Machining technology of reinforced strip steel

A technology of processing technology and reinforcing belt, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of restricting development and application, unstable quality, shortened life, etc., and achieve processing technology optimization, material saving, and connection strength big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

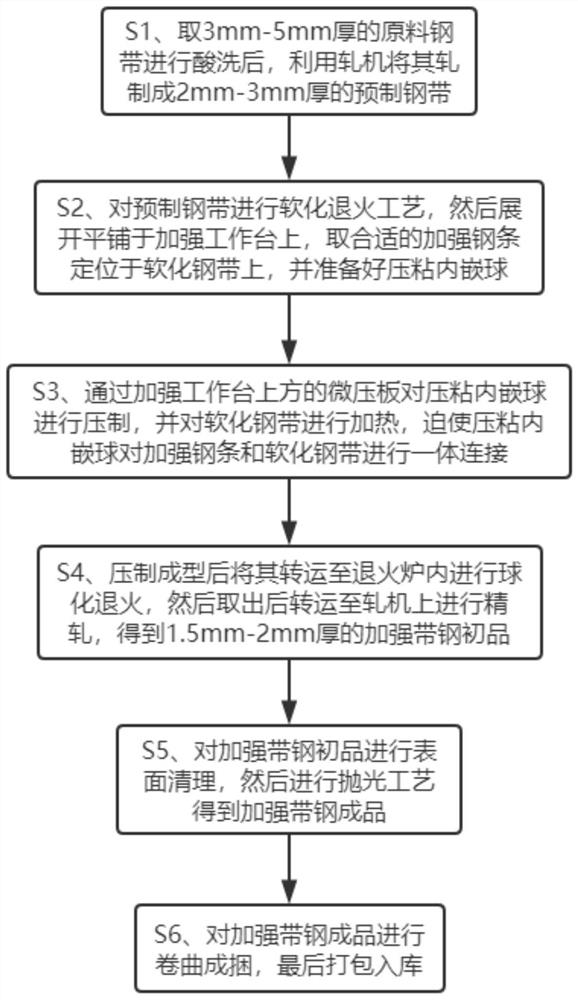

[0049] see Figure 1-3 , a processing technology for strengthening strip steel, comprising the following steps:

[0050] S1, after pickling the raw steel strip with a thickness of 3mm-5mm, utilize a rolling mill to roll it into a prefabricated steel strip with a thickness of 2mm-3mm;

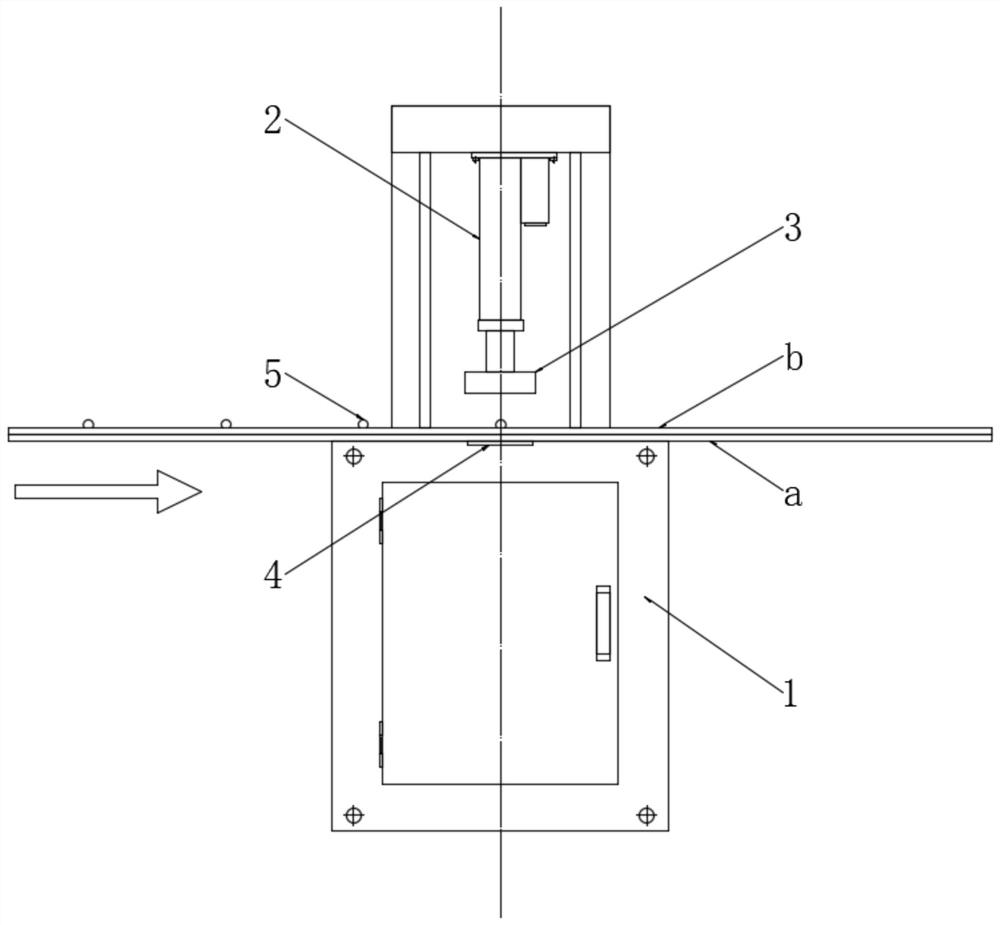

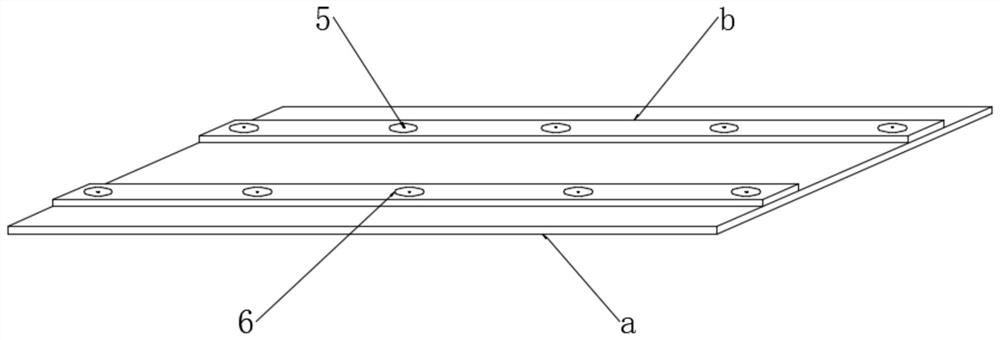

[0051] S2. Perform a softening and annealing process on the prefabricated steel strip, and then unfold it and spread it on the strengthening workbench 1, take a suitable reinforcing steel strip and position it on the softening steel strip, and prepare to press and bond the embedded ball 5;

[0052] S3. Press the pressure-bonded embedded ball 5 through the micro-press plate 3 above the workbench 1, and heat the softened steel strip, forcing the pressed-bonded embedded ball 5 to integrally connect the reinforced steel strip and the softened steel strip;

[0053] S4, transfer it to the annealing furnace for spheroidizing annealing after pressing and forming, then take it out and transfer it to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com