Ommt modified anti-icing emulsified asphalt and preparation method

An emulsified asphalt and anti-icing technology, which is applied in the preparation of asphalt, the preparation device of anti-icing emulsified asphalt, and the field of anti-icing emulsified asphalt, which can solve the problems of soft deformation or cracking, insufficient resistance, and bonding failure, etc. Problems, to achieve the effect of not easy to soften, deform or crack, increase bonding efficiency, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

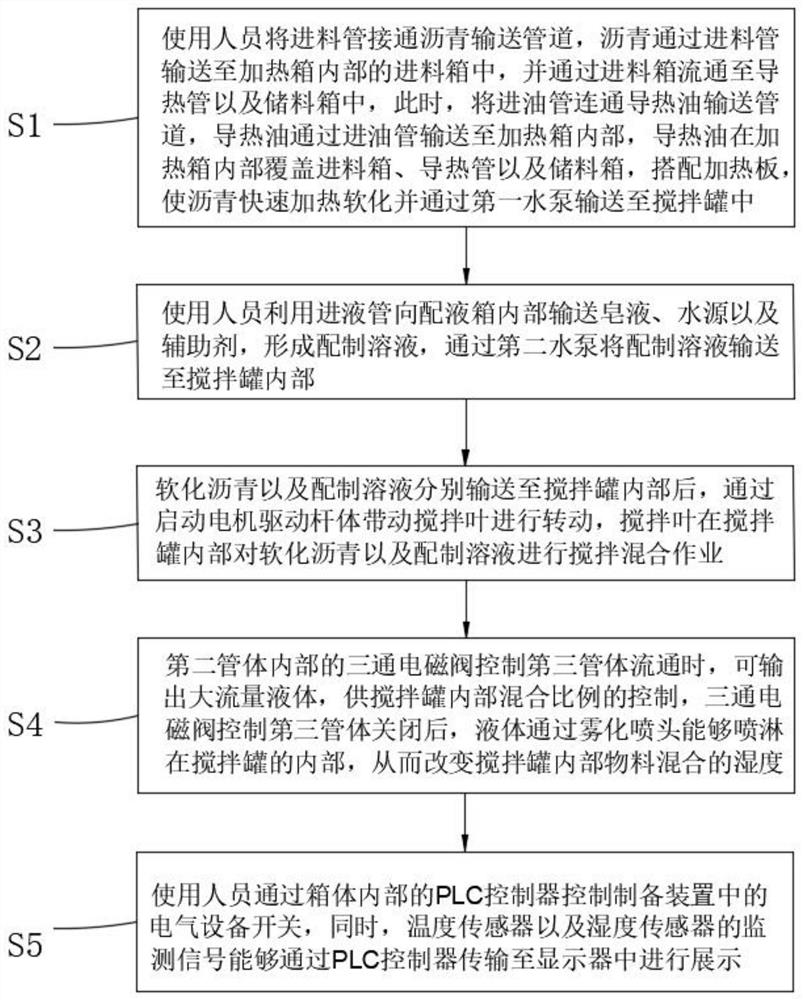

Method used

Image

Examples

Embodiment 1

[0049] The invention provides OMMT-modified anti-coagulation ice emulsified asphalt, and the formula of the OMMT-modified anti-coagulation ice emulsified asphalt includes: 40 parts of organic montmorillonite, 10 parts of modifier, and 5 parts of emulsifier. , 80 parts of base asphalt, 300 parts of deionized water, 5 parts of benzoyl peroxide and 4 parts of stabilizer.

[0050] Specifically, the modifier is selected from polystyrene-butadiene.

[0051] Specifically, the stabilizer is selected from cetyl trimethyl bromide.

Embodiment 2

[0053] The difference between this example and Example 1 is that the present invention also provides OMMT-modified anti-coagulation ice emulsified asphalt, and the formula of OMMT-modified anti-coagulation ice emulsified asphalt includes: 50 parts of soil, 15 parts of modifier, 10 parts of emulsifier, 120 parts of base asphalt, 430 parts of deionized water, 11 parts of benzoyl peroxide and 4-10 parts of stabilizer.

[0054] Specifically, the modifier is selected from styrene-butadiene rubber latex.

[0055] Specifically, the stabilizer is selected from styrene copolymer.

Embodiment 3

[0057] The difference between this example and Example 1 is that the present invention also provides OMMT-modified anti-coagulation ice emulsified asphalt, and the formula of OMMT-modified anti-coagulation ice emulsified asphalt includes: 44 parts of soil, 13 parts of modifier, 6 parts of emulsifier, 105 parts of base asphalt, 360 parts of deionized water, 9 parts of benzoyl peroxide and 7 parts of stabilizer.

[0058] Specifically, the modifier is selected as lime.

[0059] Specifically, the stabilizer is selected from cetyl trimethyl bromide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com