Jet dispensing equipment for chip packaging

A technology of chip packaging and injection point, which is applied in the direction of injection device, device for coating liquid on the surface, coating, etc., can solve the problems of circuit board scrapping, deviation, uneven extrusion, etc., and achieve quality assurance and simple and ingenious structure , Extrude the glue smoothly and evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiments of the present invention will be described in detail below, and examples of the embodiments are illustrated in the drawings, in which the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions. The following is exemplary, and is intended to be used to illustrate the invention without understanding the limitation of the invention.

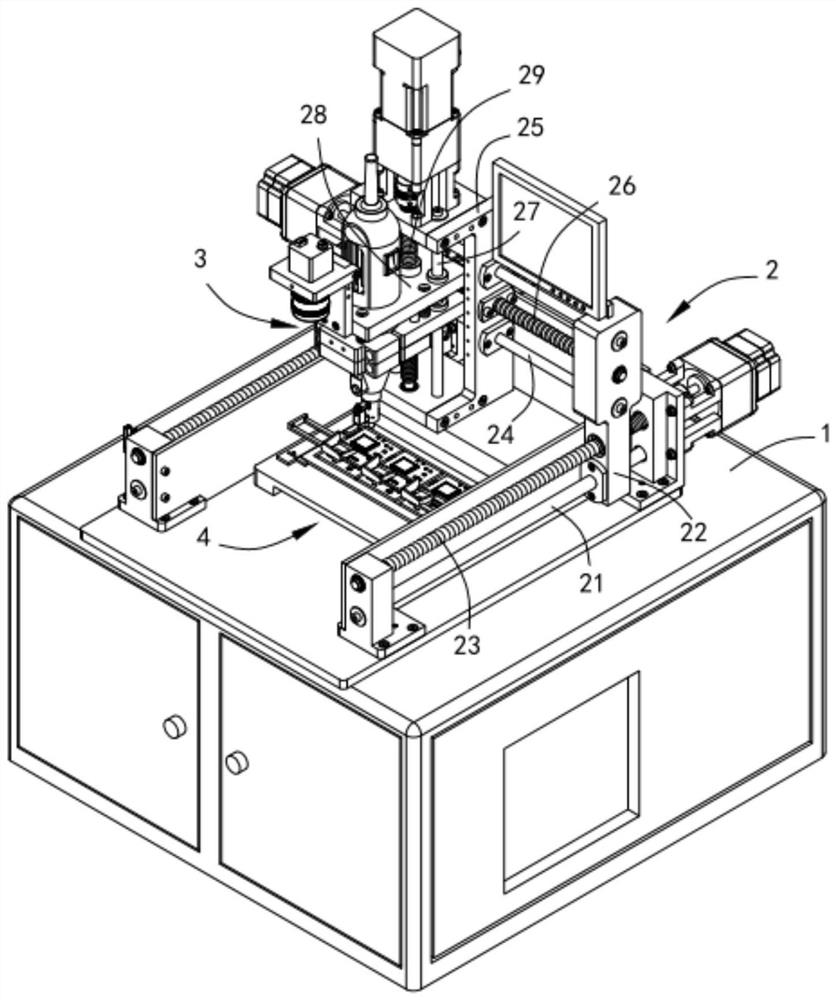

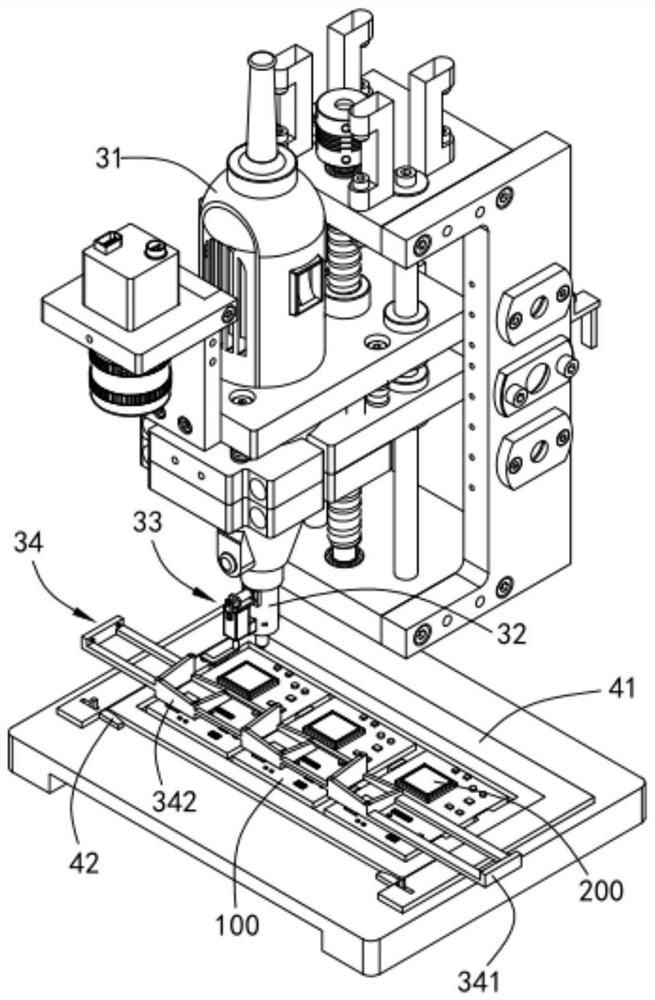

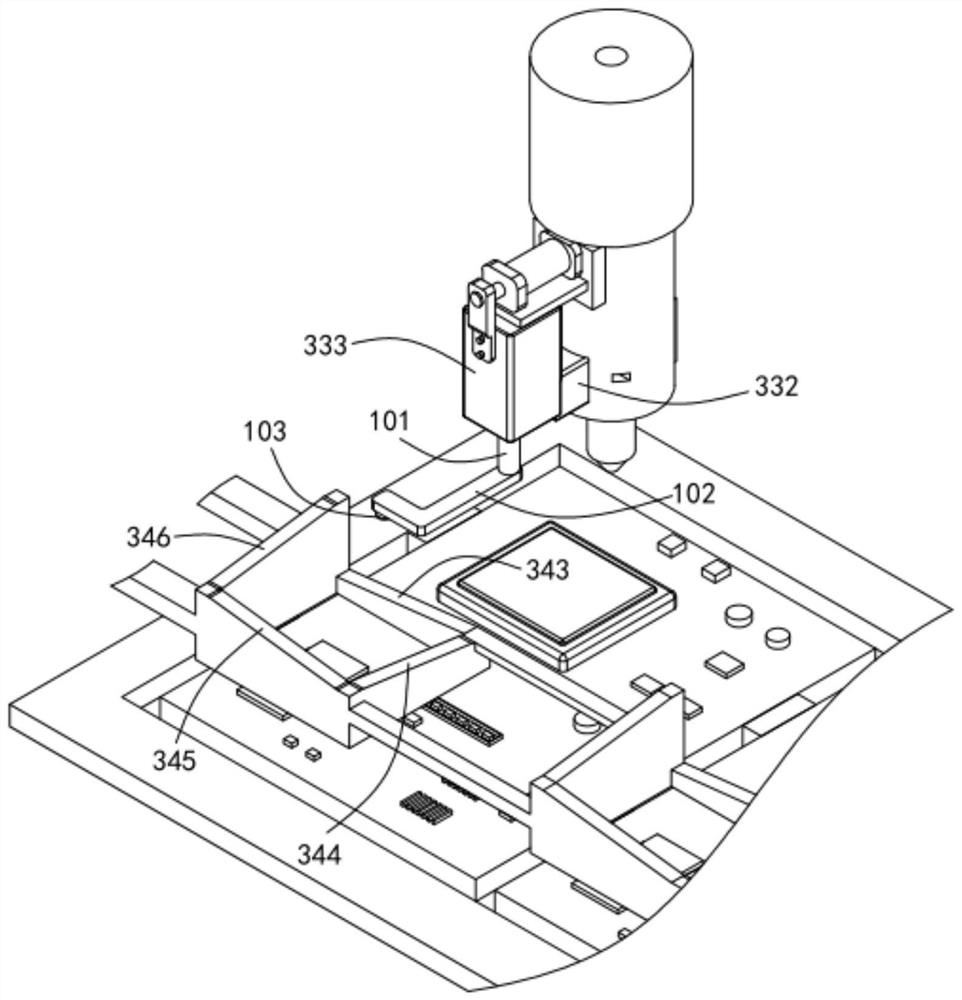

[0036] like Figure 1 to 9 As shown, a chip package is encapsulated, including a seat 1, a drive mechanism 2 disposed on the seat 1, moving a dispensing mechanism 3 that moves under the drive mechanism 2 and is provided below the dispensing mechanism 3 and fixed The positioning clamp 4 on the seat 1, the dot rubber mechanism 3 includes a tub 31 and an elongate tube 32 disposed at the bottom of the tub 31, which includes a glue segment 10 and a glue section 20, said A pilot assembly 33 is provided between the glue segment 10 and the outset section 20, and corresponding ...

Embodiment 2

[0049] like Figure 8 with Figure 9 Shown, wherein the same as in Example a, or a respective corresponding parts are designated by reference numerals embodiment, for simplicity, the following description only a point of difference with the embodiment embodiment; different from the first embodiment according to the second embodiment of the in that: further, the end surface of the pushing rubber piston 331 is provided with a blade 6, the side of the second cavity 336 further defines a clean mouth 7, defines an upper wall of the hose 32 are communication port 8, while the second cavity 336 slides to the communication port 8 at the location of the communication port 8 communicating with the cleaning port 7.

[0050] In this embodiment, the inner wall can be of a rubber section 20 is pushed in a plastic squeegee upper portion of the piston 331 is provided such that the blade 6 is reset each time after the completion of spray, avoiding the inner wall of the plastic section 20 Accumulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com