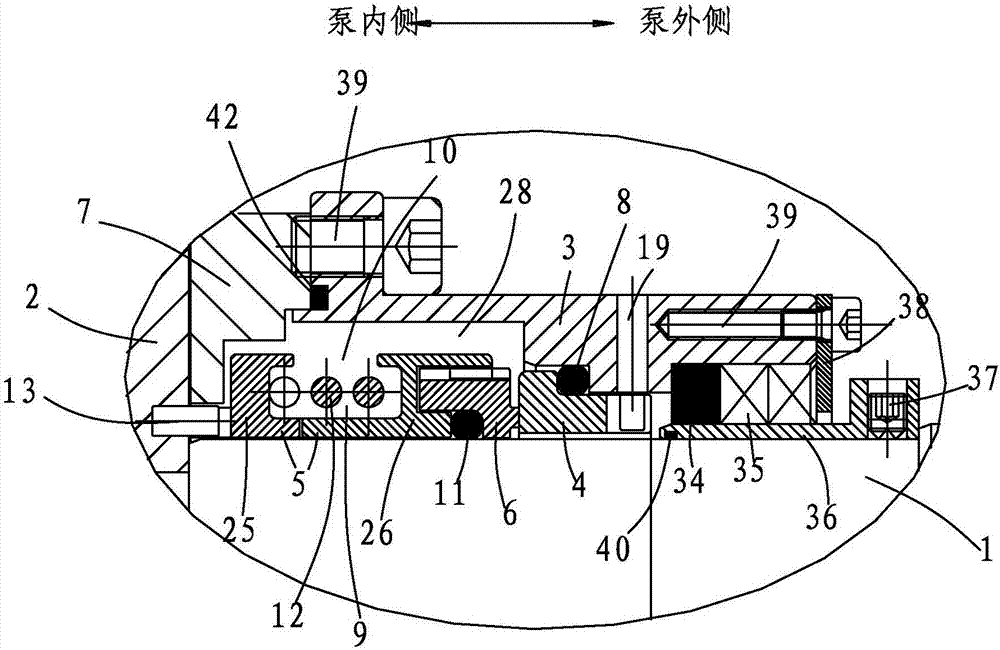

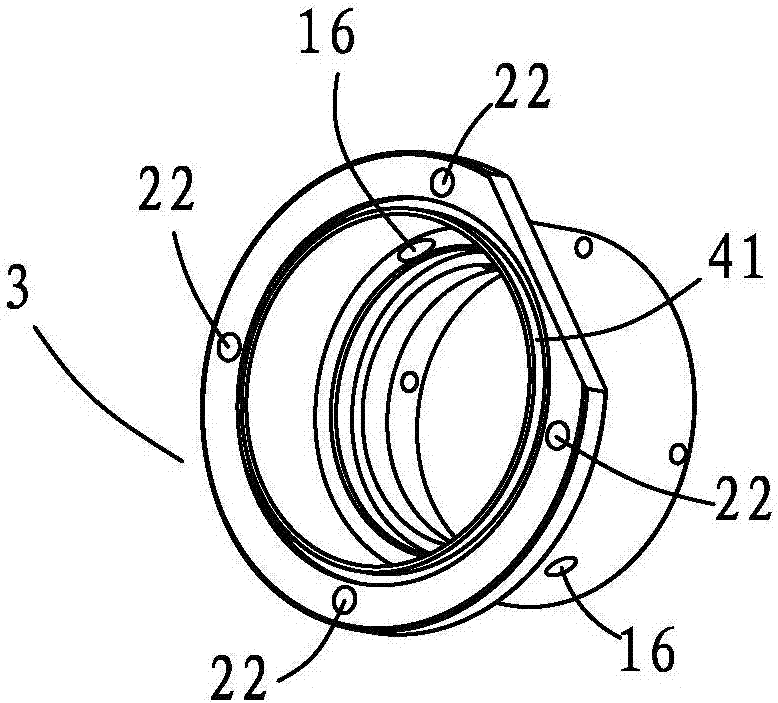

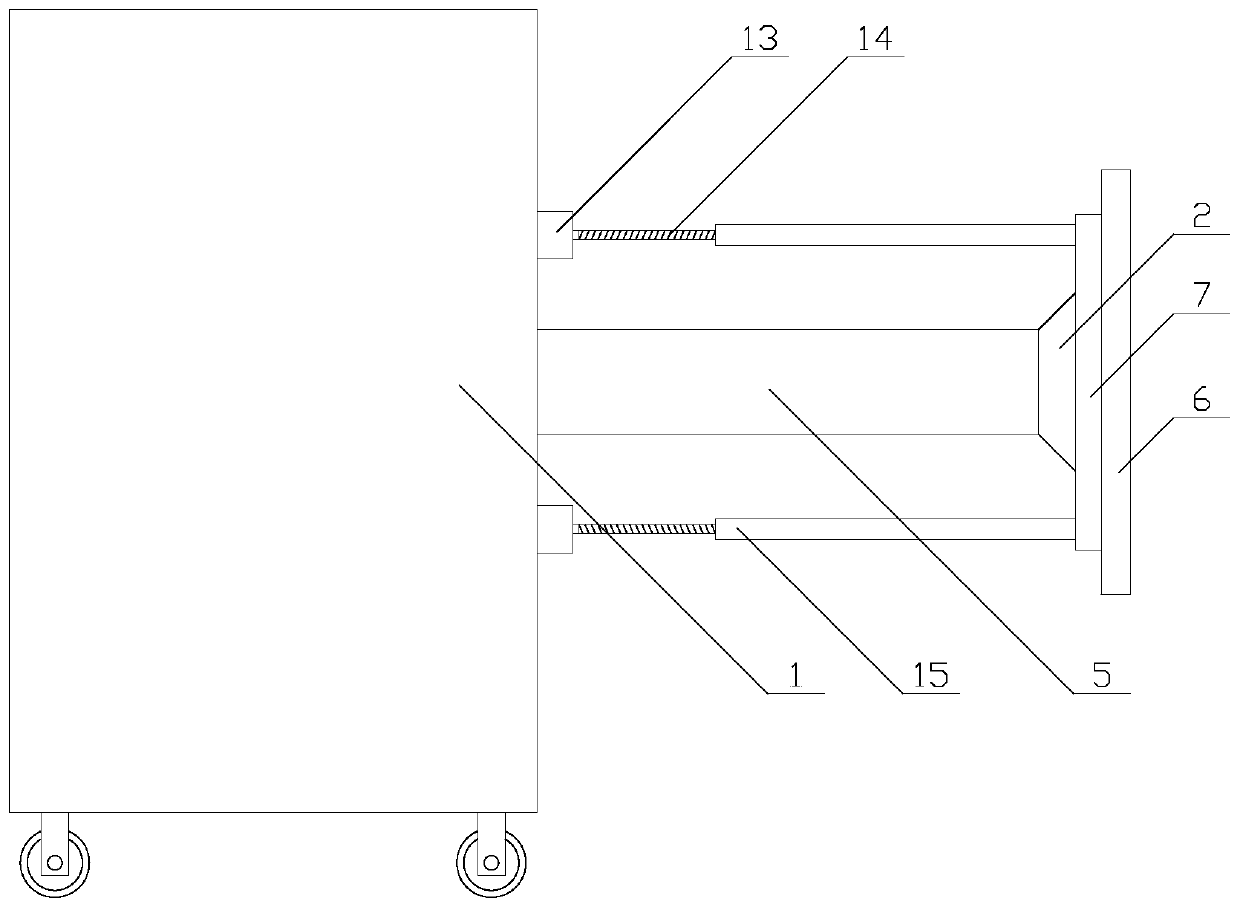

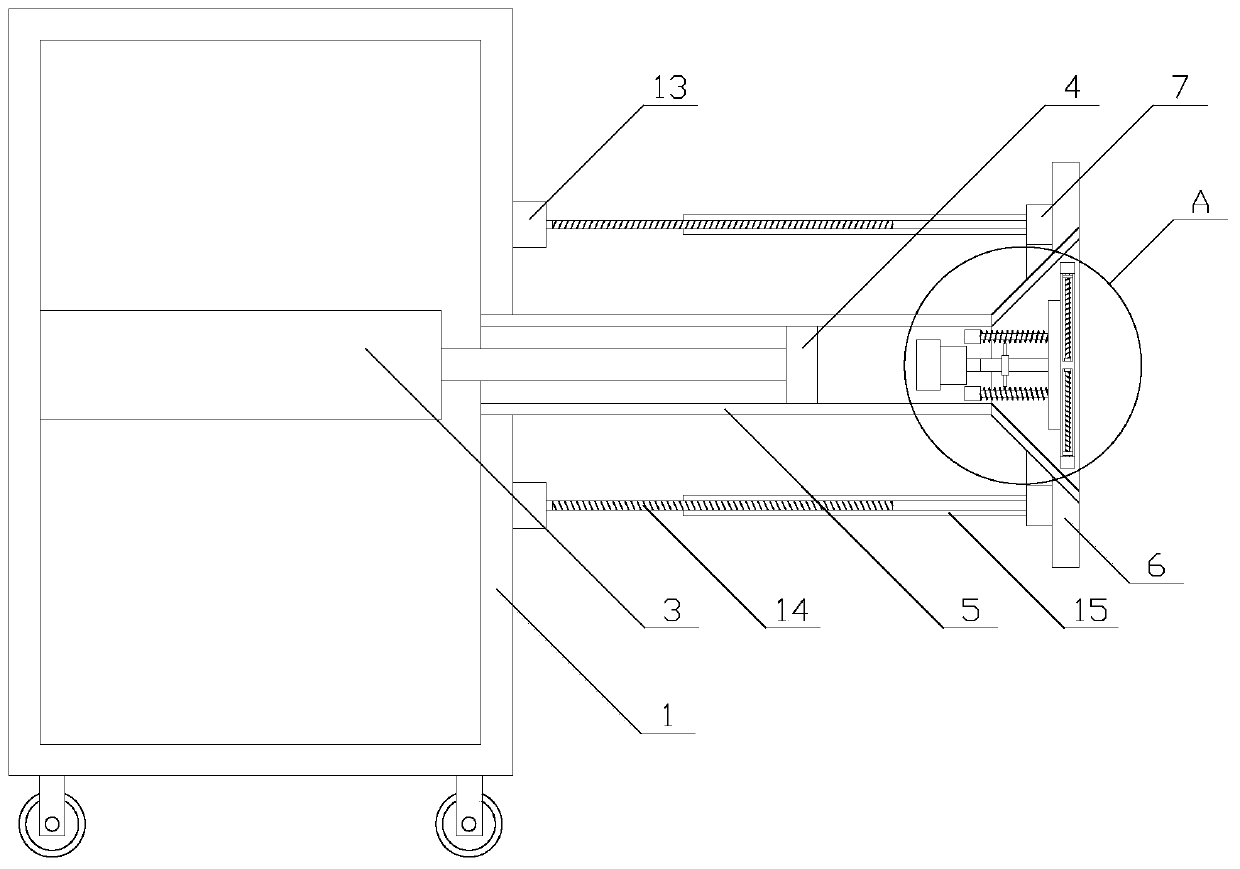

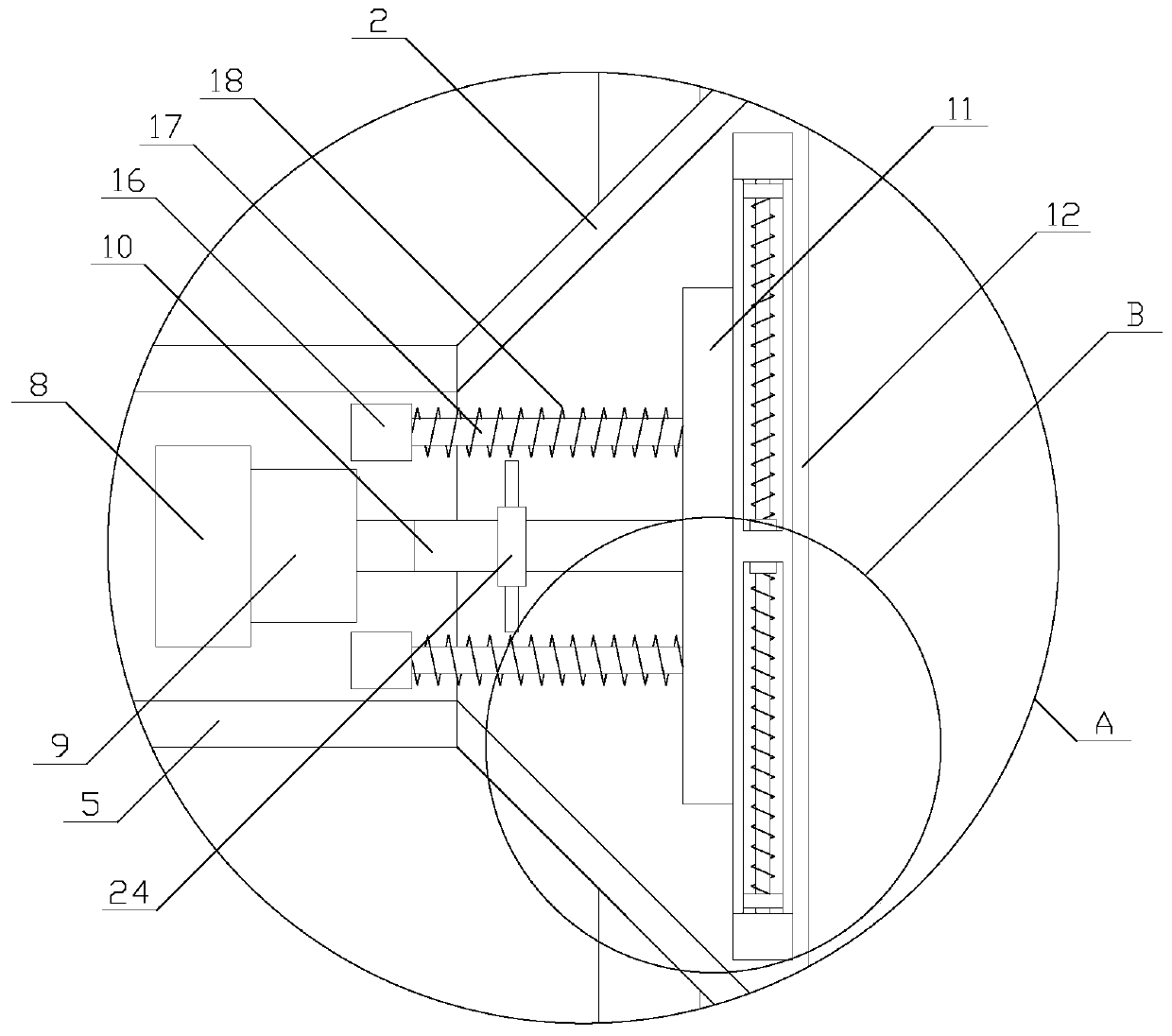

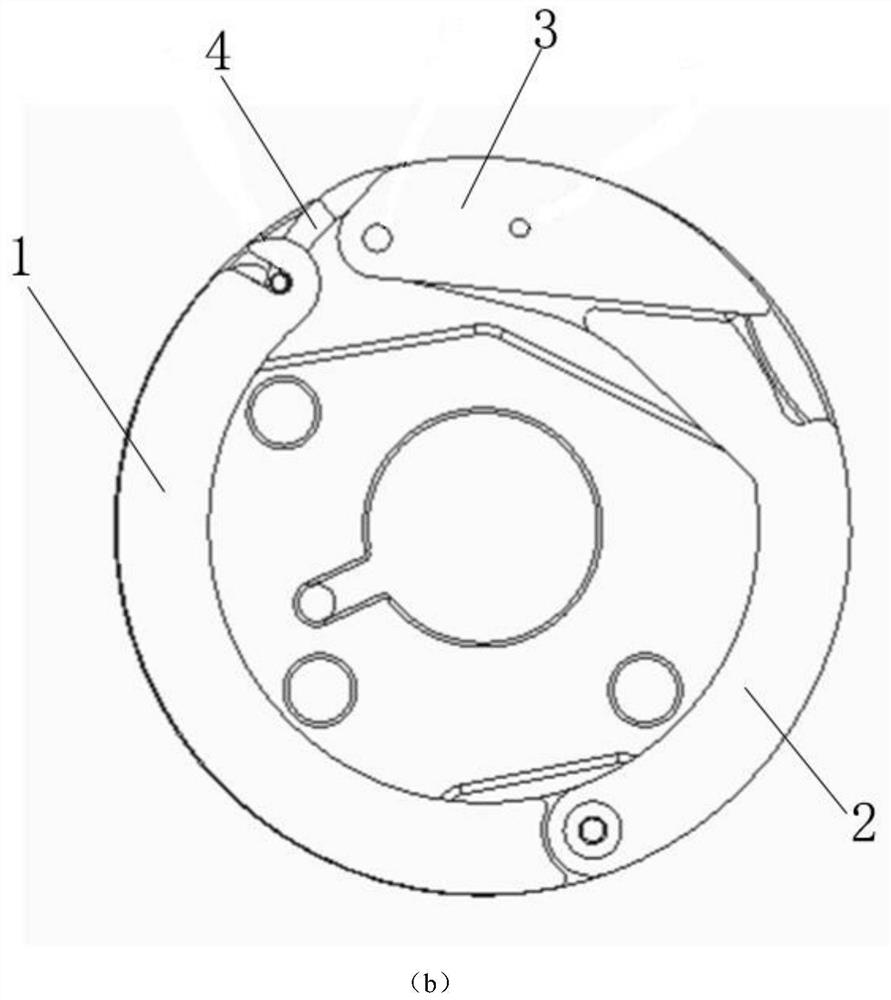

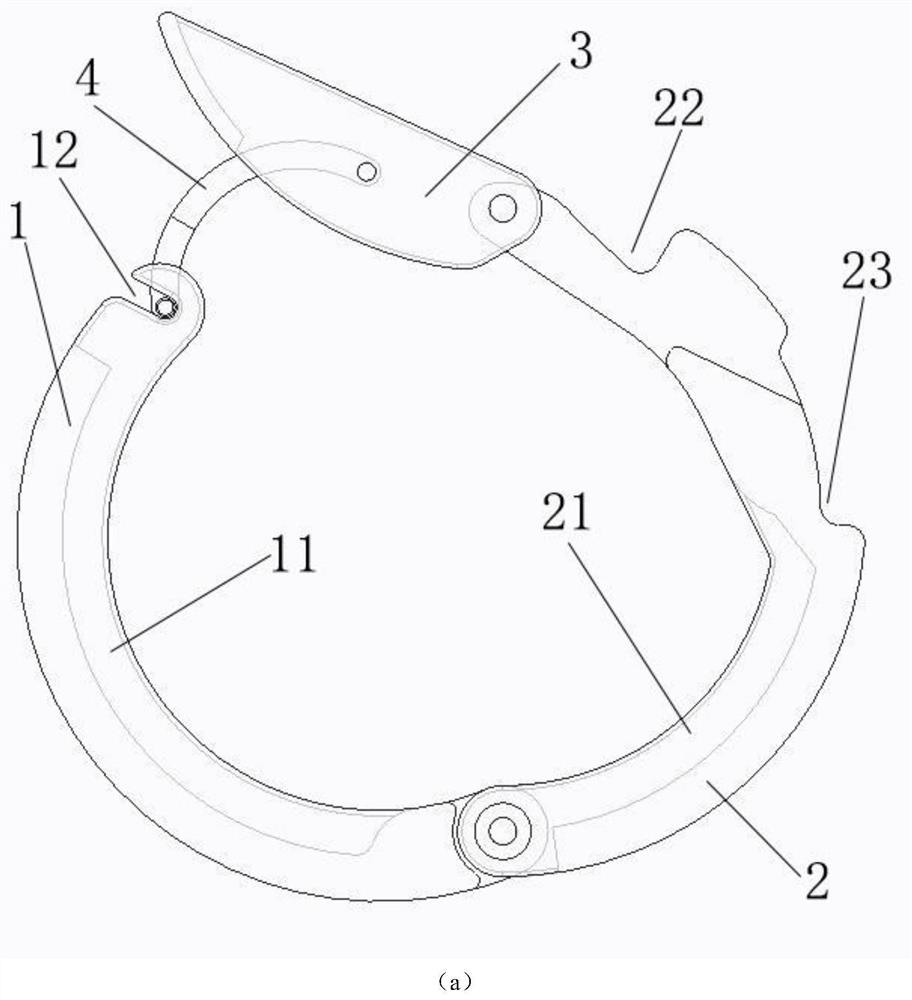

Rotor pump and shaft sealing device thereof

InactiveCN107061266AGood shaft sealing performanceImpact on shaft seal performanceRotary piston pumpsRotary piston liquid enginesImpellerEngineering

The invention provides a shaft sealing device of a rotor pump. The shaft sealing device comprises a machine seal base (3), a fixed ring (4), a movable ring base (5) and a movable ring (6) driven by the movable ring base (5). A first O-shaped ring (8) is arranged at the gap position between the fixed ring (4) and the machine seal base (3). A cavity (28) is formed between the movable ring base (5) and the machine seal base (3). The movable ring base (5) is composed of a movable ring front base (25) and a movable ring rear base (26). An outer ring (30) and an inner ring (31) which protrude in the opposite directions are arranged on each of the movable ring front base (25) and the movable ring rear base (26), a movable ring base inner cavity (9) is defined, and the respective inner rings (31) are matched in a mutually concave-convex manner. A second O-shaped ring (11) is arranged on the pump inner side of the movable ring (6). A pressed spring (12) is arranged in the movable ring base inner cavity (9). The movable ring (6) is closely attached to the fixed ring (4). The movable ring base (5) is connected with an impeller (2) through at least one transmission pin (13), one ends of the transmission pins (13) are in close-fitting connection, and the other ends of the transmission pins (13) are in floating type insertion. By means of the shaft sealing device, the shaft sealing performance of the rotor pump can be effectively improved, and the service life of the rotor pump can be effectively prolonged.

Owner:宁波邦威泵业有限公司

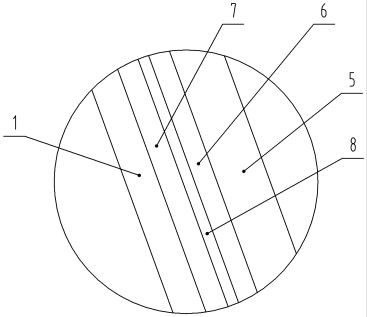

Spent fuel storage grillwork for nuclear power station

InactiveCN102479560AGuaranteed levelnessGuaranteed stabilityNuclear energy generationReactor fuel elementsNuclear powerMechanical engineering

The invention relates to a spent fuel storage grillwork, and particularly discloses a spent fuel storage grillwork for a nuclear power station. The spent fuel storage grillwork comprises four coamings, an upper support plate, a lower support plate and storage casings, wherein the upper support plate is positioned on the top of the four coamings; the lower support plate is positioned at the bottom of the coamings; the coamings, the upper support plate and the lower support plate construct a three-dimensional cavity; the storage casings are positioned in square holes of the upper support plate and the lower support plate; a bottom plate of each storage casing is positioned on the lower support plate; support legs are fixedly connected with the lower support plate; a threaded sleeve on each support leg is welded with the lower support plate; the bottom of each threaded sleeve is provided with a cylindrical boss; the upper end of each threaded sleeve is fastened with the lower support plate and the bottom plate through nuts; an adjusting screw rod is arranged in each threaded sleeve; each threaded sleeve is in threaded connection with the adjusting screw rod; the bottom of the adjusting screw rod is freely seated in a spherical concave seat of a bottom base plate; the bottom plate is provided with through holes which are communicated with the insides of the storage casings; and the through holes are communicated with through holes on the support plates. The spent fuel storage grillwork has high storage capability and high earthquake-proof performance.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

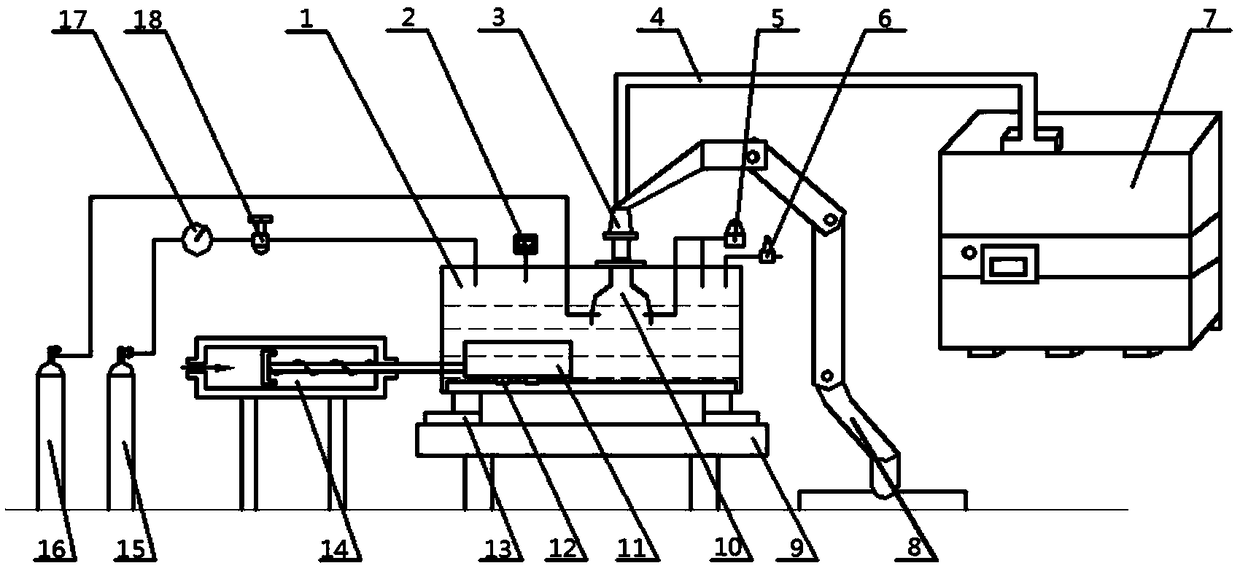

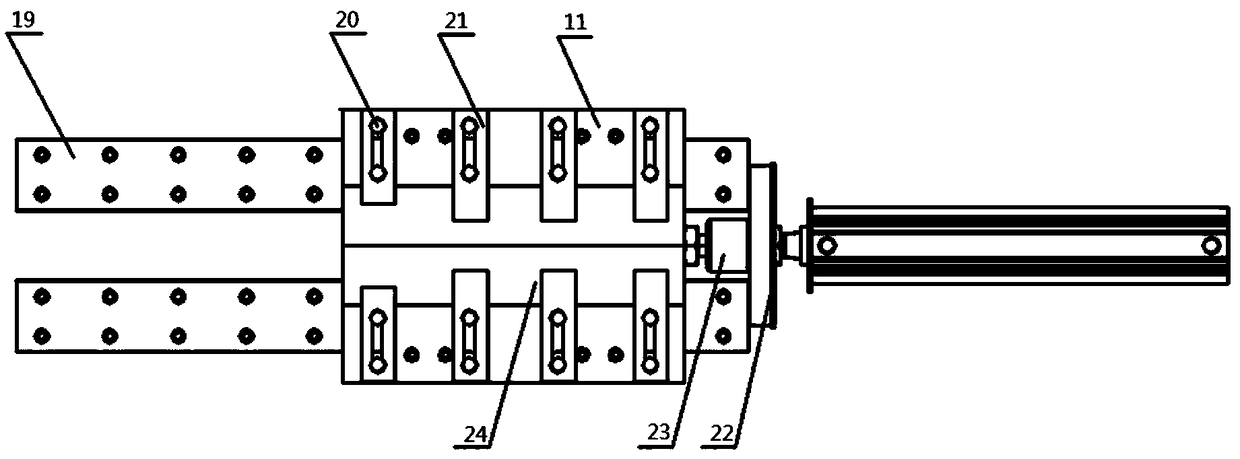

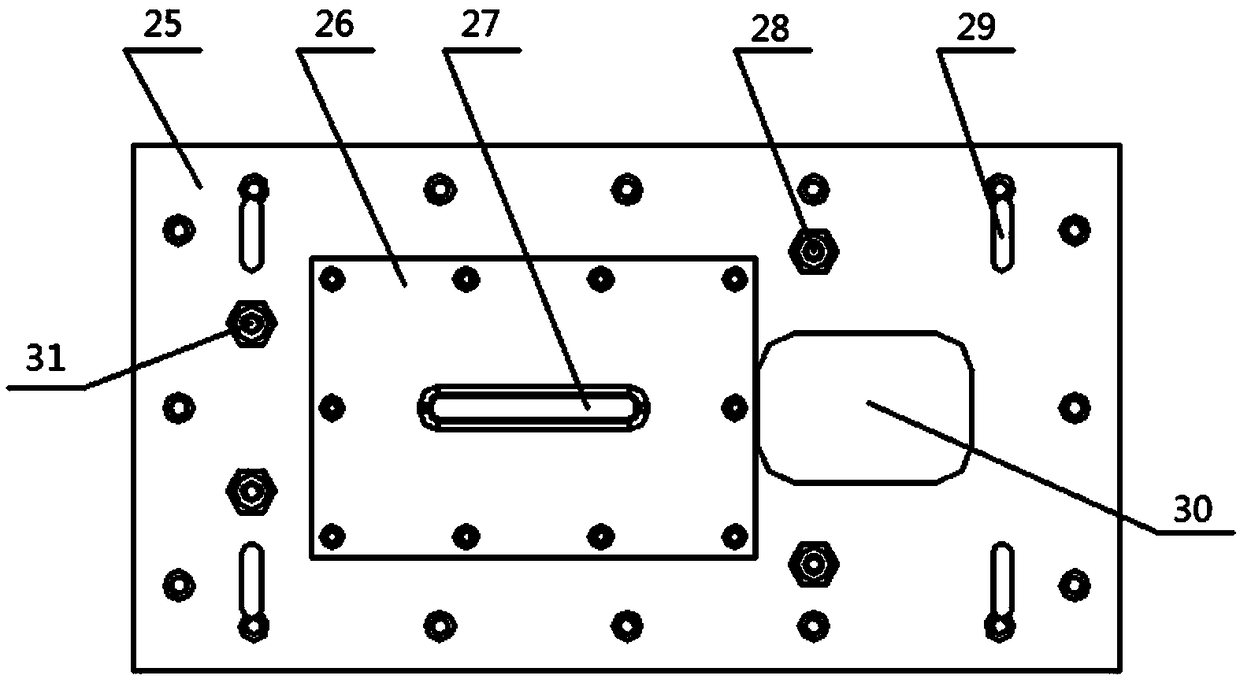

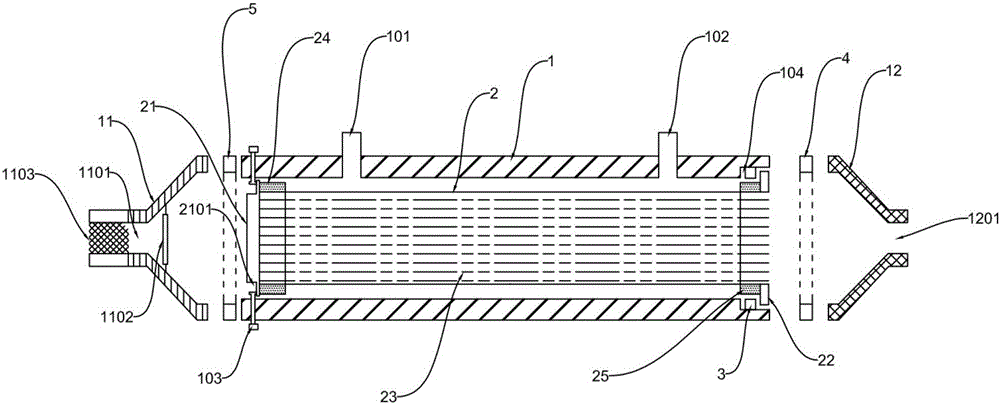

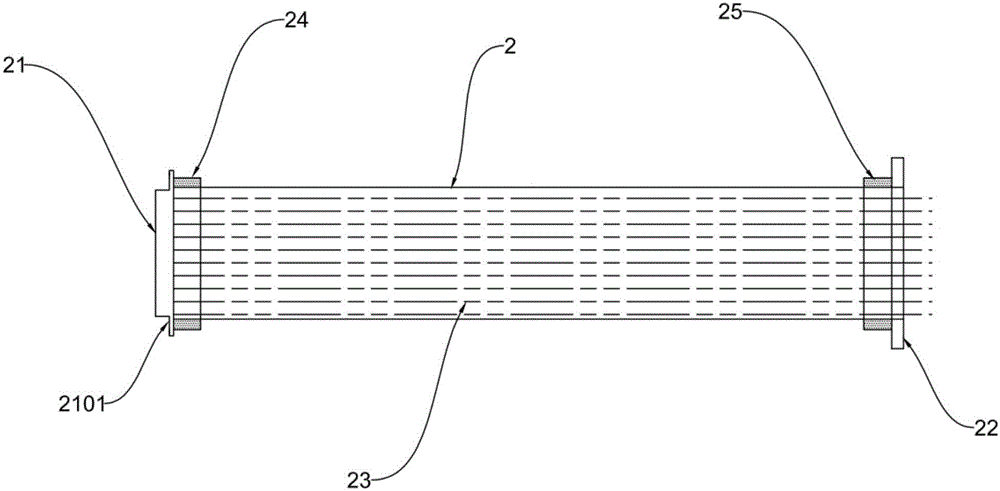

Local dry underwater laser welding system and method for simulating deep water environment

ActiveCN109014576AQuality improvementStabilize localized dry spacesLaser beam welding apparatusMarine engineeringUnderwater

Disclosed is a local dry underwater laser welding system for simulating a deep water environment, comprising a welding system, a high-pressure gas control system, a fully enclosed water tank (1), anda movable welding table (11) arranged at the bottom of the fully enclosed water tank (1). The fully-enclosed water tank (1) comprises an upper end cover plate (25) of a tank body, a lower end cover plate (32) of the tank body, and a side plate. The high-pressure gas control system together with the fully enclosed water tank (1) forms a high-pressure environment and a stable local drying space, thereby realizing high-pressure underwater laser welding of a part (24) to be welded fixed on a belt of the movable welding table (11). The invention also discloses a local dry underwater laser welding method for simulating the deep water environment, which is convenient to operate and can safely and stably obtain a high quality weld through simulating a real deep water environment.

Owner:HUAZHONG UNIV OF SCI & TECH

Glass carrying robot with high reliability

InactiveCN109731826AImprove practicalitySimple structureGripping headsCleaning using toolsEngineeringElectrical and Electronics engineering

The invention relates to a glass carrying robot with high reliability. The glass carrying robot comprises a main body, a sucker, an air cylinder, a moving plate and a connecting pipe, the connecting pipe is horizontally arranged, one side of the main body is arranged on the connecting pipe in a sleeving mode, the moving plate is vertically arranged in the connecting pipe, the connecting pipe is arranged on the moving plate in a sleeving mode, the air cylinder is fixed on the side, far away from the connecting pipe, of the main body, the air cylinder is in transmission connection with the moving plate, the sucker is installed at the end, far away from the main body, of the connecting pipe, a control mechanism is arranged on the main body, a cleaning mechanism is arranged in the sucker, andthe control mechanism comprises a connecting ring, an extruding ring and two driving assemblies. According to the glass carrying robot with the high reliability, the reliability of glass carrying is improved through the control mechanism, moreover, the function of cleaning the glass is achieved through the cleaning mechanism, and the situation that the sealing performance between the sucker and the glass is influenced by dust on the glass is avoided.

Owner:SHENZHEN LEILING GUANGTONG TECH DEV CO LTD

Quick release mechanism, end effector and robot

ActiveCN112245013AEasy to install and disassembleSimple and beautiful structureFriction grip releasable fasteningsSurgical manipulatorsSurgical ManipulationStructural engineering

The invention discloses a quick release mechanism, an end effector and a robot. The quick release mechanism comprises a first connecting part, a second connecting part rotatably connected with the first connecting part and a buckle, wherein the buckle is provided with a first turning point rotatably connected with the second connecting part, opening and closing between the buckle and the first connecting part are achieved through a connecting rod, and the connecting rod comprises an opening and closing point for being connected with the first connecting part in a matched mode and a second turning point for being rotatably connected with the buckle; and in a closed state, the connecting line of the second turning point and the opening and closing point is located below the first turning point. Rapid locking and unlocking can be achieved, the locking effect is good, operation is convenient, fast and reliable, and surgical operation is not affected.

Owner:NANJING TUODAO MEDICAL TECHNOLOGY CO LTD

Wood drying method

InactiveCN105222534AAbsorb in timeGentle absorptionDrying using combination processesWood treatment detailsWaxHeating furnace

The invention relates to the field of wood storage, and discloses a wood drying method. The method comprises the following steps of a, placing wood into liquid to be stewed, b, burying the stewed wood into high-temperature sand, c, taking out the wood from the sand and placing the wood into a heating furnace to be heated and dried under a vacuum condition, d, taking out the wood from the heating furnace and placing the wood outdoors to be naturally air-dried, and e, immersing the wood into liquid wax to form a wax film on the surface of the wood. Different from an existing drying method, the wood is dried through the high-temperature sand before being heated and dried, water is absorbed more evenly and mildly, and the drying degree in the wood is made more even, so that the fracturing phenomenon on the surface of the wood is effectively prevented, and material waste is avoided.

Owner:重庆雨帝建材有限公司

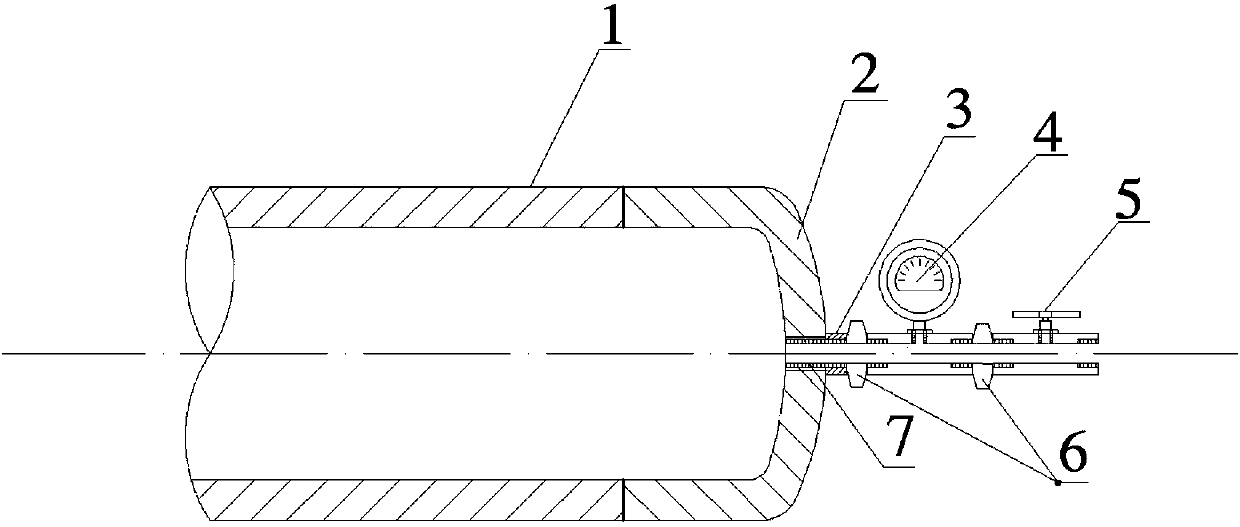

PE pipeline pressure device and method

PendingCN108051288AImprove sealingAffect the tightnessMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumEngineeringAir compressor

The invention belongs to the technical field of pipelines, and discloses a PE pipeline pressure device. The PE pipeline pressure device includes a PE plastic plug, a pressure pipe, a pressure gage, anadjustable valve and an air compressor; the PE plastic plug includes a pipe-shaped connection part and a blocking part; the pipe diameter and thickness of the pipe-shaped connection part are the sameas those of a PE pipeline to be tested; the blocking part seals one end of the pipe-shaped connection part; a round hole is formed in the blocking part, and an internal thread joint is welded to theinterior of the round hole; the first end of the pressure pipe is connected with the internal thread joint through a thread, and the second end of the pressure pipe is connected with the air compressor; the adjustable valve is arranged on the pressure pipe; the pressure gauge is arranged on the pressure pipe and is located between the adjustable valve and the first end of the pressure pipe. The PEpipeline pressure device is simple in structure, convenient to mount and resistant to high pressure; by adopting the PE pipeline pressure device and method, it is convenient to read pressure values inside the pipeline; the PE pipeline pressure device and method have a good sealing effect and can be popularized to plastic pipes of other kinds.

Owner:WUHAN UNIV OF SCI & TECH

High-strength hollow fiber membrane module and preparation method thereof

PendingCN107174957AAvoid affecting service lifeAvoid damageMembranesSemi-permeable membranesEpoxyPolymer science

The invention relates to a high-strength hollow fiber membrane module and a preparation method thereof. The high-strength hollow fiber membrane module at least comprises an outer membrane cavity and an inner membrane core which is assembled inside the outer membrane cavity, wherein one end part of the inner membrane core is taken as an epoxy resin polystyrene sealing end, and the other end part of the inner membrane core is taken as an epoxy polystyrene resin casting end; two sides of the outer membrane cavity are provided with a left end part gland and a right end part gland respectively; the left end part gland is assembled on one side of the epoxy resin sealing end; an epoxy resin flexible glue protection layer is arranged beside the epoxy resin polystyrene sealing end; an outlet end epoxy resin flexible glue protection layer is cast beside the epoxy resin polystyrene casting end. By adopting the high-strength hollow fiber membrane module, hollow fiber membrane filaments beside the casting end can be effectively prevented from being damaged, and the service life of the hollow fiber membrane module is prolonged; the airtightness of the hollow fiber membrane module, particularly on sealing parts at two ends of the membrane filaments is enhanced, the requirement on separation at a high temperature is met, and the separation efficiency is increased. At the same time, the invention further provides a preparation method of the hollow fiber membrane module.

Owner:四川久润环保科技有限公司

On-line safety valve checking method and device

ActiveCN104406781AExtended duty cycleAffect the tightnessMachine part testingOnline and offlineEngineering

The invention provides an on-line safety valve checking method and device. A safety valve is subjected to online checking through the device, the device comprises a force sensor mounted on a lifting rod, the force sensor is connected with a control system, the safety valve is arranged on a pressure vessel with slurry in the lower portion and steam in the upper portion, in a normal working pressure range of the safety valve, the control system controls lifting height and opening time of a valve stem of the safety valve by the device, and the device is enabled to finish checking after the slurry arrives at a valve port of the safety valve. Therefore, influence on sealing performance of the safety valve due to discharge of a viscous medium in a flash evaporator is avoided, further the operating period of the flash evaporator can be prolonged, cost in a series of working processes of detachment, lifting, transportation, checking, reassembling and the like during online and offline checking of the safety valve can be omitted, labor intensity of workers is lowered, and normal operation of companies is guaranteed.

Owner:GUANGXI HUAYIN ALUMINUM

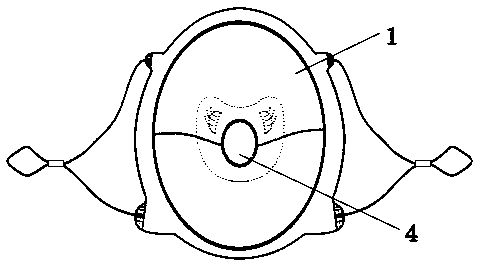

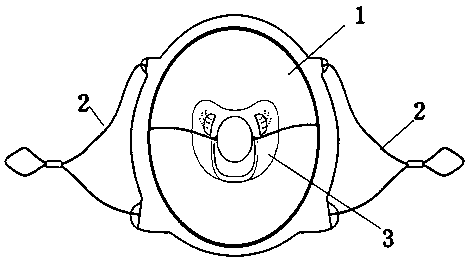

Multipurpose protective mask for infants

PendingCN111296959AAffect the tightnessAvoid fussParticle suspension analysisBaby-comfortersMechanical engineeringPacifier

The invention provides a multipurpose protective mask for infants and relates to the technical field of protective masks. The protective mask overcomes the technical defects that an existing mask forinfants is single in function and unfavorable for infants to wear and use. The mask comprises a mask body, and hanging ropes are arranged on two sides of the mask body. The mouth mask is characterizedin that a mounting seat is arranged on the mouth mask body at a position corresponding to the oral cavity, and a pacifier is mounted on the mounting seat. A pacifier, a nipple or a shaking nipple isadded on the basis of a traditional infant mask. The pacifier, the nipple and the shaking nipple can pacify the emotion of an infant in the mask using process, falling caused by inadaptability in themask using process is avoided, the pacifier, the nipple and the shaking nipple are contained in the mouth and can position the mask, and the situation that sliding influences the sealing performance of the mask body is avoided.

Owner:孙捍杰

Magnetic cloth conveying and dust removing roller of textile machinery

ActiveCN112093589ALabor savingImprove bending resistanceMechanical cleaningPressure cleaningGear wheelDust control

The invention discloses a magnetic cloth conveying and dust removing roller of a textile machinery. The magnetic cloth conveying and dust removing roller comprises a cylinder; two sealing plugs symmetrically cover the two ends of the cylinder; each sealing plug is provided with a power pipe in an inserting manner; the outer side of each power pipe is fixedly sleeved with a power gear; and an air pipe is rotatably inserted into the two power pipes jointly; and the two ends of the air pipe extend to the outer sides of the two power pipes respectively and are provided with two one-way valves correspondingly. According to the magnetic cloth conveying and dust removing roller disclosed by the invention, the mechanical energy of rotation is converted into electromagnetic energy through magneticdiscs by utilizing the rotation characteristic of the roller; the magnetic discs attract and repel each other to generate an air pressure difference; the roller can adsorb dust and discharge the dustthrough the air pipe in cooperation with the one-way air charging characteristic of a one-way air charging pipe and the one-way valve; thus, the dust falling and removal capacity of equipment is improved; and the roller surface does not need to be cleaned frequently, so labor use is reduced.

Owner:钱莉 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com