Airplane direct current appliance function detector

A technology of DC equipment and detectors, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve problems such as control line status inspection, difficulty in rapid fault location, difficulty in aircraft maintenance, etc., to improve attendance rate, shorten troubleshooting cycle, The effect of shortening the duty cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

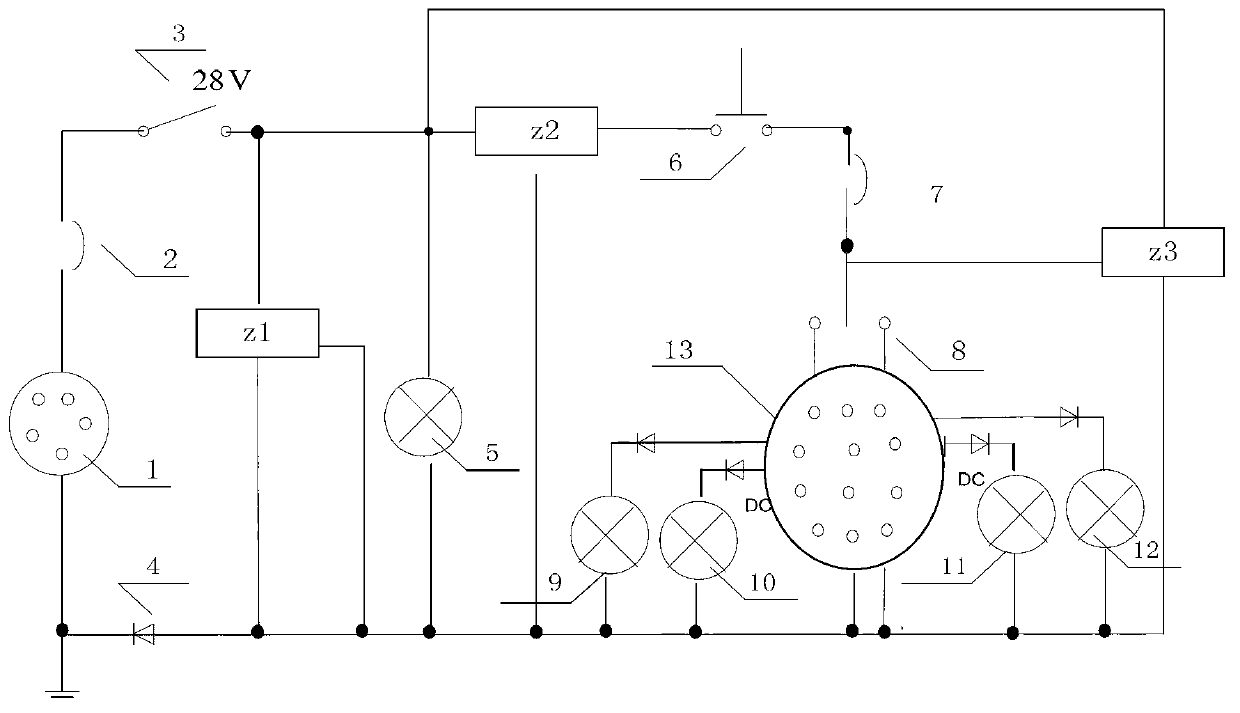

[0037] Embodiment 1. Carry out the electric mechanism of a certain type of aircraft environmental control system (taking the emergency ventilation electric valve as an example)

[0038] Periodic regular inspection or fault determination work

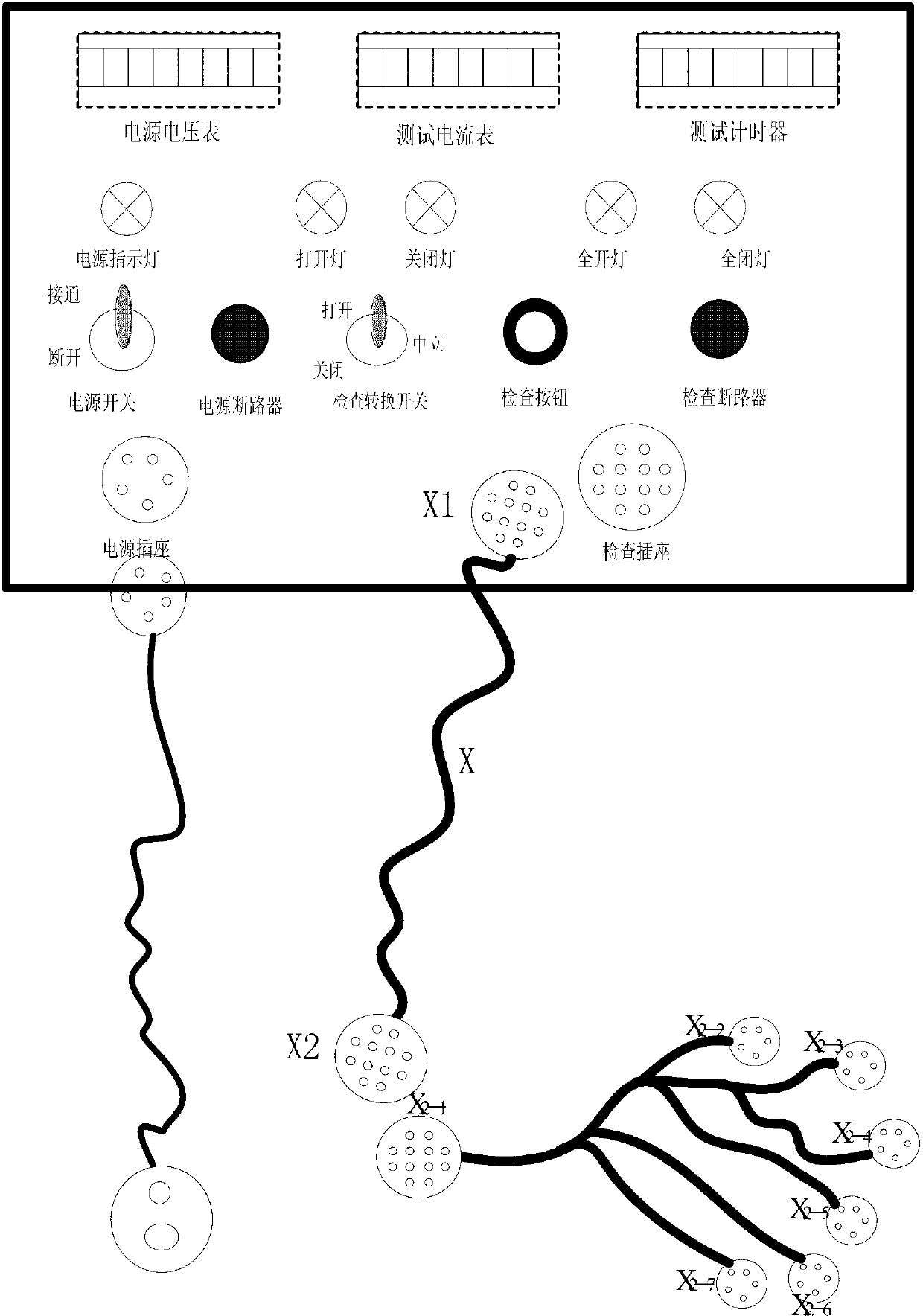

[0039] Such as figure 2 Connect the power cord and test cable to the function tester as shown, put the power switch in the "off" position, put the detection replacement switch in the "neutral" position, connect the power cord plug with the ground power vehicle (28.5±1V ), and connect each test cable and emergency ventilation electric valve to X 2-2 .

[0040] a. Turn on the power switch of the functional tester, the green light of the power indicator is on, the voltage indicator shows the ground voltage, the current indicator shows "00.000", and the timer shows "000.00";

[0041] b. Turn the detection switch to the "off" position, press the check button, at this time the "off" green light is on, wait until the "fully closed" red ligh...

Embodiment 2

[0045] Embodiment 2. Carrying out inspection without end position signal feedback of electric mechanism, valve, switch performance or fault judgment work

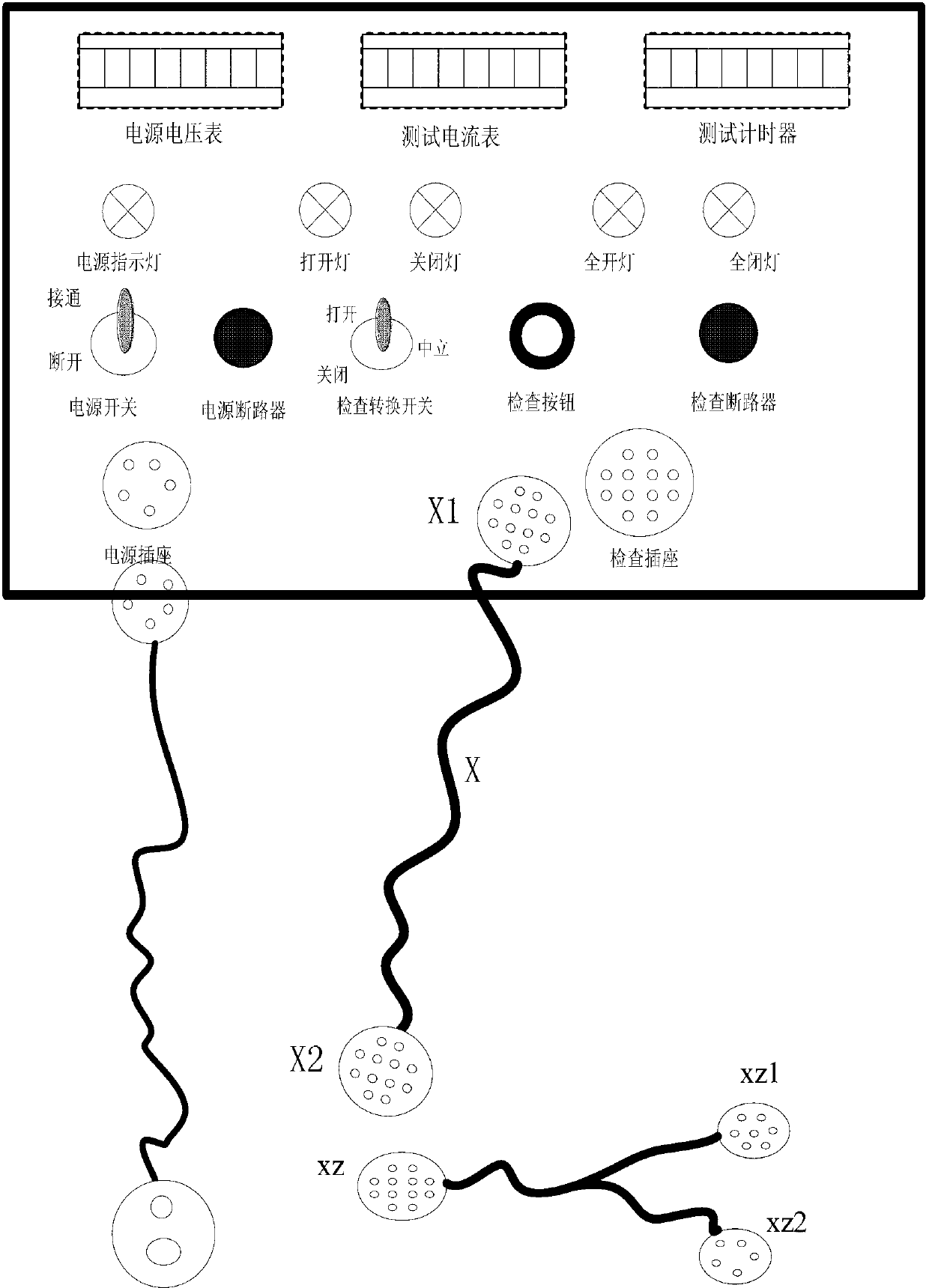

[0046] Such as image 3 Connect the power cord and test cable to the function tester as shown, put the power switch in the "off" position, put the detection replacement switch in the "neutral" position, connect the power cord plug with the ground power vehicle (28.5±1V ), and connect each test cable and the tested electric mechanism, valve, switch to the corresponding special plug.

[0047] a. Turn on the power switch of the functional tester, the green light of the power indicator is on, the voltage indicator shows the ground voltage, the current indicator shows "00.000", and the timer shows "000.00";

[0048]b. Put the detection switch in the "open" position, press the check button, at this time the "open" green light is on, the test ammeter displays the working current, and at the same time observe the changes in the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com