Patents

Literature

41results about How to "Realize online verification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Online checking method for high-tension current transformer

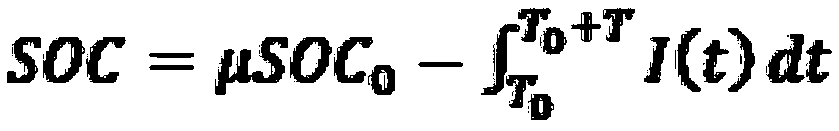

InactiveCN102401889AImprove accuracyImprove reliabilityElectrical measurementsIntegration algorithmEngineering

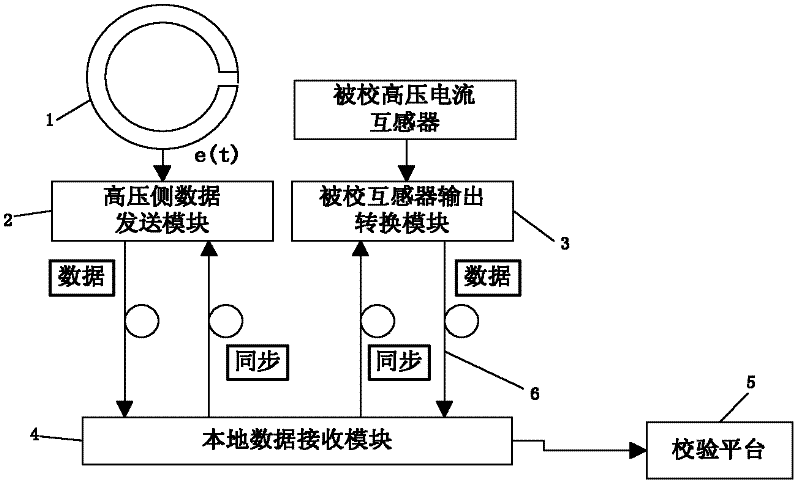

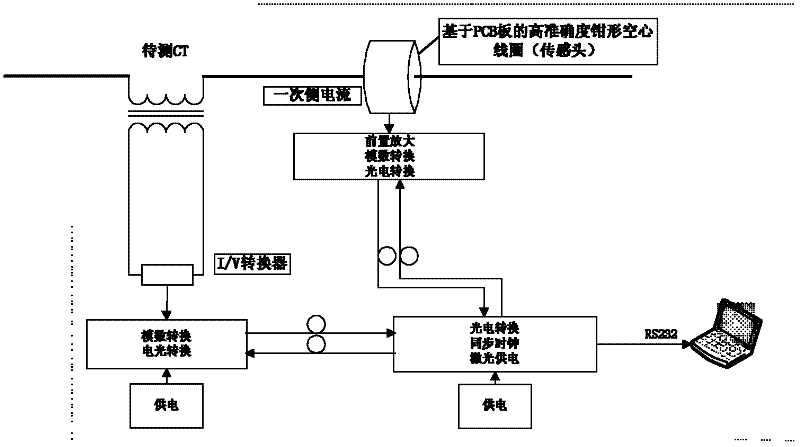

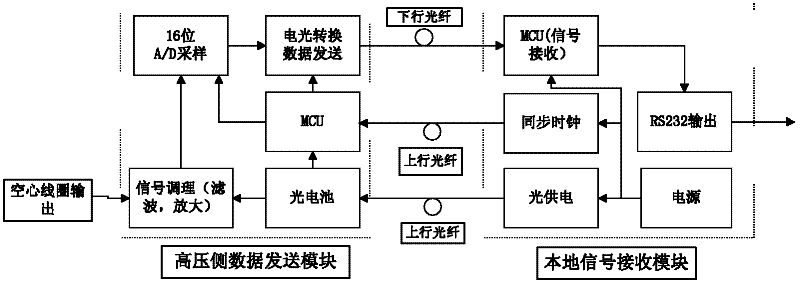

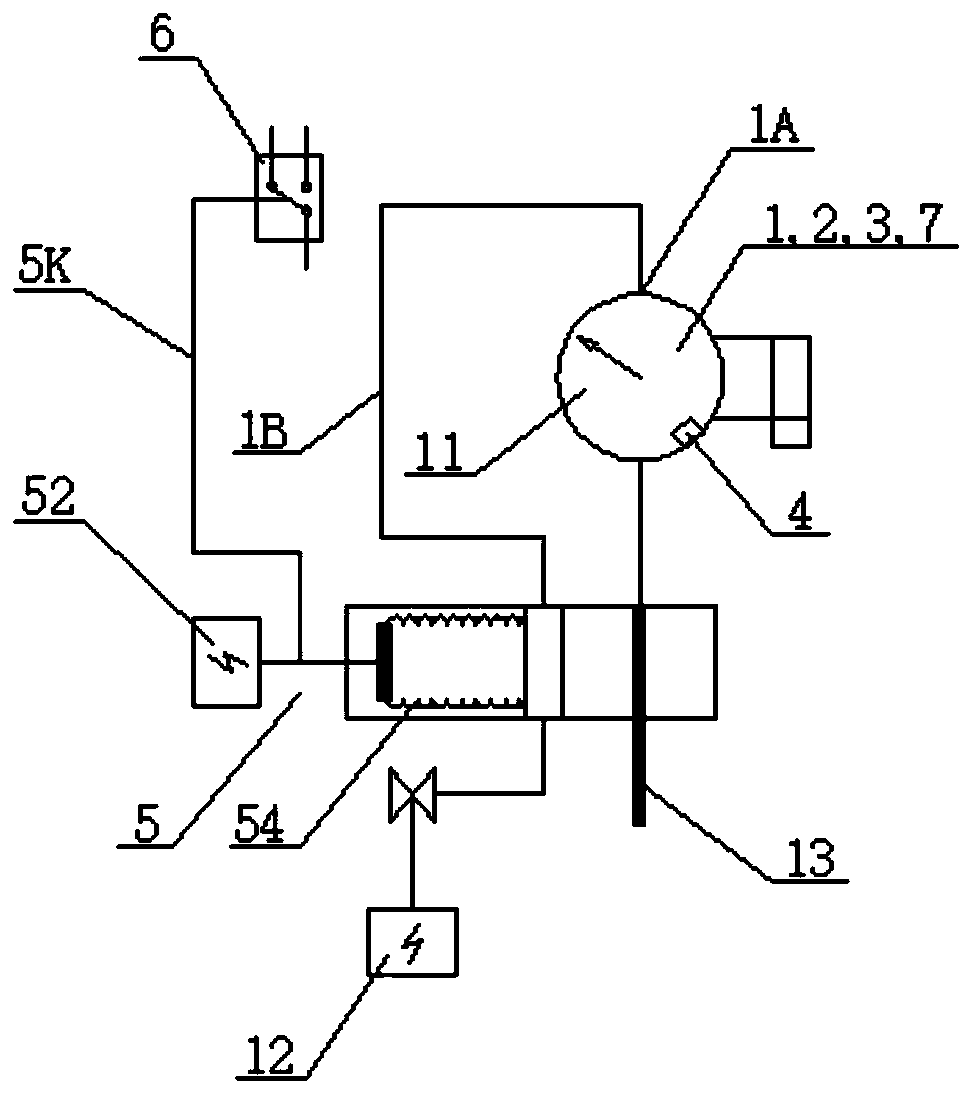

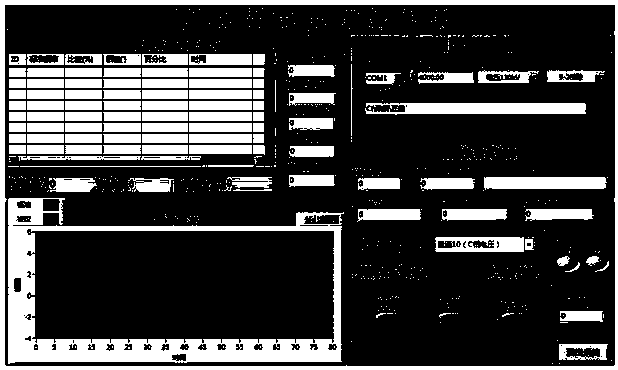

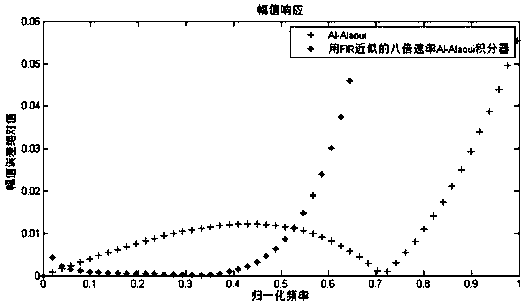

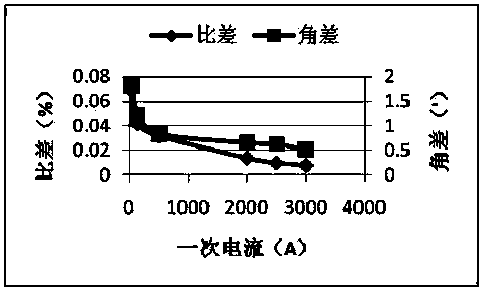

The invention relates to an online checking method for a high-tension current transformer, which can check the high-tension current transformer in the field operation with high accuracy. The online checking method is characterized in that in a return circuit of the high-tension current transformer to be checked, a high-accuracy pincerlike hollow coil based on a PCB (Printed Circuit board) is connected in series, so that the high-tension current transformer is used as a standard current transformer, the signal of the high-tension side is digitized and transmitted to the low-tension side through fiber transmission, the output value of the standard current transformer and the output value of the checked high-tension current transformer at the synchronized instant are compared through an external synchronous trigger signal, the digital integration algorithm and error theory algorithm are realized by using a virtual instrument in a checking platform, so that the accuracy of the checked high-tension current transformer in the field operation is checked, the cost of interruption is reduced, and the checking period of the high-tension current transformer is shortened.

Owner:STATE GRID ELECTRIC POWER RES INST

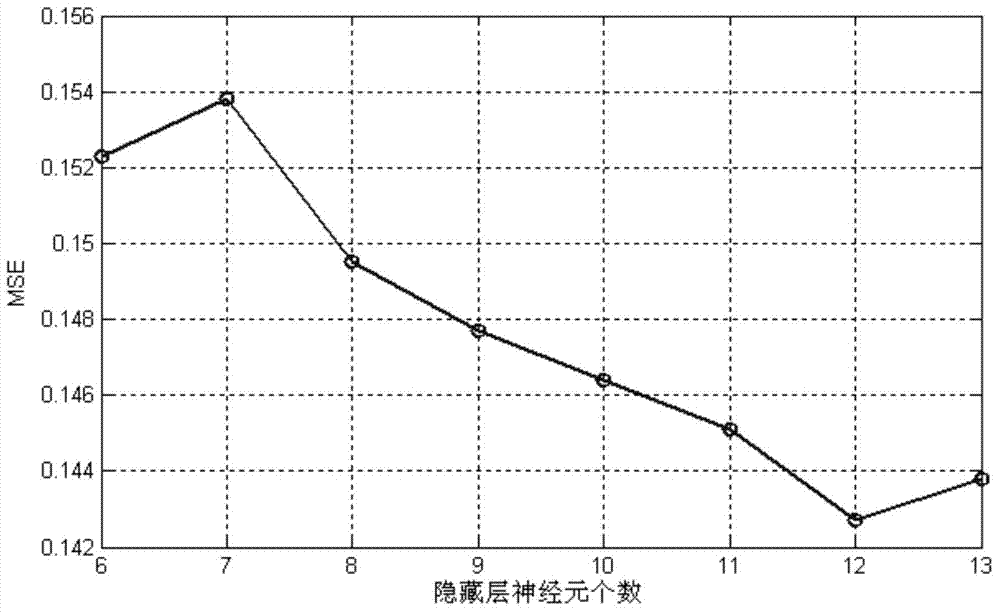

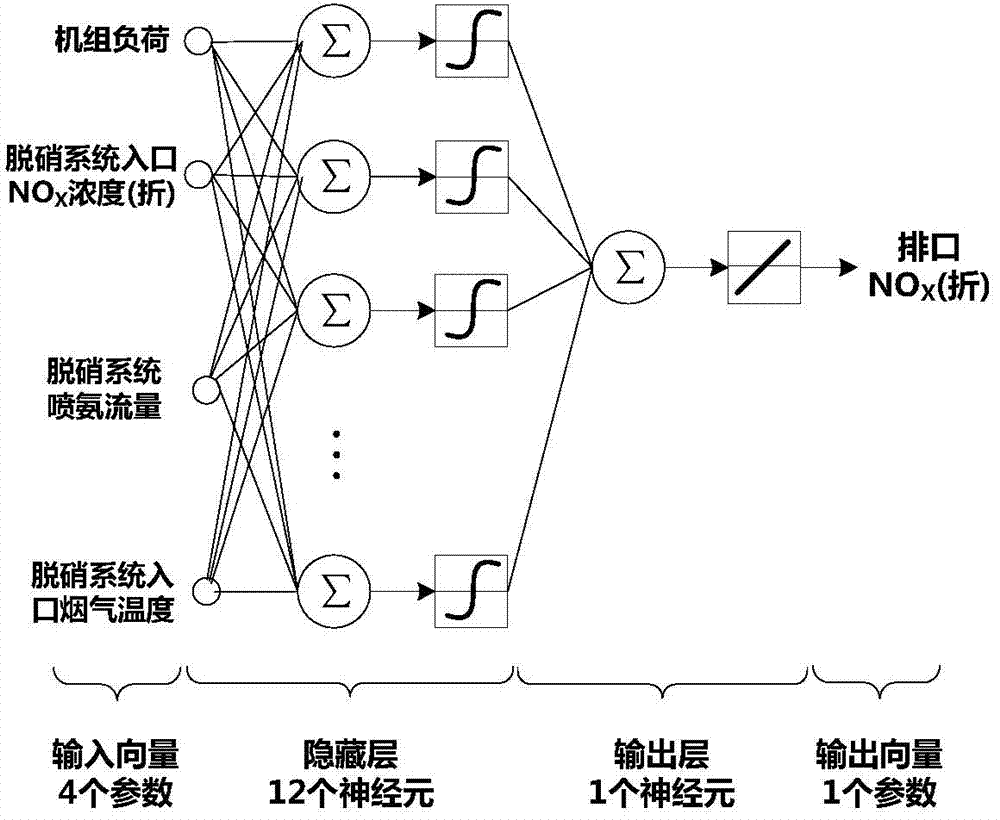

Method for predicting nitrogen oxide emission concentration of coal-fired unit based on neural network

InactiveCN104504238AImprove the level of automatic diagnosisRealize online verificationBiological neural network modelsSpecial data processing applicationsNitrogen oxideWorkload

The invention discloses a method for predicting nitrogen oxide mission concentration of a coal-fired unit based on the neural network. The method includes preprocessing key operation parameter unit load, NOx conversion concentration and smoke temperature of SCR (selective catalytic reduction) entry, ammonia spraying flow and NOx conversion concentration of an exhaust port, establishing a BP neural network, using the unit load, the NOx conversion concentration and the smoke temperature of the SCR inlet and the ammonia spraying flow as input values, and using the NOx conversion concentration of the exhaust port as output values to obtain prediction value of the nitrogen oxide emission concentration of the coal-fired unit. By the method, workload of operators is greatly reduced, and maintenance cost is reduced.

Owner:STATE GRID CORP OF CHINA +2

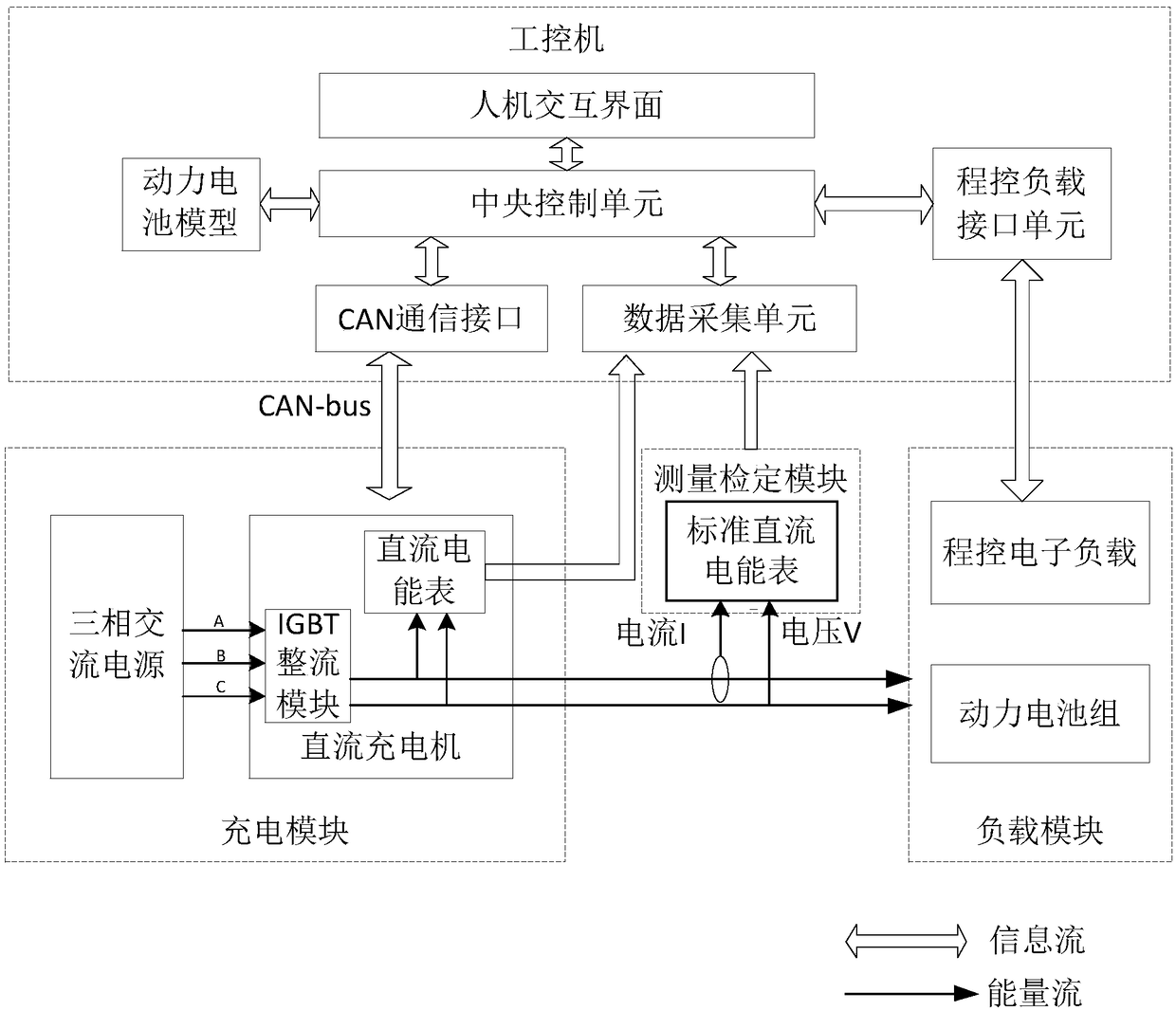

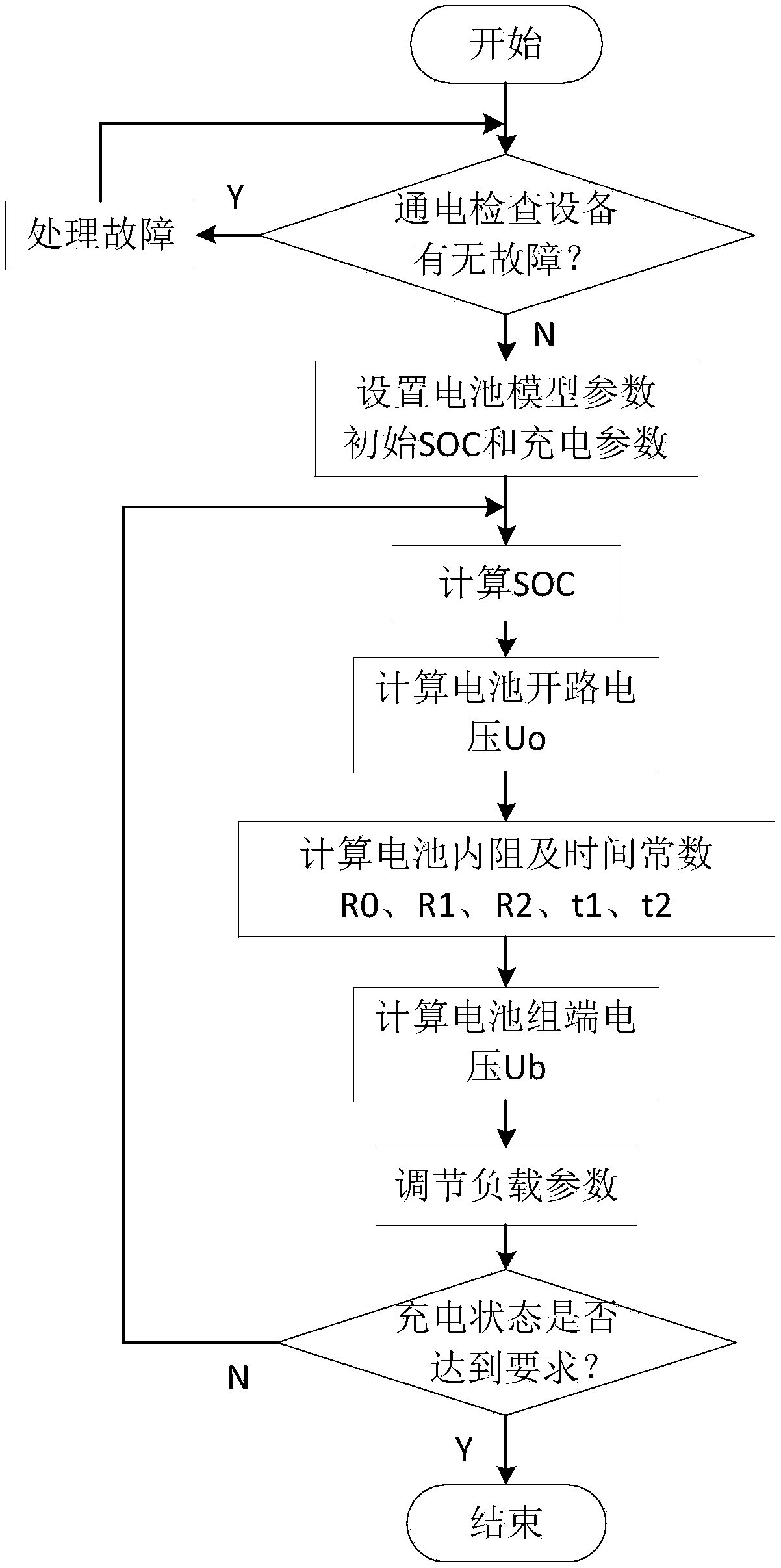

Electric vehicle off-board direct-current charger direct-current electric energy meter on-line verification system and method

InactiveCN108427092ARealize online verificationWith dynamic verification functionElectrical measurementsVerification systemElectrical battery

The invention discloses an electric vehicle off-board direct-current charger direct-current electric energy meter on-line verification system and method. The system is composed of a charging module, aload module, a measurement verification module, an industrial personal computer and related programs. By means of a virtual battery management system and a real-time pulse comparison method, direct-current charger direct-current electric energy meter on-line verification can be realized when the load module is charged; on the basis of requirements, the virtual battery management system sets different power battery types and parameters, configures charging parameters, acts on the load module, and provides corresponding loads for online verification; during a charging process, a data acquisition unit acquires detected pulses outputted by a tested direct-current electric energy meter and standard electric energy pulses outputted by a standard direct-current electric energy meter; and the number of the standard electric energy pulses is compared with the number of the detected direct-current electric energy pulses, so that the direct-current electric energy meter of a direct-current charger can be verified. With the system and method of the invention adopted, real-time online verification can be performed on the direct-current electric energy meter of an on-site off-board direct-current charger, and safe and accurate on-line verification of electric energy measurement can be realized.

Owner:JIANGSU UNIV

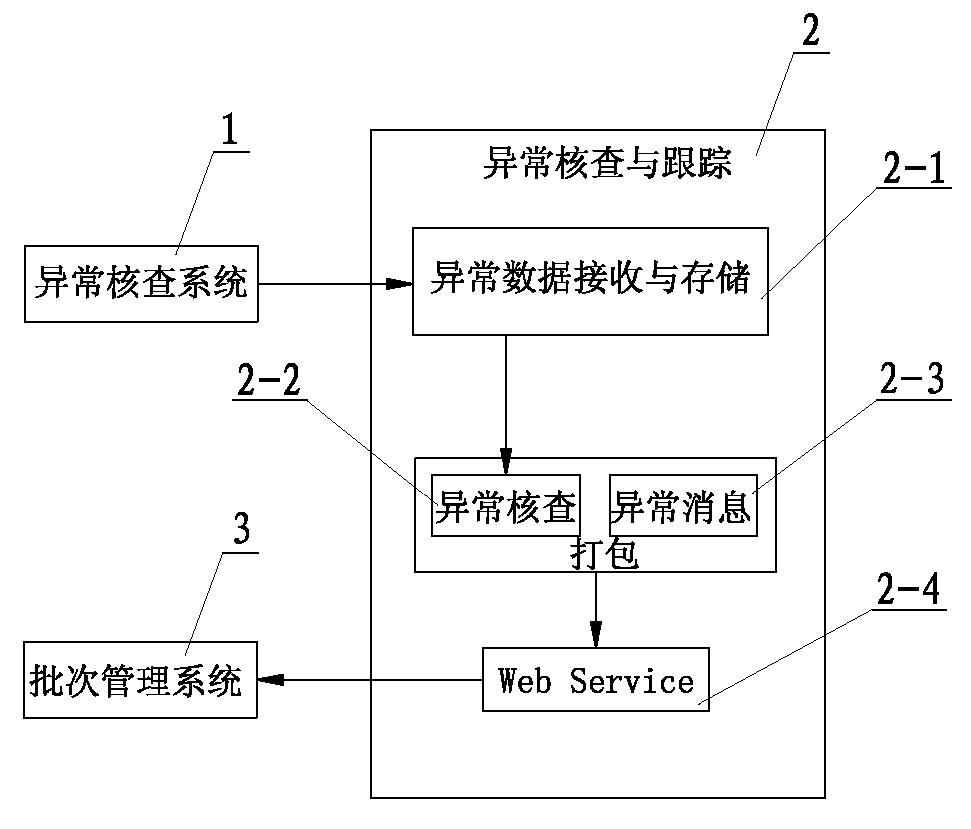

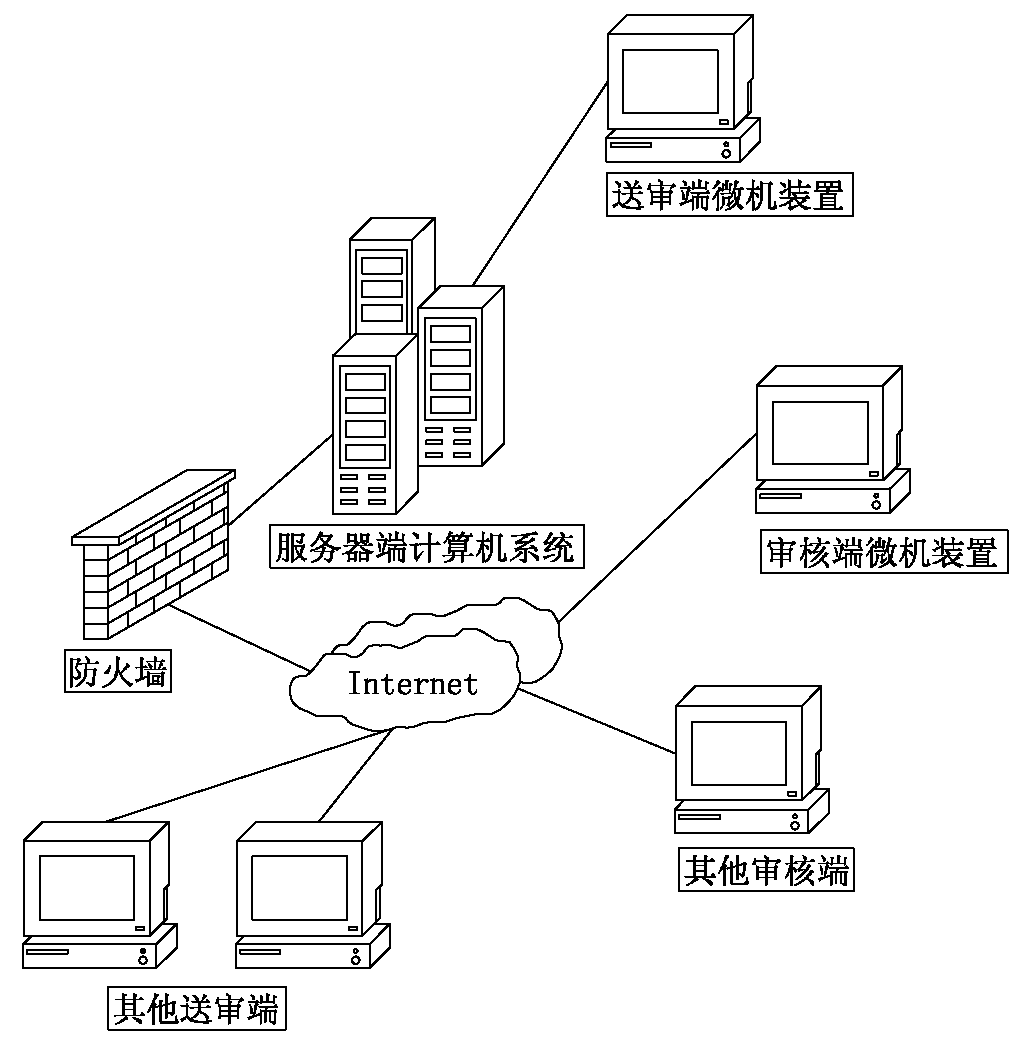

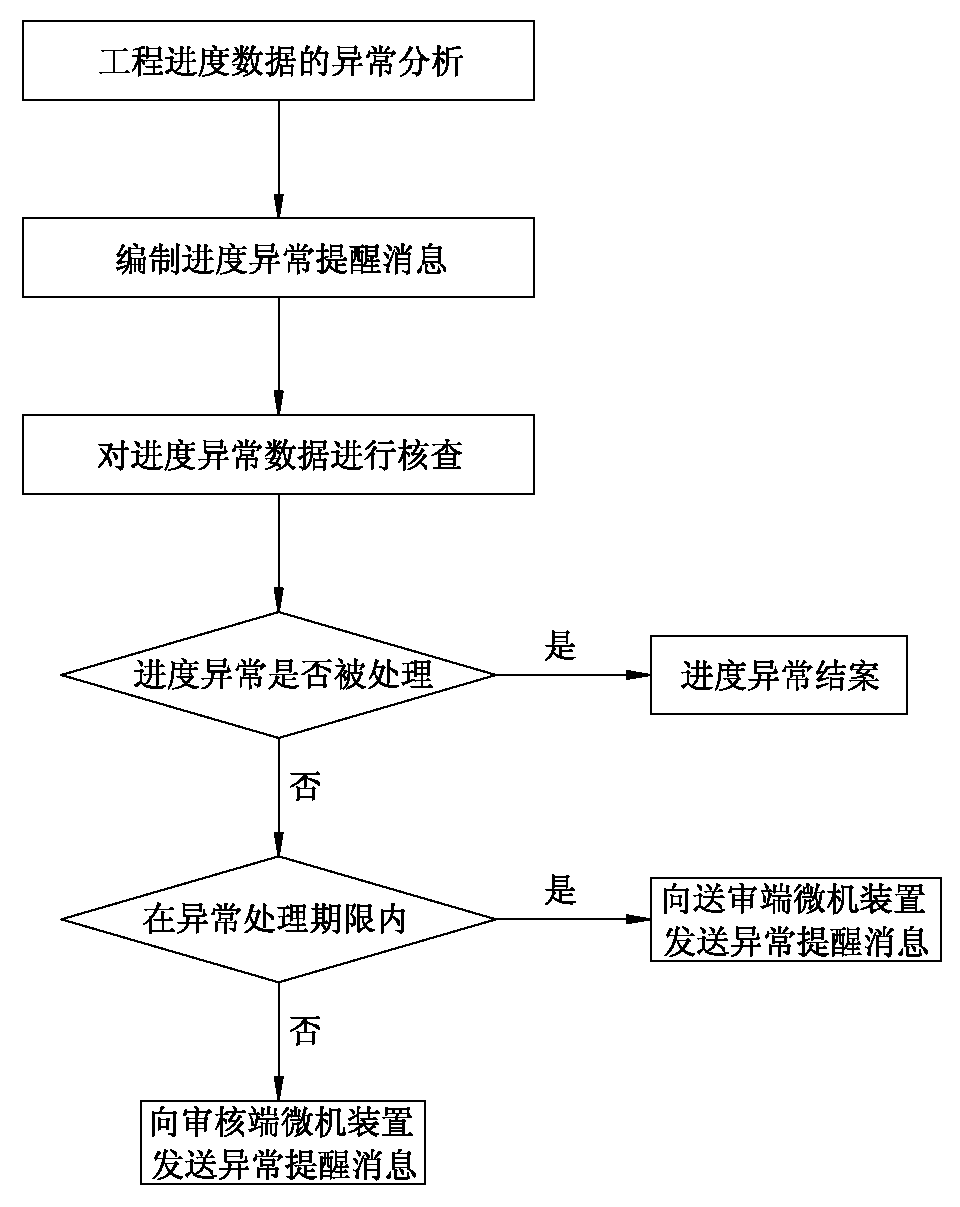

On-line management method of checking and tracking of job schedule abnormalities

InactiveCN103136161ARealize online analysisRealize online verificationDigital computer detailsResourcesData transformationEngineering

The invention relates to an on-line management method of checking and tracking of job schedule abnormalities. According to the method, based on a remote interaction platform, through interaction and data conversion among a submitting end microcomputer device, an audit end microcomputer device and a server end computer system, on-line analysis of the job schedule abnormalities and on-line checking and tracking of job schedule abnormality data processing are achieved. An object oriented operation interface is published through the server computer system, data is stored in a data base server and shared by all the operators using the platform, operating authorization is controlled through authorization, and when the realtime performance of the data is ensured, the data is controlled not to be changed at will. The on-line management method of the checking and the tracking of the job schedule abnormalities is beneficial to urging a duty officer to process schedule abnormality data in time, and reducing losses caused by unordered abnormality processing.

Owner:BEIJING JIANLONG HEAVY IND GROUP

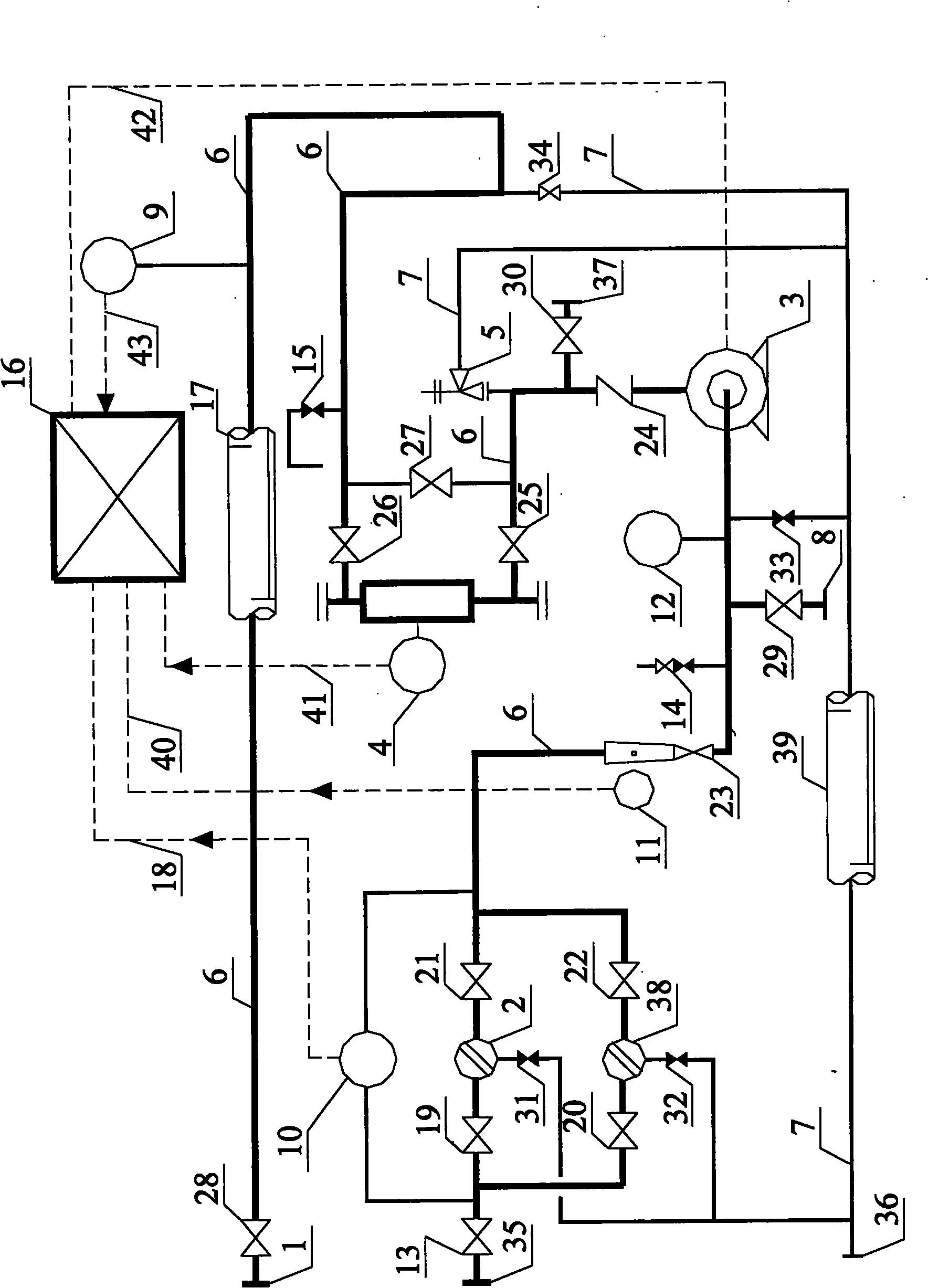

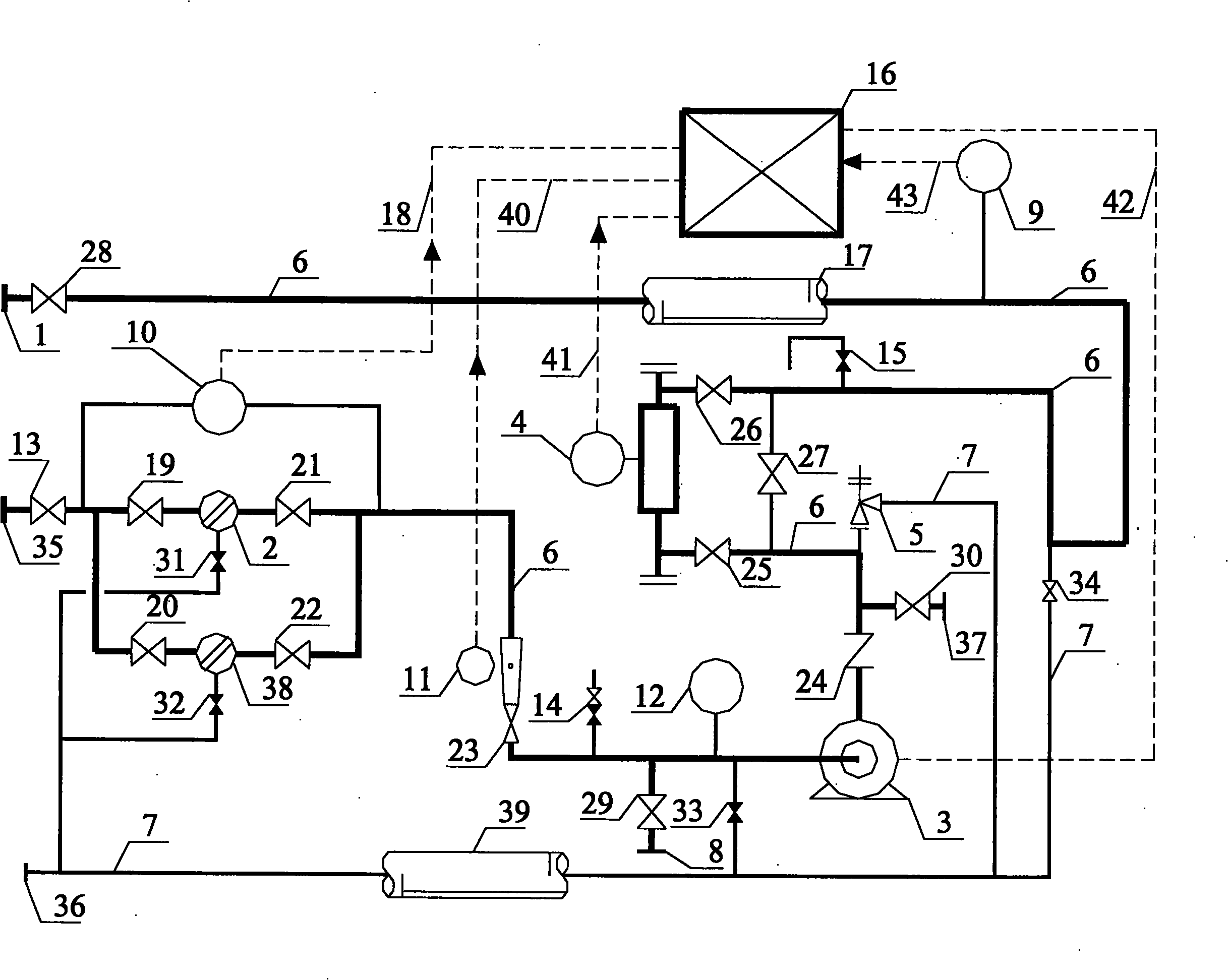

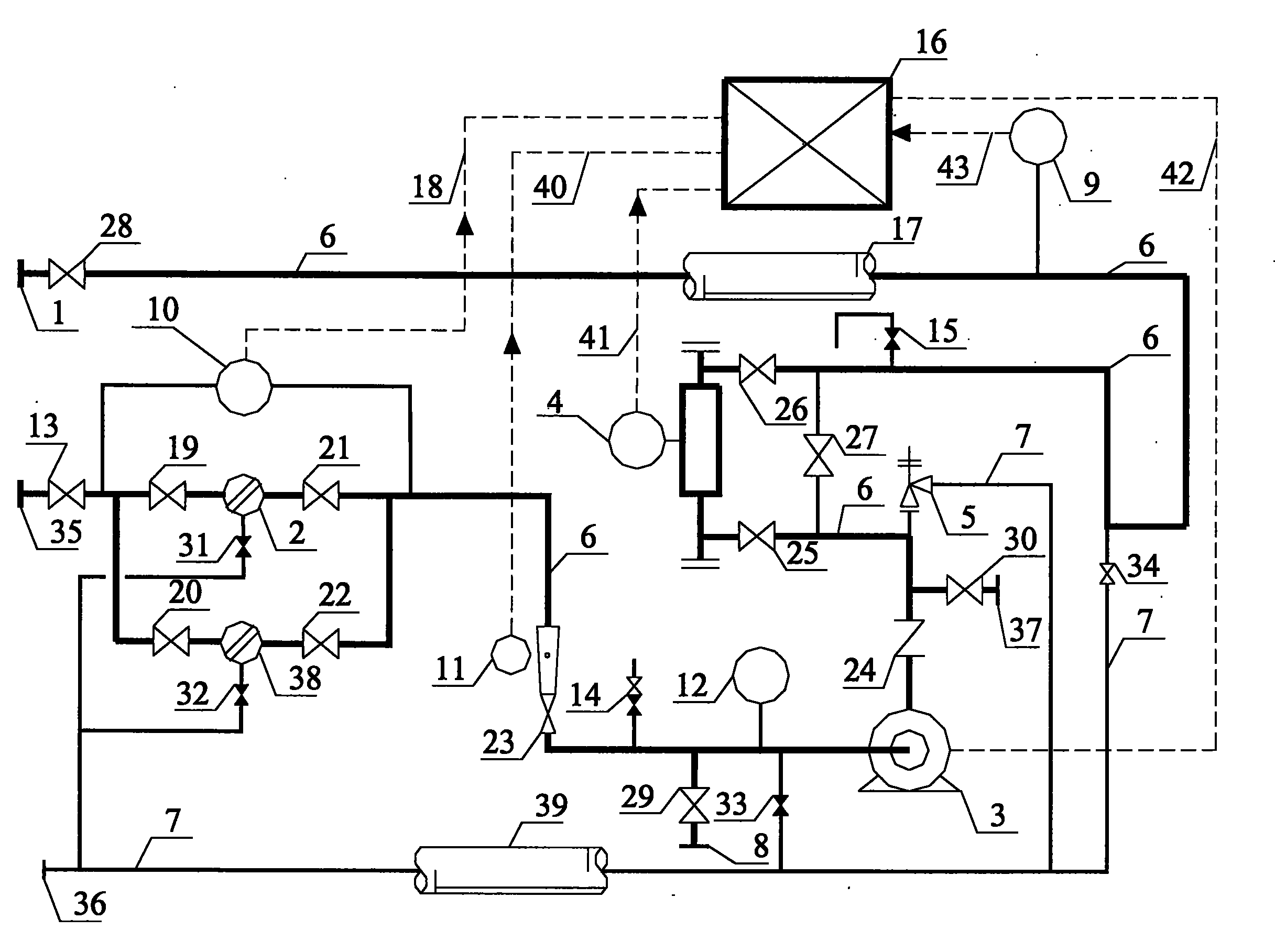

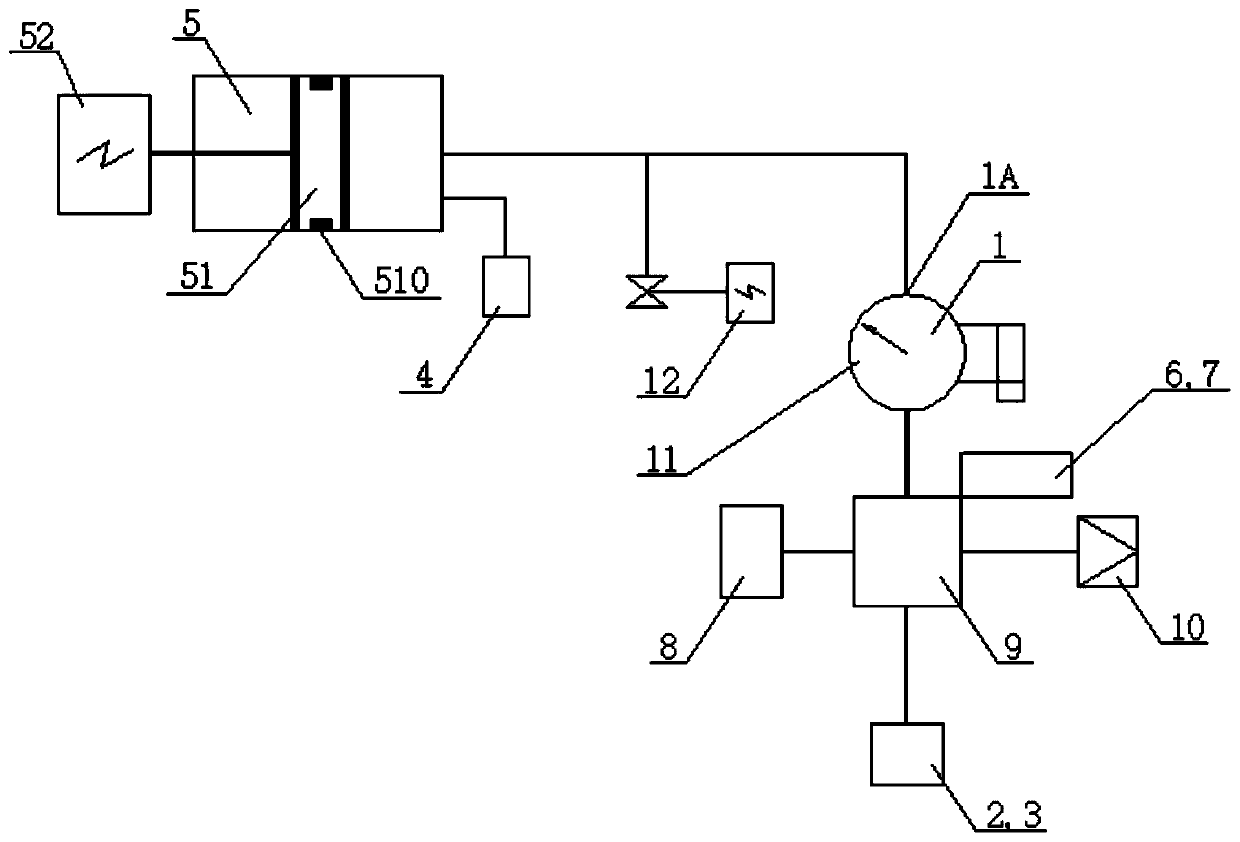

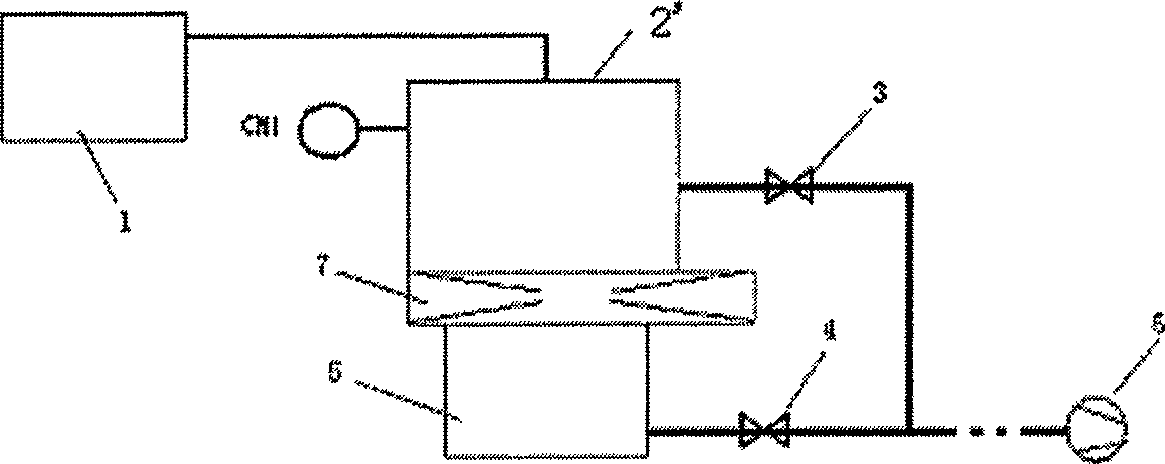

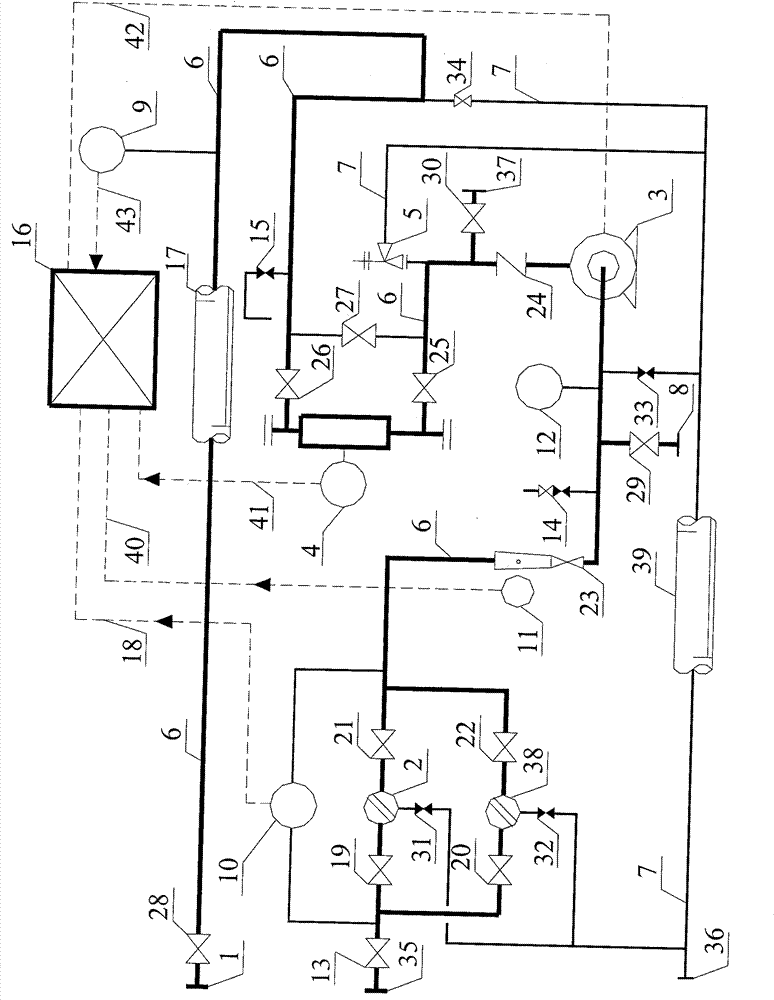

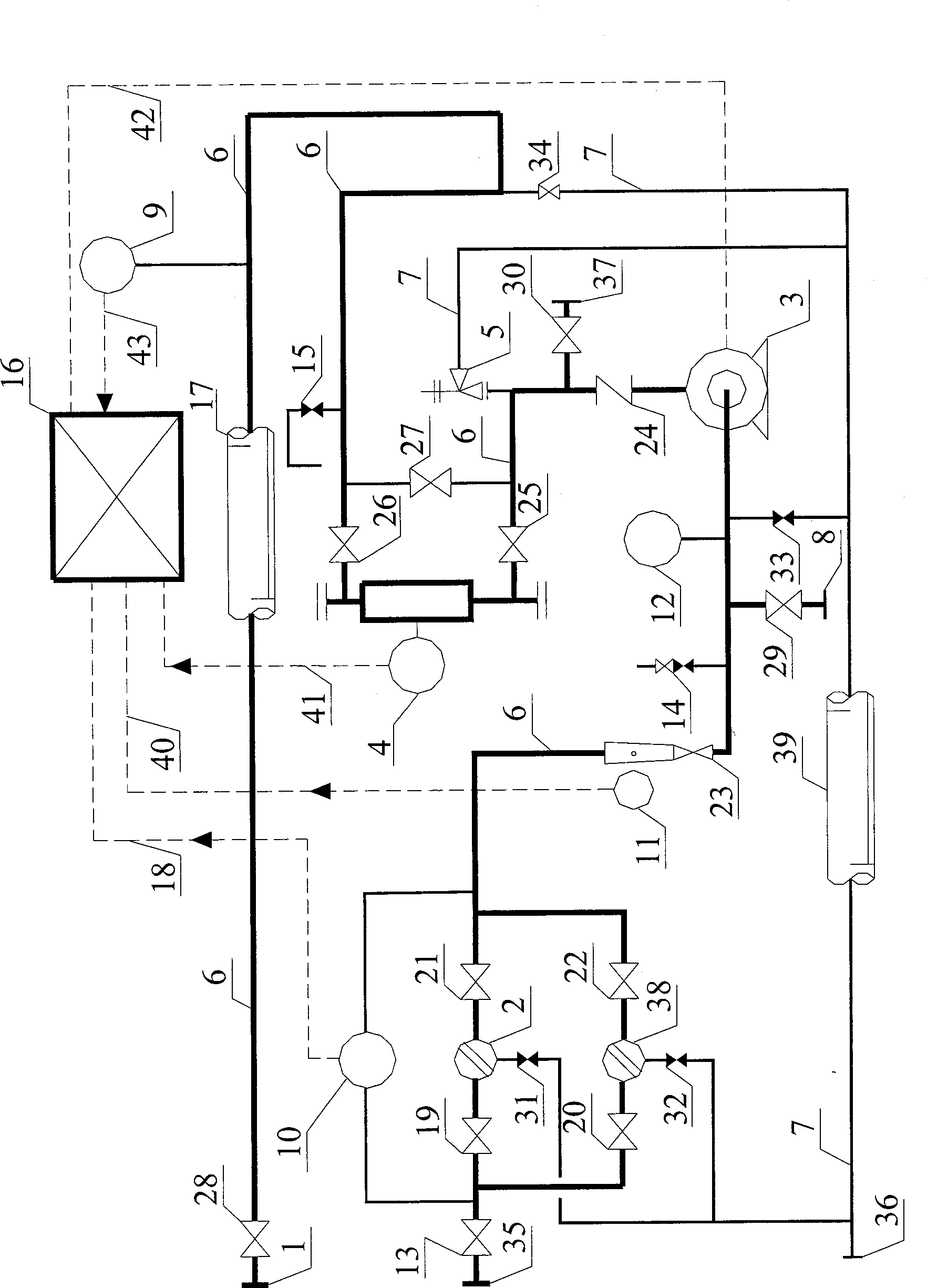

Online density measurement method and device of petroleum transmission pipeline

ActiveCN102313139AImprove accuracyImprove stabilityVolume/mass flow measurementPipeline systemsElectricityMeasurement device

The invention discloses an online density measurement method and device of a petroleum transmission pipeline. The online density measurement device is characterized in that one section of process main pipeline (6) with a constant-temperature electric tracing and insulating function (17) is serially connected to a bypass pipeline arranged on a pipeline to be measured, and the inlet end and the outlet end of the process main pipeline (6) are respectively controlled by process valves. Starting from the process valve (13) at the inlet end of the process main pipeline (6), oil flowing through the process main pipeline (6) is sequentially subjected to the following flows of: 1, filtering and draining; 2, measuring of pressure difference of two filtering ends; 3, flow testing; 4, manual sampling; 5, online checking; 6, pressure detecting; 7, draining; 8, sampling of a sampling pump (3); 9, online checking; 10, heat expansion safety protecting; 11, online density detecting; 12; exhausting; 13, processing of an intelligent pressure transformer; and 14, pressure difference measuring, flow detecting, sampling, online density detecting, and sending of signals to an apparatus junction box (16)and then an SCADA (Supervisory Control And Data Acquisition) system by the intelligent pressure transformer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

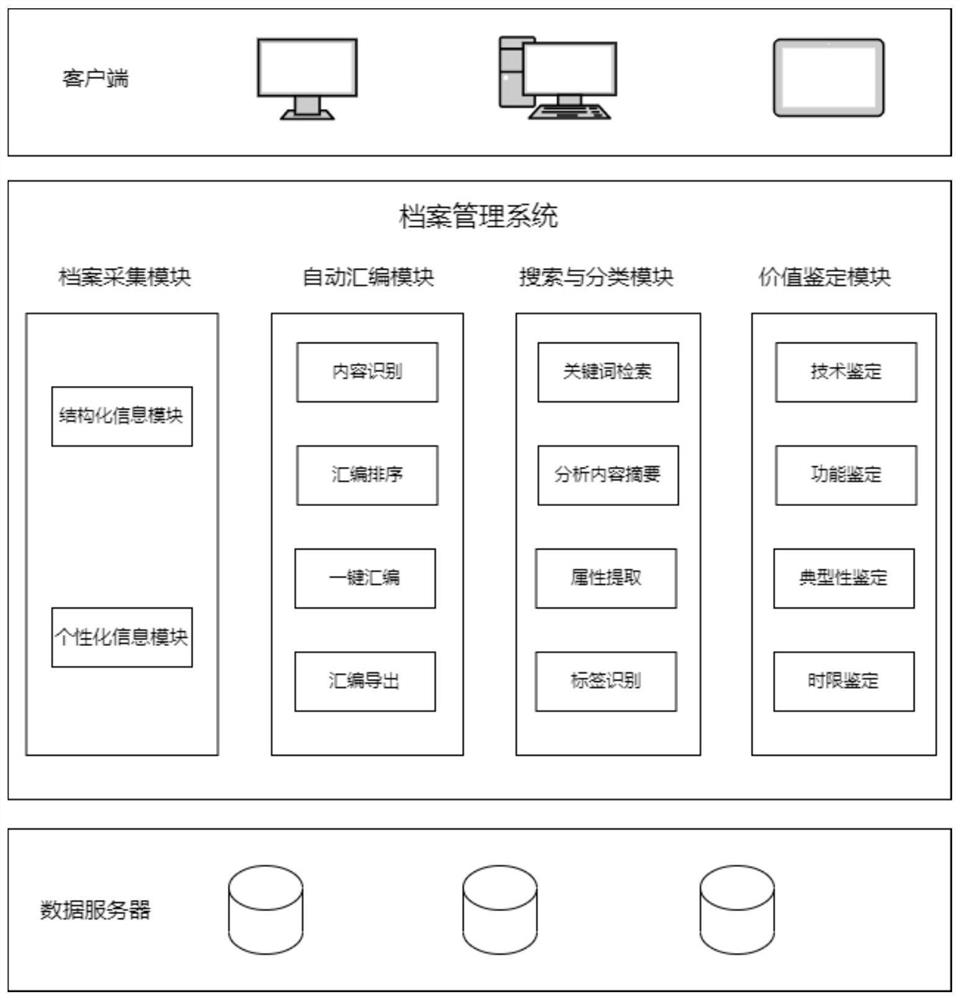

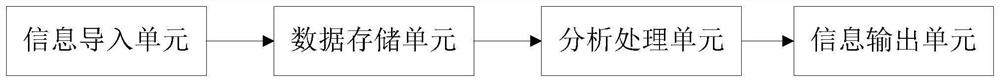

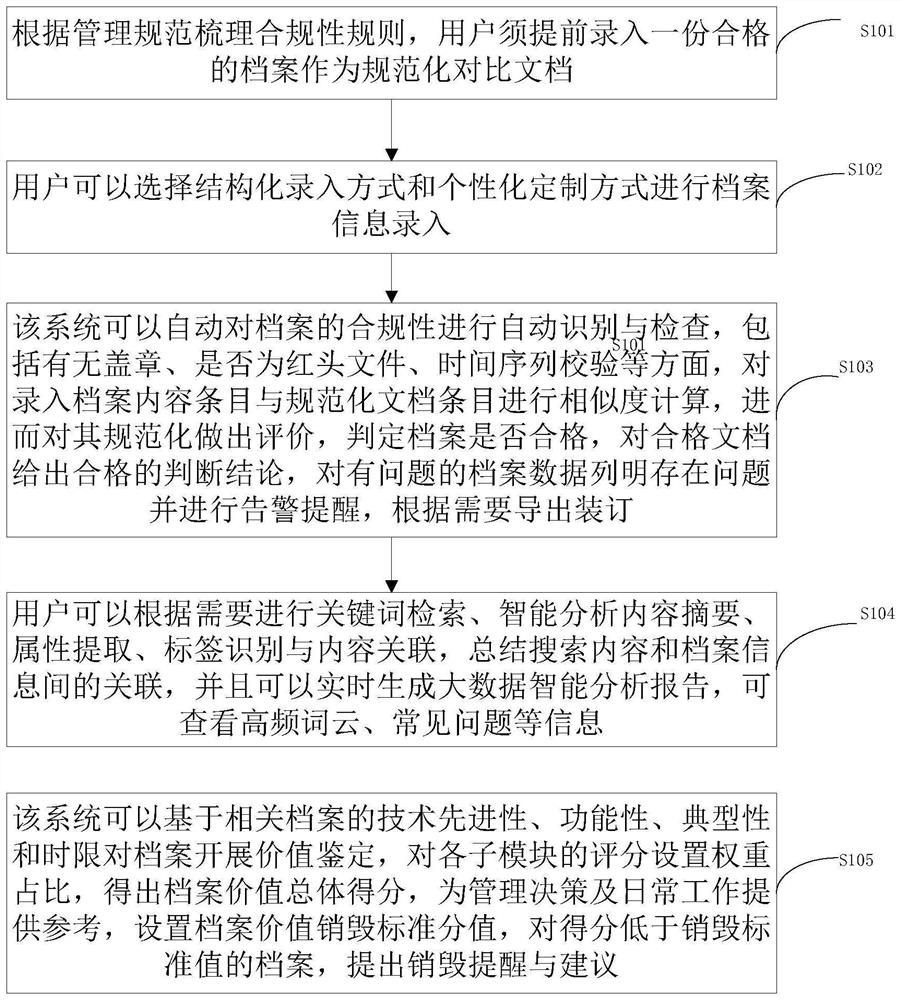

Archive management system based on artificial intelligence

InactiveCN114297140ASolve problemsSolve the real problemStill image data indexingCharacter and pattern recognitionEngineeringIntelligent management

The invention belongs to the technical field of archive management, and discloses an archive management system based on artificial intelligence, which comprises an archive acquisition module, an automatic assembly module, a search and classification module and an archive value identification module, the archive acquisition module is used for acquiring user archive information and performing compliance verification on archives; the automatic assembly module is used for achieving automatic assembly of the archives and exporting and binding the archives according to needs; the search and classification module is used for realizing keyword retrieval and providing big data intelligent analysis; and the archive value identification module is used for realizing intelligent identification of archive values, and value scoring provides reference for management decision and daily work. According to the archive management system based on artificial intelligence provided by the invention, difficulties and problems encountered in current archive management are solved, archive data compliance online verification, automatic assembly, intelligent search classification and archive value identification are realized, and the intelligent management level of archives is improved.

Owner:李莉

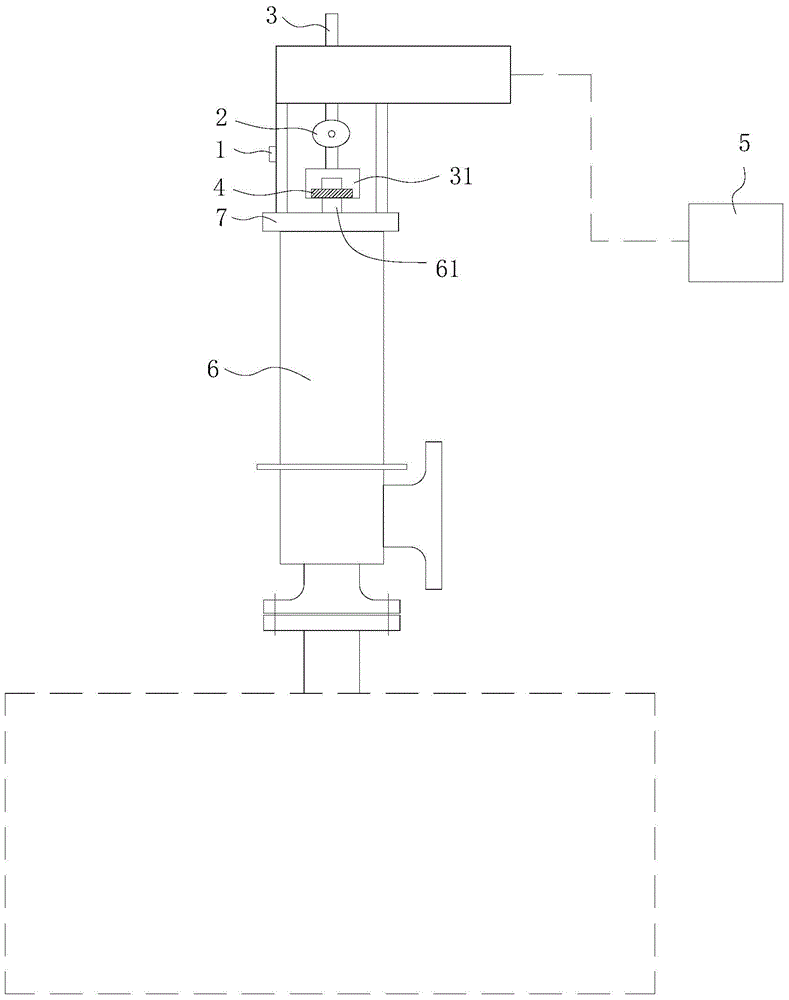

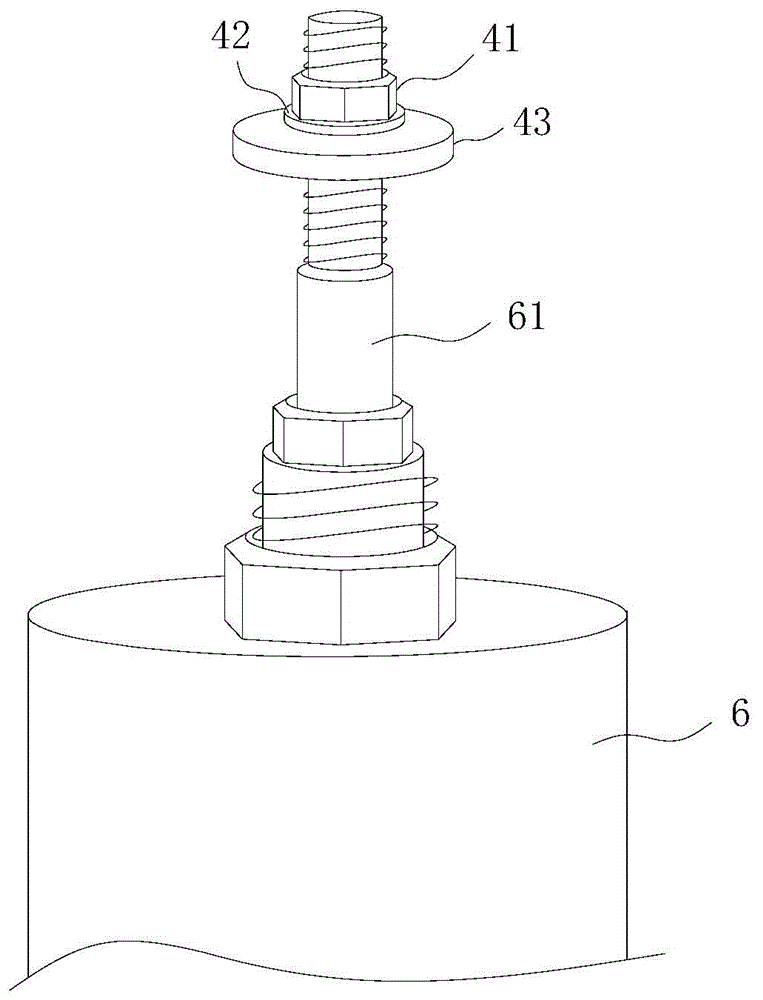

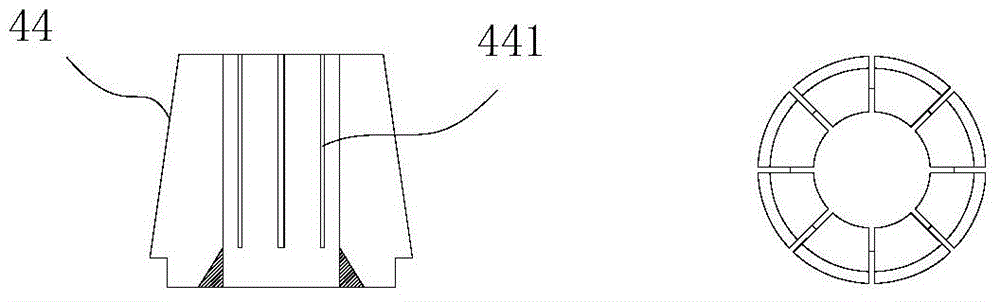

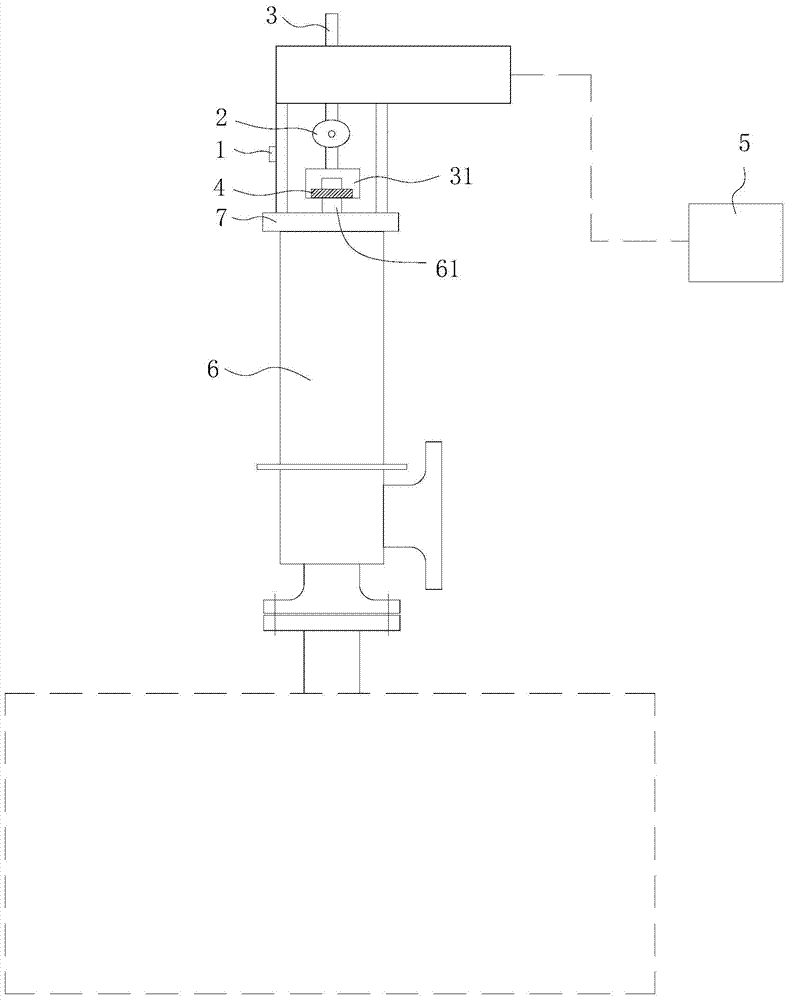

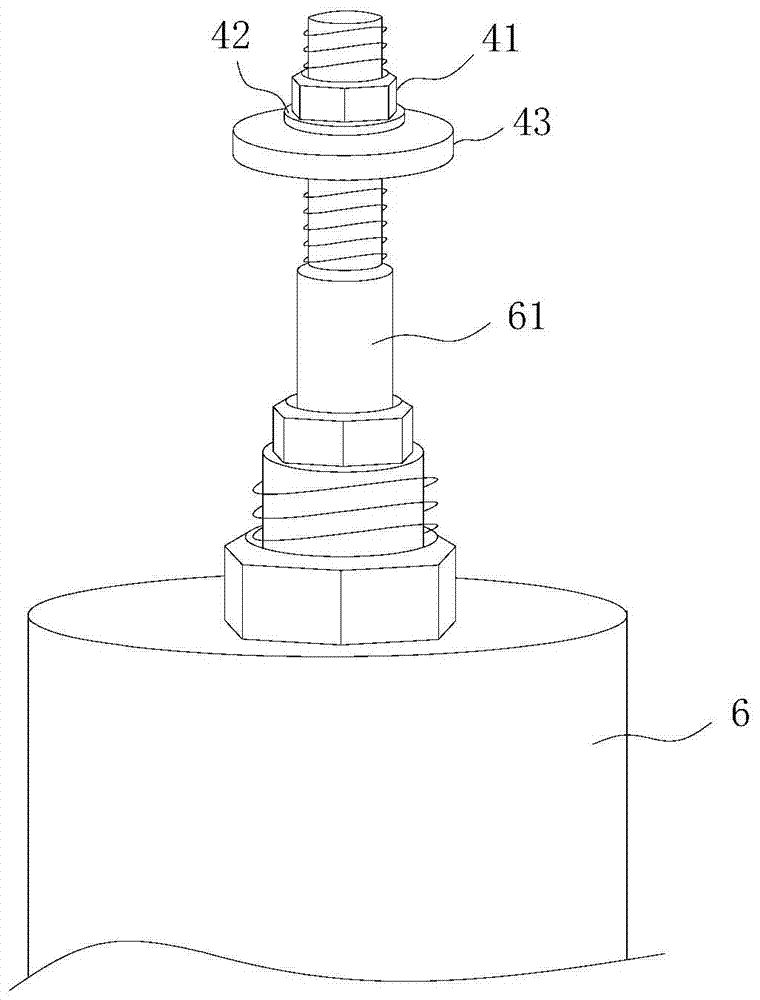

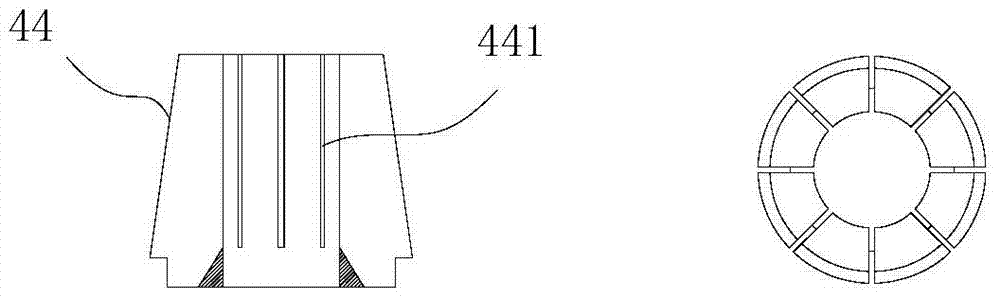

On-line safety valve checking method and device

ActiveCN104406781AExtended duty cycleAffect the tightnessMachine part testingOnline and offlineEngineering

The invention provides an on-line safety valve checking method and device. A safety valve is subjected to online checking through the device, the device comprises a force sensor mounted on a lifting rod, the force sensor is connected with a control system, the safety valve is arranged on a pressure vessel with slurry in the lower portion and steam in the upper portion, in a normal working pressure range of the safety valve, the control system controls lifting height and opening time of a valve stem of the safety valve by the device, and the device is enabled to finish checking after the slurry arrives at a valve port of the safety valve. Therefore, influence on sealing performance of the safety valve due to discharge of a viscous medium in a flash evaporator is avoided, further the operating period of the flash evaporator can be prolonged, cost in a series of working processes of detachment, lifting, transportation, checking, reassembling and the like during online and offline checking of the safety valve can be omitted, labor intensity of workers is lowered, and normal operation of companies is guaranteed.

Owner:GUANGXI HUAYIN ALUMINUM

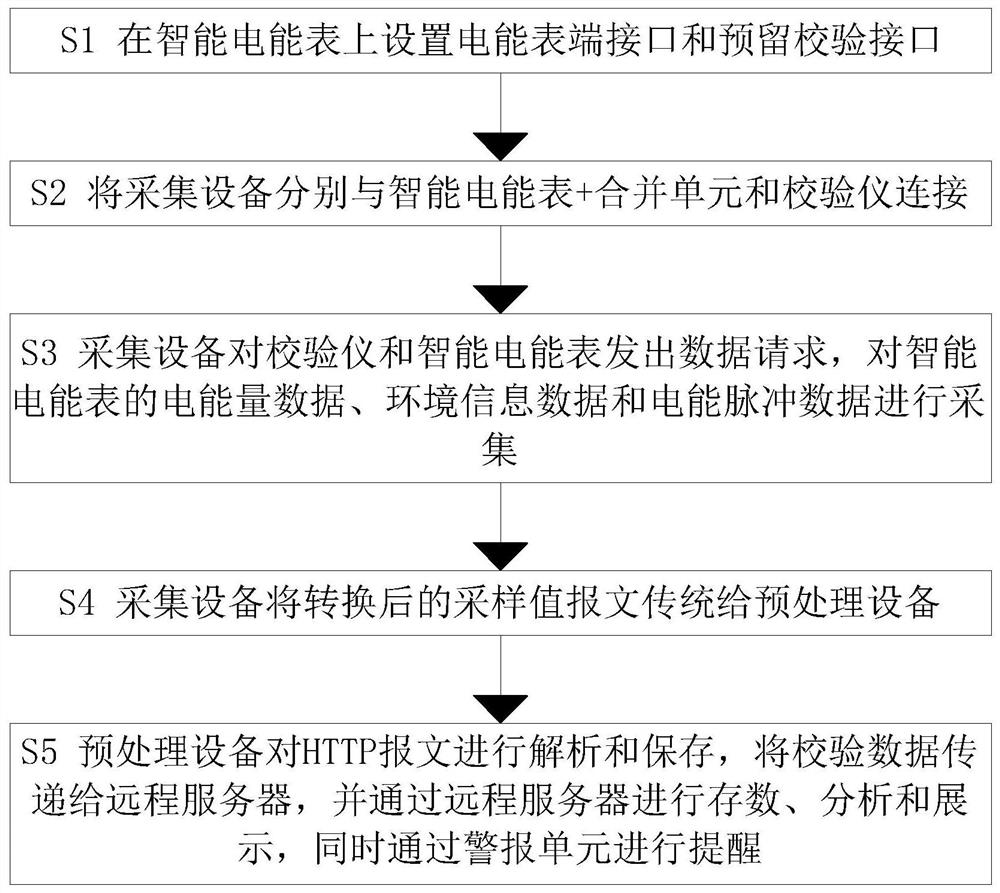

Remote online verification method for intelligent electric energy meter

PendingCN112255584ARealize online verificationGuaranteed accuracyElectrical measurementsAcquisition apparatusControl engineering

Owner:NORTH CHINA GRID MEASUREMENT CENT +1

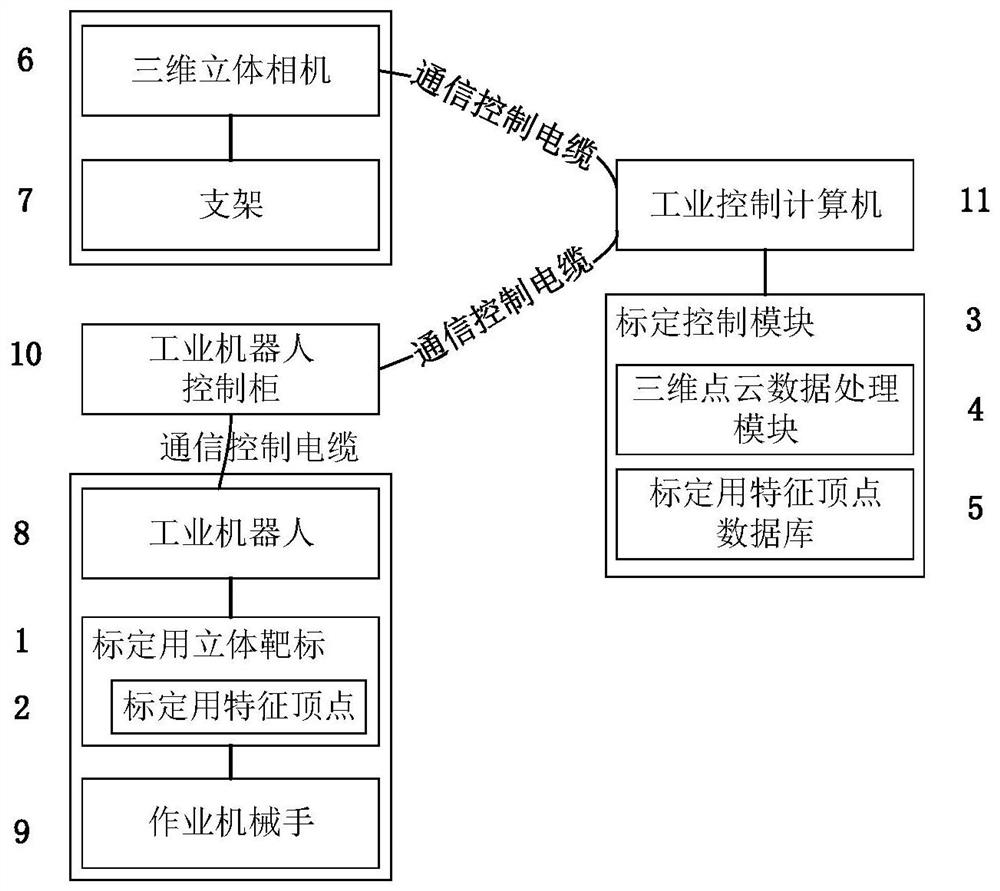

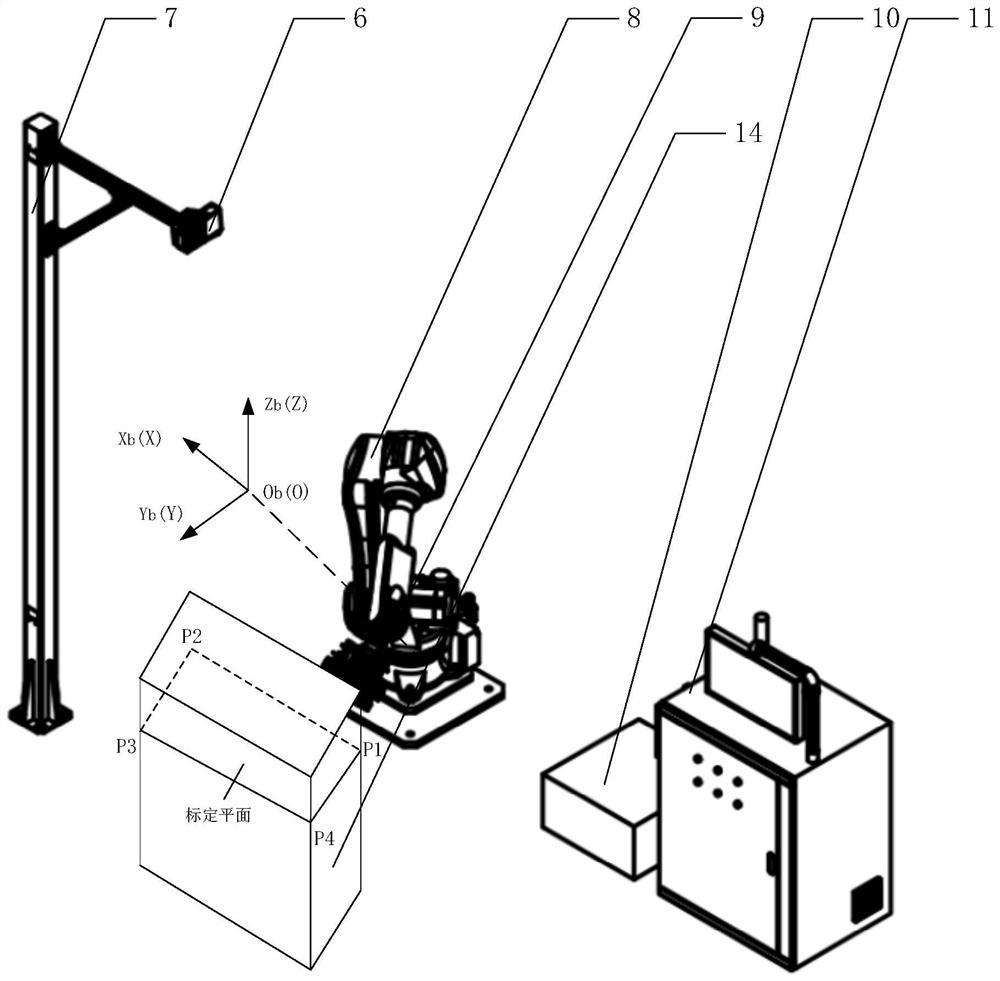

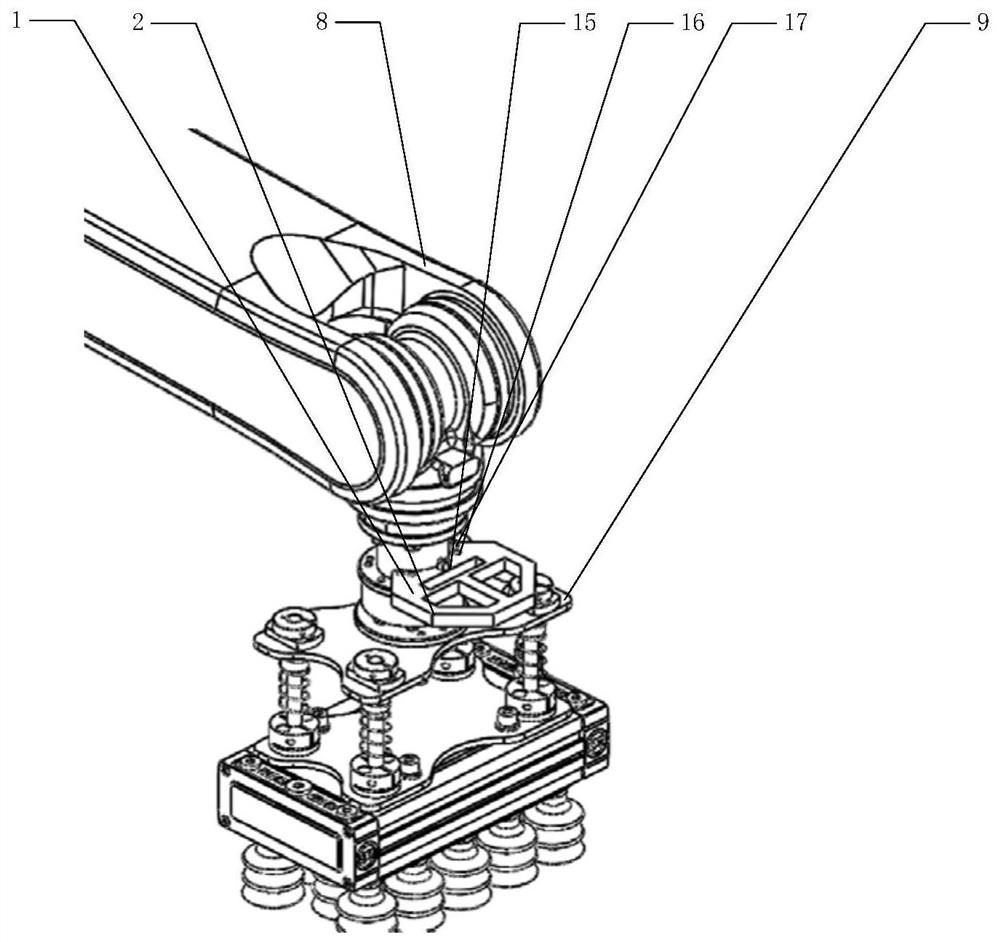

Three-dimensional camera pose online calibration device and method for industrial robot

PendingCN112356073AHigh precisionSimplify the calibration processProgramme-controlled manipulatorImage enhancementRobot handPoint cloud

The invention discloses a three-dimensional camera pose online calibration device and method for an industrial robot. The three-dimensional camera pose online calibration method comprises the steps that the industrial robot drives a three-dimensional target for calibration to move to a calibration point location in a certain pose; a three-dimensional camera can measure three-dimensional point cloud data in a space and output local three-dimensional point cloud data of the three-dimensional target for calibration and of a structural part nearby the three-dimensional target to a calibration control module of an industrial control computer, and the calibration control module processes, resolves and obtains three-dimensional coordinates of visible characteristic vertexes for calibration undera three-dimensional camera coordinate system; the three-dimensional coordinates of all visible characteristic vertexes for calibration under an industrial robot coordinate system are identified, searched and obtained; and a coordinate transformation matrix between the three-dimensional camera and the industrial robot is resolved. The method does not need additional calibration tool accessories, and has the characteristics of high efficiency, high precision and capability of checking or calibrating the coordinate transformation matrix between the three-dimensional camera and the industrial robot on line after a manipulator is mounted and in the use process.

Owner:XIAN ZHONGKE PHOTOELECTRIC PRECISION ENG CO LTD

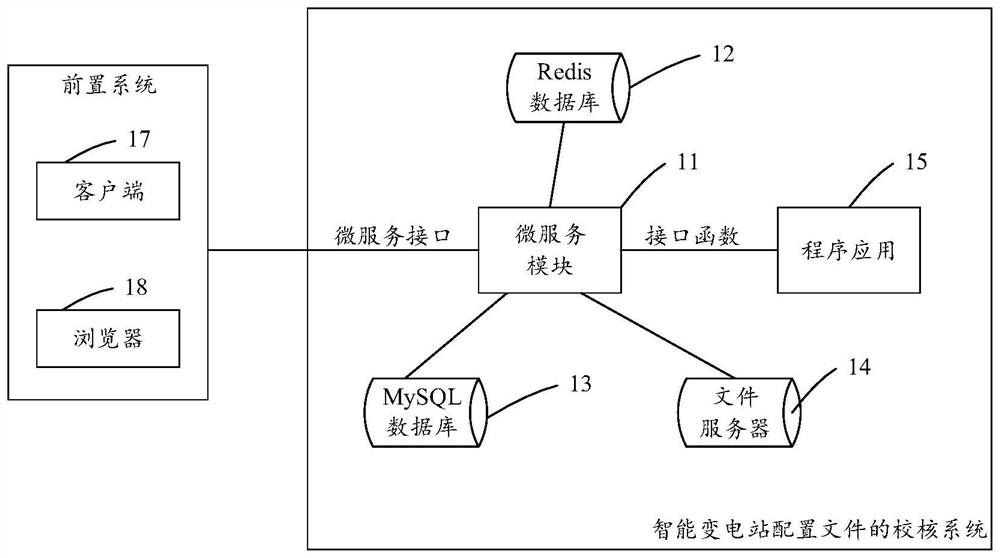

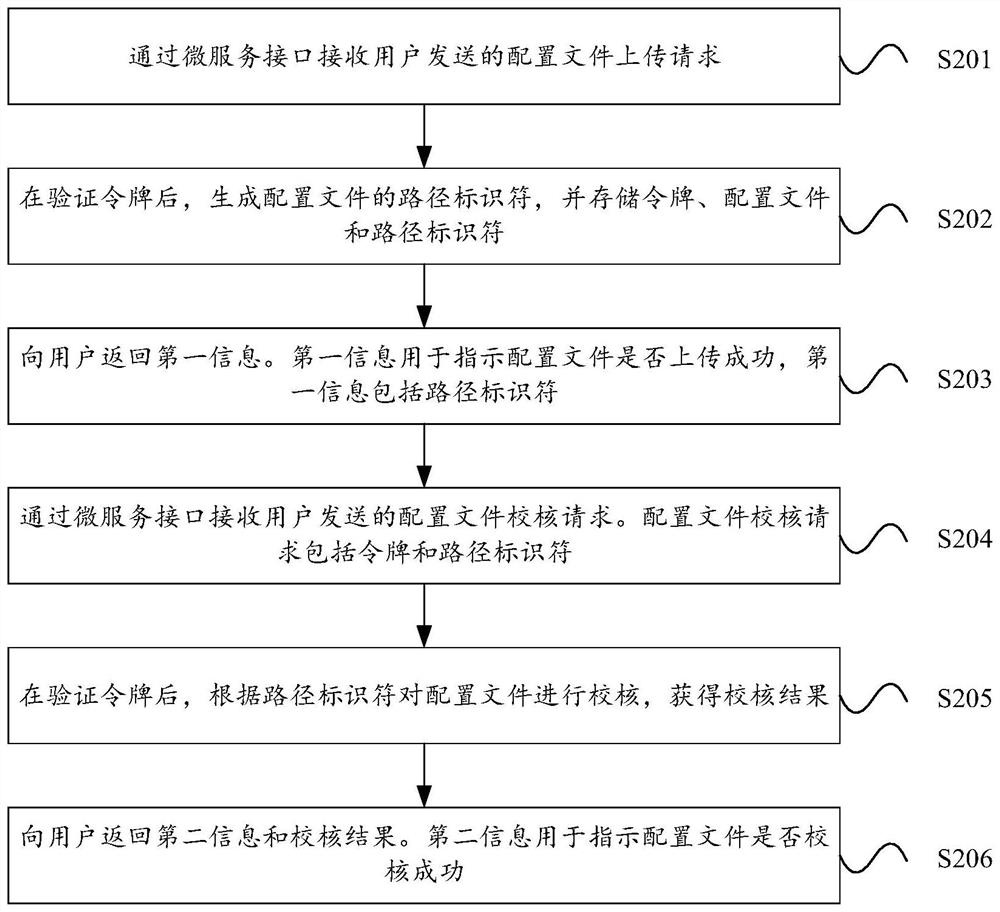

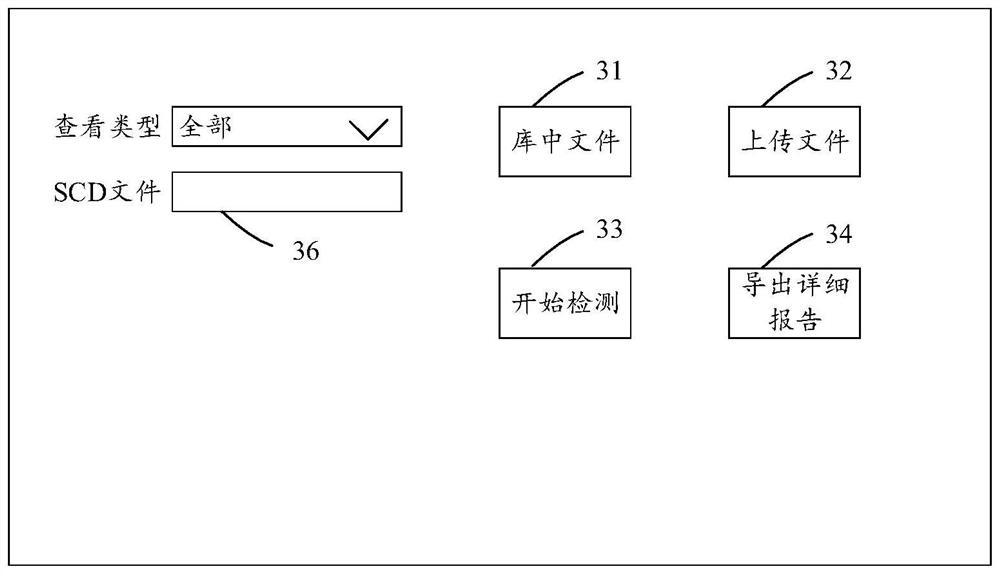

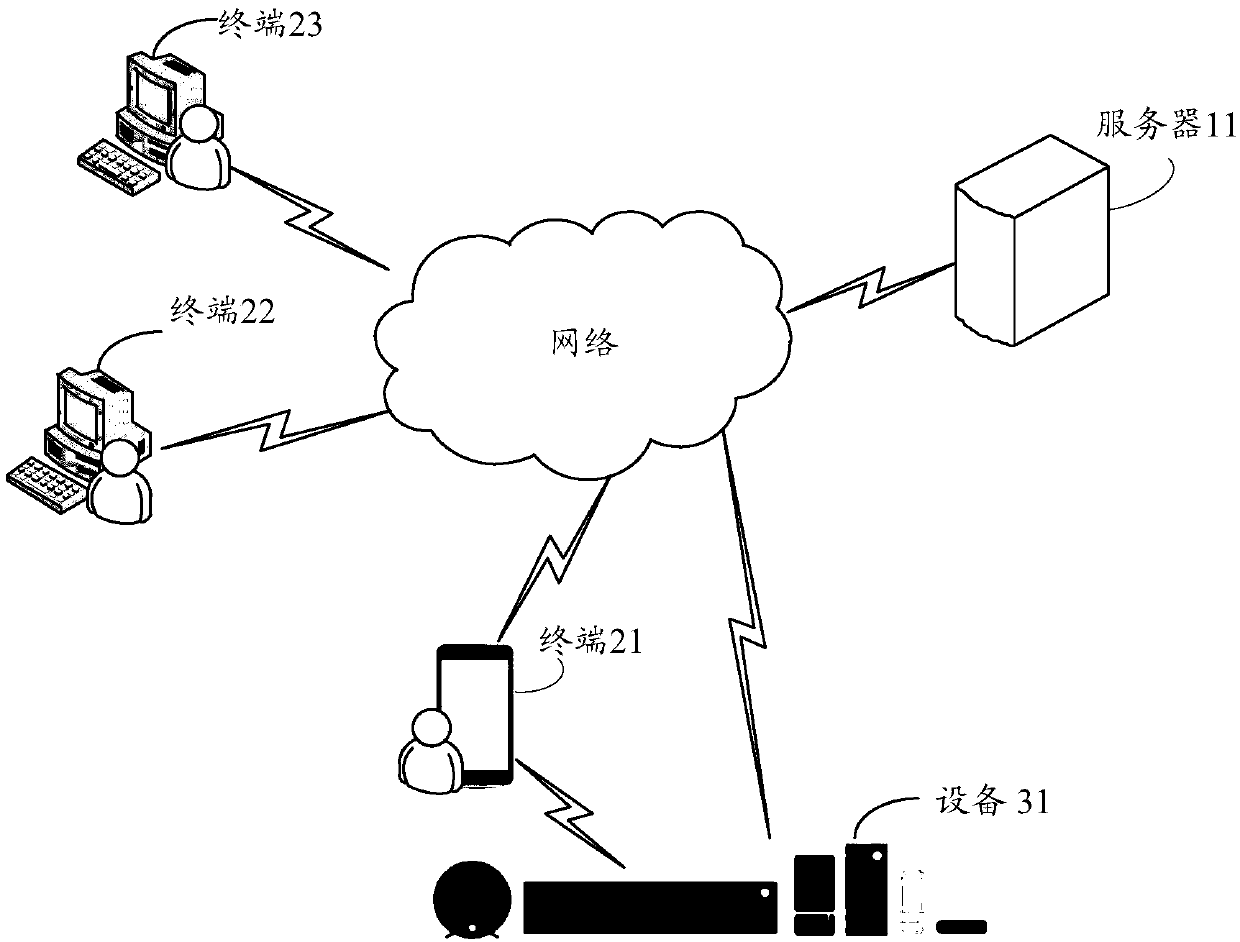

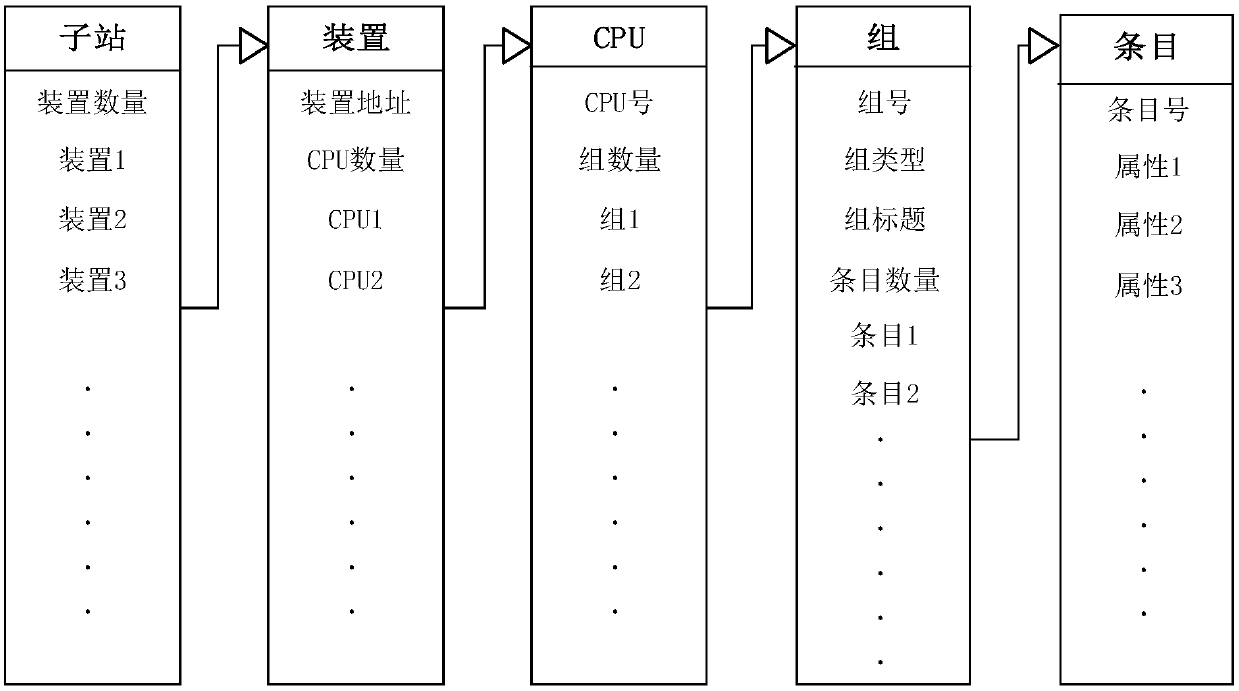

Method, device, equipment and system for checking configuration file of intelligent substation

PendingCN114429408ARealize online verificationImprove adaptabilityData processing applicationsRelational databasesPathPingSmart substation

The invention relates to the technical field of power system automation, and provides an intelligent substation configuration file checking method, device, equipment and system. The checking method for the configuration file of the intelligent substation comprises the following steps: receiving a configuration file uploading request sent by a user through a micro-service interface; after the token is verified, generating a path identifier of the configuration file, and storing the token, the configuration file and the path identifier; first information used for indicating whether the configuration file is successfully uploaded is returned to the user; receiving a configuration file checking request sent by a user through the micro-service interface, wherein the configuration file checking request comprises a token and a path identifier; after the token is verified, checking the configuration file according to the path identifier to obtain a checking result; and returning second information for indicating whether the configuration file is successfully checked and a checking result to the user. The micro-service interface is provided for the outside based on the micro-service architecture, online checking of the intelligent substation configuration file is achieved, and the adaptability of the checking mode is improved.

Owner:CHINA SOUTHERN POWER GRID COMPANY +1

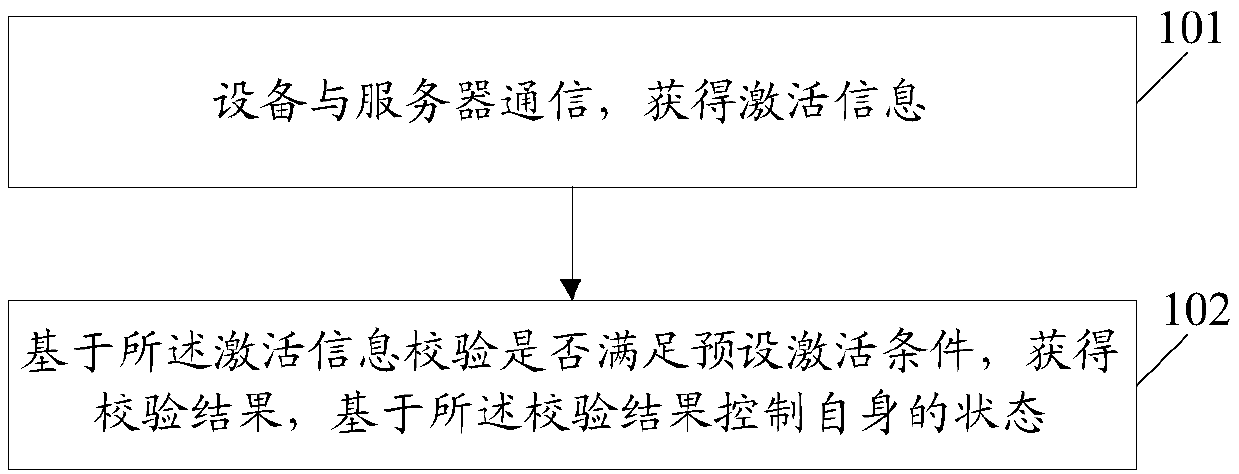

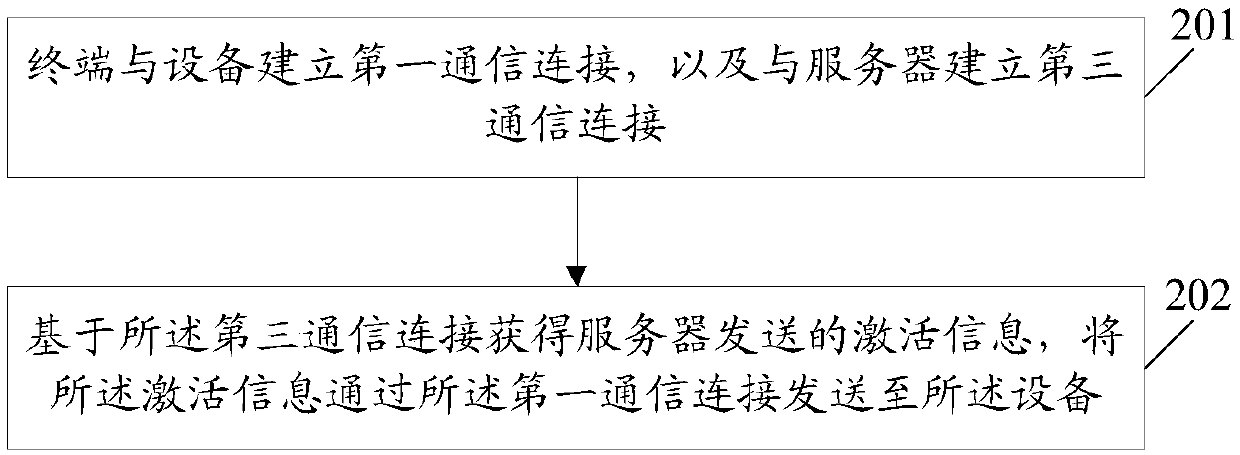

Control methods and systems, equipment and a computer memory medium

PendingCN109673012ARealize online verificationBuying/selling/leasing transactionsSecurity arrangementComputer memoryComputer science

The embodiments of the invention disclose control methods and systems, equipment and a computer memory medium. A method comprises the steps that the equipment communicates with a server and obtains activation information; and the equipment checks whether a preset activation condition is satisfied or not based on the activation information, obtains a check result and controls own state based on thecheck result.

Owner:LITTLE BIRD CO LTD

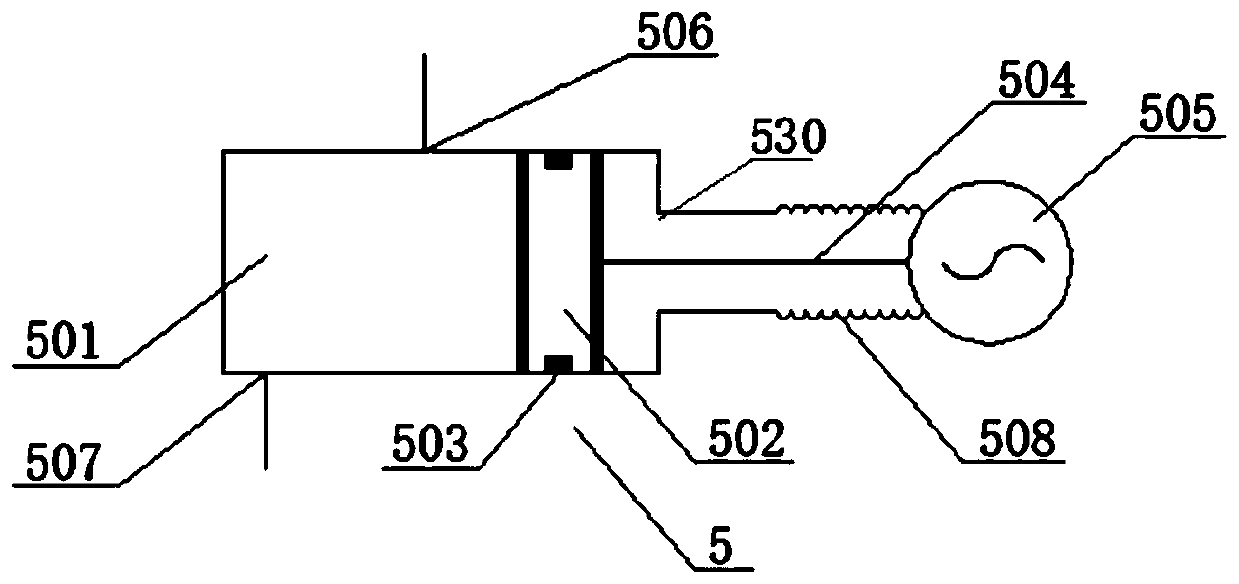

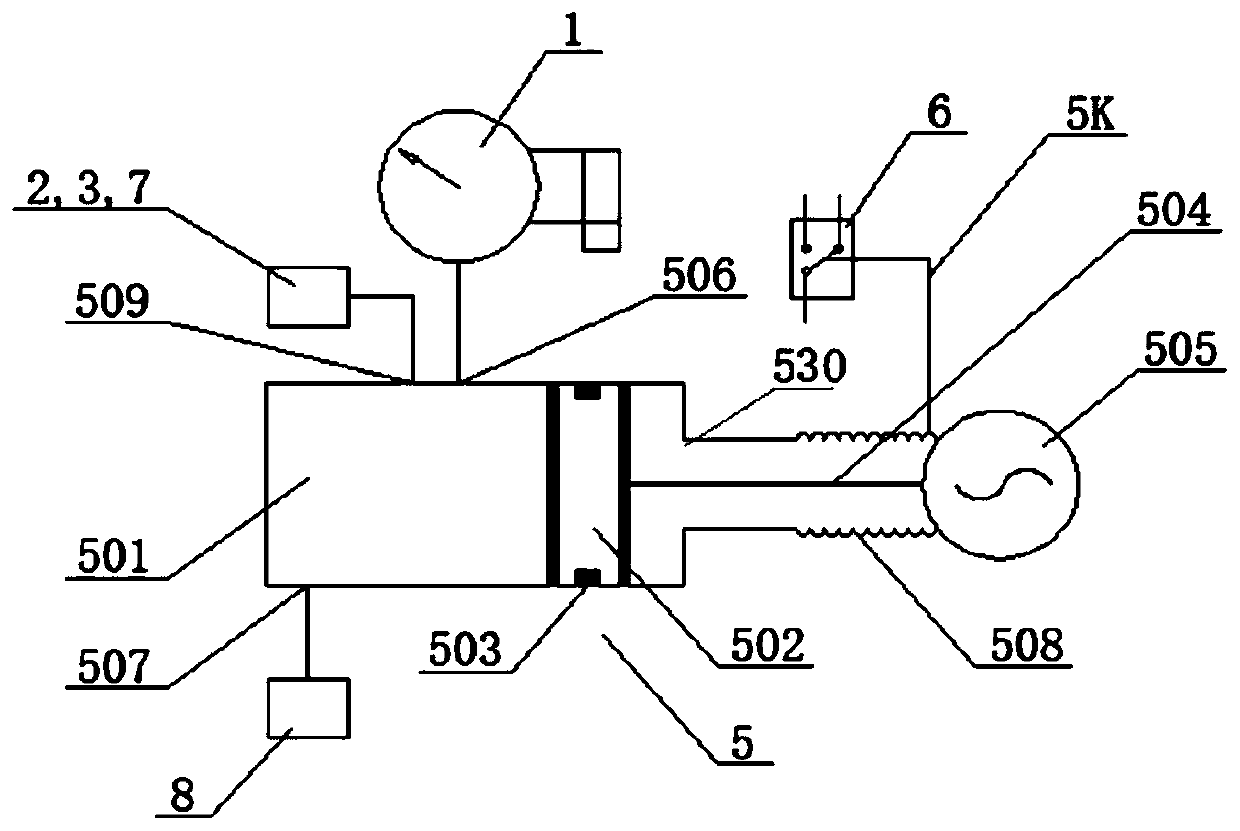

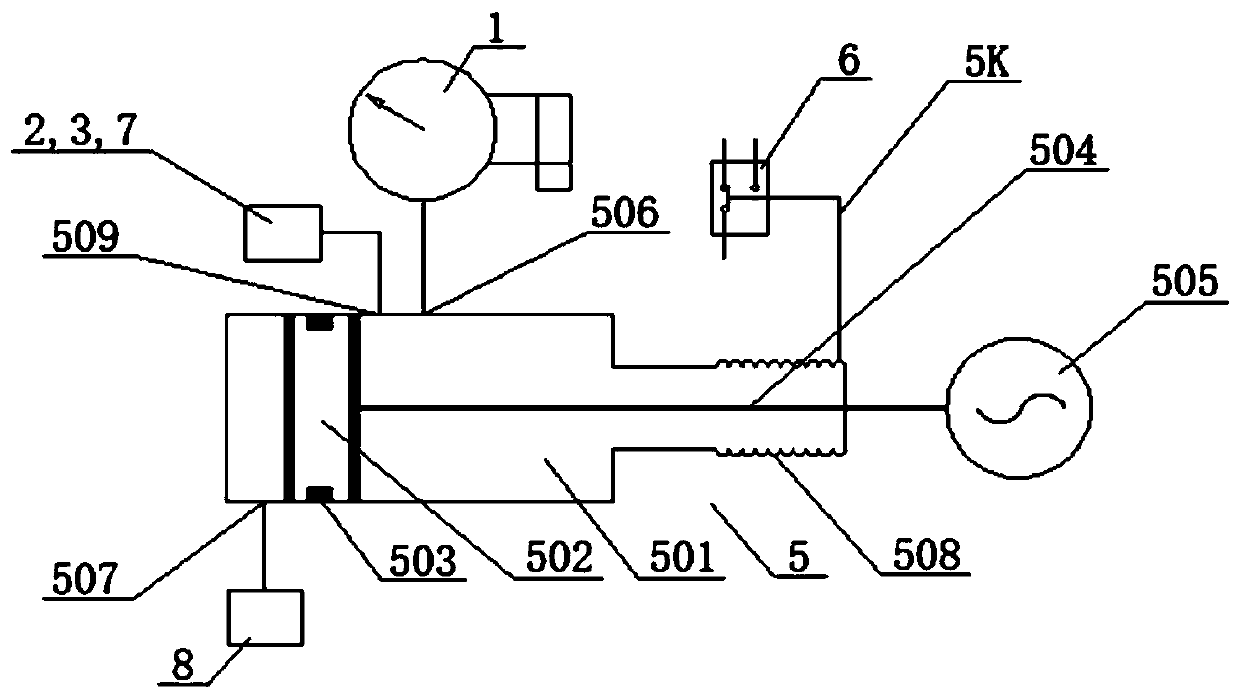

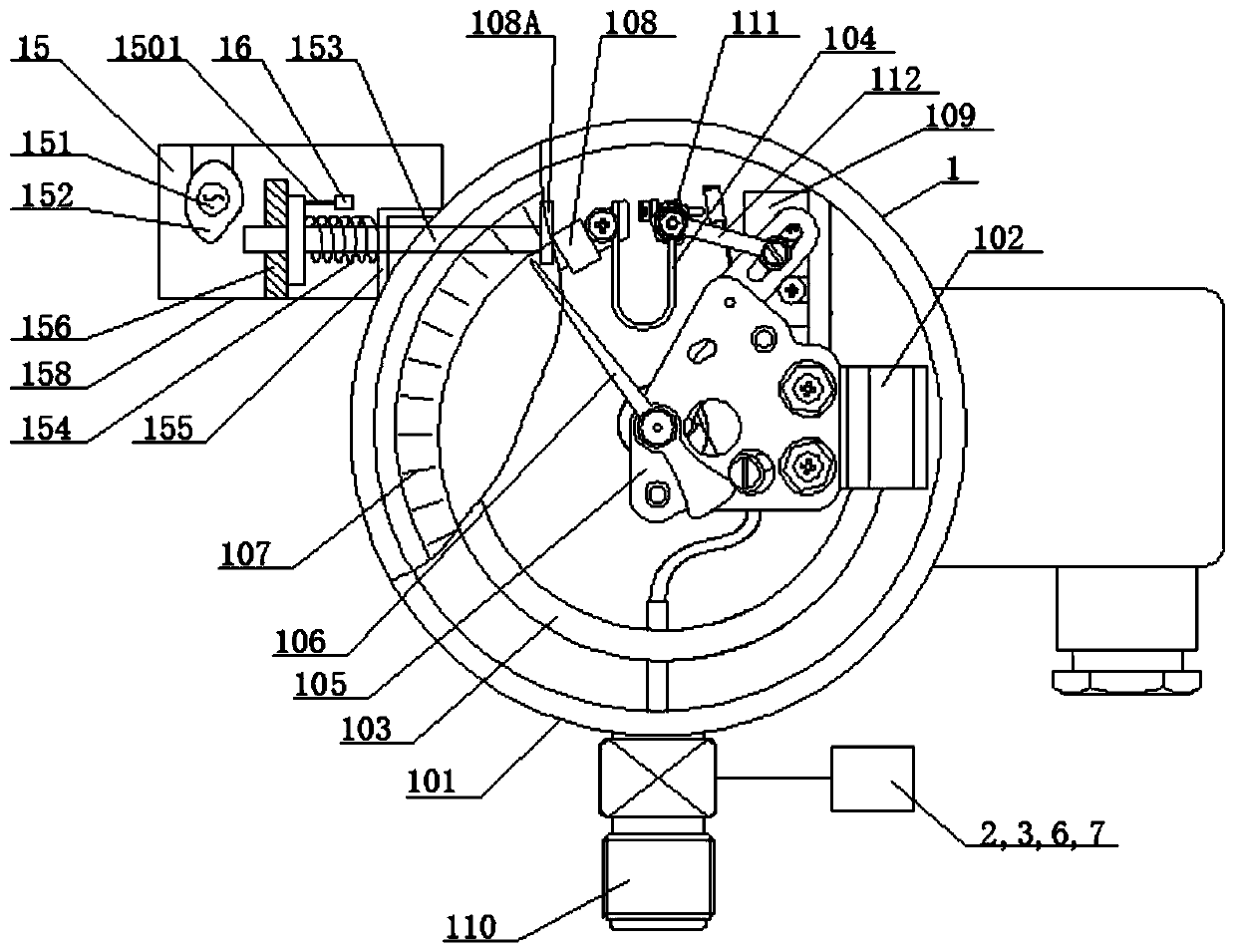

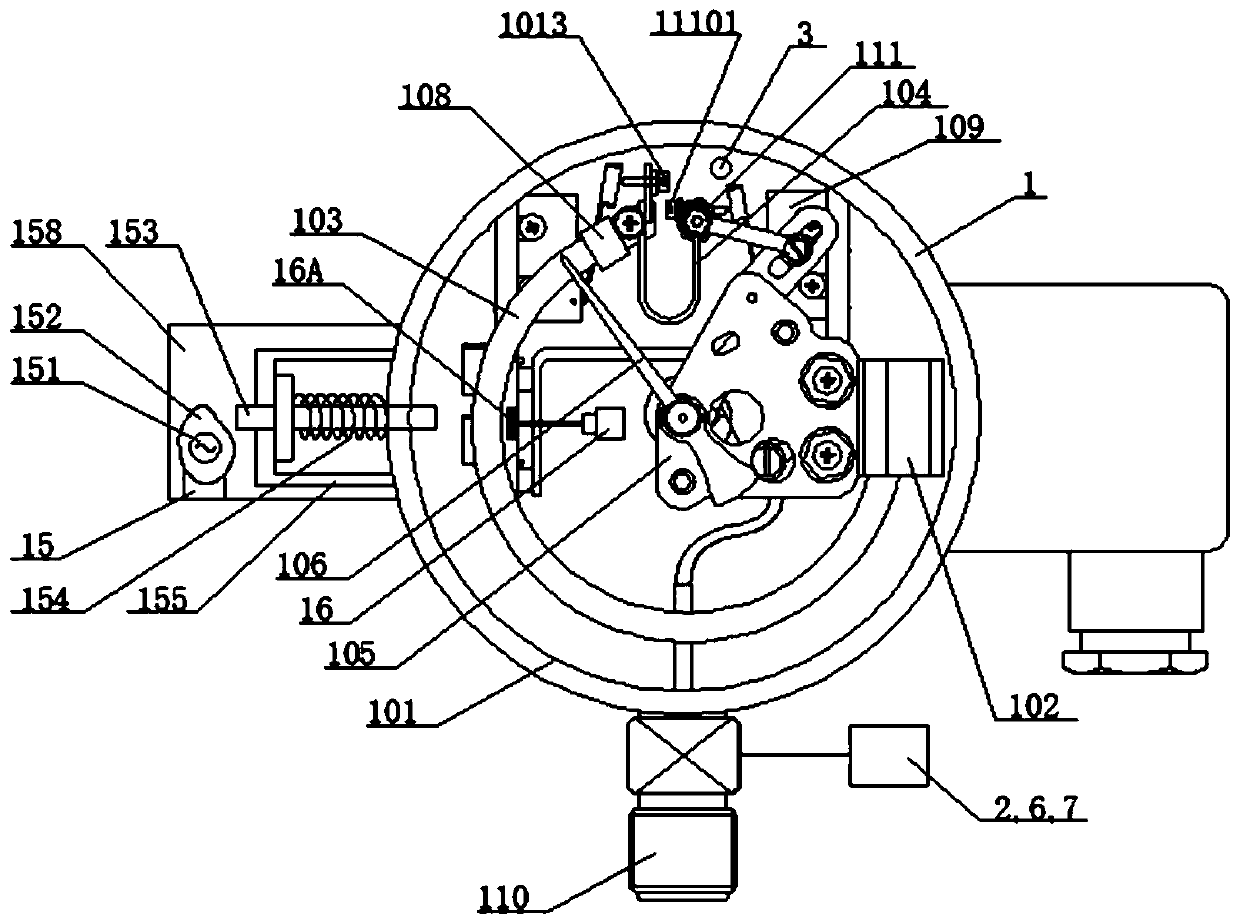

Gas circuit partition pressure adjusting mechanism for online verification of density relay

PendingCN110954816ARealize online verificationSpecific gravity by measuring pressure differencesFluid pressure control using electric meansPower gridEngineering

The invention provides a gas circuit partition pressure adjusting mechanism for online verification of a density relay, the gas circuit partition pressure adjusting mechanism comprises a gas circuit partition pressure adjusting mechanism body, the pressure adjusting mechanism body comprises a sealed cavity, a partition piece, a connecting rod and a driving part, and the sealed cavity is provided with a first interface and a second interface; a gas circuit of the gas circuit partition pressure regulating mechanism body is communicated with a gas circuit of the gas density relay through a firstinterface and is communicated with a gas circuit of electrical equipment through a second interface; the driving part drives the connecting rod so as to drive the partition piece to move in the sealedcavity; a gas path between the first interface and the second interface is isolated; the volume of the sealed cavity is changed according to the position change of the partition piece; therefore, thepressure of the gas density relay is adjusted to rise and fall, the gas density relay is enabled to generate contact signal action, online verification of the gas density relay is realized, verification can be completed without going to the site by maintainers, the reliability and efficiency of a power grid are greatly improved, and the cost is reduced.

Owner:SHANGHAI ROYE ELECTRICAL CO LTD

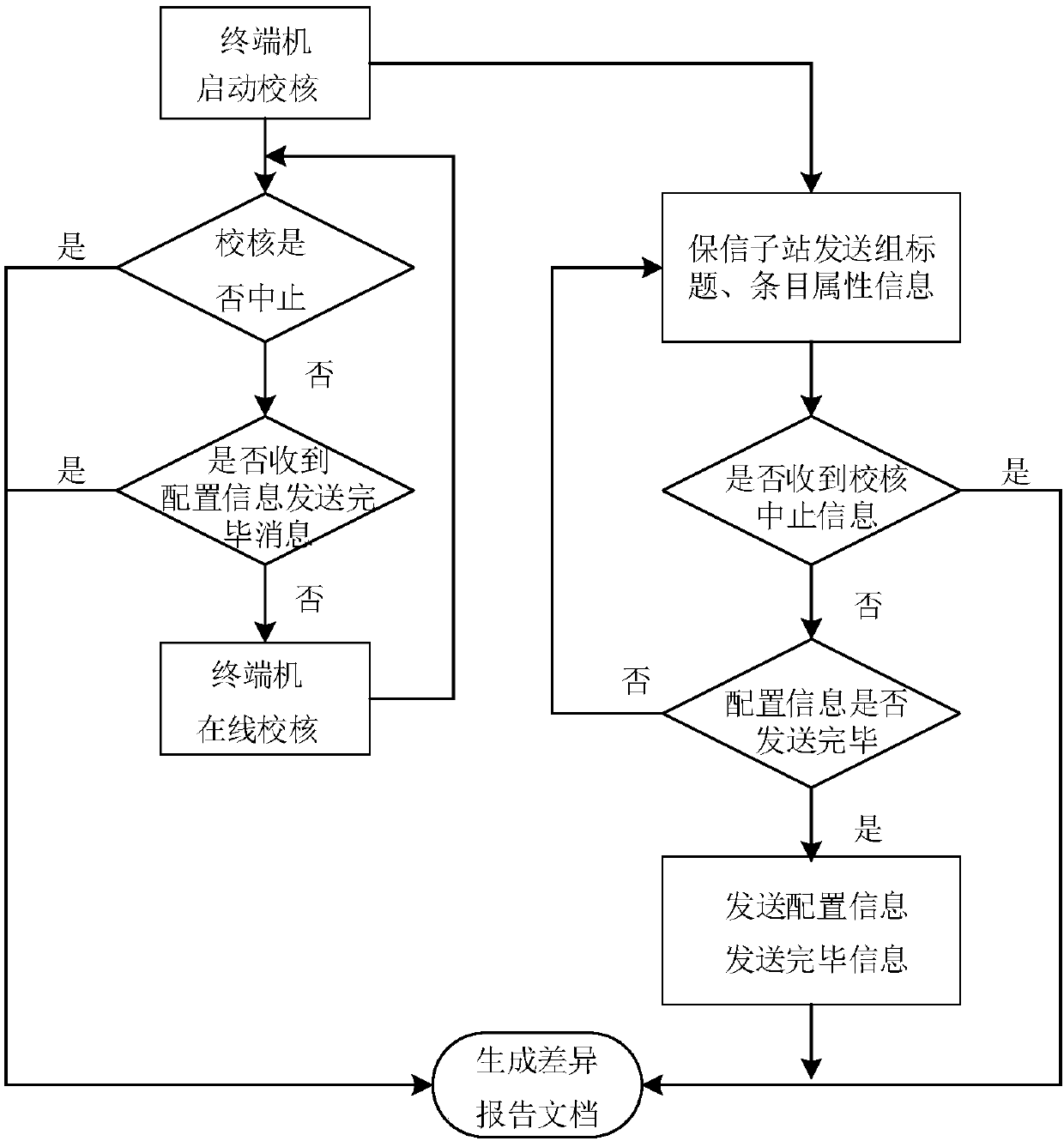

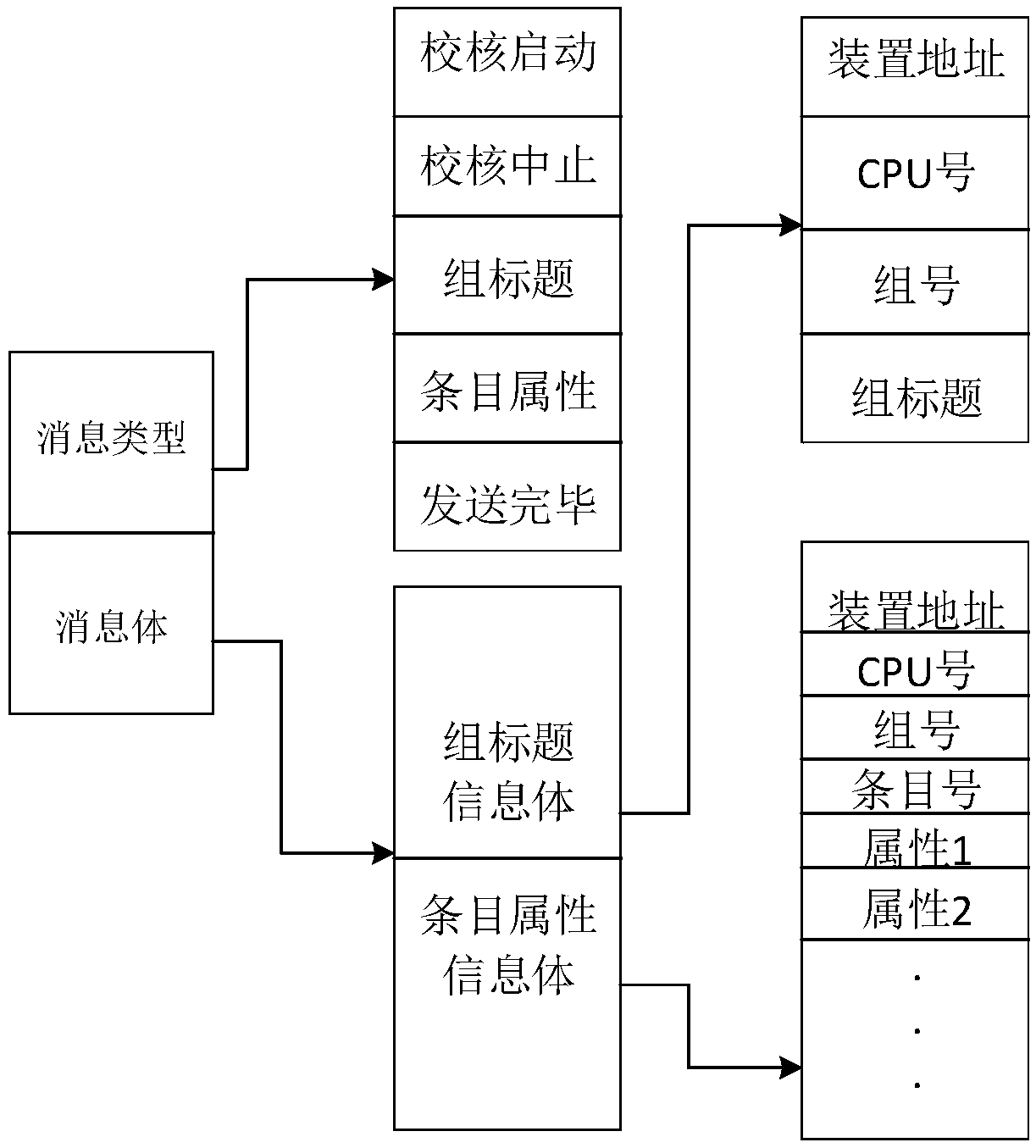

Remote verification method for configuration information of information protection substation

InactiveCN107948241ARealize online verificationRealize checkCircuit arrangementsTransmissionPower-system automationOperating system

The invention relates to the field of power system automation, in particular to a remote verification method for configuration information of an information protection substation. The remote verification method comprises the steps of constructing a data model of the configuration information of the configuration information of the information protection substation, and establishing a message communication mechanism of the information protection substation and a terminal machine, thereby realizing online verification of the configuration information of the information protection substation. Theremote verification method can realize verification of the configuration information of the information protection substation under the condition that the information protection substation does not quite operation, facilitates the operation and maintenance personnel to confirm the current running configuration, and further analyzes the configuration of the information protection substation online.

Owner:XJ ELECTRIC +2

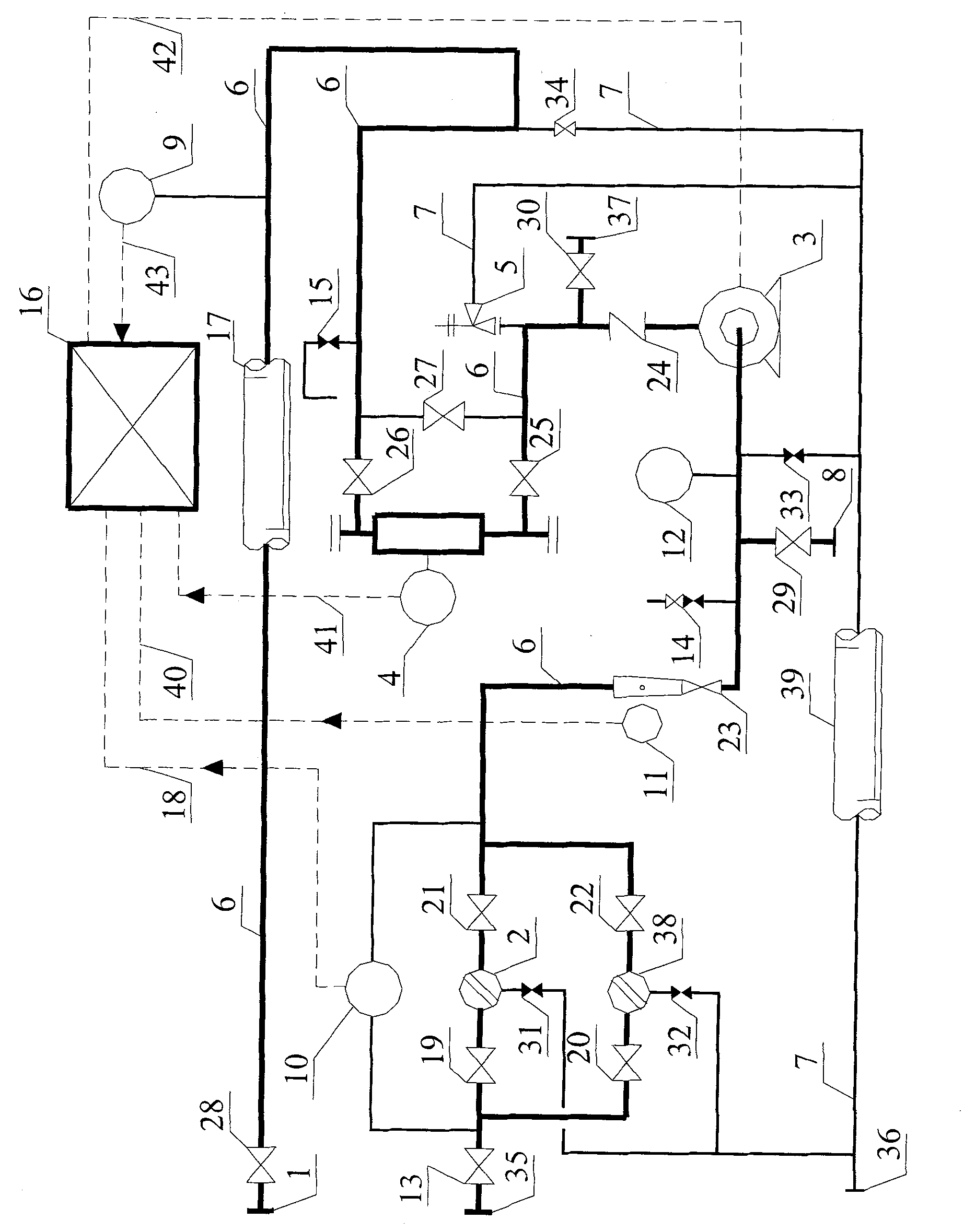

Oil conveying pipeline on-line density measuring device

ActiveCN102313137AConstruction standardizationBuilding modularPipeline systemsExhaust valveDifferential pressure

The invention discloses an oil conveying pipeline on-line density measuring device. A process main pipeline [6] of a constant-temperature electric heat tracing and thermal insulation device [17] is connected in series to a pipeline to be tested through a flange (1) [1] and a flange (2) [35] at the two outer ends, and is sequentially provided with parallel filter (1) [2] and filter (2) [38] and a differential pressure transmitter [10], a flow switch [11], a serial process valve (6) [23], a bypass manual sampling valve [14], a bypass on-line verification port (1) [8], a bypass in-situ pressure gauge [12], a bypass drainage pipeline [7], a sampling pump [3], a serial process valve (7) [24], a bypass on-line verification port (2) [37], a bypass thermal expansion safety valve [5], an on-line densimeter [4], a bypass exhaust valve [15], a bypass drainage pipeline [7] and an intelligent pressure transmitter [9] which are arranged in front of and behind the filters from the inlet end; and an instrument junction box [16] is connected with an SCADA (Supervisory Control And Data Acquisition) system.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

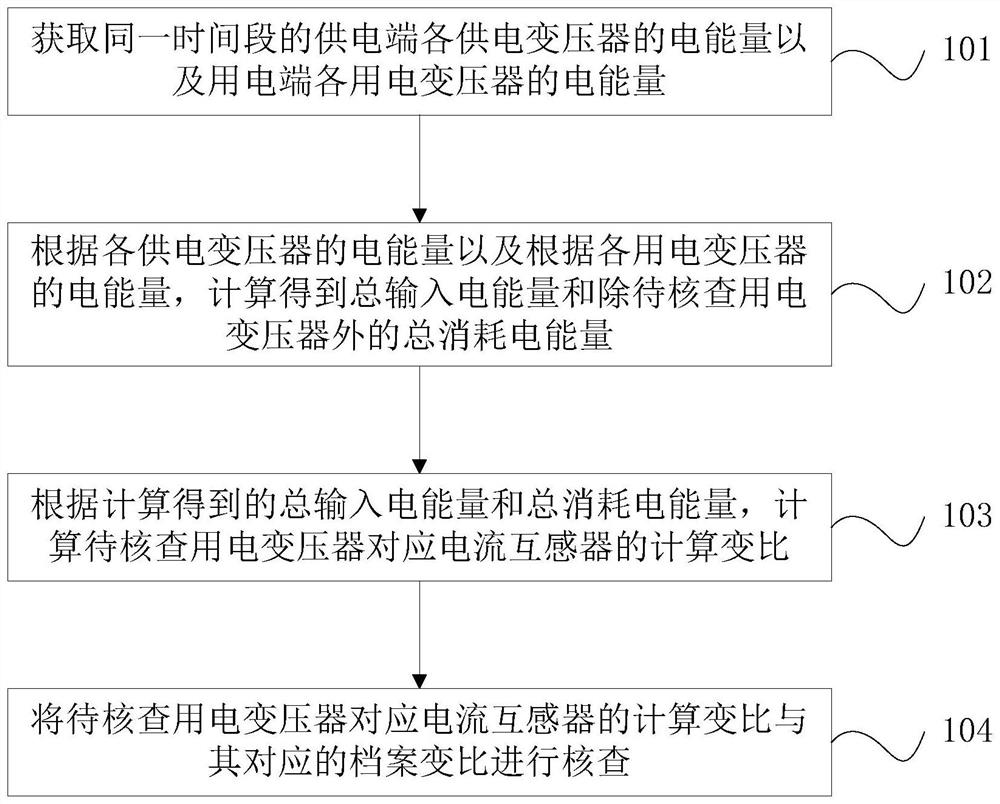

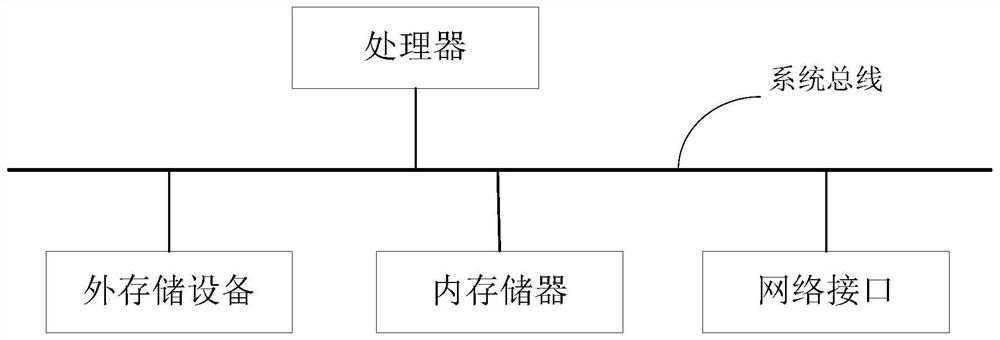

Power distribution network current transformer transformation ratio checking method and device, equipment and medium

PendingCN114062996ANo stealingRealize online verificationElectrical measurementsPower usageControl theory

The invention discloses a power distribution network current transformer transformation ratio checking method and device, equipment and a medium. The method comprises the following steps of: acquiring electric energy of each power supply transformer at a power supply end and electric energy of each power utilization transformer at a power utilization end in the same time period; according to the electric energy of each power supply transformer and the electric energy of each power utilization transformer, calculating to obtain total input electric energy and total consumed electric energy except a to-be-checked power utilization transformer; according to the calculated total input electric energy and total consumed electric energy and the consumed electric energy of the to-be-checked power utilization transformer, calculating a transformation ratio of a current transformer corresponding to the to-be-checked power utilization transformer; and checking the calculated transformation ratio of the current transformer corresponding to the to-be-checked power utilization transformer and a corresponding archive transformation ratio. According to the invention, the online checking of the transformation ratio of a power distribution network current transformer is realized by using the electric energy data, and the efficiency and reliability of the transformation ratio checking of the power distribution network current transformer are improved.

Owner:国网四川省电力公司营销服务中心 +1

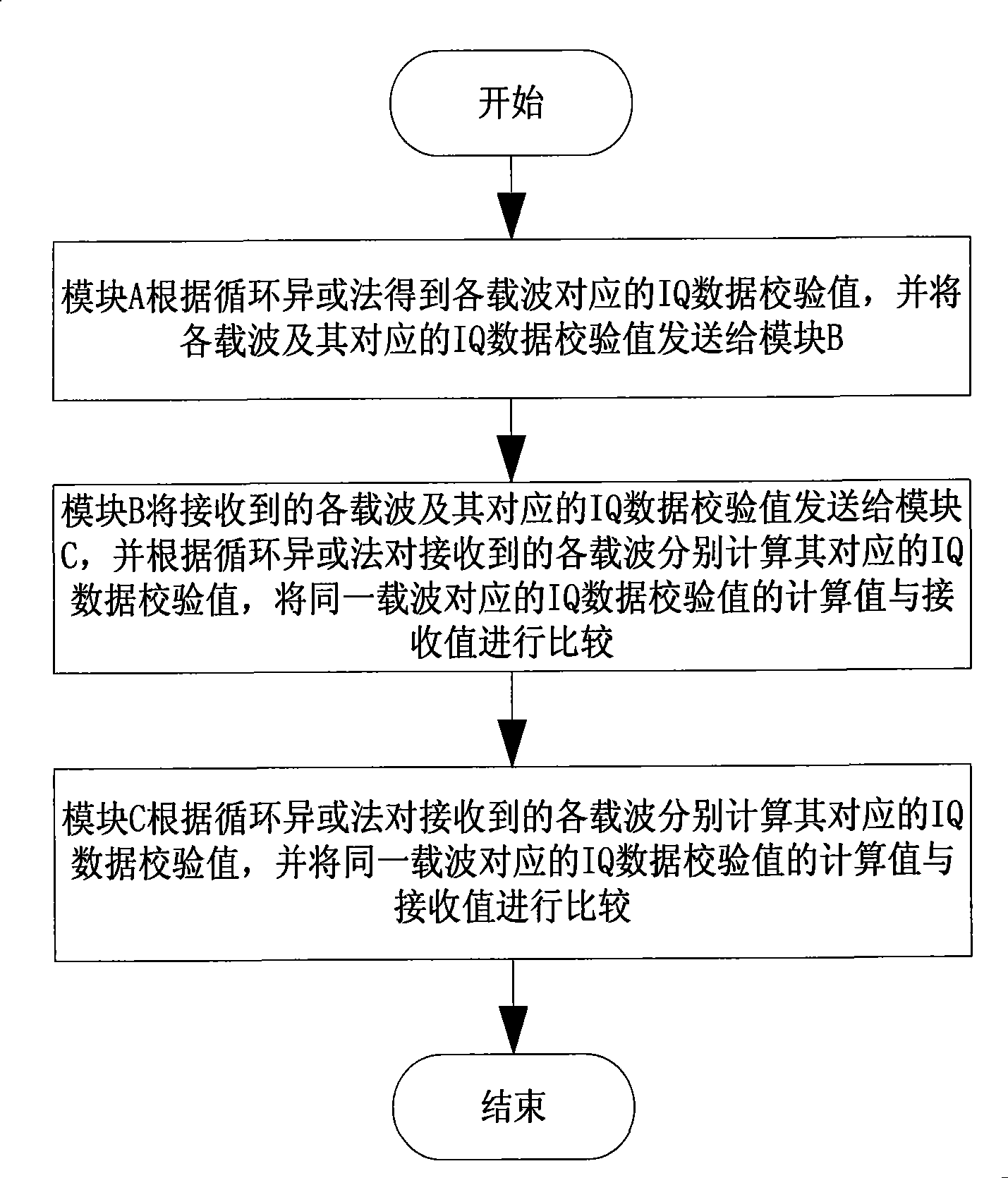

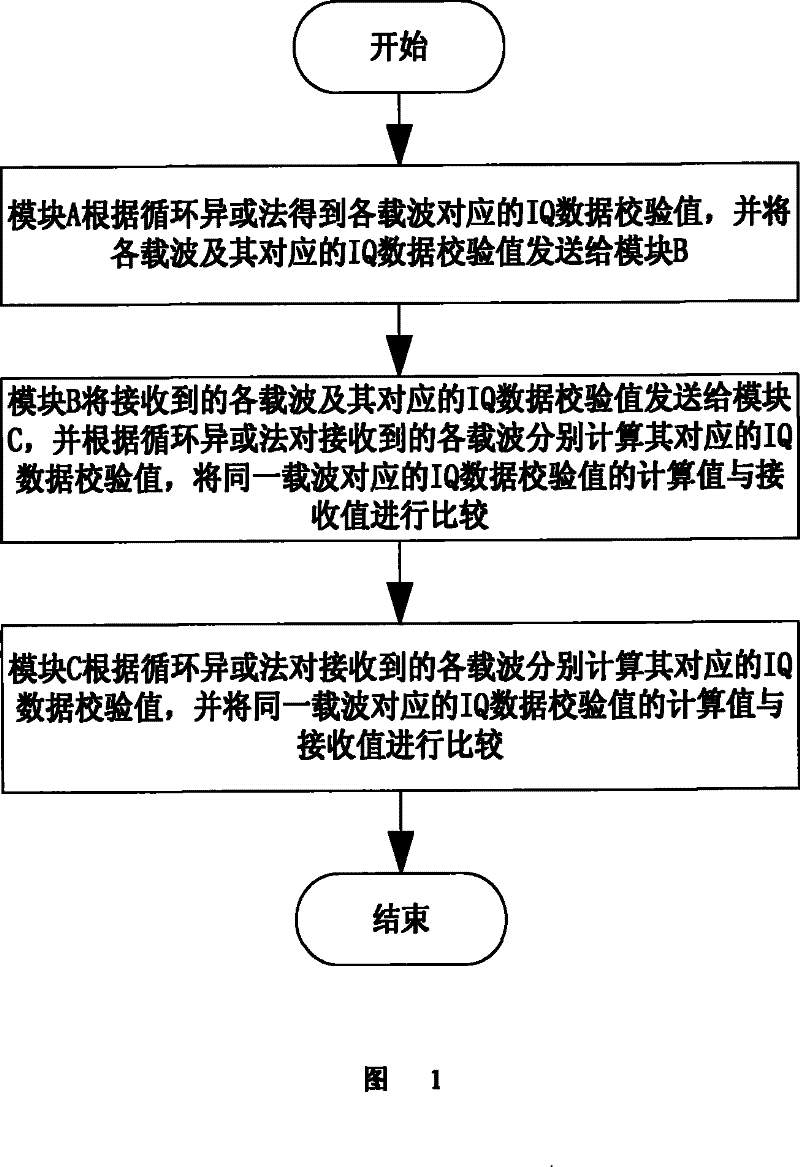

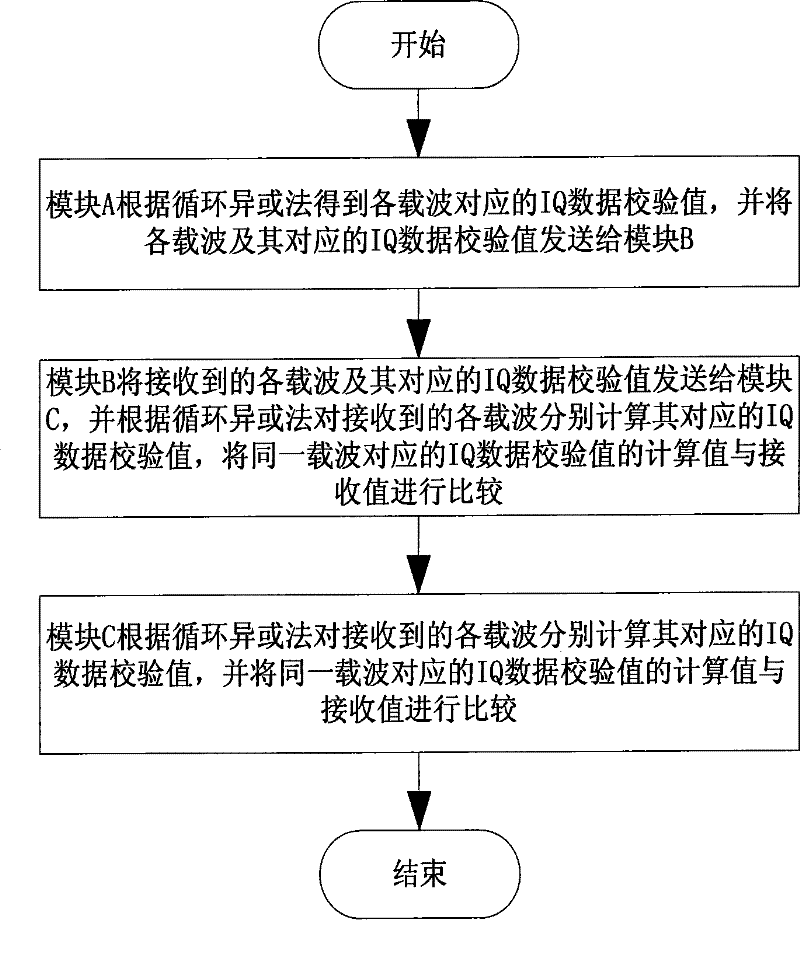

Checking method for quadrature modulation data transmitted between baseband unit and radio frequency unit

InactiveCN101383678ARealize online verificationWide range of dataError preventionOrthogonal multiplexQuadrature modulationData calibration

The invention discloses a calibration method of quadrature modulation data transmitted between a baseband unit and a radio frequency unit, which comprises: 1, a module A obtains IQ data calibration values corresponding to carriers, and the carriers and the corresponding IQ data calibration values are sent to a module B; 2, the module B sends the received carriers and the received corresponding IQ calibration values thereof to a module C, respectively calculates the corresponding IQ data calibration values of the received carriers, and compares the calculated values of the corresponding IQ data calibration values of one carrier with receiving values, so as to judge the transmission between the module A and the module B; 3, the module C respectively calculates the corresponding IQ data calibration values of the received carriers, and compares the calculated values of the corresponding IQ data calibration values of one carrier with receiving values so as to judge the transmission between the module B and the module C. The technical proposal of the invention realizes the on-line calibration of all IQ data.

Owner:ZTE CORP

Gas density relay with online self-checking function and checking method thereof

PendingCN111446113AAchieve maintenance-freeImprove reliabilityElectric switchesCircuit interrupters testingControl engineeringPower grid

The invention provides a gas density relay with an online self-checking function and a checking method thereof. The gas density relay comprises a gas density relay body, a first pressure sensor, a second pressure sensor, a temperature sensor, an air pressure chamber, a pressure adjusting mechanism, an online checking contact signal sampling unit and an intelligent control unit. A gas circuit and an air pressure chamber of the pressure regulating mechanism are connected with the second pressure sensor; the pressure is adjusted to rise and fall through the pressure adjusting mechanism; and the gas density relay body is subjected to contact action, the contact action is transmitted to the intelligent control unit through the online checking contact signal sampling unit, the intelligent control unit detects a contact signal action value and / or a return value of the gas density relay body according to a density value during the contact action, verification work is completed, and maintenancepersonnel do not need to go to the site for verification. And meanwhile, the pressure regulating mechanism is not connected with the gas density relay body or an SF6 gas circuit of the electrical equipment so that a sealing requirement is reduced, reliability of a power grid is improved, and manufacturing cost is reduced.

Owner:SHANGHAI ROYE ELECTRICAL CO LTD

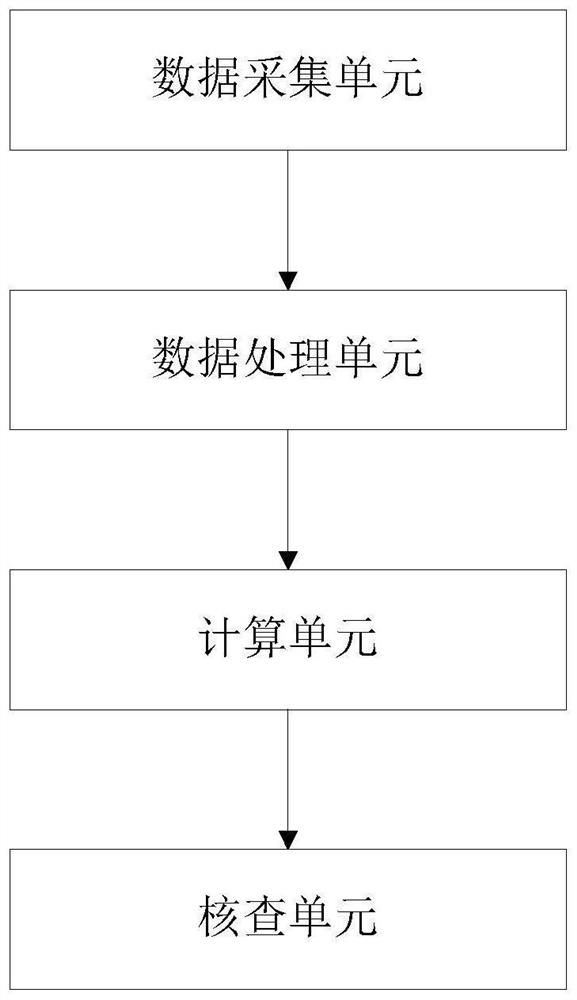

Trace gas management system and management method

InactiveCN107040432ARealize online managementRealize online verificationData processing applicationsTechnology managementTrace gas emissionsManagement system

The invention relates to a gas management system, particularly a trace gas management system and management method. The system comprises a data management system, a data collection system, a trace gas emission calculation system, a trace gas emission list and report generation system and a trace gas emission check system. A data server is arranged in the data management system. The data management system is in two-way communication connection with the data collection system, the trace gas emission calculation system, the trace gas emission list and report generation system and the trace gas emission check system and is used for storing, processing and searching data of the connected systems. According to the trace gas management system provided by the invention, online management of regional trace gas in a corresponding range can be realized, in particular, online check can be realized, a report can be generated, the cost is effectively reduced, and the efficiency is improved.

Owner:SHENZHEN RUIRONGCHUANG ELECTRONICS TECH CO LTD

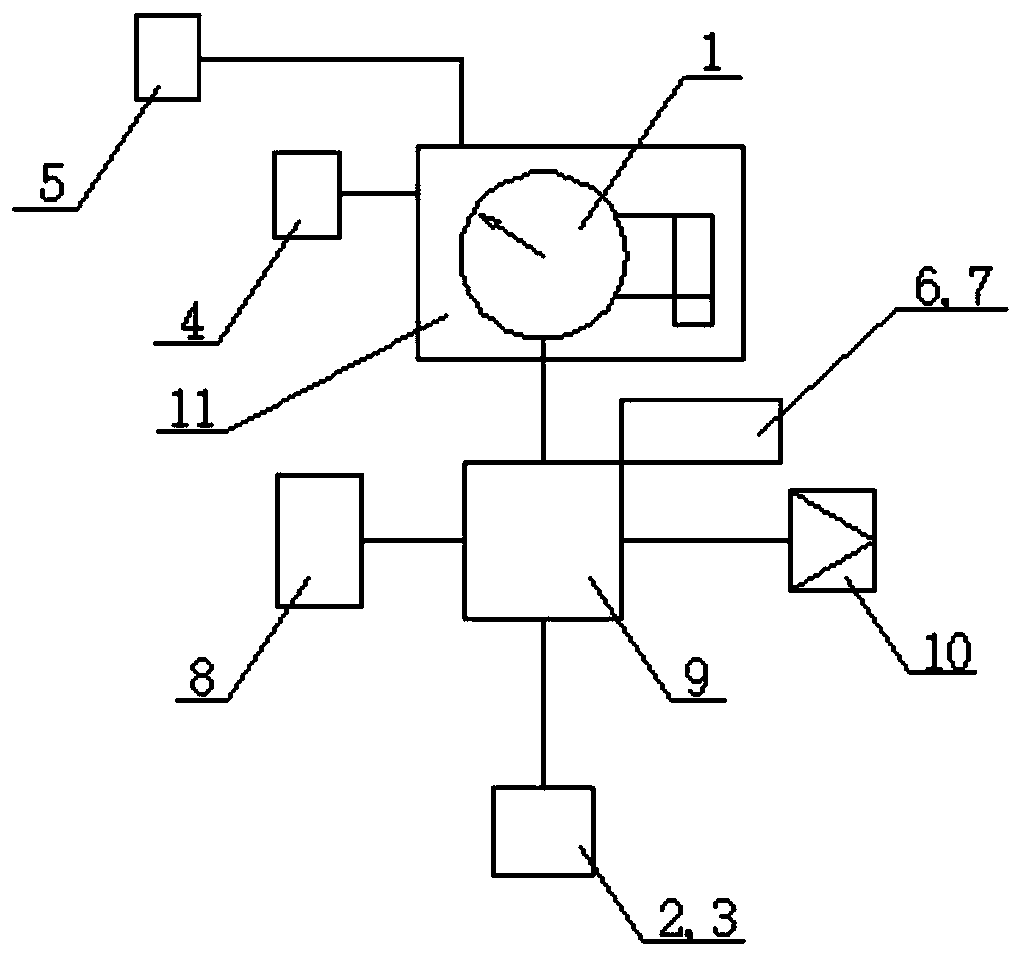

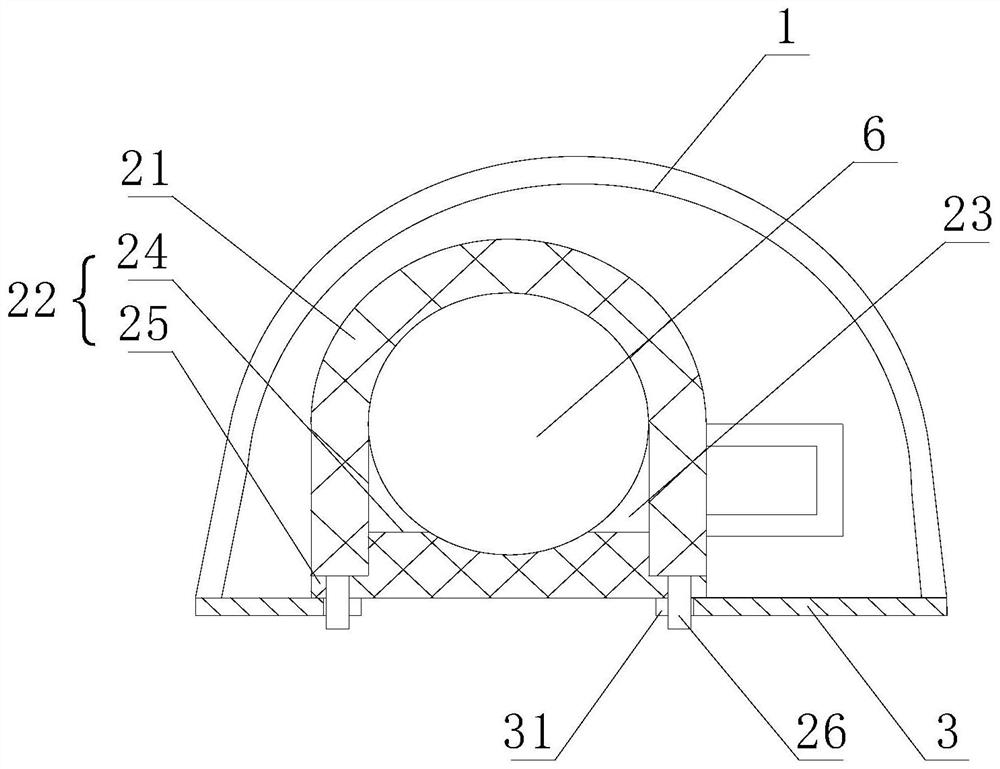

On-line verification system for voltage and current transformers

Provided in the invention is an on-line verification system for voltage and current transformers. The system is composed of a standard transformer, a verified transformer, and a PC machine. The standard transformer consists of a primary sensing unit, an acquisition transmission unit, and a main control module; the primary sensing unit is connected to the acquisition transmission unit connected tothe main control module; and the main control module is connected to the PC machine. A voltage or current signal outputted by the primary sensing unit is transmitted to the acquisition transmission unit at a low-voltage side by a shielding cable for signal processing; the outputted signal is transmitted to the main control module by a first fiber; after framing processing, the processed signal asa standard signal is transmitted to the PC machine. According to the on-line verification system, online verification the voltage and current transformers in operation is realized simultaneously by using one set of acquisition transmission unit and main control module, so that the equipment investment is saved substantially and the complexity of the system is reduced.

Owner:CHINA THREE GORGES UNIV

Gas density relay with online self-checking function and checking method thereof

PendingCN111446111AImprove reliabilityRealize the intelligent management of the whole life cycleHigh-tension/heavy-dress switchesCircuit interrupters testingControl engineeringPower grid

The invention provides a gas density relay with an on-line self-checking function and a checking method thereof. The gas density relay is used for high-voltage and medium-voltage electrical equipmentand comprises a gas density relay body, a first pressure sensor, a temperature sensor, a force measuring sensor, a driving contact actuating mechanism and an intelligent control unit. The driving contact actuating mechanism is configured to directly or indirectly drive a signal actuating mechanism of the gas density relay body to displace; the gas density relay body is enabled to generate a contact signal action; the intelligent control unit detects an alarm and / or locking contact signal action value and / or return value of the gas density relay body according to a density value of the contactaction; and verification work of the gas density relay can be completed without the need for maintenance personnel to go to the site, reliability of a power grid is improved, efficiency is increased,operation and maintenance cost is reduced, and a maintenance-free gas density relay can be realized.

Owner:SHANGHAI ROYE ELECTRICAL CO LTD

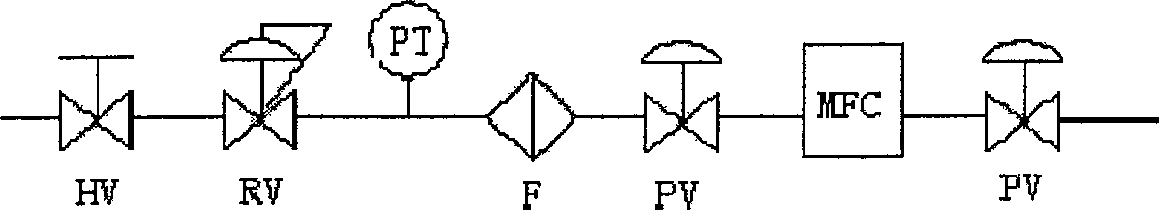

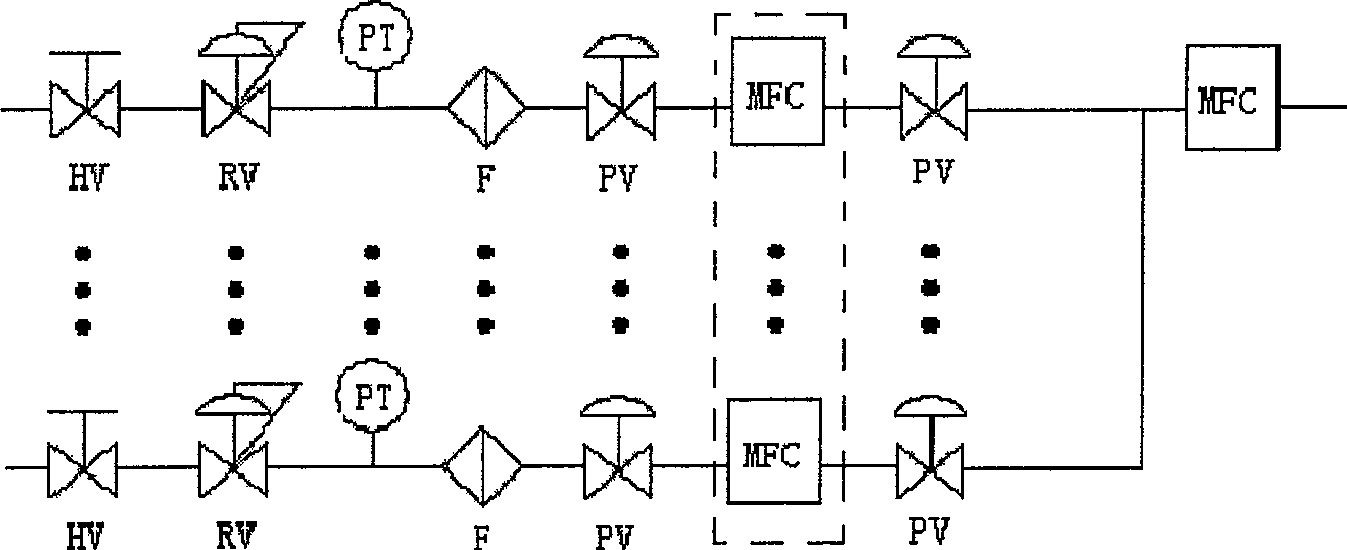

Mass flow controller on-line correction device

ActiveCN100543623CRestrictions to reduce inspectionShorten the timeFlow control using electric meansElectric testing/monitoringInlet valveEngineering

The invention relates to the technical field of microelectronics, in particular to the on-line calibration of MFC (mass flow controller) used in the gas path system of semiconductor equipment. A new type of mass flow controller online calibration device disclosed by the present invention includes: a temperature sensor, a vacuum gauge, an air box and a mass flow controller connected thereto, a dry pump, and a chamber, a normally closed inlet valve . A normally closed outlet valve and its control device, wherein the normally closed inlet valve and the normally closed outlet valve are connected to the chamber.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

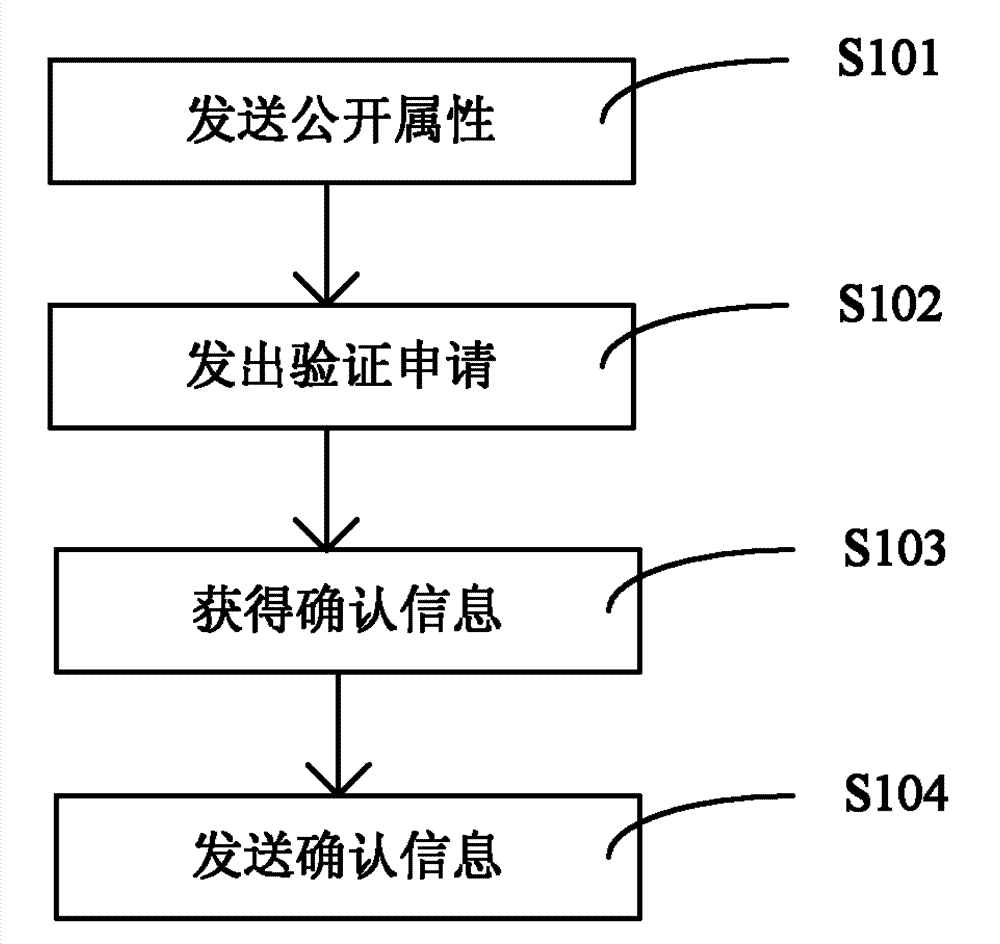

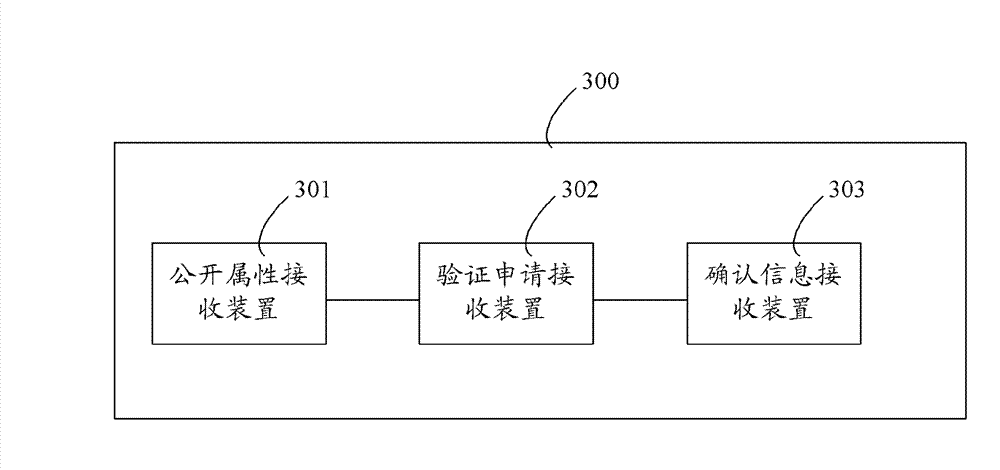

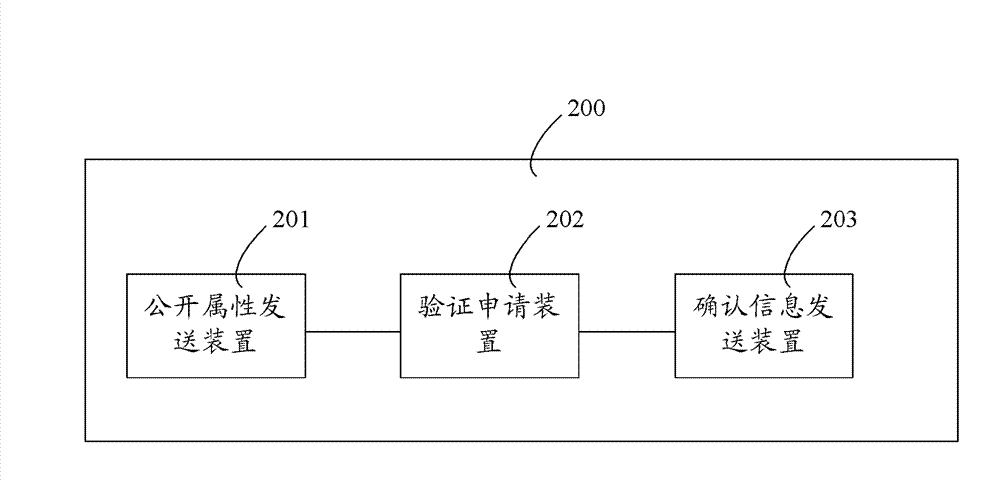

Object property security on-line verifying method and device

ActiveCN103595700ALow costReliable Online VerificationPayment protocolsTransmissionComputer securityValidation methods

Owner:CHINA UNIONPAY

Method for verifying quadrature modulation data transmitted between baseband unit and radio frequency unit

InactiveCN101383678BRealize online verificationWide range of dataError preventionOrthogonal multiplexQuadrature modulationCarrier signal

The invention discloses a verification method for orthogonal modulation data transmitted between a baseband unit and a radio frequency unit, including: 1. Module A obtains the IQ data verification value corresponding to each carrier, and verifies each carrier and its corresponding IQ data 2. Module B sends each received carrier and its corresponding IQ data check value to module C, and calculates the corresponding IQ data check value for each received carrier, and the same The calculated value of the IQ data check value corresponding to the carrier is compared with the received value to make a judgment on the transmission between module A and module B; 3. Module C calculates the corresponding IQ data check value for each received carrier , and compare the calculated value of the IQ data check value corresponding to the same carrier with the received value to make a judgment on the transmission between module B and module C. The technical scheme of the invention realizes online verification of all IQ data.

Owner:ZTE CORP

Oil conveying pipeline on-line density measuring device

ActiveCN102313137BImprove accuracyImprove stabilityPipeline systemsExhaust valveDifferential pressure

The invention discloses an oil conveying pipeline on-line density measuring device. A process main pipeline [6] of a constant-temperature electric heat tracing and thermal insulation device [17] is connected in series to a pipeline to be tested through a flange (1) [1] and a flange (2) [35] at the two outer ends, and is sequentially provided with parallel filter (1) [2] and filter (2) [38] and a differential pressure transmitter [10], a flow switch [11], a serial process valve (6) [23], a bypass manual sampling valve [14], a bypass on-line verification port (1) [8], a bypass in-situ pressure gauge [12], a bypass drainage pipeline [7], a sampling pump [3], a serial process valve (7) [24], a bypass on-line verification port (2) [37], a bypass thermal expansion safety valve [5], an on-line densimeter [4], a bypass exhaust valve [15], a bypass drainage pipeline [7] and an intelligent pressure transmitter [9] which are arranged in front of and behind the filters from the inlet end; and an instrument junction box [16] is connected with an SCADA (Supervisory Control And Data Acquisition) system.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

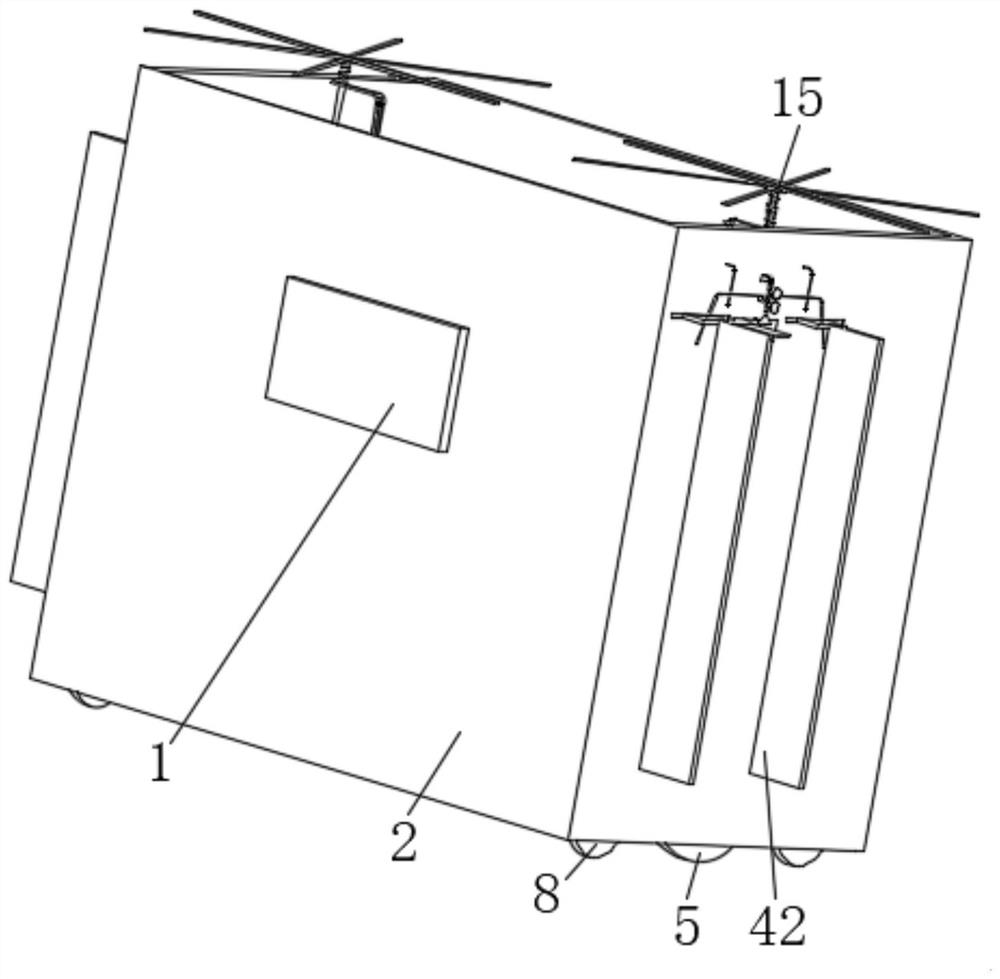

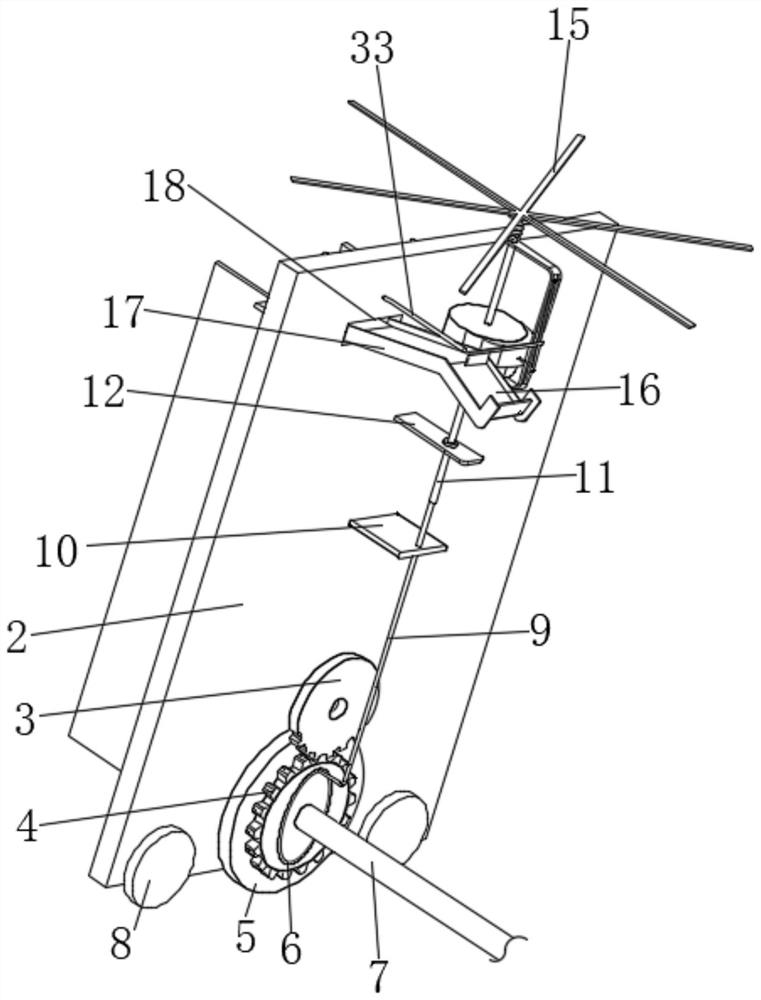

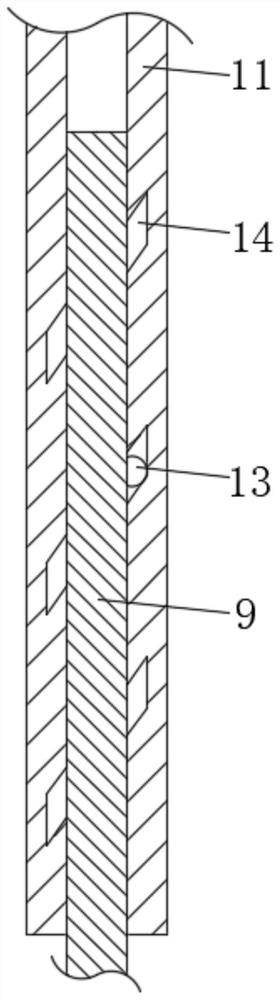

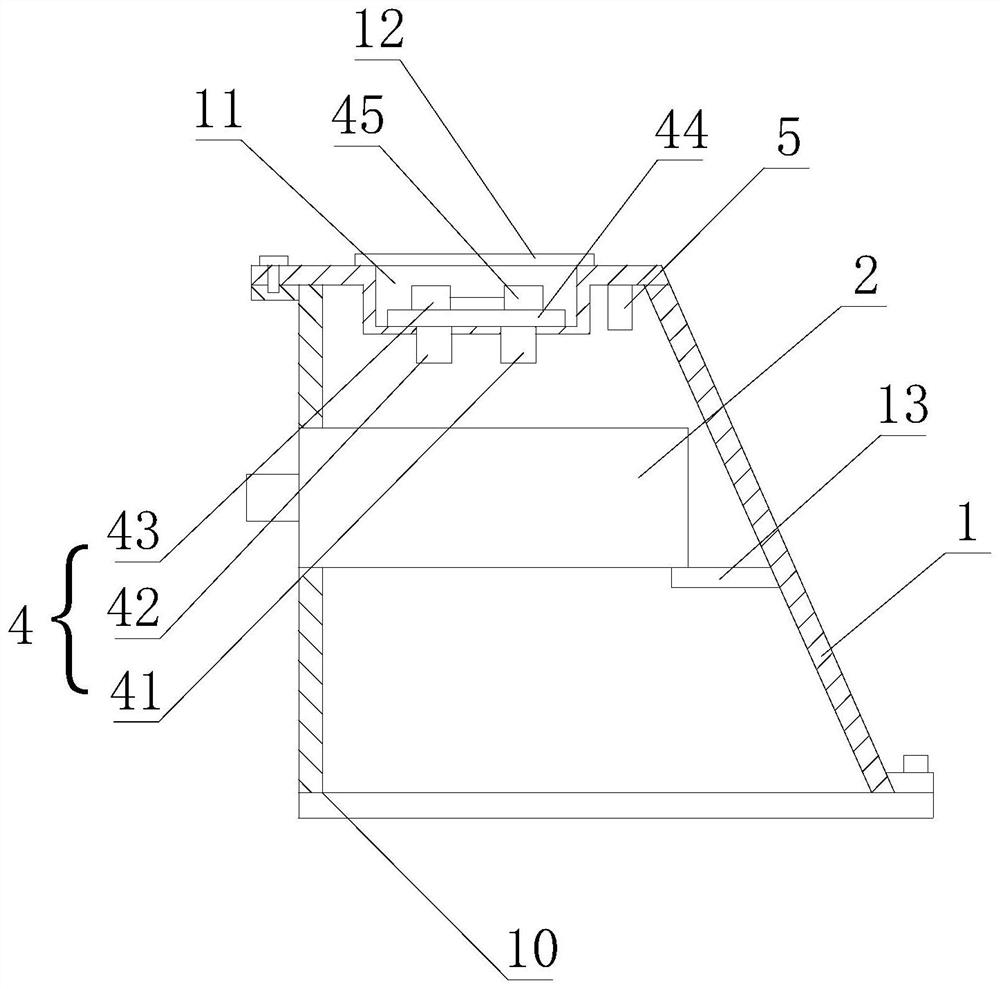

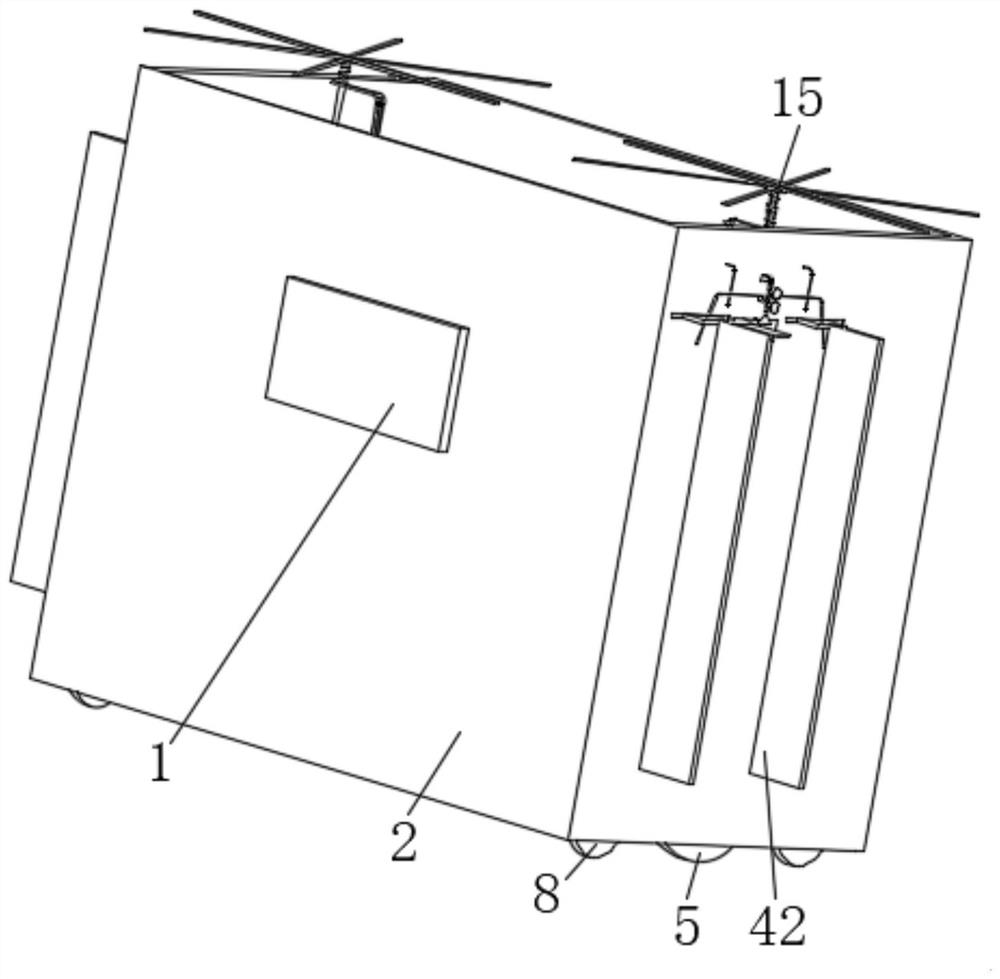

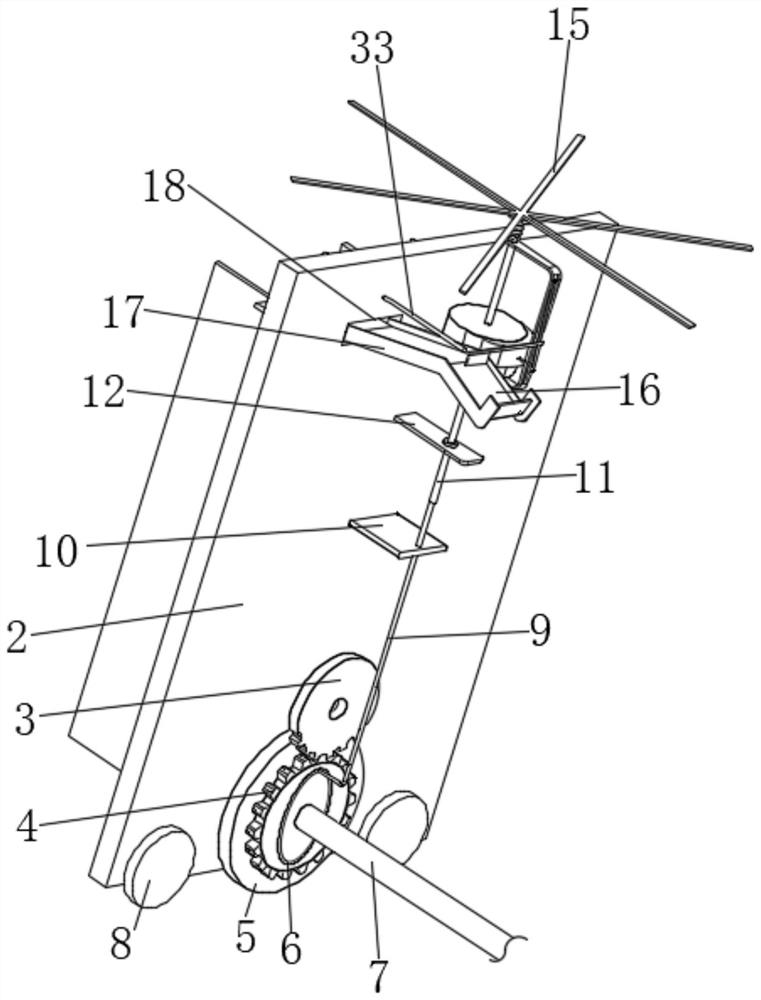

An intelligent examination room monitoring robot capable of human-computer interaction and using method thereof

ActiveCN113601530BAchieve interactionRealize online verificationCommunication jammingManipulatorDrive wheelGear drive

Owner:深圳市华方信息产业有限公司

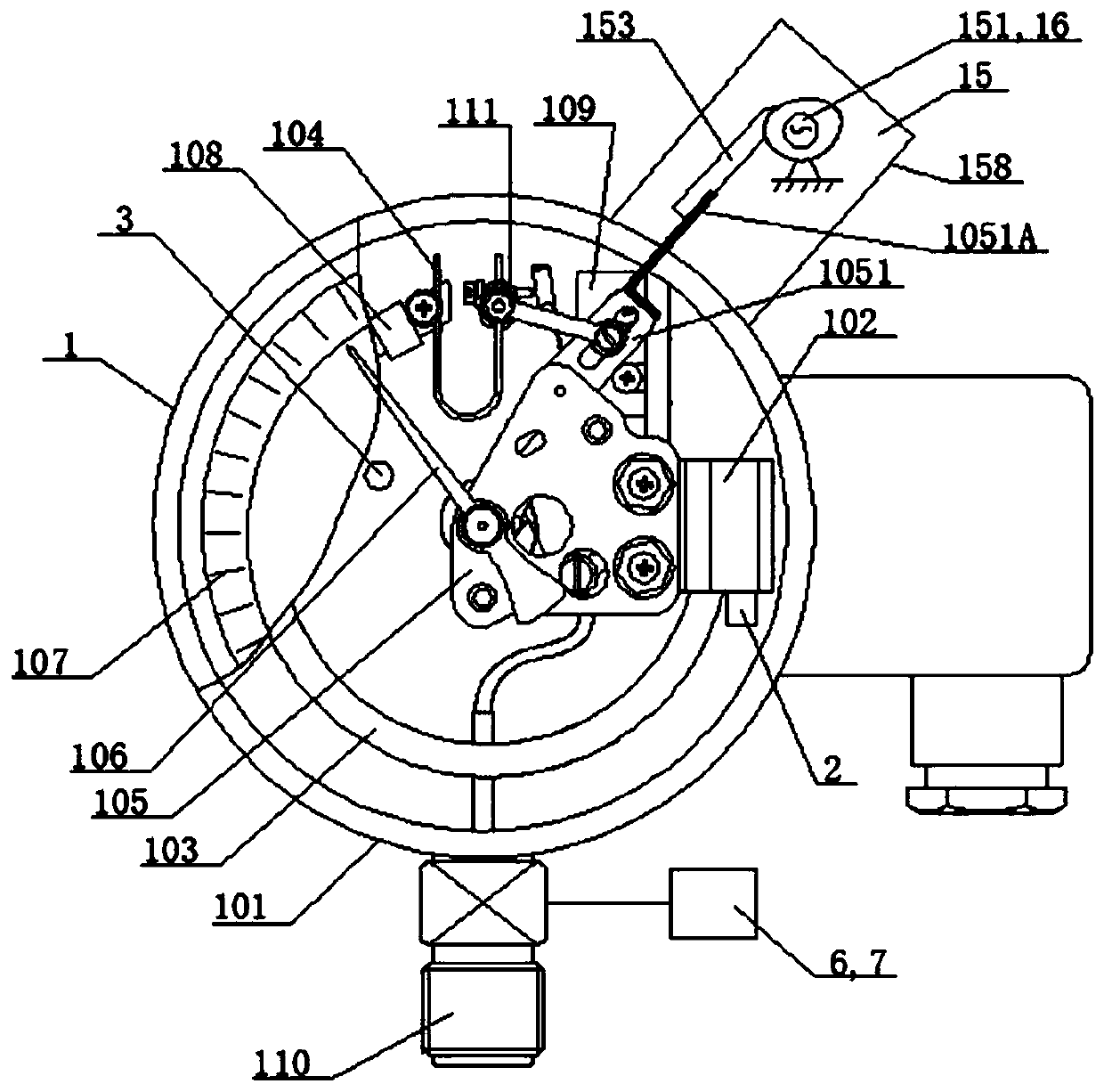

SF6 density relay verification device based on temperature compensation

PendingCN114295968ARealize online verificationReal-time monitoring of working statusCircuit interrupters testingThermodynamicsEngineering

The invention relates to an SF6 density relay verification device based on temperature compensation, which comprises a shell, a fixing sleeve and a fixing rod, the fixing sleeve comprises a U-shaped ring and a pressing ring, a fixing hole is formed between the U-shaped ring and the pressing ring, one end of the fixing rod is fixedly connected to the shell, the other end of the fixing rod is connected with the pressing ring, a temperature adjusting assembly is arranged between the fixing sleeve and the shell, and the temperature adjusting assembly is connected with the shell. The SF6 density relay has the advantages that the SF6 density relay is fixed in the shell through the fixing sleeve, and due to the fact that the shell is internally provided with the temperature adjusting assembly, the temperature of the constant-temperature environment where the SF6 density relay is located is changed through the temperature adjusting assembly; the density relay is triggered to give an alarm and lock a contact through the change of the constant-temperature environment temperature, the pressure value is obtained through the environment temperature, and the purpose of pressure change caused by gas flow is achieved without using SF6 gas, so that the problem of SF6 emission is avoided, and the environmental protection property and the economical efficiency are better.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JINHUA POWER SUPPLY CO

Intelligent examination room monitoring robot capable of realizing human-computer interaction and use method thereof

ActiveCN113601530AAchieve interactionRealize online verificationCommunication jammingManipulatorDrive wheelGear drive

The invention discloses an intelligent examination room monitoring robot which comprises a man-machine interaction module, wherein a shell is arranged on the man-machine interaction module, a non-complete gear driven by a power mechanism to rotate is rotationally connected to the interior of the shell through a fixed shaft, and teeth on the non-complete gear are in transmission engagement with a transmission gear; the transmission gear is coaxially and fixedly connected with a driving wheel rotating on the inner wall of the shell in a limited mode, an oval guide groove is formed in the surface of the transmission gear, a transmission shaft is fixedly connected to the circle center of the driving wheel, and a driven wheel matched with the driving wheel is rotationally connected to the inner wall of the shell through a fixed shaft; and the inner wall of the oval guide groove is slidably connected with a lifting arm. Through cooperative use of the mechanisms, the problems that in the actual use process, due to the fact that in the highly tense environment of an examination room, an invigilation teacher is prone to making mistakes, meanwhile, a large amount of manpower is consumed for invigilation, and inconvenience is brought to use are solved.

Owner:深圳市华方信息产业有限公司

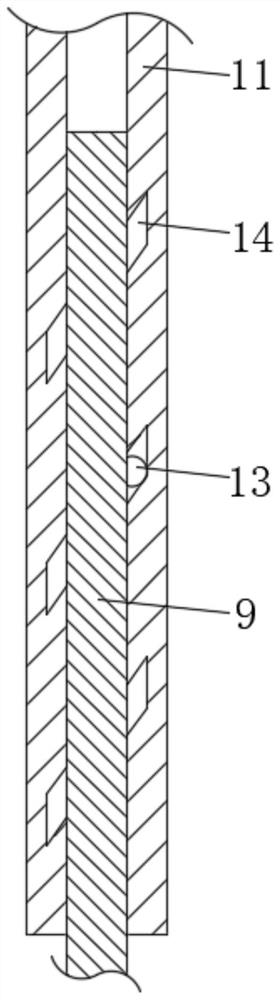

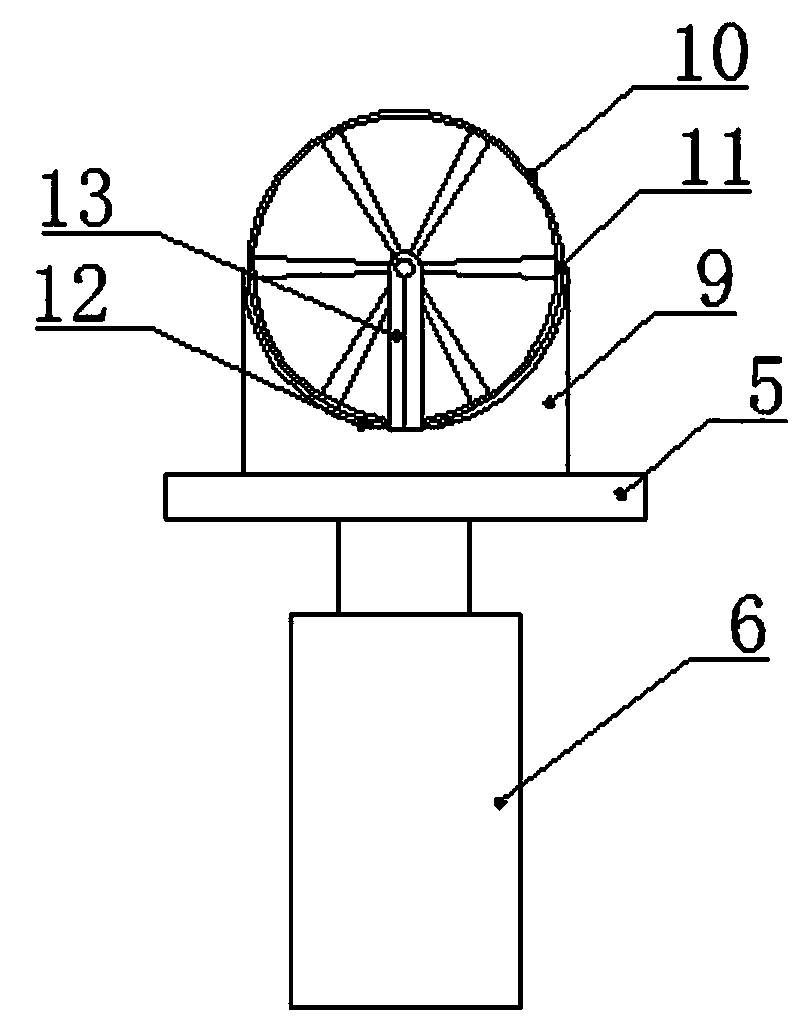

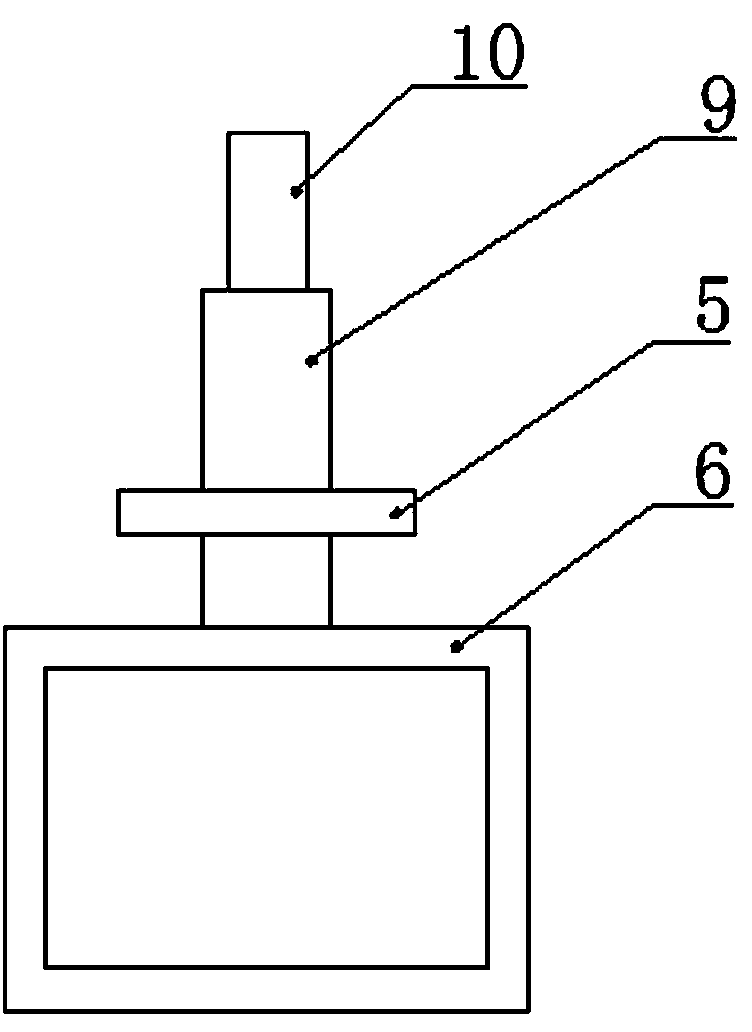

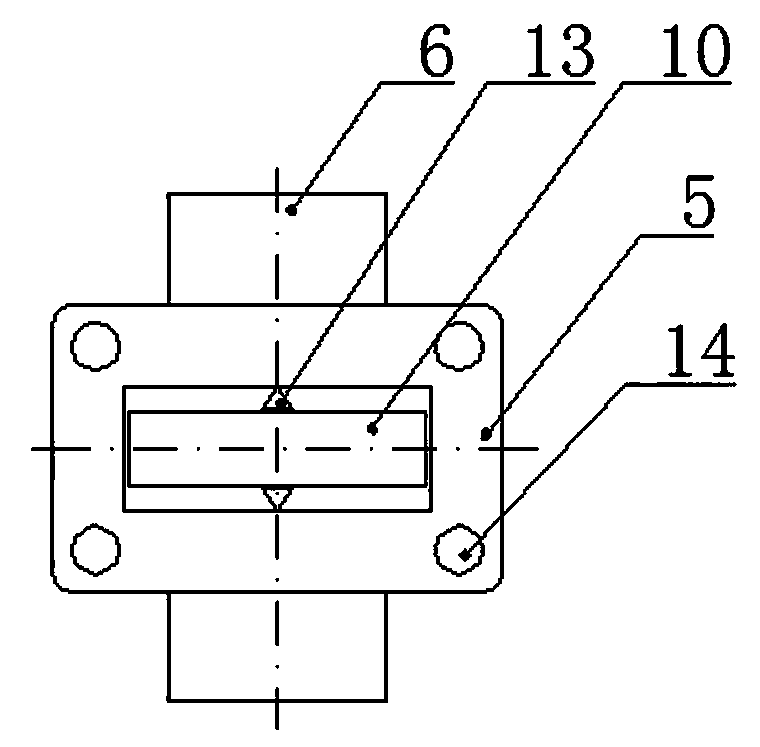

Calorimeter online detector and calorimeter matched with the same

The invention disclose a calorimeter online detector, which is characterized by comprising a detection meter head, a substrate, an impeller and a counting mechanism, wherein the detection meter head is arranged at the tail end of the substrate, the impeller is rotationally mounted at the front end of the substrate, and the counting mechanism is arranged between the impeller and the detection meter head. The calorimeter online detector has the advantage that, when a calorimeter is in verification, the calorimeter online detector is directly mounted on the mounting base of the calorimeter, so that the calorimeter can be online verified. Thereby, the service life of the calorimeter can be maximally prolonged, and the expense for detecting the calorimeter also can be greatly reduced.

Owner:BEIJING HAOCHEN JIECHUANG ENERGY SAVING EQUIPCO

Online density measurement method and device of petroleum transmission pipeline

ActiveCN102313139BImprove accuracyImprove stabilityVolume/mass flow measurementPipeline systemsThermodynamicsTransformer

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

On-line verification method and device for safety valve

ActiveCN104406781BExtended duty cycleAffect the tightnessMachine part testingWorking pressureControl system

The invention provides an on-line safety valve checking method and device. A safety valve is subjected to online checking through the device, the device comprises a force sensor mounted on a lifting rod, the force sensor is connected with a control system, the safety valve is arranged on a pressure vessel with slurry in the lower portion and steam in the upper portion, in a normal working pressure range of the safety valve, the control system controls lifting height and opening time of a valve stem of the safety valve by the device, and the device is enabled to finish checking after the slurry arrives at a valve port of the safety valve. Therefore, influence on sealing performance of the safety valve due to discharge of a viscous medium in a flash evaporator is avoided, further the operating period of the flash evaporator can be prolonged, cost in a series of working processes of detachment, lifting, transportation, checking, reassembling and the like during online and offline checking of the safety valve can be omitted, labor intensity of workers is lowered, and normal operation of companies is guaranteed.

Owner:GUANGXI HUAYIN ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com