Preparation method of hydroxyl-terminated polymethylphenyl siloxane with controllable viscosity

The technology of polymethylphenylsiloxane and methylphenylcyclosiloxane is applied in the field of preparation of hydroxyl-terminated polymethylphenylsiloxane, which can solve the problem that water cannot be precisely controlled, viscosity is uncontrollable, and Problems such as wide molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of a viscosity-controllable hydroxyl-terminated polymethylphenylsiloxane, comprising the following steps:

[0027] A) mixing methyl phenyl cyclosiloxane and methyl cyclosiloxane, dehydration under vacuum condition, to obtain dehydrated material;

[0028] B) Add a double-ended hydroxysiloxane head-sealing agent and an alkaline catalyst to the dehydrated material, heat up to 90-110°C, and after 3-6 hours of reaction, continue to heat up to 120-160°C, and stir with nitrogen for 1- 3 hours;

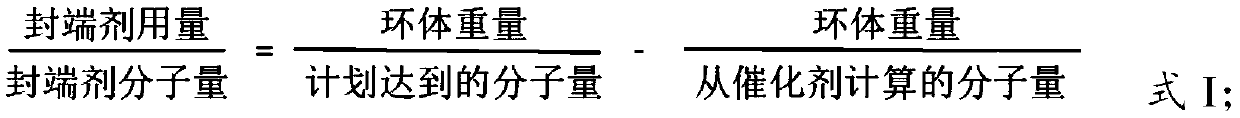

[0029] The dosage of the double-ended hydroxysiloxane head capping agent can be calculated according to formula (1), and accounts for 0.05% to 5% of the total weight of the ring body.

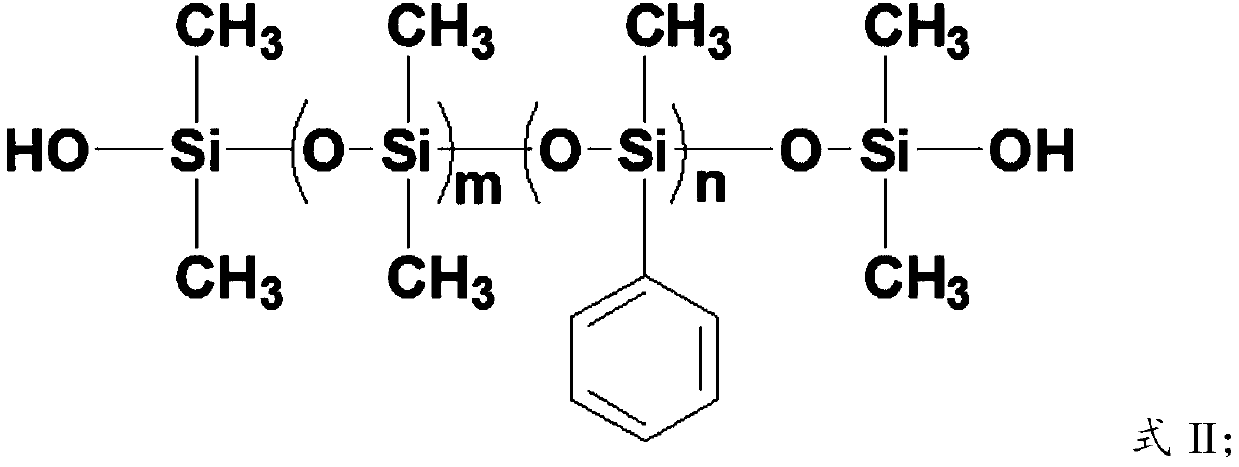

[0030] C) The reaction product obtained in the step B) is removed under vacuum conditions to obtain a viscosity-controllable hydroxyl-terminated polymethylphenylsiloxane having the structure of formula I.

[0031] In the present invention, the methylphenylcy...

Embodiment 1

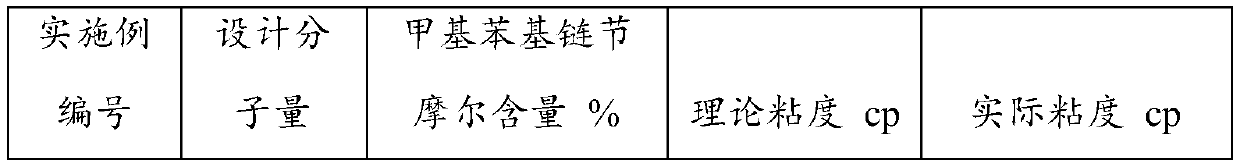

[0047] Weigh 68g of trimethyltriphenylcyclotrisiloxane and 296g of octamethylcyclotetrasiloxane (the molar ratio of methylphenylsiloxane to dimethylsiloxane is 1:8) Put it into a 500mL three-necked reaction flask, dehydrate it for 0.5h at 60℃ and -0.095Mpa vacuum; then add 12.1g of dihydroxytetramethyldisiloxane head sealing agent and 0.19g of tetramethylammonium hydroxide alkali glue The catalyst was heated to 90 °C, and the equilibrium reaction was carried out for 6 hours; then, after the temperature was raised to 140 °C, the nitrogen was stirred for 3 hours until no basic gas escaped; finally, the temperature was raised to 160 °C and the temperature was reduced under -0.098Mpa vacuum for 3 hours. The low boilers are removed in vacuo to obtain methyl phenyl 108 gum which is colorless and transparent with controllable viscosity. The molecular weight and viscosity of the product were tested by gel permeation chromatography (GPC) and rotational viscometer, and the results are s...

Embodiment 2

[0049] Weigh 136g of tetramethyltetraphenylcyclotetrasiloxane, 296g of hexamethylcyclotrisiloxane (the molar ratio of methylphenylsiloxane and dimethylsiloxane is 1:4) Put it into a 500mL three-necked reaction flask, dehydrate it at 40°C and a vacuum of -0.095Mpa for 2h; then add 10.4g of dihydroxyhexamethyltrisiloxane capping agent and 0.28g of tetraethylammonium hydroxide alkali glue catalyst , heat up to 100°C, equilibrate reaction for 4h; then heat up to 120°C, stir with nitrogen for 2h, until no basic gas escapes; finally, heat up to 170°C and take off under the condition of -0.098Mpa vacuum for 2h, vacuum The low boilers are removed to obtain methyl phenyl 108 glue which is colorless, transparent and controllable in viscosity. The molecular weight and viscosity of the product were tested by gel permeation chromatography (GPC) and rotational viscometer, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com