Pillow type packaging machine

A pillow-type packaging machine, packaging film technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as materials being easily stuck in the sealing position, affecting the sealing of the heat sealing head, and crushing the filled material, and achieving structural Simple, short bonding time, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

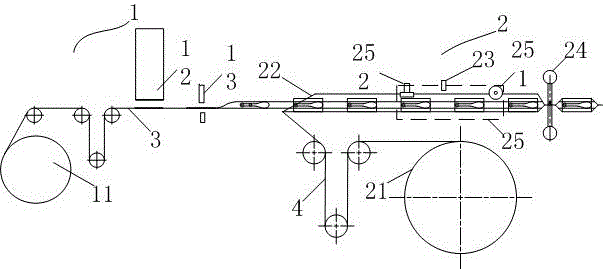

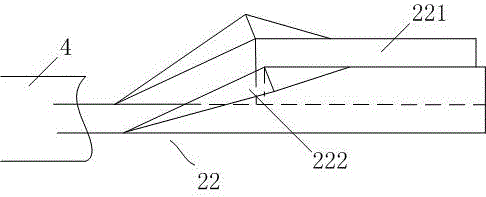

[0023] Such as figure 1 The shown pillow packaging machine includes a restriction tape placement unit 1 and a packaging unit 2, the restriction tape placement unit 1 is arranged at the film inlet end of the packaging unit 2, and the restriction tape placement unit 1 includes a first film releasing roller 11. A blanking device 12 and a hot pressing device 13 , the first film releasing roller 11 superimposes the restriction tape 3 on the packaging film 4 .

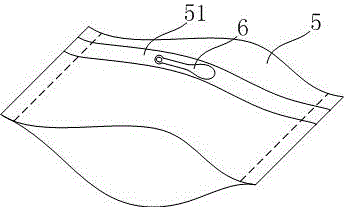

[0024] The blanking device 12 and the hot-pressing device 13 are sequentially arranged at the front end of the restraint belt placement unit, and after the material falls from the blanking device 12 to the restraint belt, it is thermally bonded to the restraint belt by the hot-press device 13 The restraint belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com