Gas circuit partition pressure adjusting mechanism for online verification of density relay

A technology of density relay and pressure regulation, applied in the field of electric power, which can solve the problems of flashover, reduction of insulation strength on the surface of insulating parts, damage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

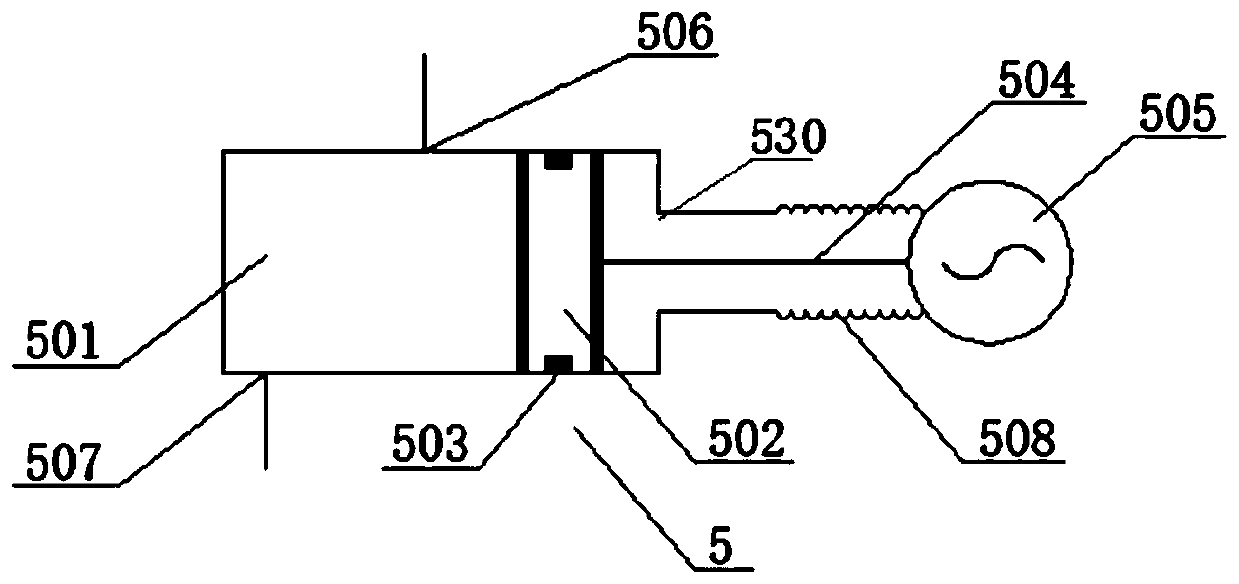

[0083] figure 1 It is a schematic structural diagram of an air circuit cutoff pressure adjustment mechanism provided in Embodiment 1 of the present invention. Such as figure 1 Said, an air circuit cutoff pressure adjustment mechanism for on-line verification of density relays, comprising: an air circuit isolation pressure adjustment mechanism body 5, the air circuit isolation pressure adjustment mechanism body 5 includes a sealed cavity 501, and the sealed cavity The side wall of the cavity 501 is provided with a first interface 506 connected with the gas path of the gas density relay, and a second interface 507 connected with the gas path of the electrical equipment, the first interface 506 and the second The relative positions of the interfaces 507 are staggered. The sealed chamber 501 is provided with a partition 502, which is in sealing contact with the inner wall of the sealed chamber 501. The partition 502 includes, but is not limited to, one of a piston and a sealed p...

Embodiment 2

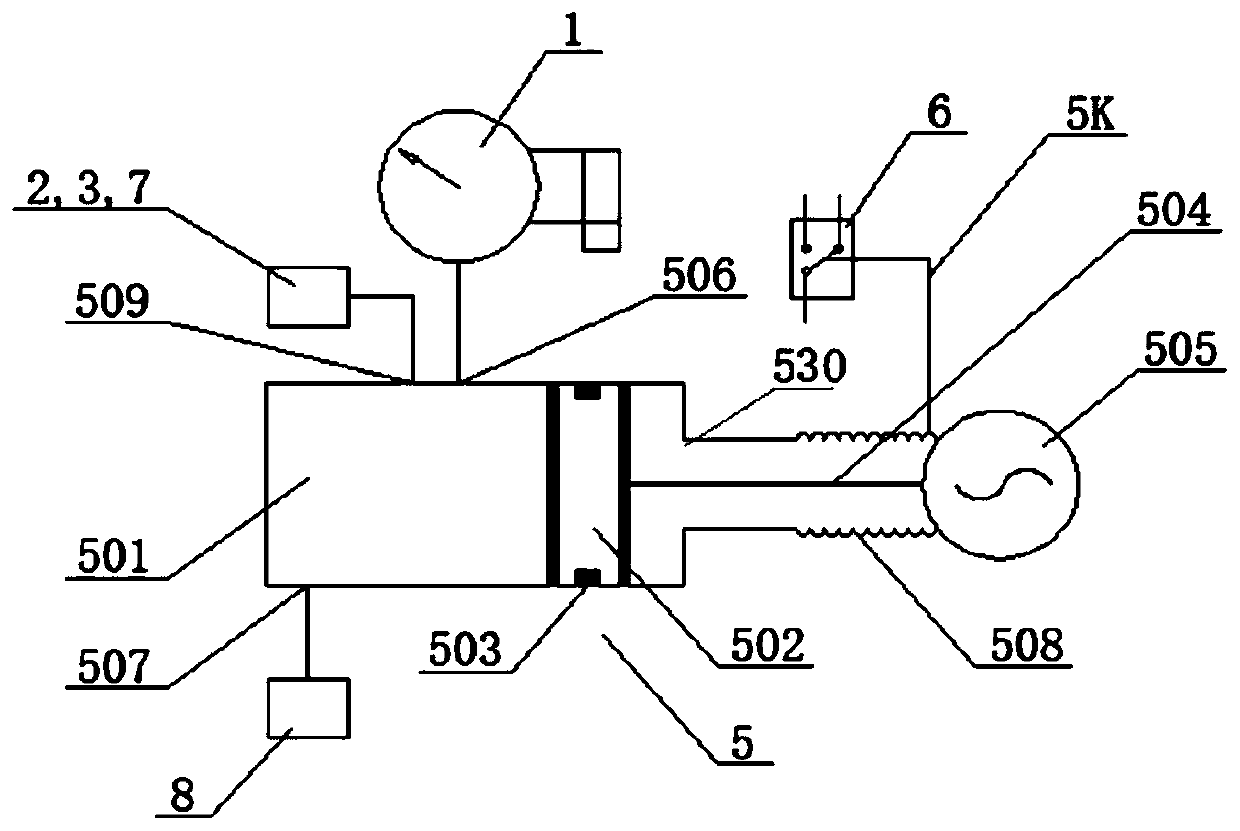

[0088] figure 2 It is a schematic structural diagram of an air circuit cutoff pressure regulating mechanism in working state provided by Embodiment 2 of the present invention. Such as figure 2 As shown, a gas circuit cutoff pressure adjustment mechanism for on-line verification of density relays includes: pressure sensor 2, temperature sensor 3, gas circuit cutoff pressure adjustment mechanism body 5, online verification contact signal sampling unit 6, and intelligent control unit 7. The pressure sensor 2, the temperature sensor 3 and the intelligent control unit 7 are arranged on the body 5 of the air circuit cutoff pressure regulating mechanism.

[0089] Specifically, the body 5 of the air circuit cut-off pressure regulating mechanism includes a sealed cavity 501, a cut-off piece 502, a cut-off seal 503, a connecting piece 504, a driving component 505, a first interface 506, a second interface 507, a seal coupling 508, The fourth interface 509, the contact signal interl...

Embodiment 3

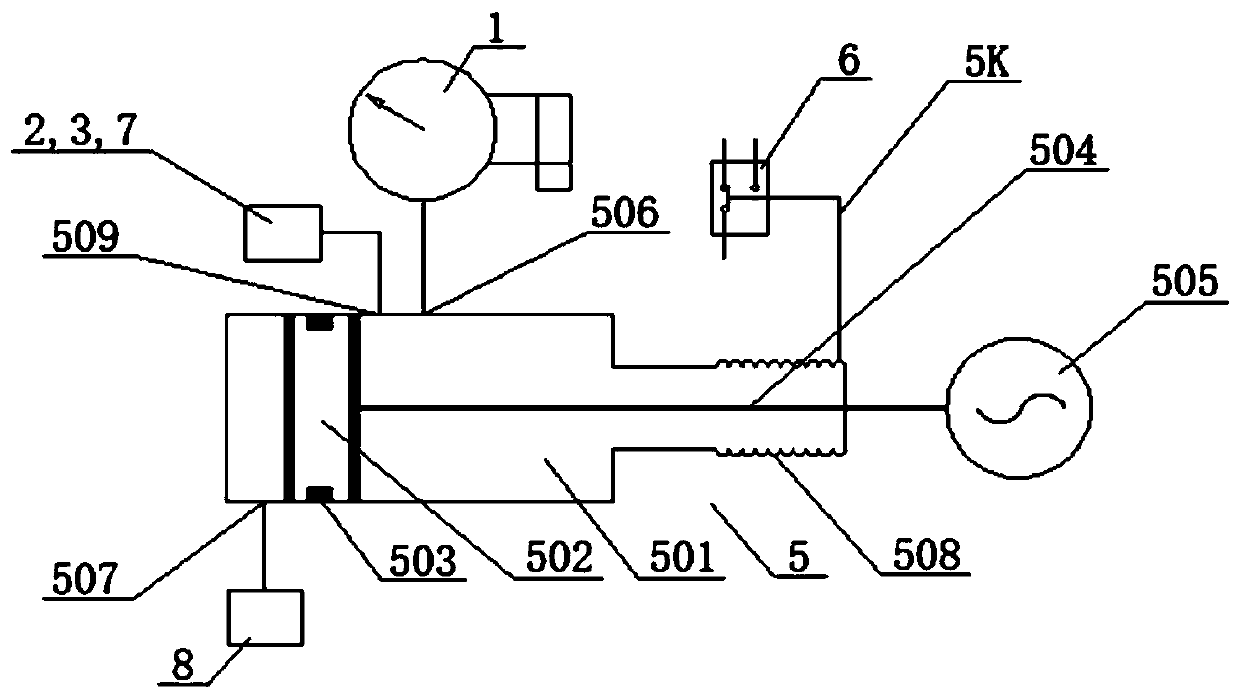

[0112] Such as Figure 5 As shown, a gas circuit cut-off pressure adjustment mechanism provided by Embodiment 3 of the present invention includes: a pressure sensor 2, a temperature sensor 3, a valve 4, a gas circuit cut-off pressure adjustment mechanism body 5, an online verification contact signal sampling unit 6, Intelligent control unit 7, multi-way connector 9. Among them, the body 5 of the gas circuit cutoff pressure regulating mechanism includes a sealed cavity 501, a cutoff piece 502, a cutoff seal piece 503, a connecting piece 504, a driving part 505, a first interface 506, a second interface 507, a third interface 511, a connecting piece Seal 510 , cavity (or housing) 512 . One end of the valve 4 is connected to the third interface 511 , and the other end of the valve 4 is connected to the multi-way joint 9 . The first interface 506 is disposed between the second interface 507 and the third interface 511 . The connector 504 is sealed with the sealing cavity 501 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com