Mass flow controller on-line correction device

A technology for mass flow and calibration equipment, applied in the field of microelectronics, can solve the problems of limited flow of mass flow controller MFC, long calibration time, and inability to calibrate, so as to achieve online calibration and reduce calibration. time, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

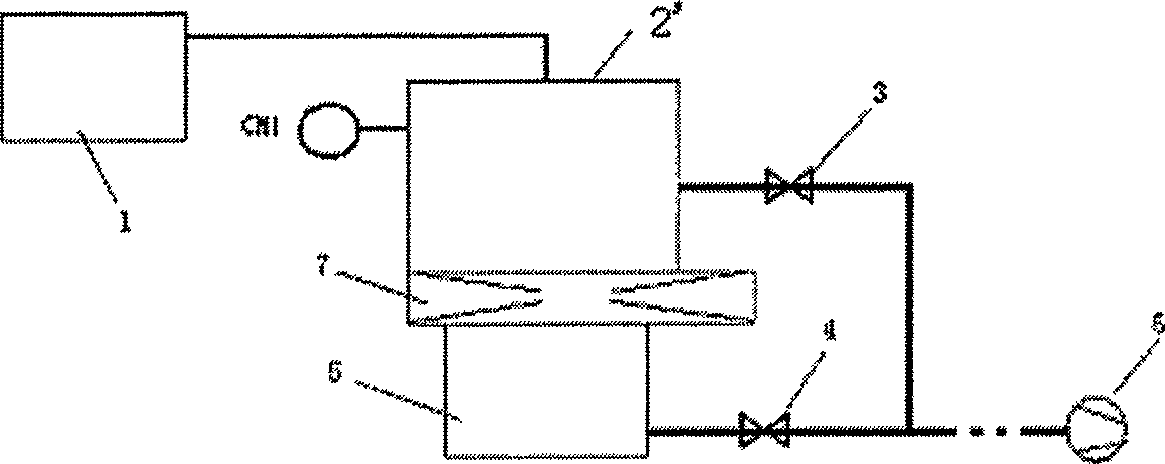

[0020] Such as Figure 4 , Figure 5 As shown, when the present invention is implemented, it includes a chamber 2 and a temperature sensor 8 connected thereto, a vacuum gauge CM1, an air box 1 and a mass flow controller MFC connected thereto, a dry pump 6, a normally closed inlet valve 9, and a normally closed outlet The valve 10 and its control device, wherein one end of the normally closed inlet valve 9 is connected to the chamber 2, and the other end is connected to the gas box 1, and one end of the normally closed outlet valve 10 is connected to the chamber 2, and the other end is connected to the dry pump 6 connect. Wherein, the volume reduction of the chamber 2 is 200cc to 500cc.

[0021] Such as Figure 4~6 As shown, the working process of the present invention is as follows: first draw the vacuum of the calibration chamber,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com