On-line safety valve checking method and device

A calibration method and safety valve technology, which can be used in the testing of measuring devices, instruments, and mechanical parts, etc., can solve the problems of long ordering cycle of safety valve spare parts and affect normal production, so as to reduce labor intensity and ensure normal operation. , the effect of prolonging the working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method and device for on-line verification of a safety valve according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

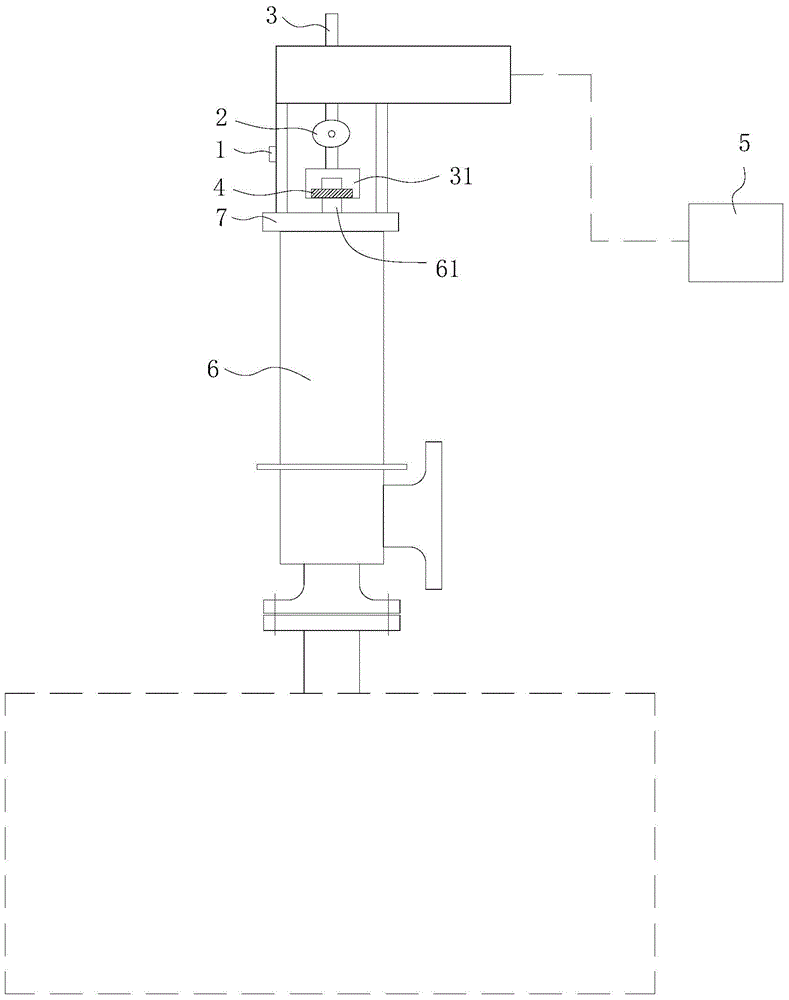

[0027] see figure 1 and figure 2 , is the first embodiment of an on-line calibration device for a safety valve of the present invention, which includes a displacement sensor 1, a force sensor 2, a lifting rod 3 and a fastener 4, and the displacement sensor 1 and the force sensor 2 use wires and a control system 5 Connect, this control system 5 is made of computer and motor.

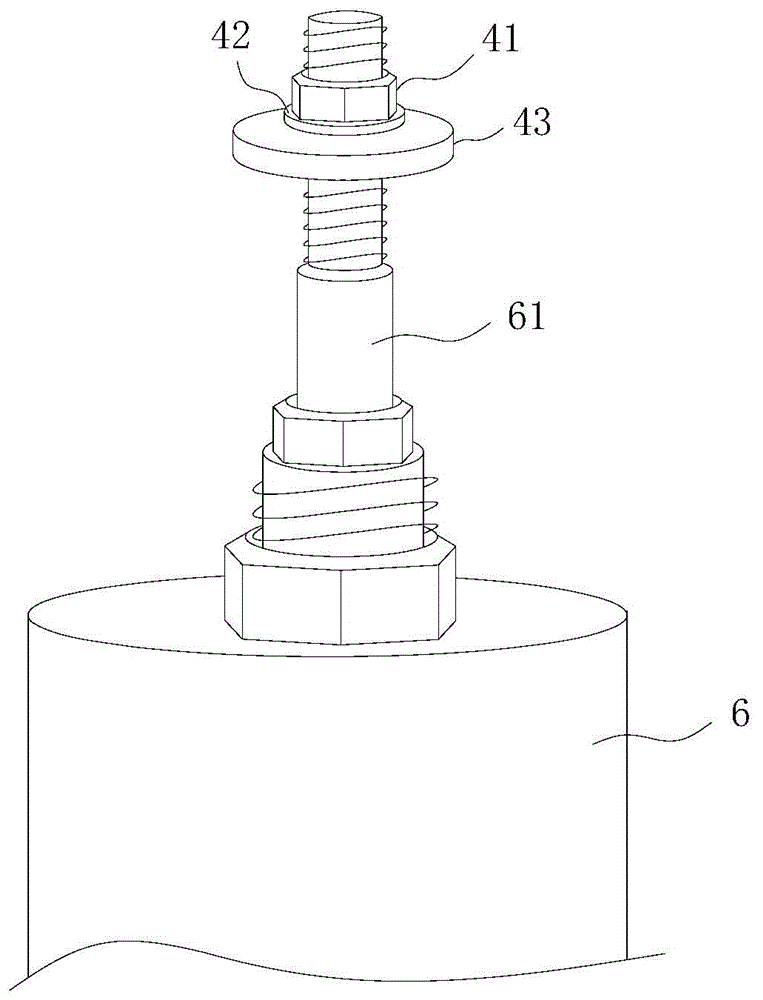

[0028] The valve stem 61 of the safety valve 6 is provided with an external thread.

[0029] The fastener 4 includes a nut 41 , a washer 42 and a fixing cap 43 , and the width of the fixing cap 43 is relatively larger than that of the nut 41 . The fixing cap 43 is embedded in the external thread of the valve stem 61 , and is screwed with the valve stem 61 through the nut 41 to prevent the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com