A light and small pan-tilt frame torque motor and photoelectric code disc combined connection device

A photoelectric encoder and torque motor technology, applied in the field of aerial remote sensing, can solve the problems of inconsistent size, weight, torque angle measurement accuracy, no integrated connection device, difficult to select accurately, etc., achieving light weight, easy equipment maintenance and Improved, compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

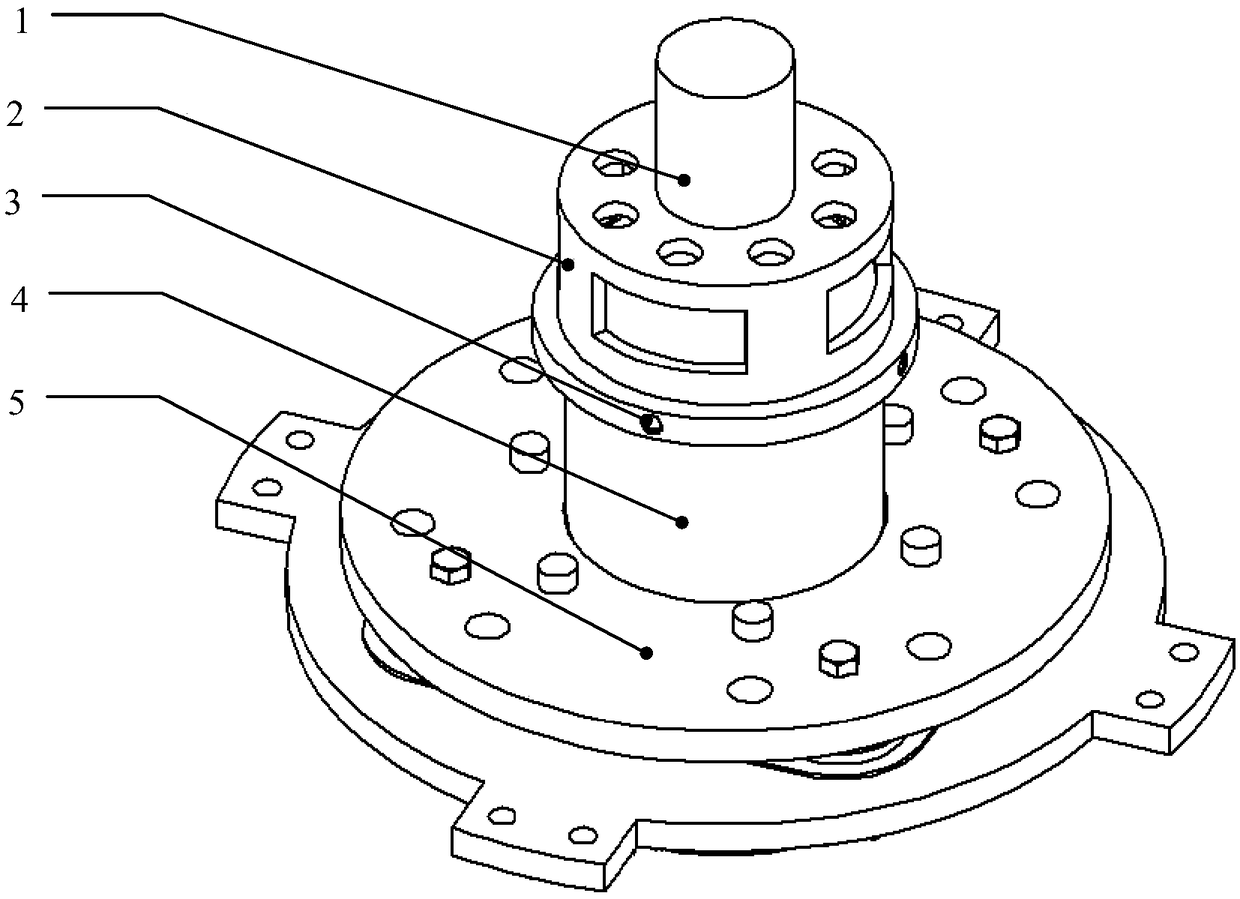

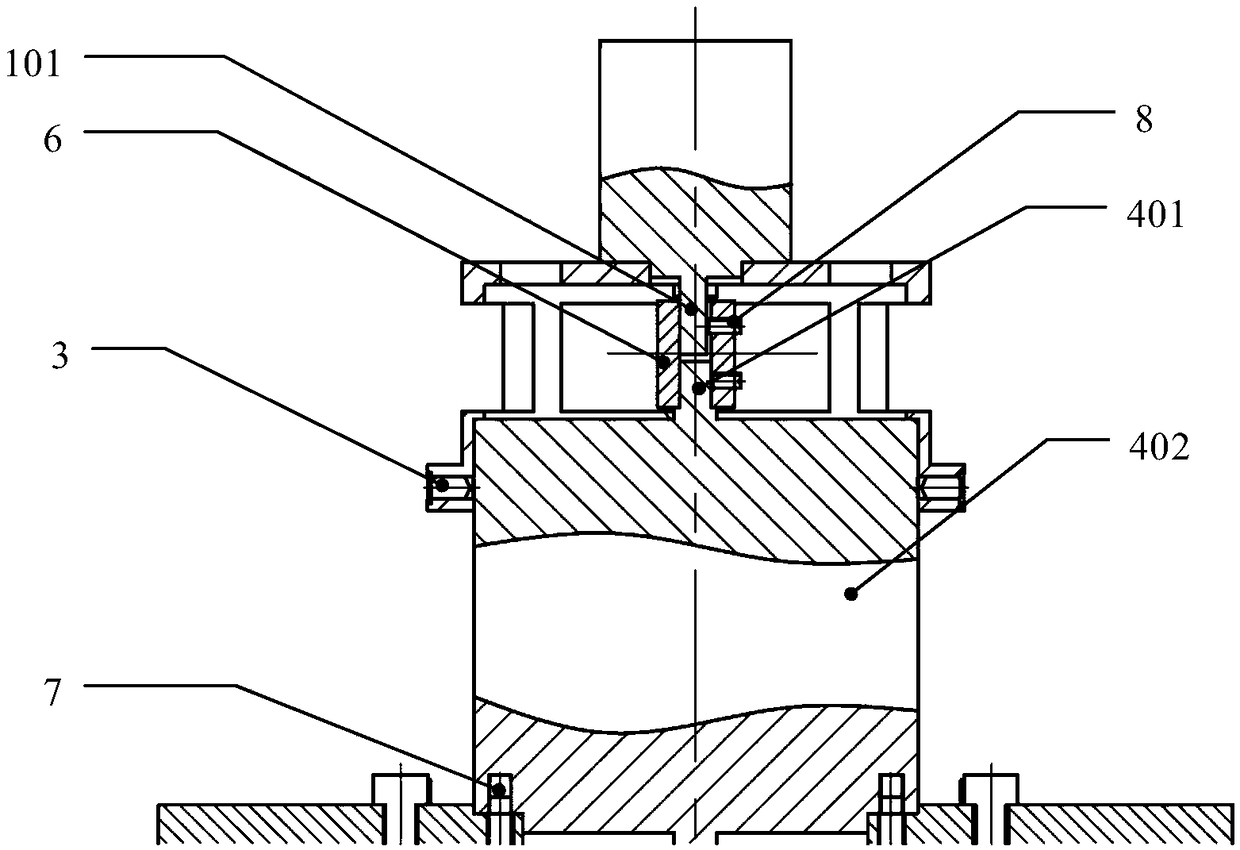

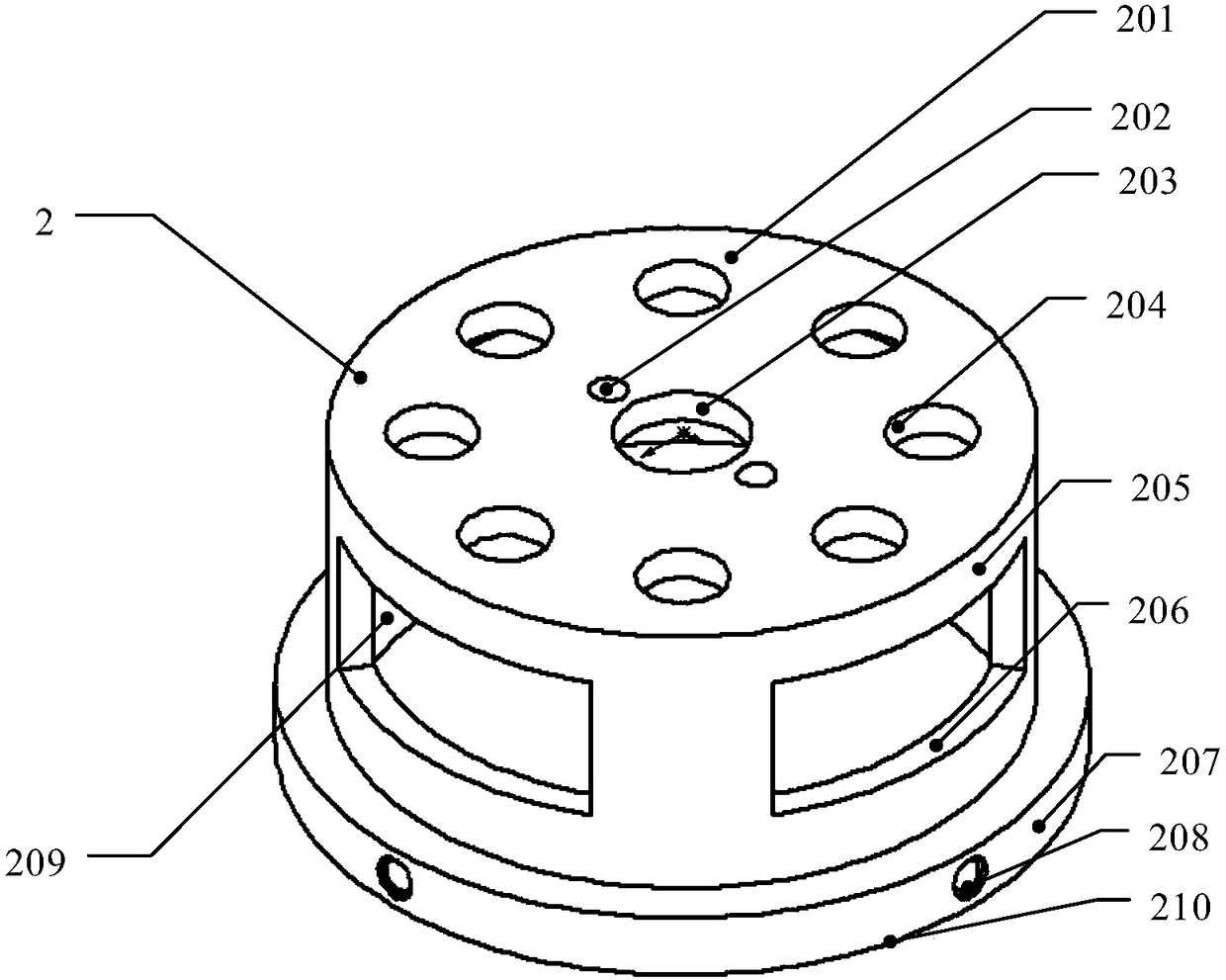

[0022] Such as figure 1 and figure 2 As shown, the connecting device includes a photoelectric code disc 1, a photoelectric code disc bracket 2, four photoelectric code disc bracket set screws 3, a frame torque motor 4, a motor mounting base 5, a coupling 6, four A motor stator set screw 7 and two coupling set screws 8; four photoelectric code disc support set screws 3 are radially tightened, and the photoelectric code disc support 2 and the stator of the frame moment motor 4 are connected by static friction The upper and lower parts are tightly connected together; the four motor stator set screws 7 are axially fixed and installed the stator part 402 of the frame torque motor 4 with the motor mounting base 5, so as to realize the photoelectric code disc support 2 and the frame torque motor The integrated fixed installation of the stator part of 4 and the motor installation base 5; the two coupling set screws 8 are tightened radially, and the main shaft 101 of the photoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com