Anti-jamming open-type gate valve

An open-type, plug-in valve technology, applied in valve details, valve devices, sliding valves, etc., can solve problems such as affecting the service life of the plug-in valve, affecting the valve sealing effect, lack of open-type plug-in valve, etc., to ensure the work. Continuity, saving resources, improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

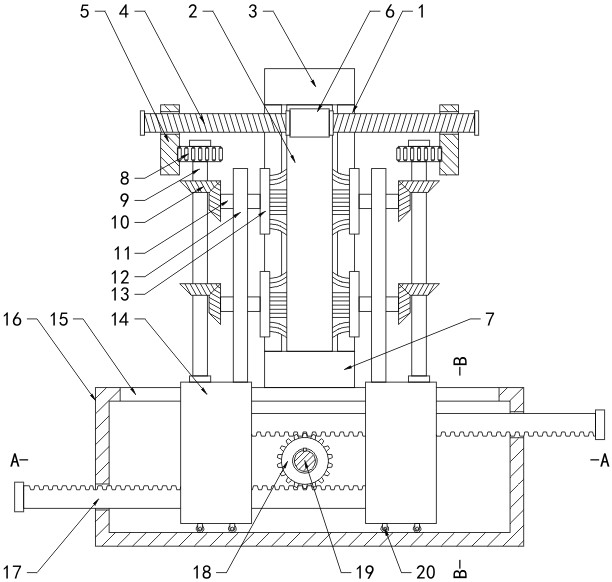

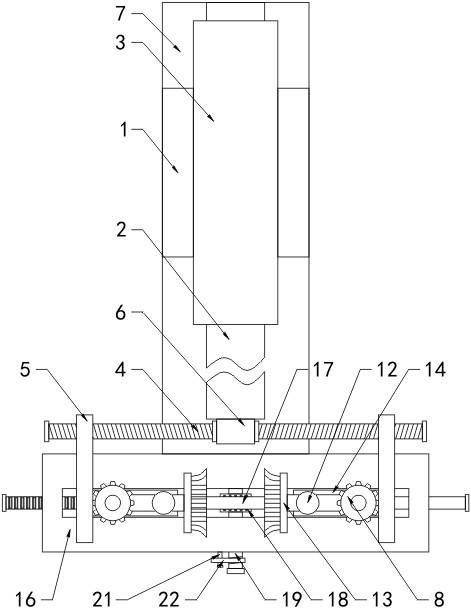

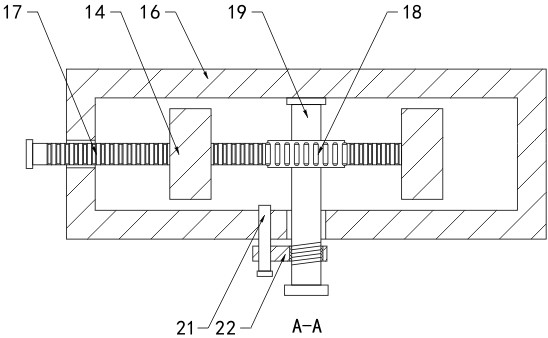

[0032] see Figure 1-5 , an anti-clogging open-type flapper valve, comprising a valve body 1 with a valve seat 7 at the bottom, a movable valve plate 2 inside the valve body 1 to realize the on-off of the valve body 1, and a valve body 1 on the top The driver 3 that drives the valve plate 2 to move, the side of the valve plate 2 close to the top is fixedly connected with the fixed block 6, and the two ends of the fixed block 6 are installed with the threaded rod 4 through the bearing rotation, and the fixed block 6 and the threaded rod 4 follow the valve plate 2 Synchronous movement, the first rack 5 is sleeved on the outside of the threaded rods 4 on both sides, the first rack 5 moves synchronously with the threaded rods 4, the side of the valve seat 7 is detachably connected to the adjustment box 16, and the top of the adjustment box 16 begins to have The chute 15 is slidingly connected with a symmetrically arranged and highly adapted slider 14 inside the chute 15, which is ...

Embodiment 2

[0034] The difference from Example 1 is that

[0035] see Figure 5 The outer wall of the second rotating shaft 11 and the inner surface wall of the bracket of the brush 13 are elastically connected by a spring 23. When the second rotating shaft 11 rotates, the brush 13 is driven to rotate, and the sundries on the valve plate 2 are cleaned. Falling, under the elastic effect of spring 23, hair brush 13 bounces up and down, cleans the sundries on valve plate 2 between hair brushes 13, improves the cleaning effect to valve plate 2.

Embodiment 3

[0037] The difference from Example 1 is that

[0038] see figure 1 with figure 2 , the first rack 5 and the threaded rod 4 are threadedly connected. During the adjustment of the distance between the brushes 13, the continuity of the transmission between the first rack 5 and the first gear 8 should also be ensured to control the first rack 5 and the first gear 8. A rack 5 does not rotate in the horizontal direction. By rotating the threaded rod 4, the position of the first rack 5 on the threaded rod 4 is adjusted according to the principle of thread transmission, so that the first rack 5 and the first gear 8 are always meshed. Transmission connection, wherein, when the threaded rod 4 rotates forward, the first rack 5 moves horizontally inward, and when it rotates reversely, the first rack 5 moves horizontally outward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com