Magnetic cloth conveying and dust removing roller of textile machinery

A technology for cloth conveying and textile machinery, which is applied in the field of magnetic-driven cloth conveying dust removal rollers of textile machinery, can solve the problems of inability to reduce dust and dust, and achieve the effects of reducing labor force, increasing bending resistance and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

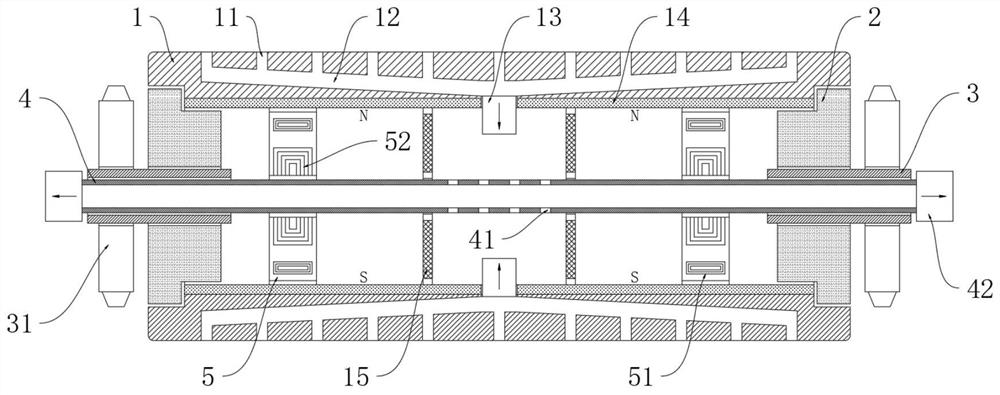

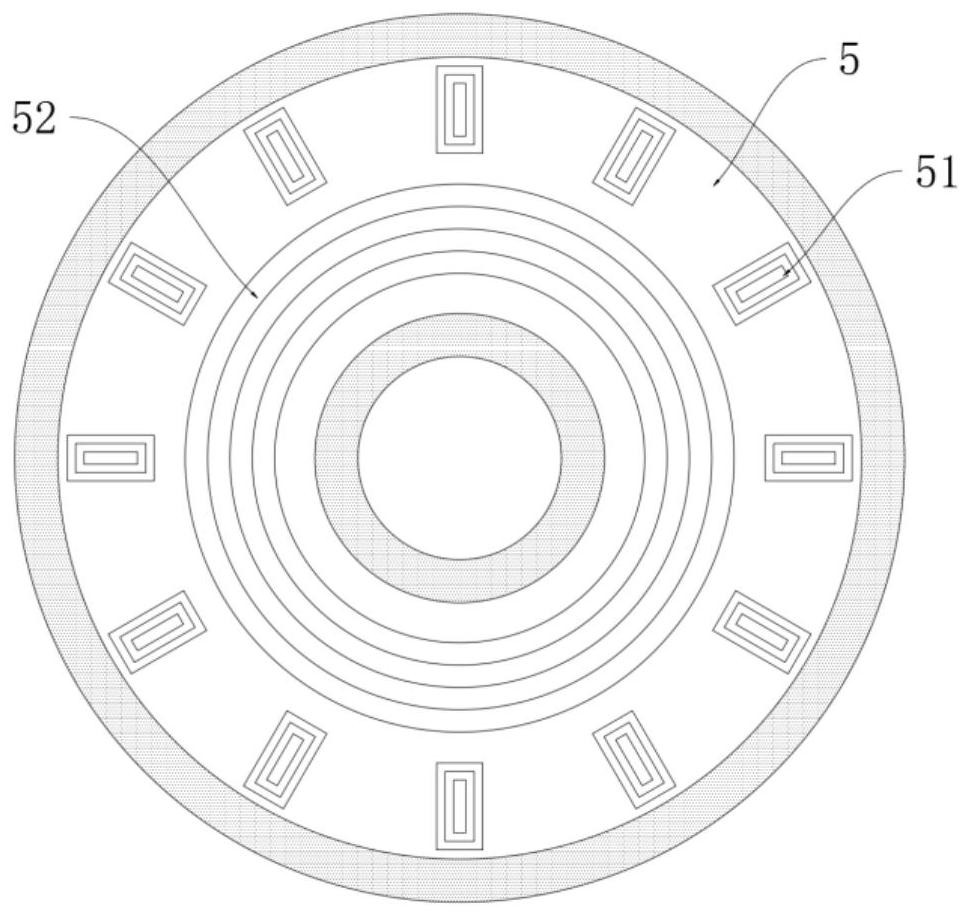

[0019] refer to Figure 1-2 , a textile machine magnetic cloth conveying dedusting roller, including a roller 1, two symmetrical covers on both ends of the roller 1 are provided with two sealing plugs 2, each sealing plug 2 is inserted with a power tube 3, each The outer sides of the power tubes 3 are fixedly set with power gears 31, and the two power tubes 3 are co-rotated and inserted with a gas pipe 4. The valve 42 and the air pipe 4 are located on a section of the roller 1, and the symmetrical sliding sleeve is provided with two magnetic disks 5, and a plurality of energy-capturing windings 51 and an electromagnetic winding 52 are respectively installed in the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com