Rotor pump and shaft sealing device thereof

A shaft seal and rotor pump technology, which is applied in the direction of rotary piston pumps, pumps, rotary piston/swing piston pump components, etc. Problems such as the elasticity of the pressure spring can be improved to improve the shaft sealing performance, improve the service life and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

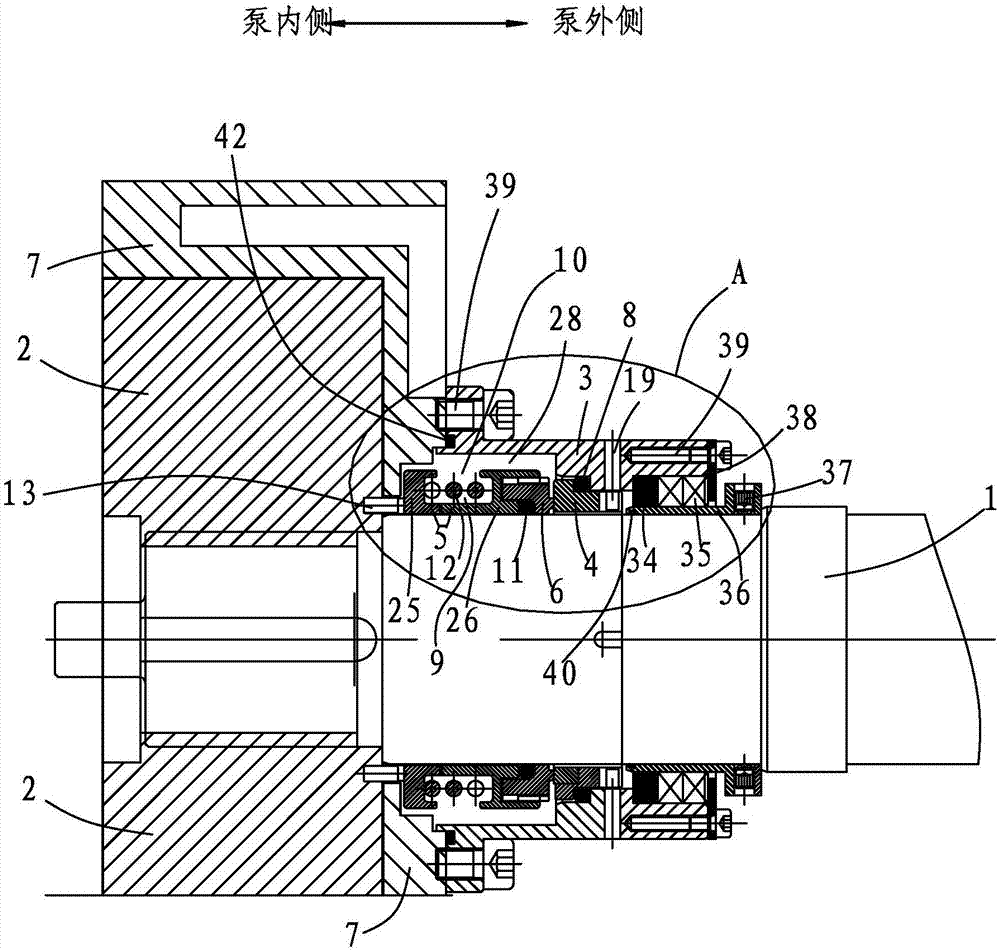

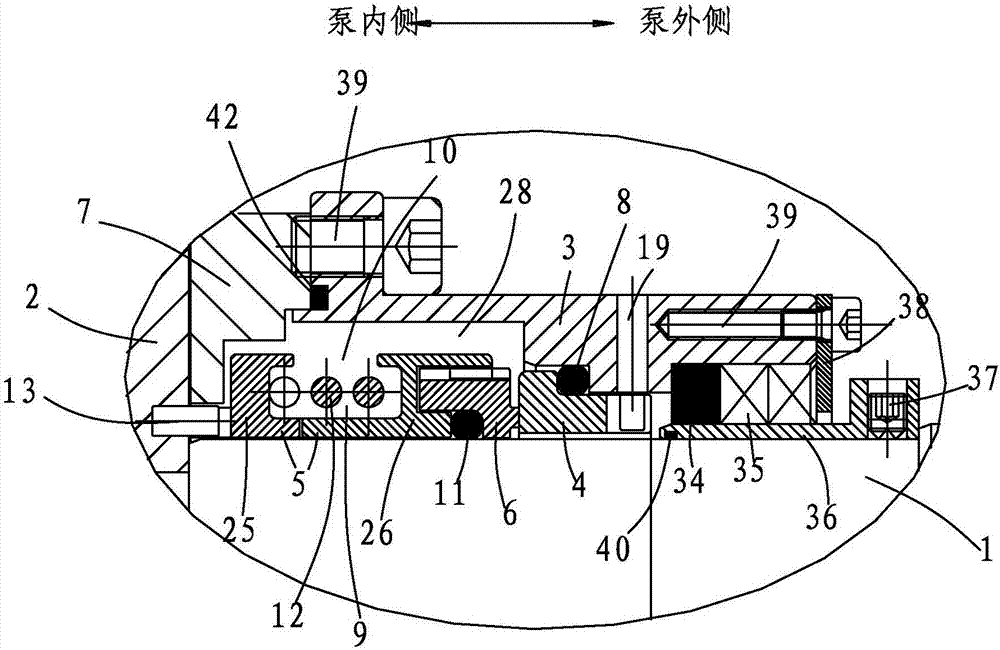

[0042] Such as figure 1 As shown, a shaft sealing device of a rotor pump, the shaft 1 of the rotor pump is fixedly connected with the impeller 2 as the rotor, and the shaft sealing device includes a mechanical seal seat 3, a stationary ring 4, a moving ring seat 5 and its The driving moving ring 6 is cylindrical and is set outside the shaft 1; the mechanical seal seat 3 is set outside the moving ring seat 5 and is fixedly connected with the pump body 7. The mechanical seal seat 3 includes a material section and an un The sealing section that allows material to enter, the inner diameter of the material section is larger than the inner diameter of the sealing section. The static ring 4 is located in the inner cavity of the sealing section of the mechanical seal seat 3 close to the material section, is directly sleeved on the outside of the shaft 1, and is connected with the mechanical seal seat 3 . Specifically, the following connection methods can be used: the machine seal sea...

Embodiment 2

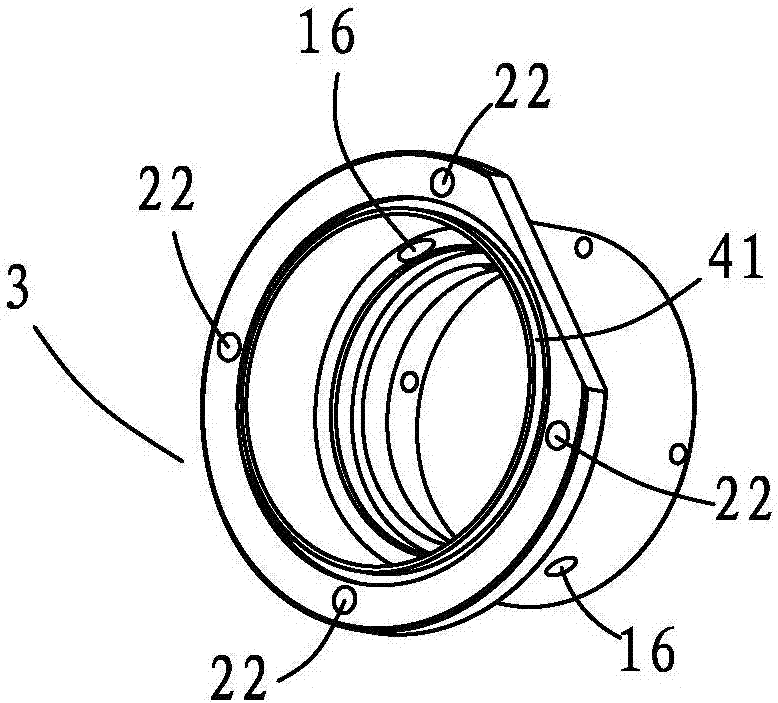

[0056] Such as Figure 16 , Figure 23 As shown, in this embodiment, on the basis of Embodiment 1, the material section and the sealing section of the mechanical seal seat 3 are separately set as the mechanical seal front seat 43 and the mechanical seal rear seat 44, and the mechanical seal seat 3 is composed of the mechanical seal front seat 43 The assembly assembled with the mechanical seal back seat 44, the inner side of the pump of the mechanical seal front seat 43 is provided with a flange end, and a plurality of connecting holes 22 are opened along the circumference of the flange end, the inner cavity of the pump body 7 is provided with a flange installation cavity, and the mechanical seal The flange end of the front seat 43 is embedded in the flange installation cavity, and the machine seal seat 3 is fixedly connected with the pump body 7 through a plurality of bolts 39 from the inner cavity of the pump body 7, and the flange end of the front seat 43 of the machine seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com