Dynamic seal device

A dynamic sealing and sealing ring technology, applied in the direction of engine sealing, transmission parts, transmission boxes, etc., can solve the problems of short life, inability to withstand high pressure, inapplicability, etc., and achieve high service life, good sealing performance, and improved The effect of seal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

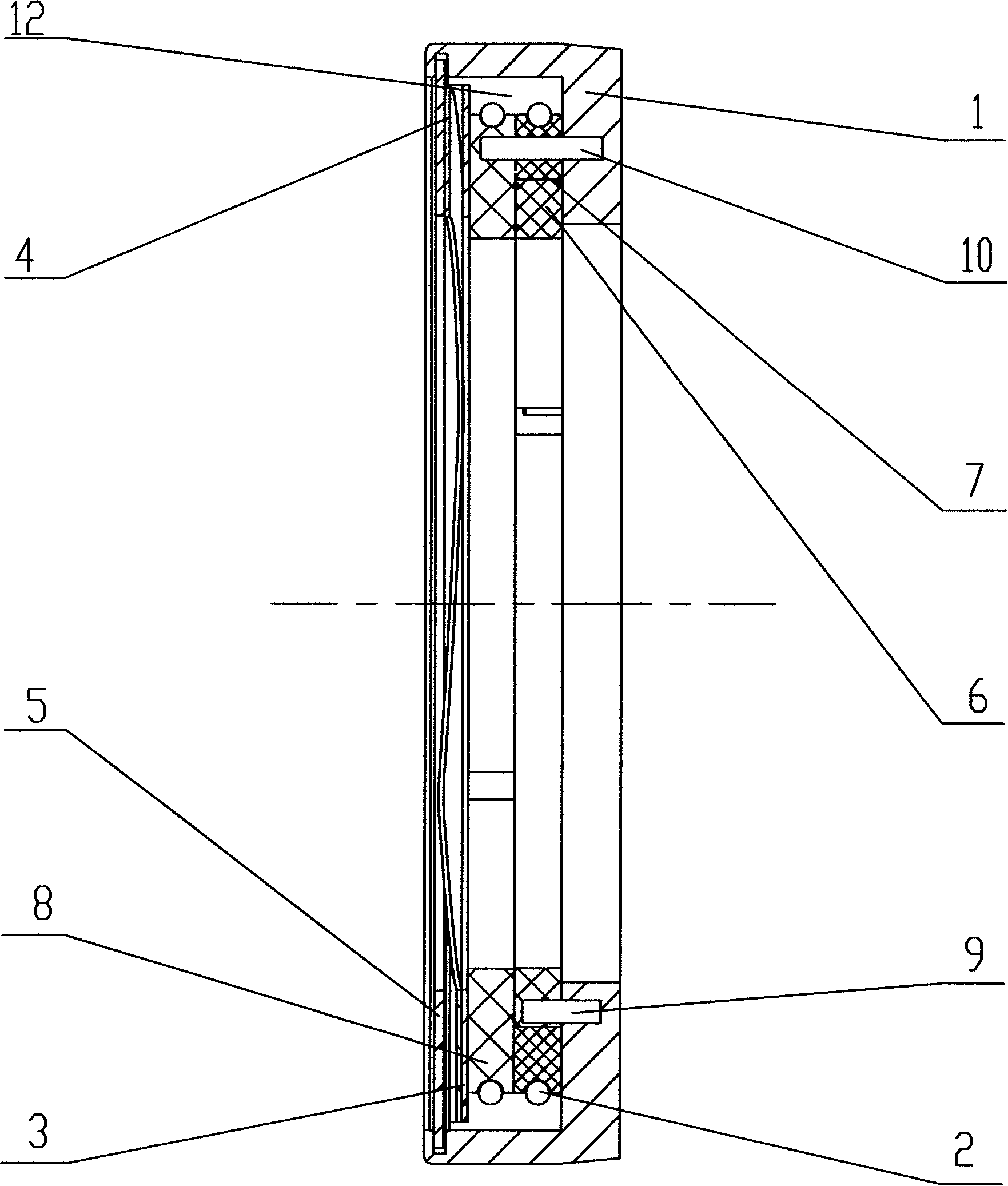

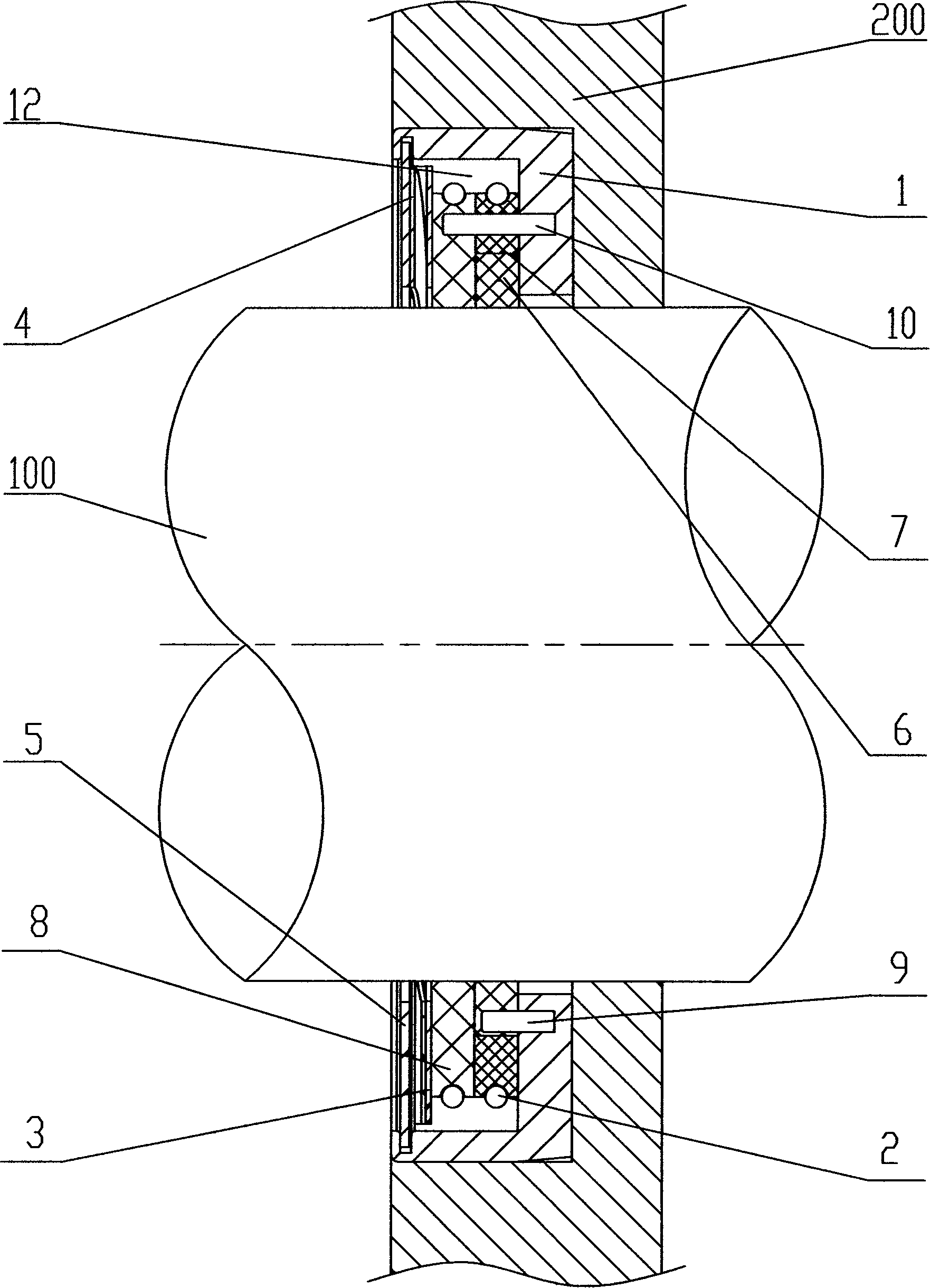

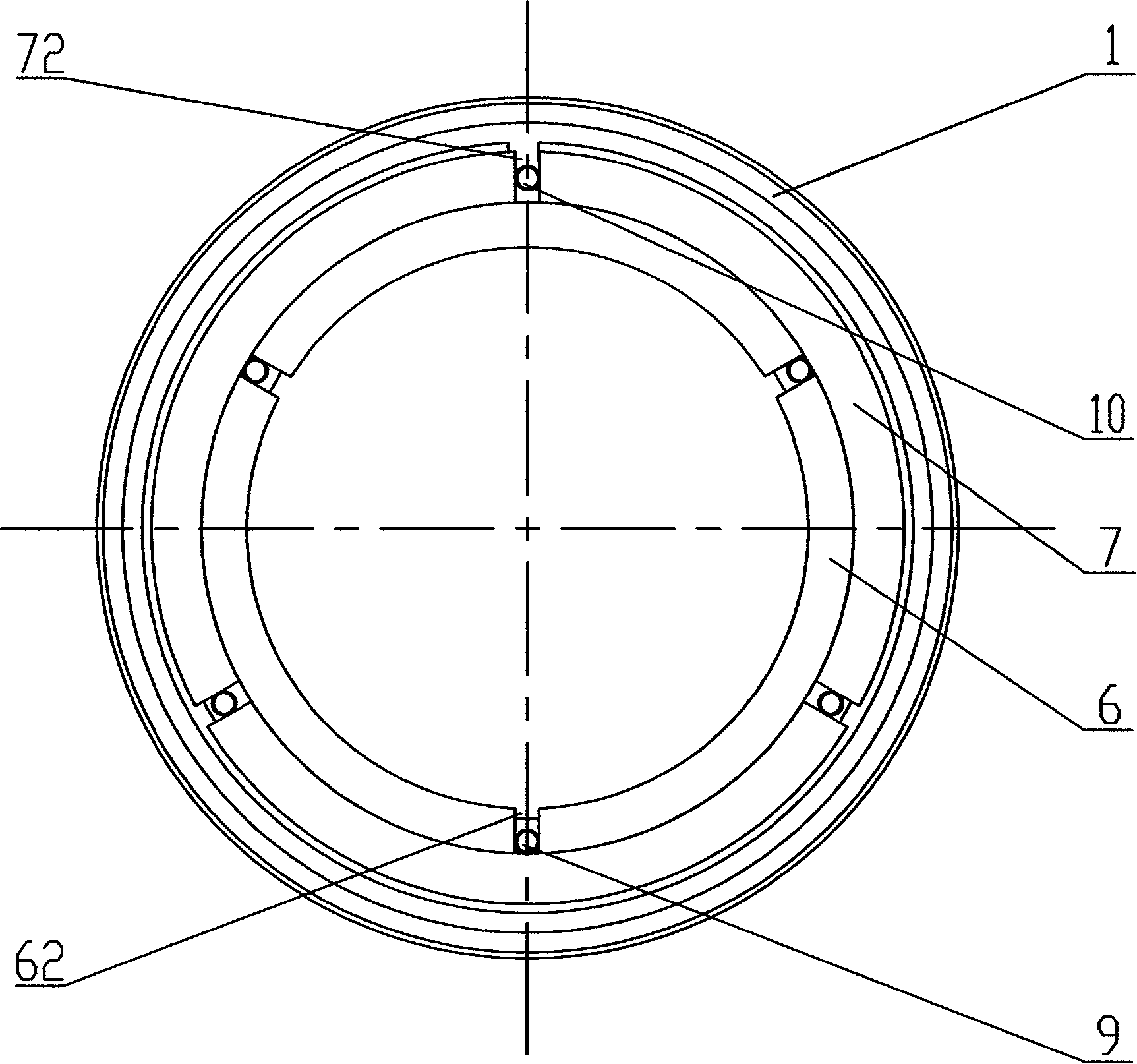

[0021] see figure 1 and figure 2 , is a preferred embodiment of the present invention. The dynamic sealing device of the present invention is installed between the rotating shaft 100 and the box body 200, and is sleeved on the rotating shaft 100. It includes a seat body 1, a sealing ring group, a spring ring 2, Adjust washer 3, spring washer 4 and pressure plate 5.

[0022] The seat body 1 is ring-shaped, and its outer end face is sunken inward to form a cavity 12. The sealing ring group, spring ring 2, adjustment washer 3, spring washer 4 and pressure plate 5 are all installed in the cavity of the seat body 1. cavity 12. An annular groove (not shown in the figure) is provided at the outermost end of the seat body 1 , that is, the open end of the cavity 12 , and the pressure plate 5 is located in the annular groove. The adjusting washer 3 and the spring washer 4 are located between the pressure plate 5 and the sealing ring set, wherein the adjusting washer 3 is stacked on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com