Electric connector and LED lamp

An electrical connector and LED light source technology, applied in the electrical field, can solve problems such as high welding difficulty, complicated manufacturing process, and high production cost, and achieve the effects of simplifying the production process, reducing production cost, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

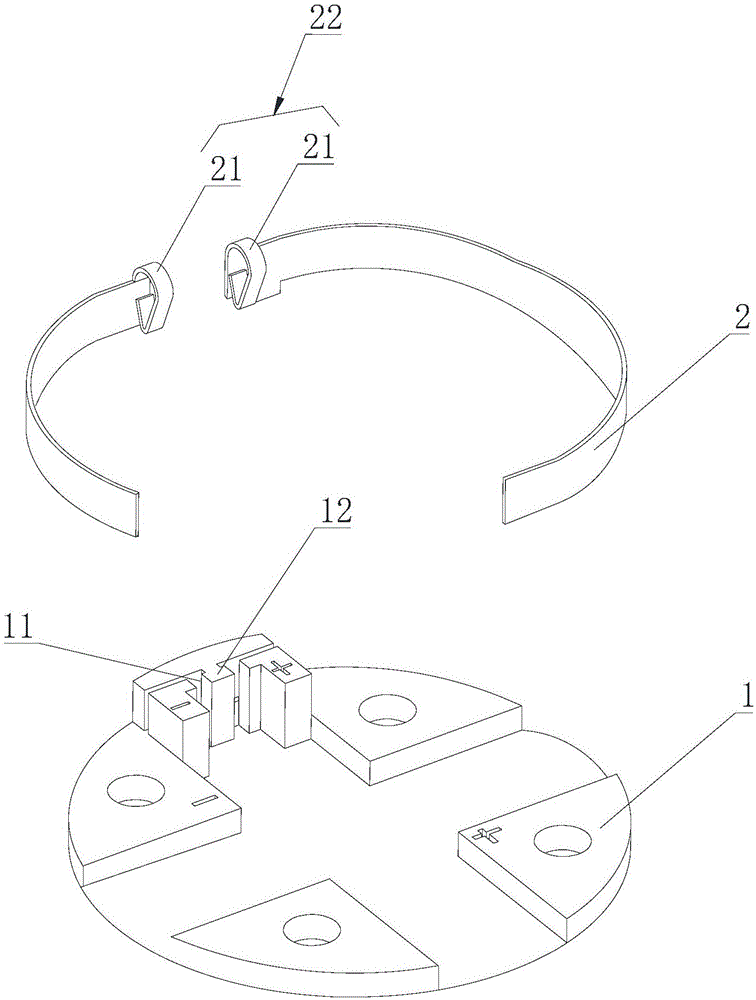

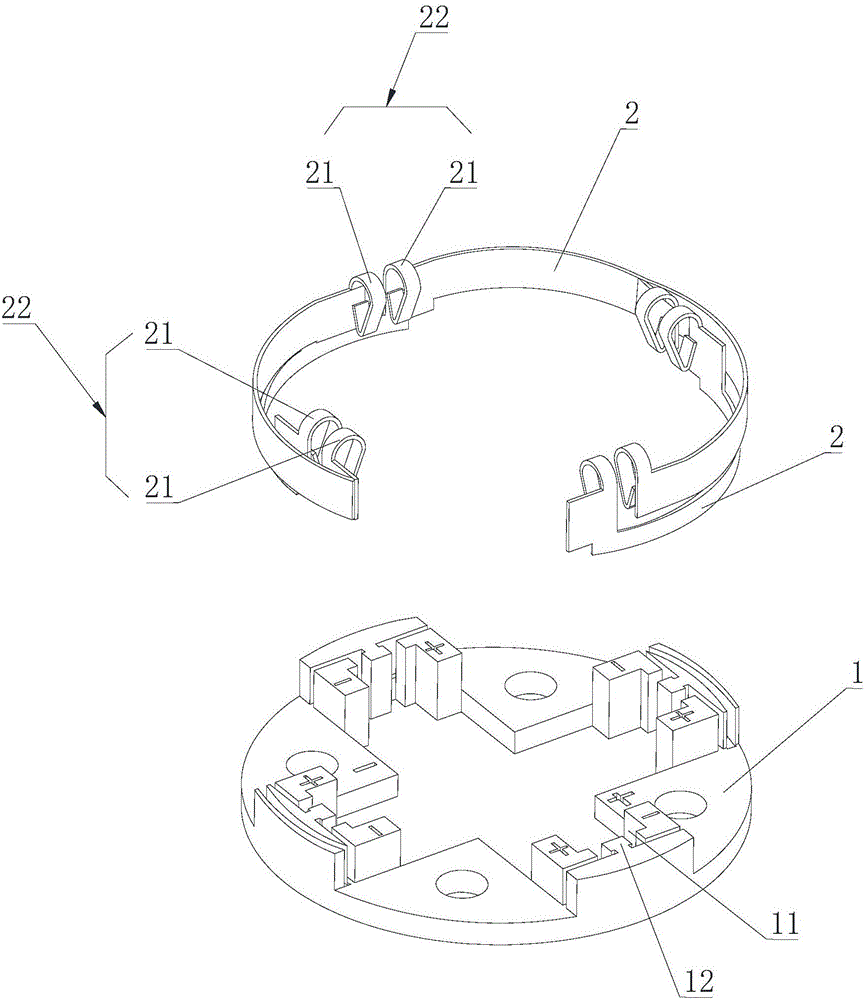

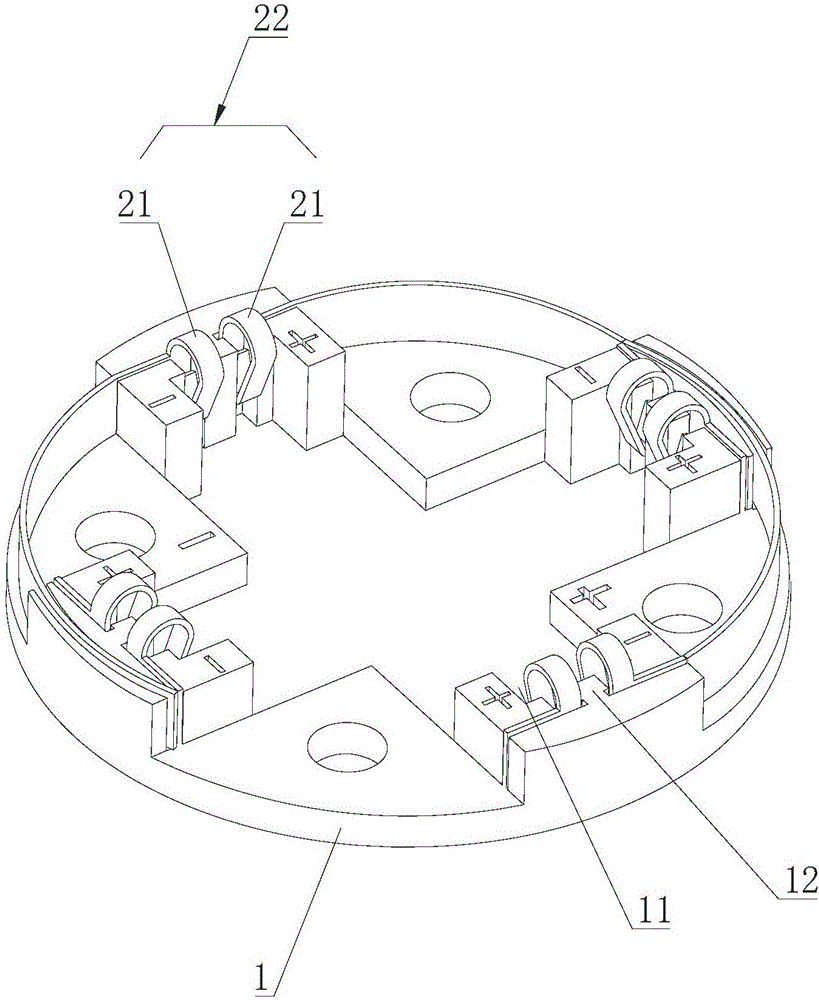

[0041] Please refer to figure 2 as well as image 3 , the second embodiment of the present invention is:

[0042] An electrical connector, comprising an insulating base and two conductive parts, there is a distance between the two conductive parts and fixed on the insulating base respectively, the conductive parts are strip-shaped structures, and the conductive parts are There are four contact parts, the conductive part is made of metal material, and the contact part is bent into an elastic shrapnel structure. The contact parts on the two conductive parts are respectively close to each other and arranged at intervals to form four parts. The four electrode parts are arranged in a ring around the center of the insulating base. Two electrodes and a plurality of LED light sources are respectively arranged on the front of the LED light source board, and the two electrodes are arranged on the LED light source board. The bottom of the light source board, the LED light source is ar...

Embodiment 3

[0045] Please refer to Figure 4 , Embodiment three of the present invention is:

[0046] An electrical connector, comprising an insulating base and five conductive parts with a strip structure, the five conductive parts have distances between them and are fixed on the insulating base respectively close to each other, wherein two adjacent conductive parts A contact portion is provided at the ends away from and close to each other, and a contact portion is provided at each end of the other three conductive parts. Shrapnel structure, the contact parts on the two conductive parts are respectively close to each other and arranged at intervals to form four electrode parts, the four electrode parts are arranged in a ring around the center of the insulating base, and the conductive parts connect the four LED light sources in series .

[0047] The insulating base is provided with a positioning groove matching the electrode portion of the conductive member, and the electrode portion ...

Embodiment 4

[0048] Please refer to Figure 5 , the fourth embodiment of the present invention is:

[0049] An LED lamp, including a lampshade, a driver, a base, a radiator, a fixing piece, and four LED light source boards, and also includes an electrical connector according to any one of the second or third embodiments above, and the driver is arranged on the base Inside, the radiating body is arranged on the base, the electrical connector is arranged on the radiating body, and is fixed with the radiating body by screws, and the conductive part in the electrical connector is electrically connected with the driver, The LED light source board is electrically connected to the contact portion in the electrical connector; the fixing member is connected to the base, and the electrical connector is arranged in an accommodating cavity formed by the fixing member and the base; the lampshade is fixed to the fixing member connected, the filament, the electrical connector and the radiator are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com