Welding method of copper tube

A welding method and technology for copper pipes, which are applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of good fluidity of copper liquid, poor adhesion, and difficult to control welding, and improve welding quality. , Reduce the generation of pores and ensure the effect of welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

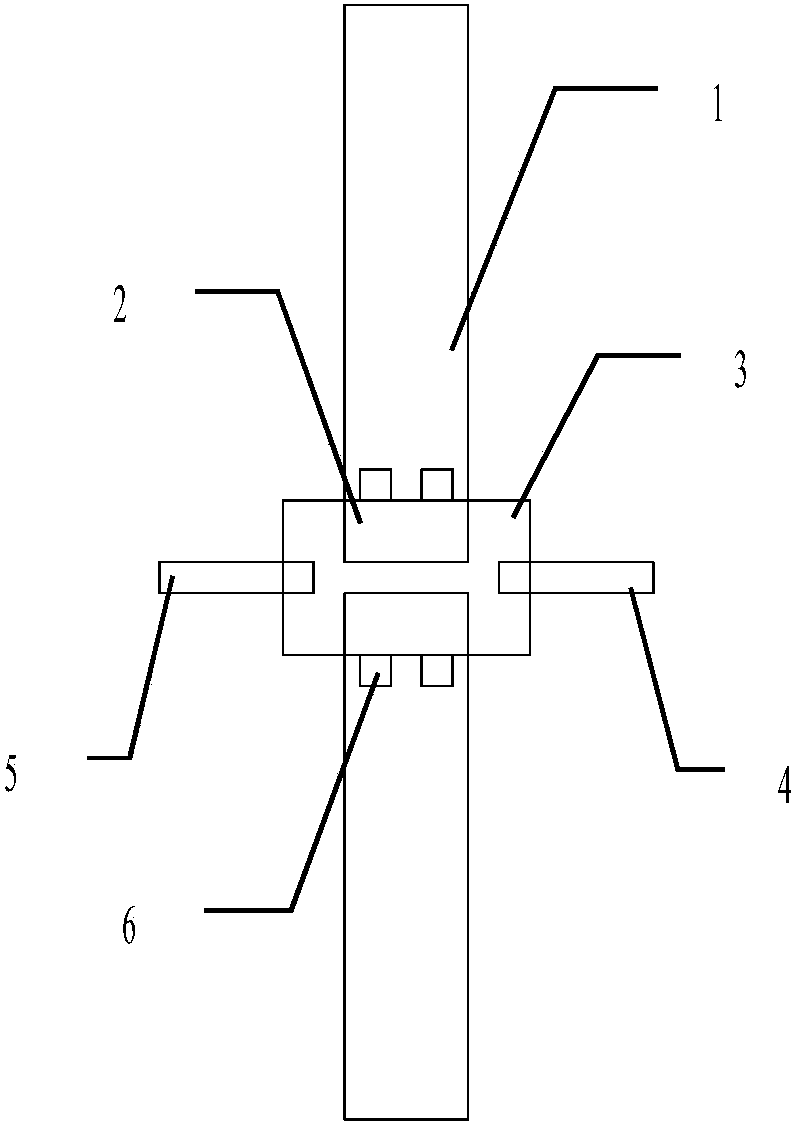

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0019] The invention provides a copper tube welding method, comprising:

[0020] Step 1. Clean the surface of the copper tube 1 to be welded. Before welding, the oxide film, oil and other dirt on the bevel edge and surface of the copper tube must be cleaned to avoid defects such as pores. After cleaning, use a copper wire wheel or The stainless steel wire wheel is polished near the groove until it reveals a metallic luster;

[0021] Step 2. Preheat the bevel 2 and both ends of the copper tube to be welded. The preheating temperature should not be too high, otherwise the mechanical properties of the welded joint will be easily reduced;

[0022] Step 3. Place the copper tube to be welded vertically. Compared with flat welding, the connection surface of the vertical welding tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com