Oil conveying pipeline on-line density measuring device

A technology for density measurement and oil pipelines, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as no sewage system, pipeline cathodic protection current loss, density measurement operation and accuracy impact, etc., to achieve Save floor space and operating room, avoid cathodic protection current loss, reduce equipment investment and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

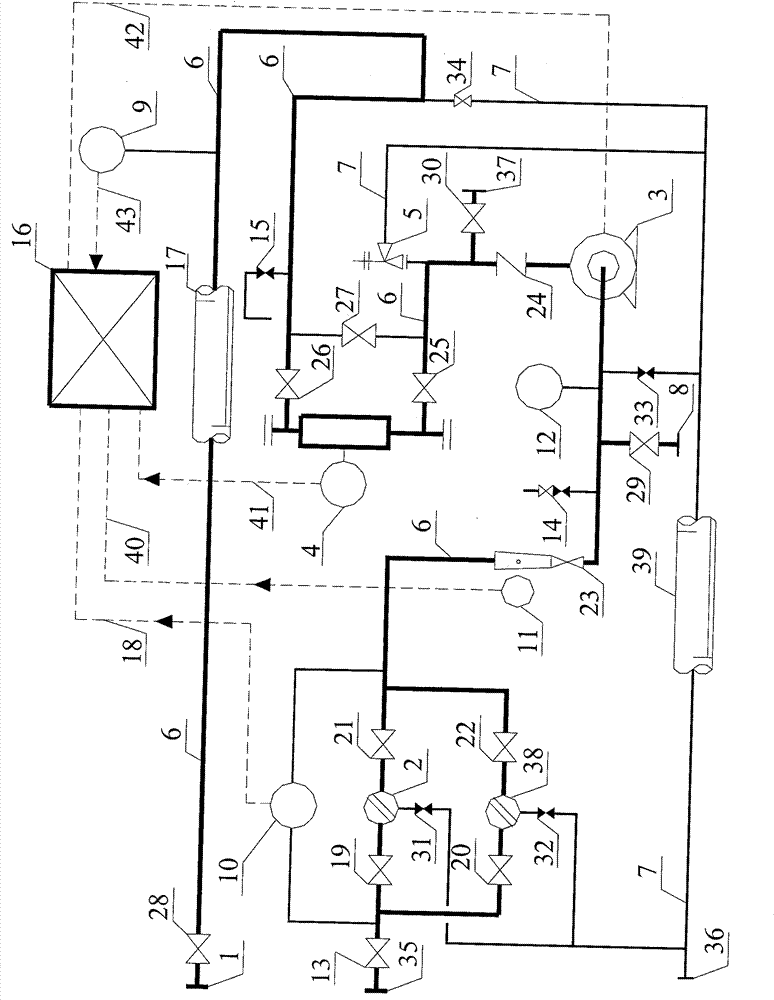

[0043] Embodiment. This example is an online density measuring device used in the Lanzhou-Zhengzhou-Changsha refined oil pipeline engineering test. The composition of the online density measuring device of the oil pipeline is as follows: figure 1 As shown, it consists of flange (1) 1, flange (2) 35, magnetic filter (1) 2, magnetic filter (2) 38, sampling pump 3, online density meter 4, thermal expansion safety valve 5, process supervisor Line 6, sewage pipeline 7, online verification port (1) 8, online verification port (2) 37, intelligent pressure transmitter 9, intelligent differential pressure transmitter 10, flow switch 11, local pressure gauge 12, multiple Process valve, manual sampling valve 14, exhaust valve 15, instrument junction box 16, constant temperature electric mixing heat and heat preservation 17, and multiple instrument cables. A bypass pipeline is set on the pipeline to be tested, and a section of the main process line 6 for testing is connected in series on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com